Types Plexiglas / Acrylate that you can have laser cut

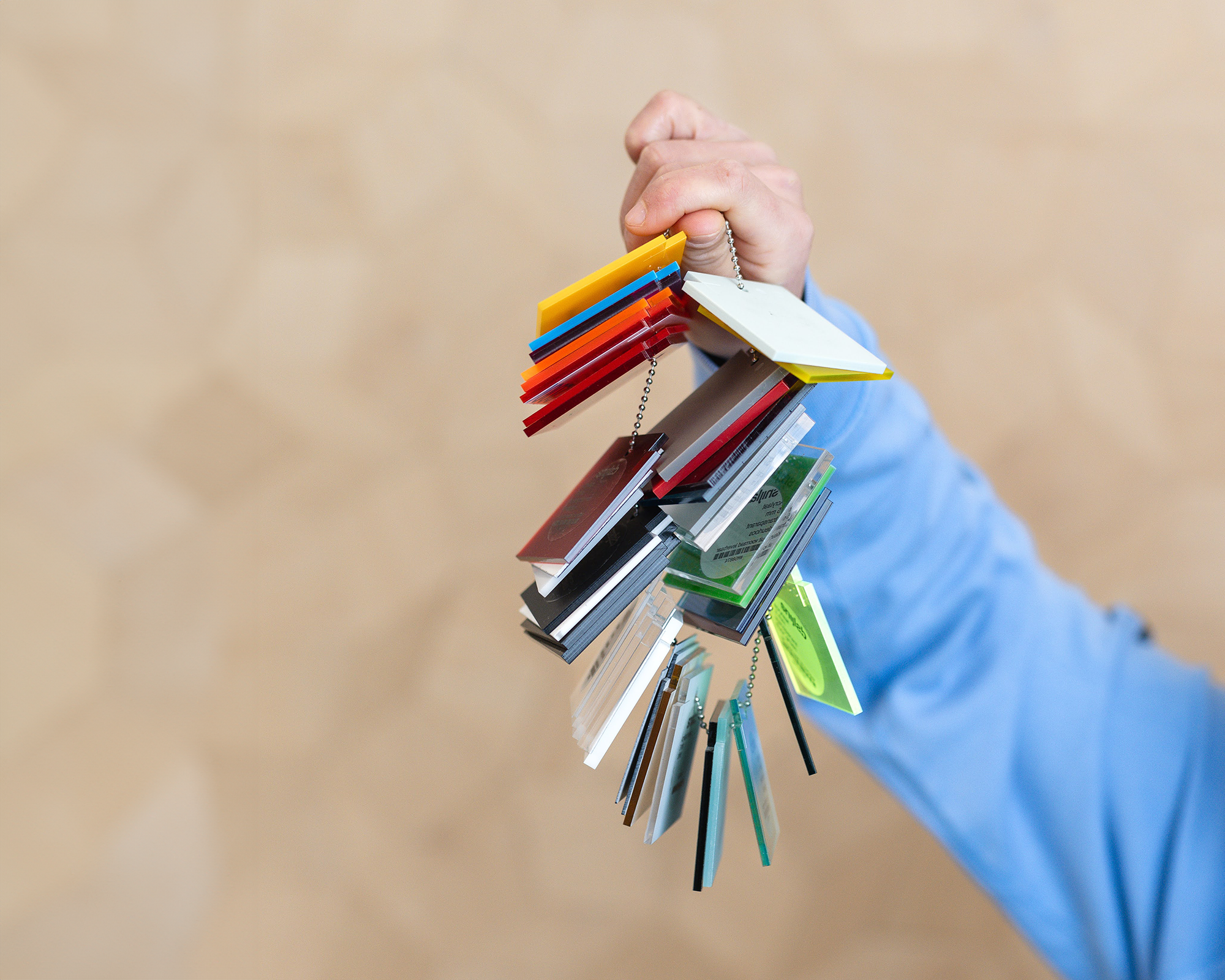

Samples of Plexiglas / Acrylate compare?

Order one material sample chain and compare all types Plexiglas / Acrylate in your own hand. This way you make a well-informed decision about your design.

Samples provide a representative picture of the quality Snijlab delivers.

To the samplesAlle soorten Plexiglas / Acrylate onder elkaar

| Name | Thickness | Color | Max. size |

|---|

Info about Plexiglas / Acrylate

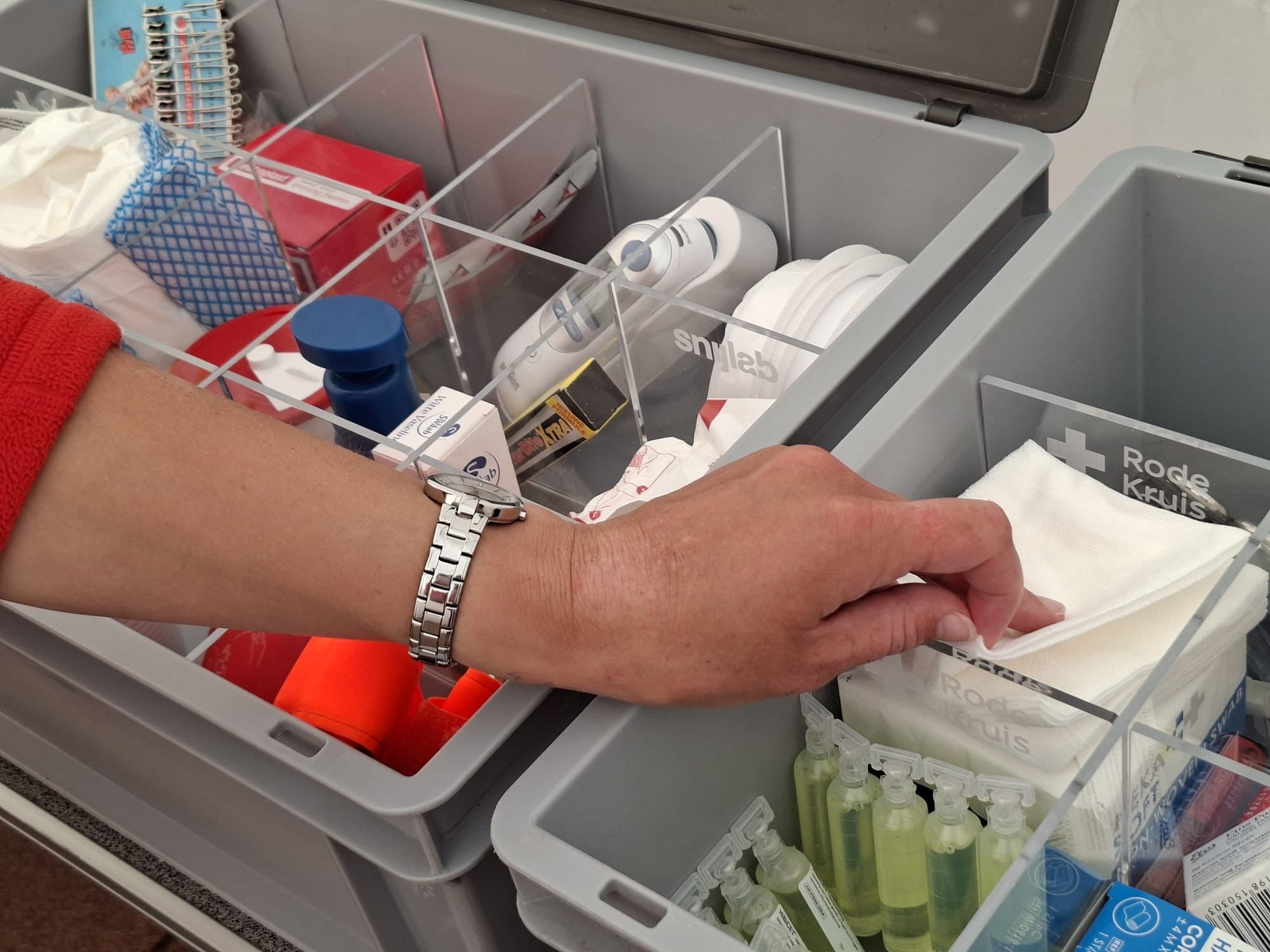

Plexiglass, also known as Perspex, PMMA and Acrylic, can be laser cut very easily. Laser cutting is inexpensive and precise. It allows you to create customized pictures or designs. Plexiglas comes in beautiful colors, matt, gloss and transparent. Upload your drawing and see immediately what it costs to laser cut it. Then get your plexiglass delivered quickly.

About the names

Plexiglass is the most familiar brand name of a material actually called Acrylic. The technical name is PMMA, or Polymethylmethacrylate. But no one remembers that so it is often popularly called Plexiglas. Other brand names are Perspex Altuglas, Satinglas, greencast, etc. Lexan is a different material. In fact, that is polycarbonate and it is not good for laser cutting. We usually call Perspex acrylic because we supply this material from several brands. However, it is all the exact same material.

What is Perspex or acrylic?

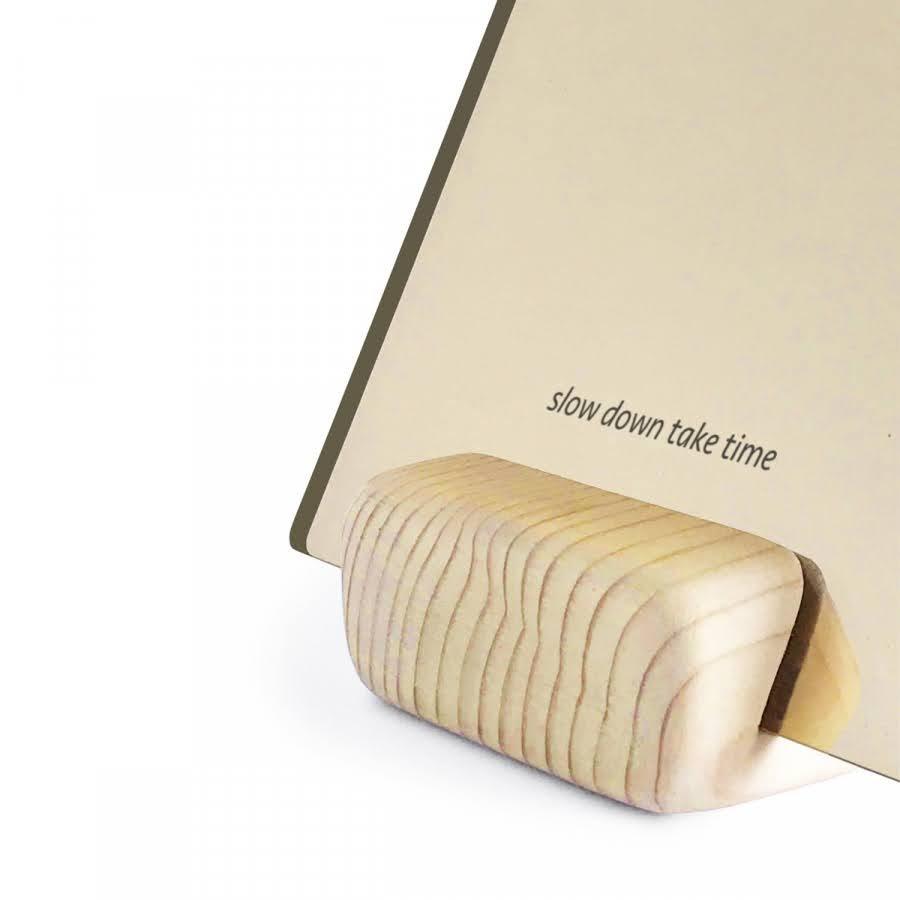

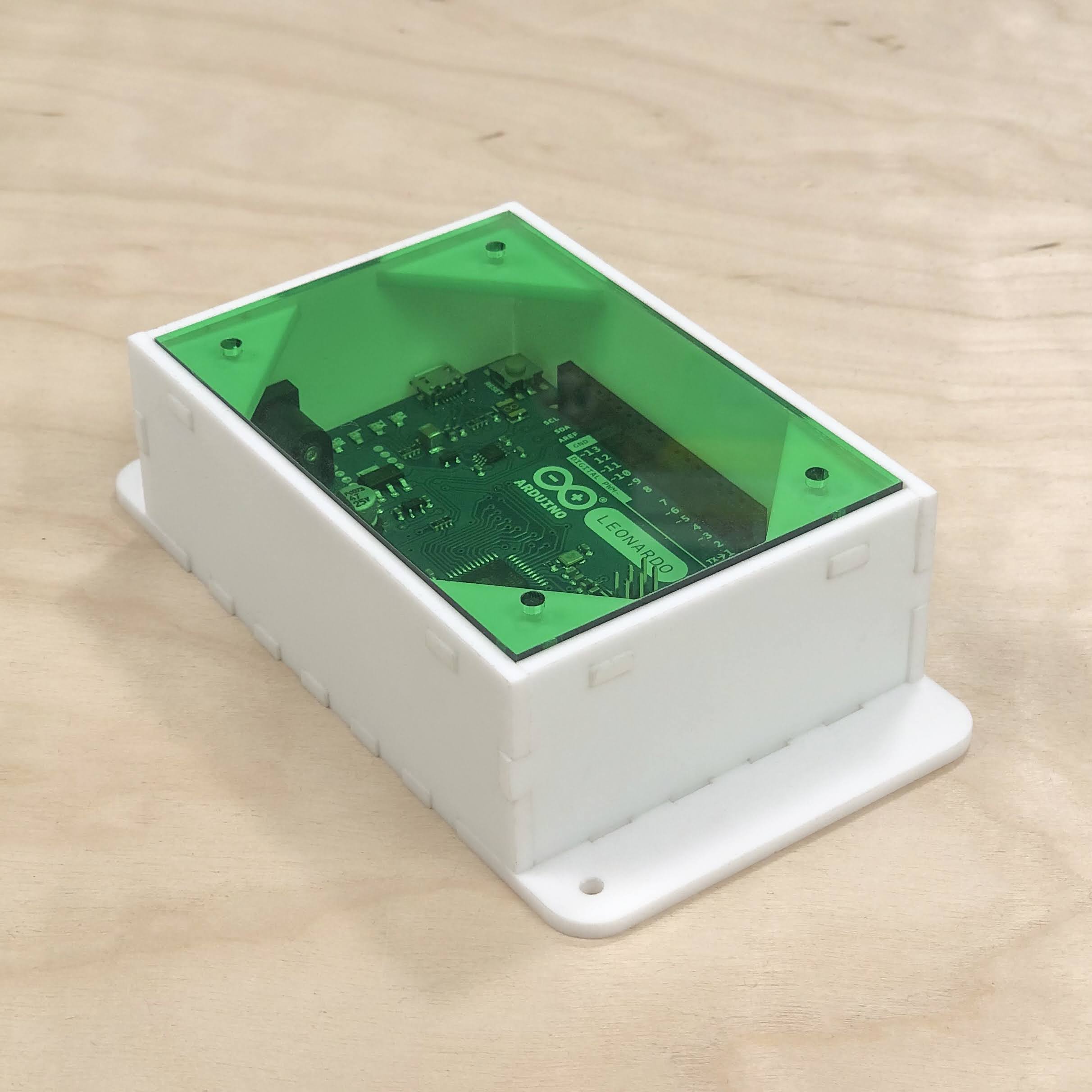

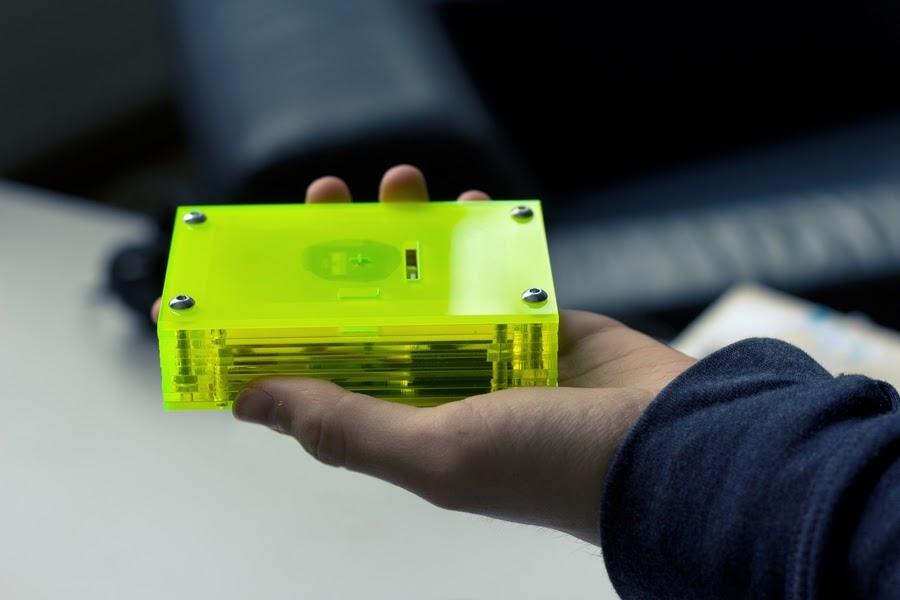

In short: plastic sheet often used for design, lettering, model making, enclosures, etc.

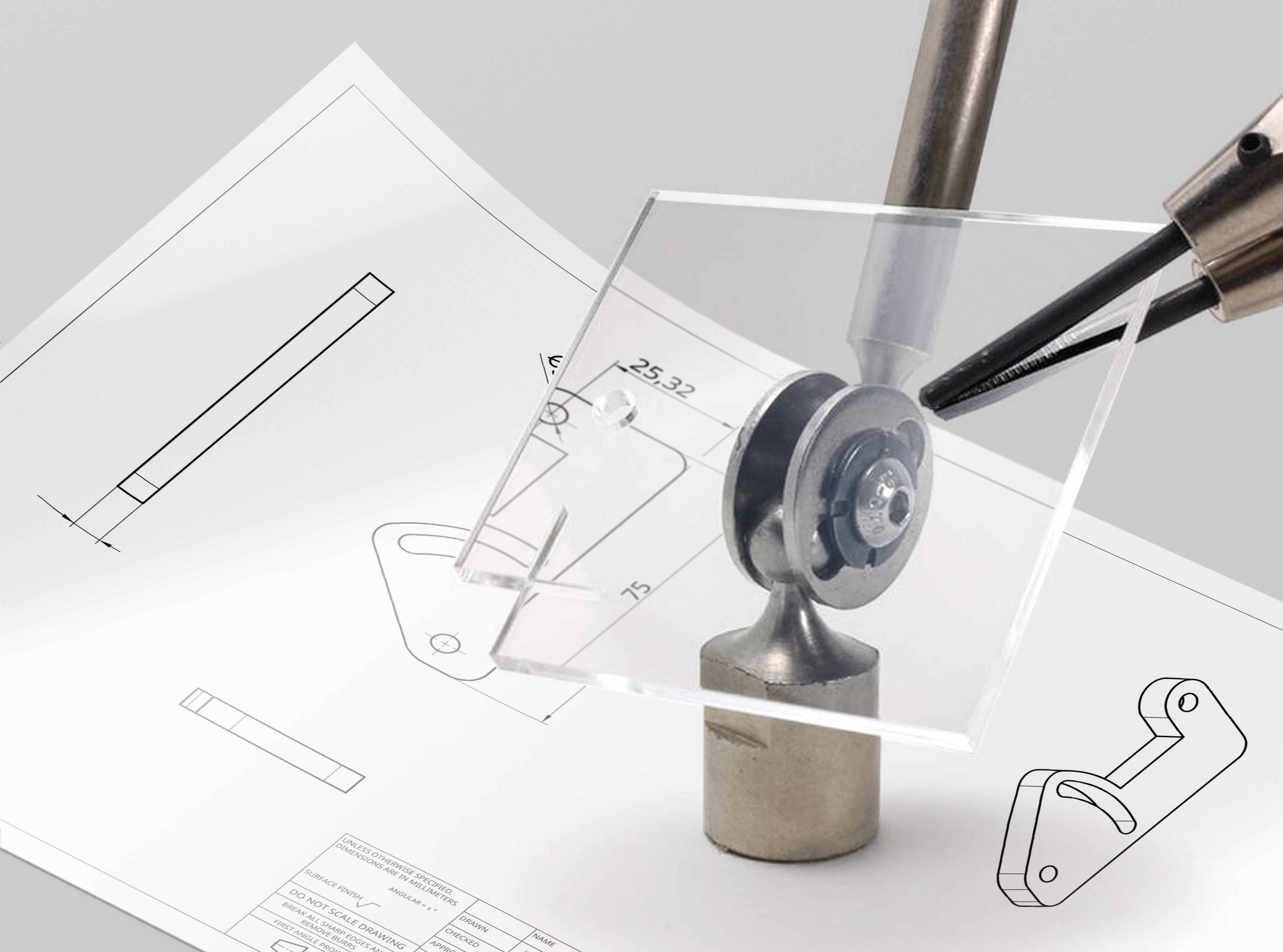

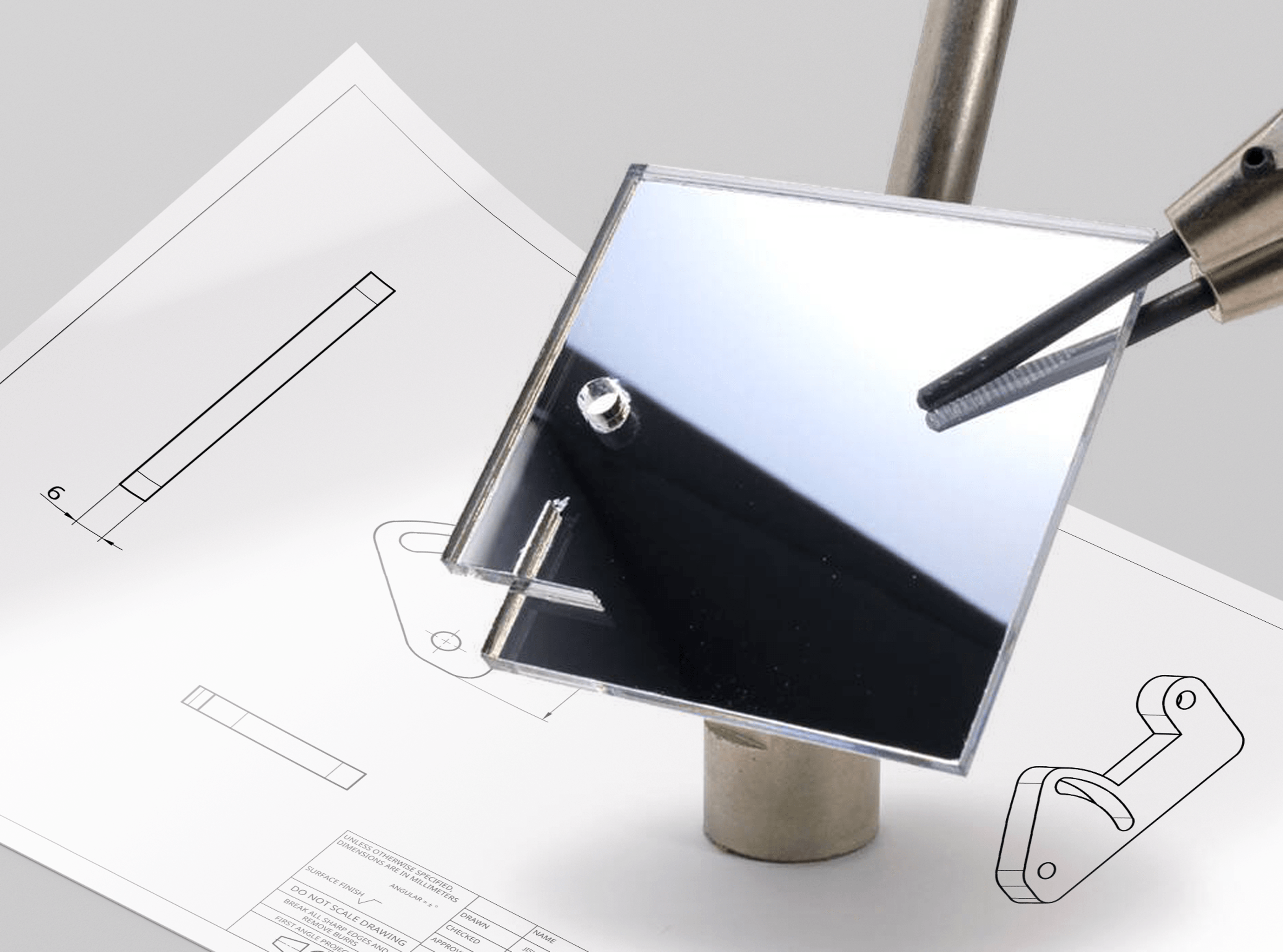

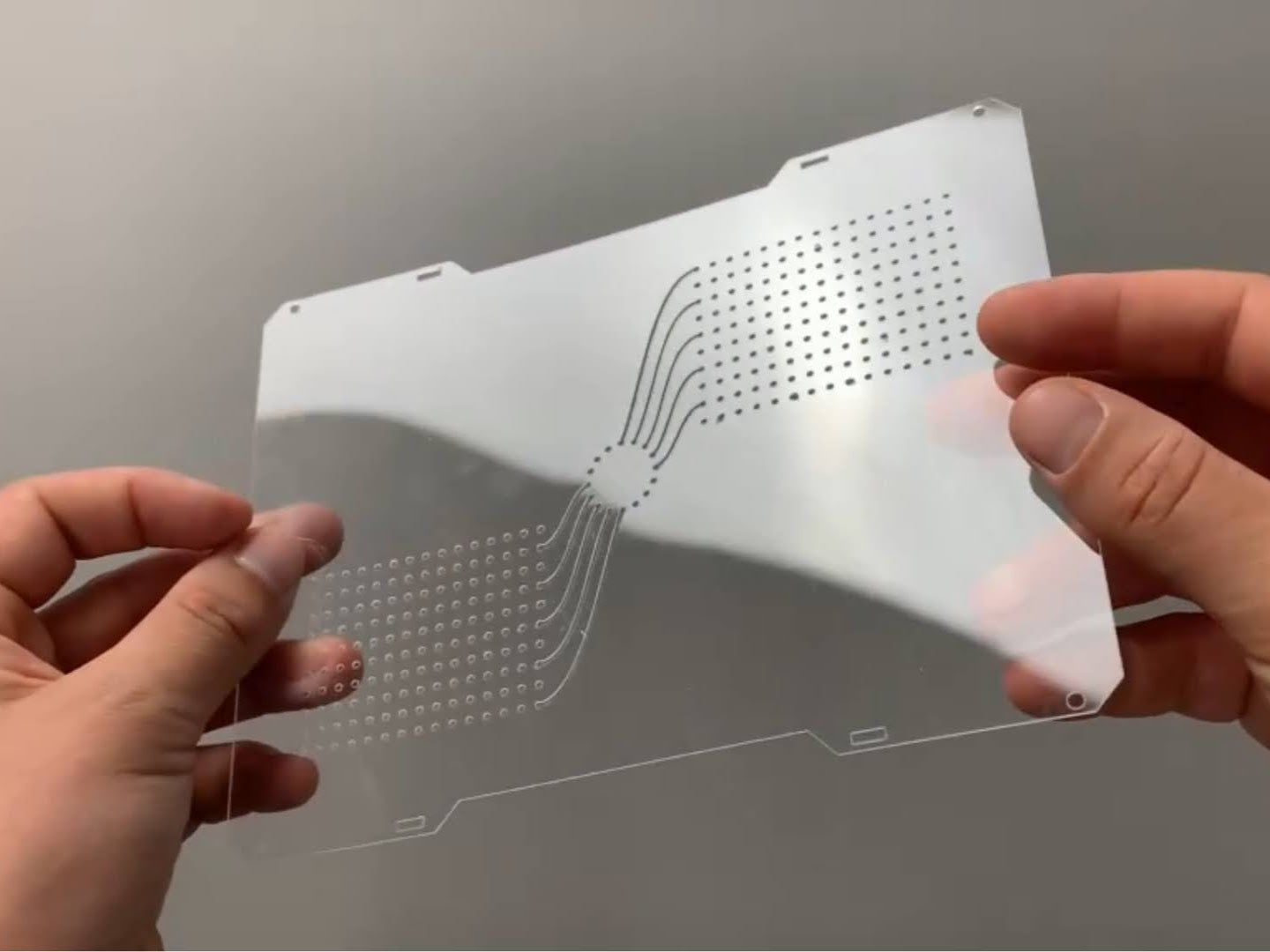

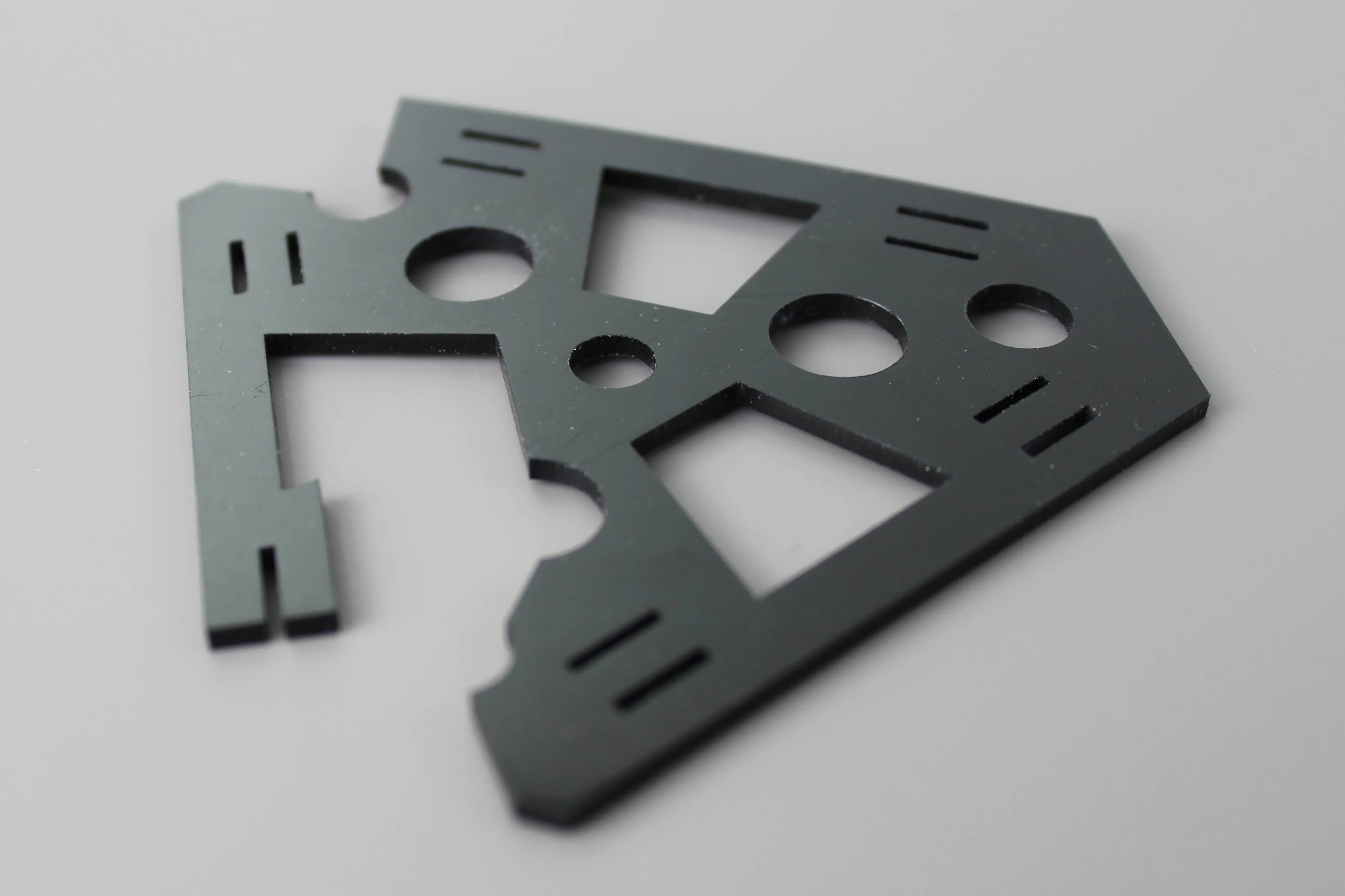

Perfectly laser cut

Acrylic is the most frequently chosen plastic for laser cutting. This is because it is a beautiful material that also comes out of the laser beautifully. With beautiful shiny edges and without defects because there is a protective film on both sides. This is how you create high end professional looking designs.

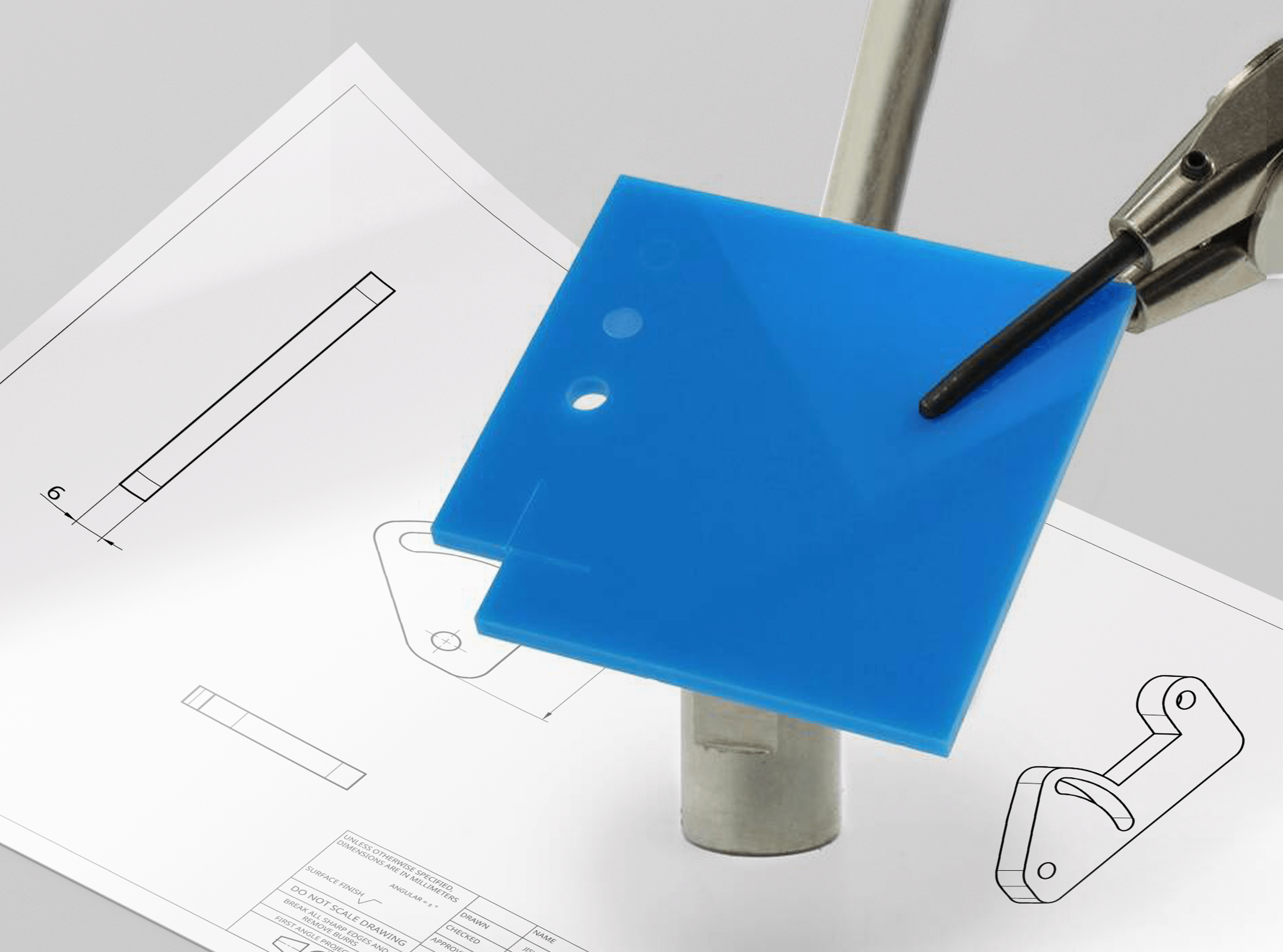

Crystal clear, UV resistant and suitable for outdoor use

Plexiglass is widely used for lettering (facade letters, logos, signs, etc) and signing. This is because it remains beautiful and retains its color even outdoors under various weather conditions. Clear is just as transparent and clear as real glass. Clear acrylic you have without color or with colors. You also have semi-transparent acrylic and colored acrylic.

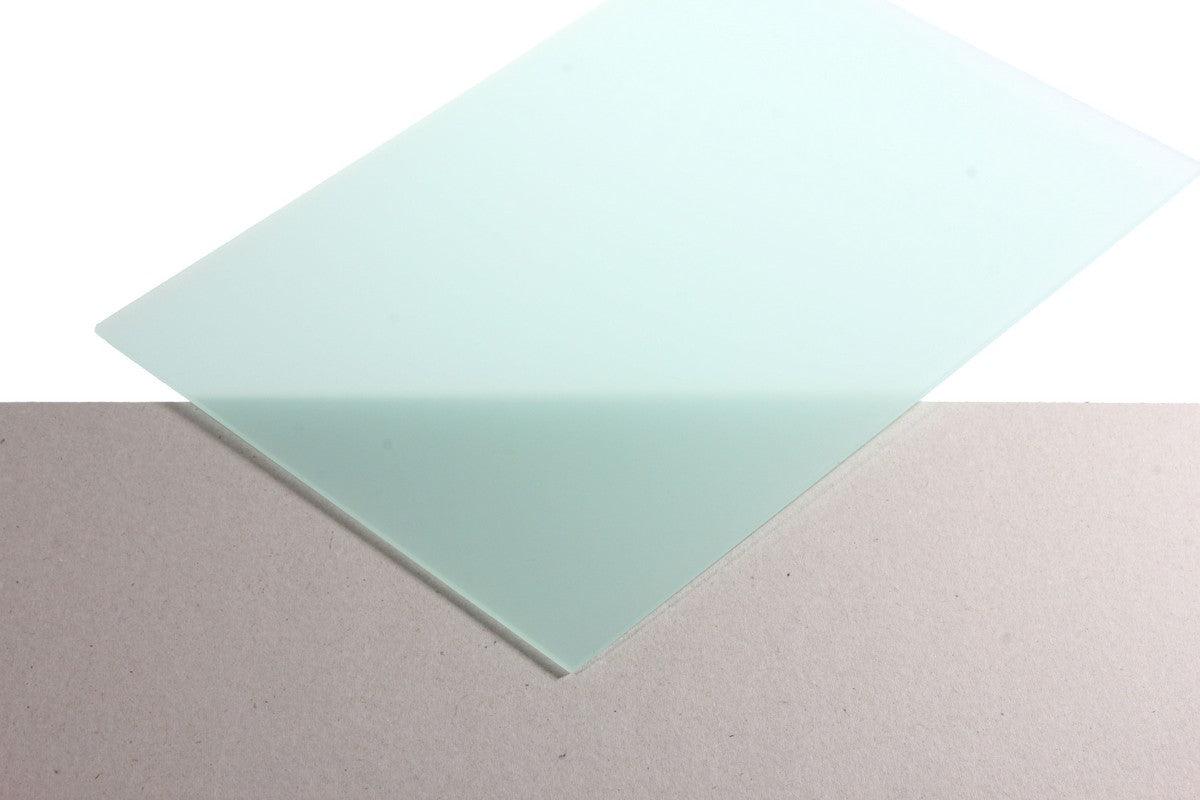

Frost, frosted, gloss and opal and milk glass

There is a lot of jargon in the world of plexiglass. We explain:

- Frost means it has a matte (grainy) surface and is translucent (translucent). Frost can be had in colorless but also colored.

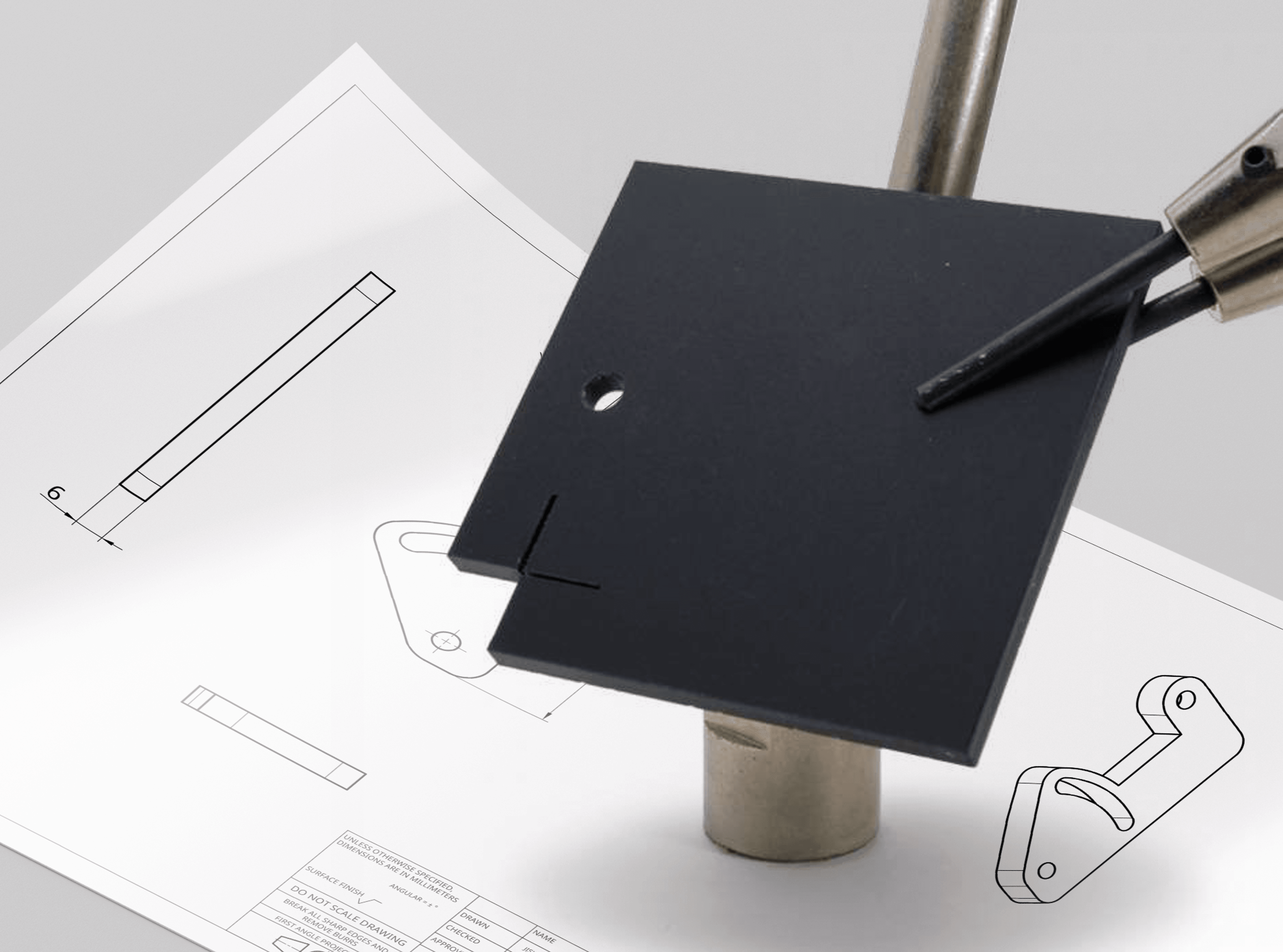

- Matt. This refers to non-transparent (opaque) sheets with a matt surface.

- gloss. 'Standard' (i.e. if it is not frosted or matte) then the surface of acrylic is glossy. You have both colorless (clear) and colored as transparent as colored opaque shiny acrylic.

- opal is shiny, white acrylic that lets a light through. You also call it milk glass.

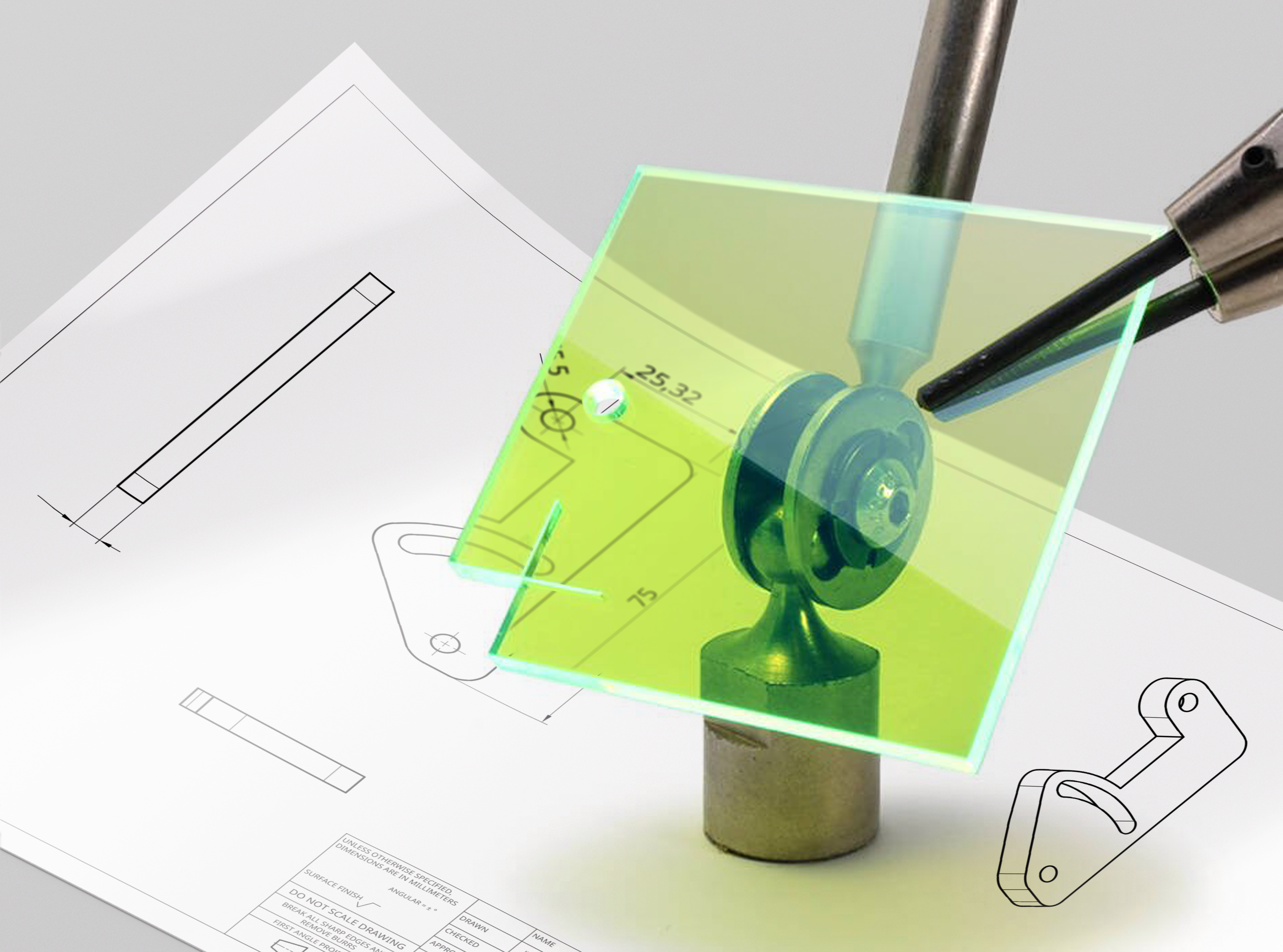

- Fluorescent or fluorine. Fluorescent colors of transparent plates. If you hold blacklight (UV light) to this, the edges, laser engravings and the whole plate light up brightly. Even in ordinary sunlight this effect is already there, though not as strong.

- Bright or crystal clear. By this is meant transparent uncolored. Or most similar to glass.

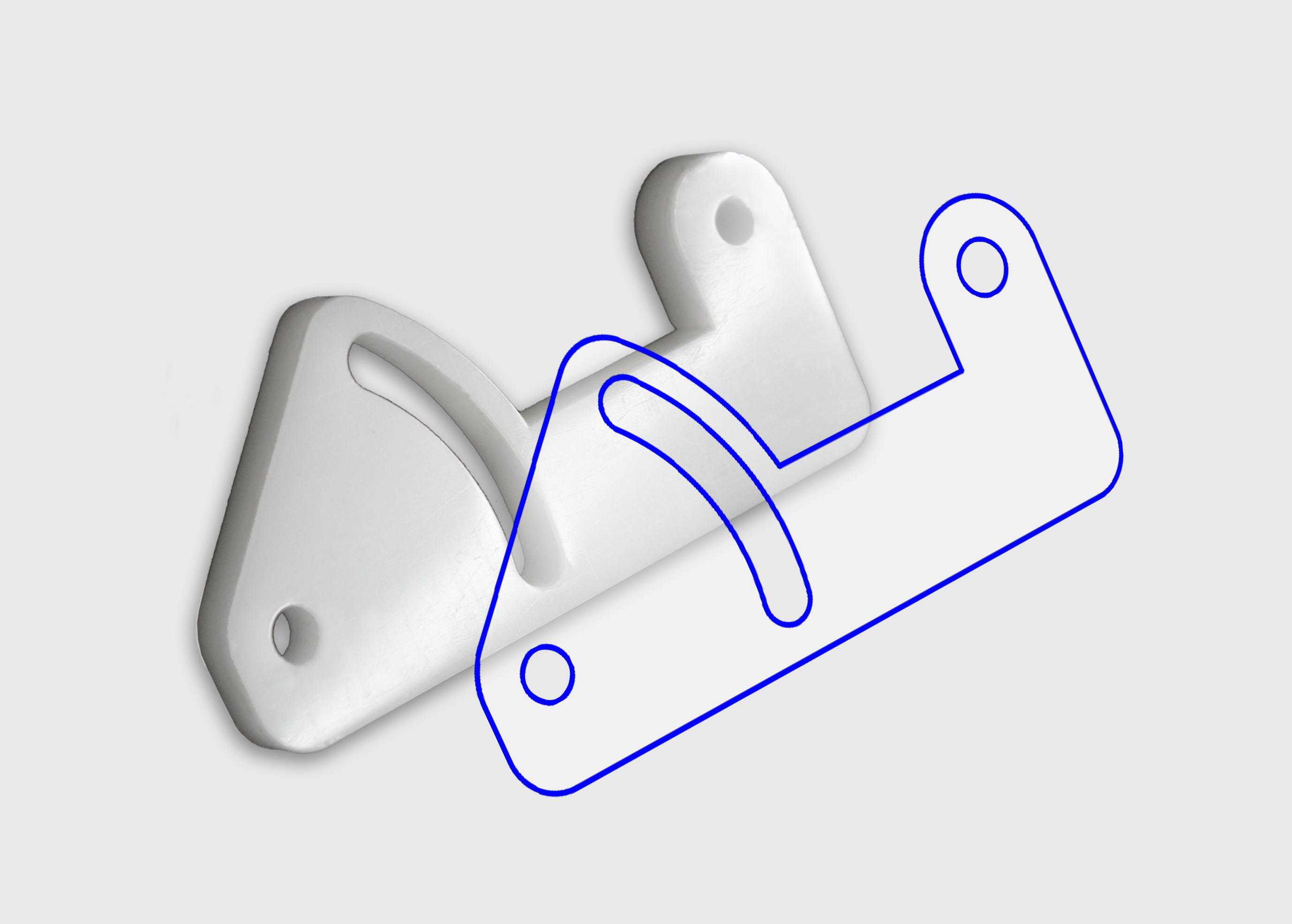

Mirror

Mirror acrylate is crystal clear with a reflective layer on the underside. It is a beautiful material and on sight indistinguishable as glass mirrors. You have it in natural (uncolored) but also in gold (gold mirror), anthracite (anthracite mirror) and pink.

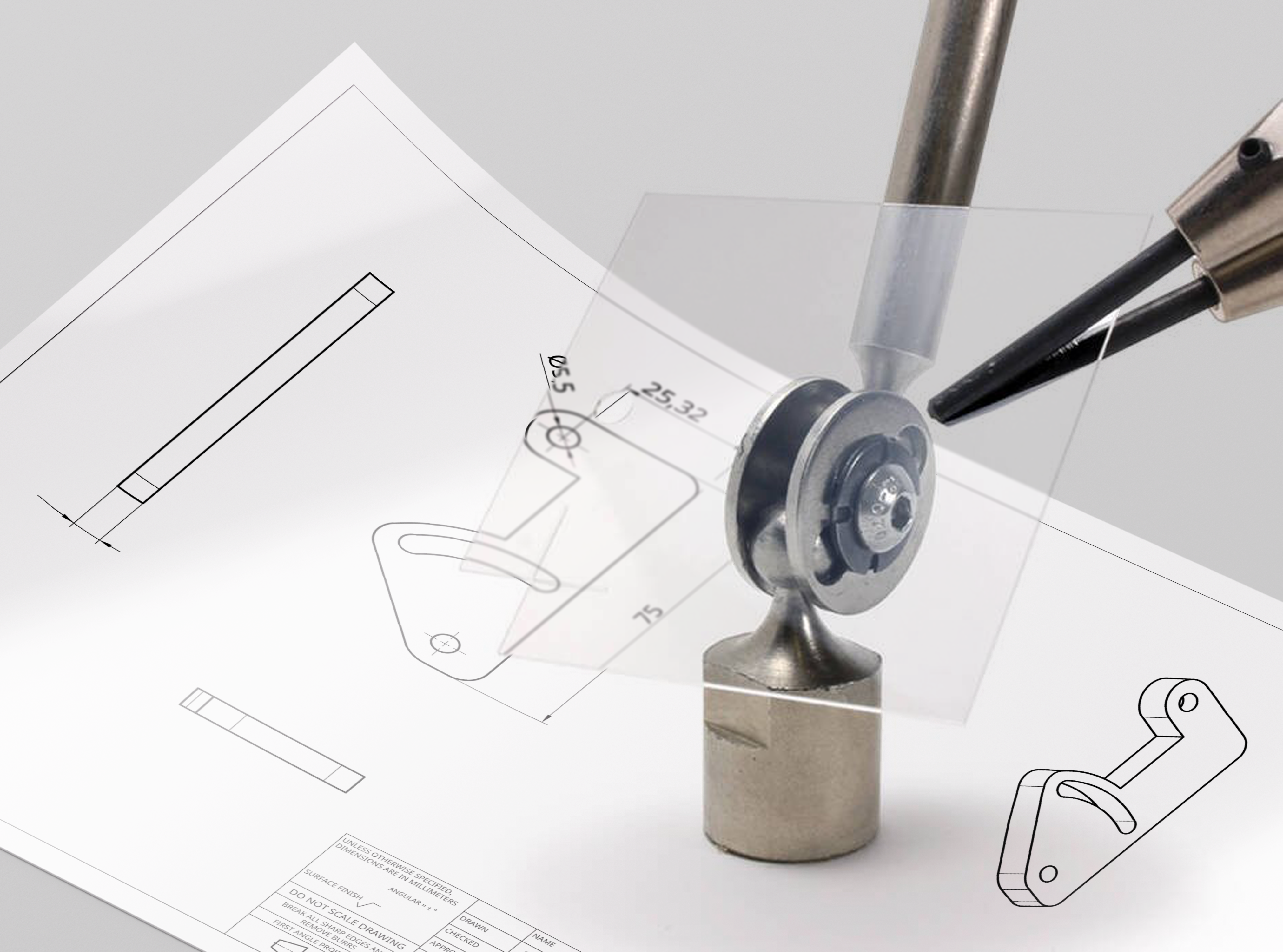

Mirror acrylic is also perfect for laser cutting into any shape you want.

Durability

Plexiglass can and does be 100% recycled. Many of our acrylics are made from waste streams. Cuttings from our acrylic we keep separate and are collected by a specialized party who take too back to the factory for recycling.

Thicknesses

Plexiglass comes in different thicknesses. The most common thickness is 3 mm. We have many colors of this in stock.

-

0.5 mm precision acrylic

- 1 mm clear acrylic

- 2 mm clear acrylic

-

3, 4, 5, 6, mm clear acrylic

- 3 mm extruded acrylic

- 3 mm mirror acrylic

Cast or extruded

There are two ways PMMA sheet can be made. Most of the acrylics we offer (and which are common for lasering) are cast.

Cast means that the liquid acrylic is poured onto a large glass plate and cools there until it hardens.

Cast acrylic has the following properties:

- good to laser engraving (engraving becomes matte and whitish)

- varies somewhat in thickness.

- Available in many colors and variations.

The other production method is extrusion. This involves pressing the liquid acrylic from a mold into a flat sheet. Our mirror acrylic and Extruded acrylic are extruded.

Extruded acrylic is also referred to as XT in the name and has the following properties:

- constant(er) in thickness.

- poorly engravable (no contrast is created).

- fewer variants available.

What does laser cutting plexiglass cost?

That depends entirely on your design. How big it is, how many pieces you order, etc. We have developed a handy online tool that calculates exactly what it costs as soon as you upload your design.

To give you an indication (prices ex. VAT):

- Cutting a small plate to size costs €15 - €20

- Laser cutting a complex design costs €30 - €200

- Laser cutting a small part in series costs €0.5 - €5 per piece

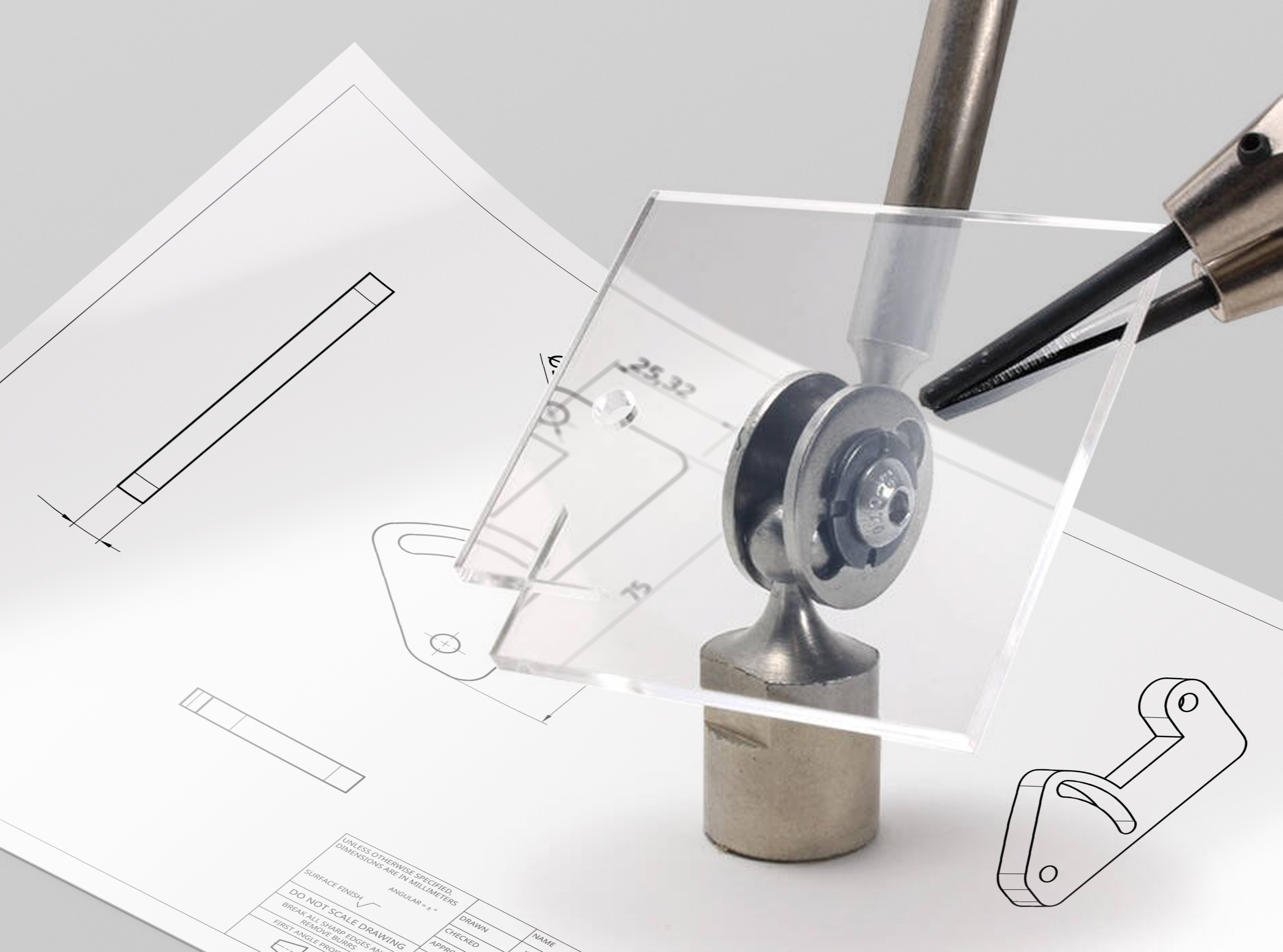

Laser cutting plexiglass online

Would you like to have plates cut yourself or create your own design and have it cut? You can. To do this, you need a digital drawing of what you want to cut. This is a 1:1 drawing in format AI, DWG, DXF or vectorPDF in which each line simply becomes a cut through the plate. More about the drawing rules.

Do you have a drawing? Create a free account at account.snijlab.co.uk and drag your drawing into the browser. Then choose the material of your choice and you will immediately see the price to laser it to size. Next, choose a delivery date. That can be as soon as the next business day or same day (if you come to pick it up in Rotterdam). Order and pay online and get it delivered quickly.

Don't come out? Our customer service is here for you!