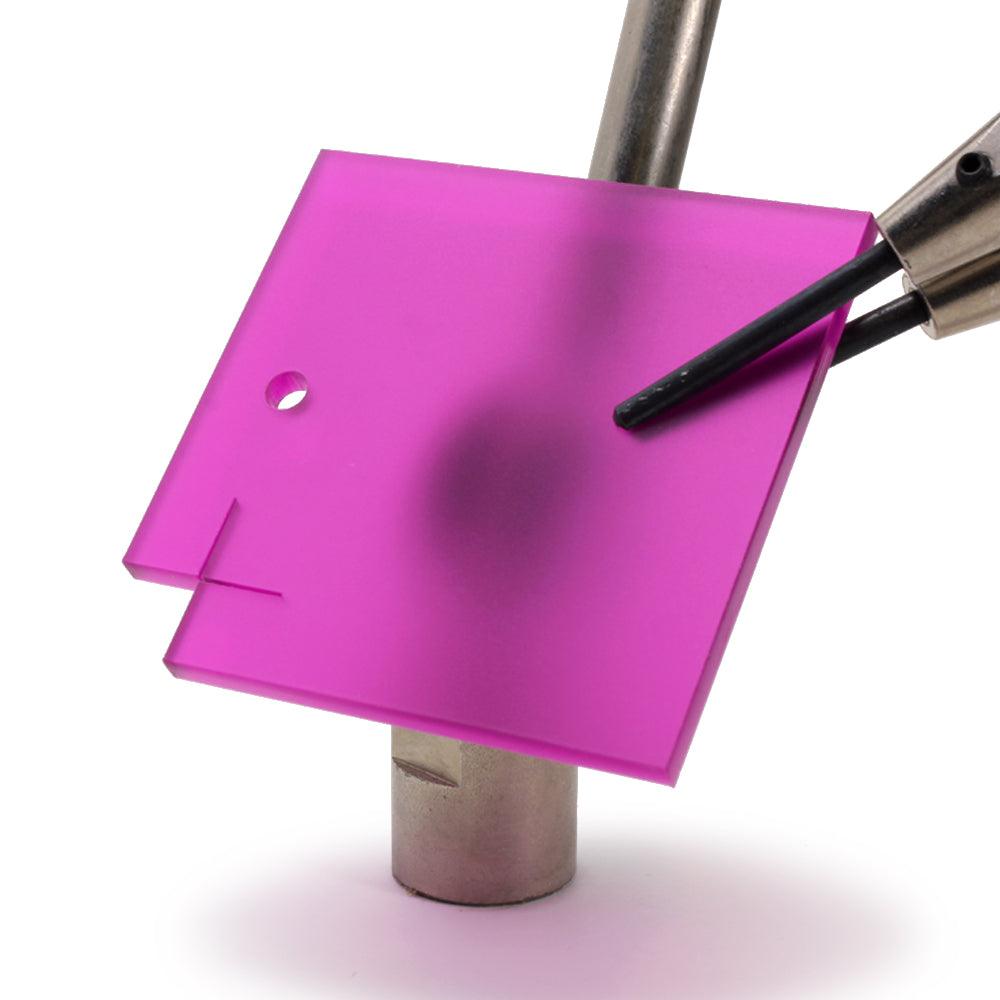

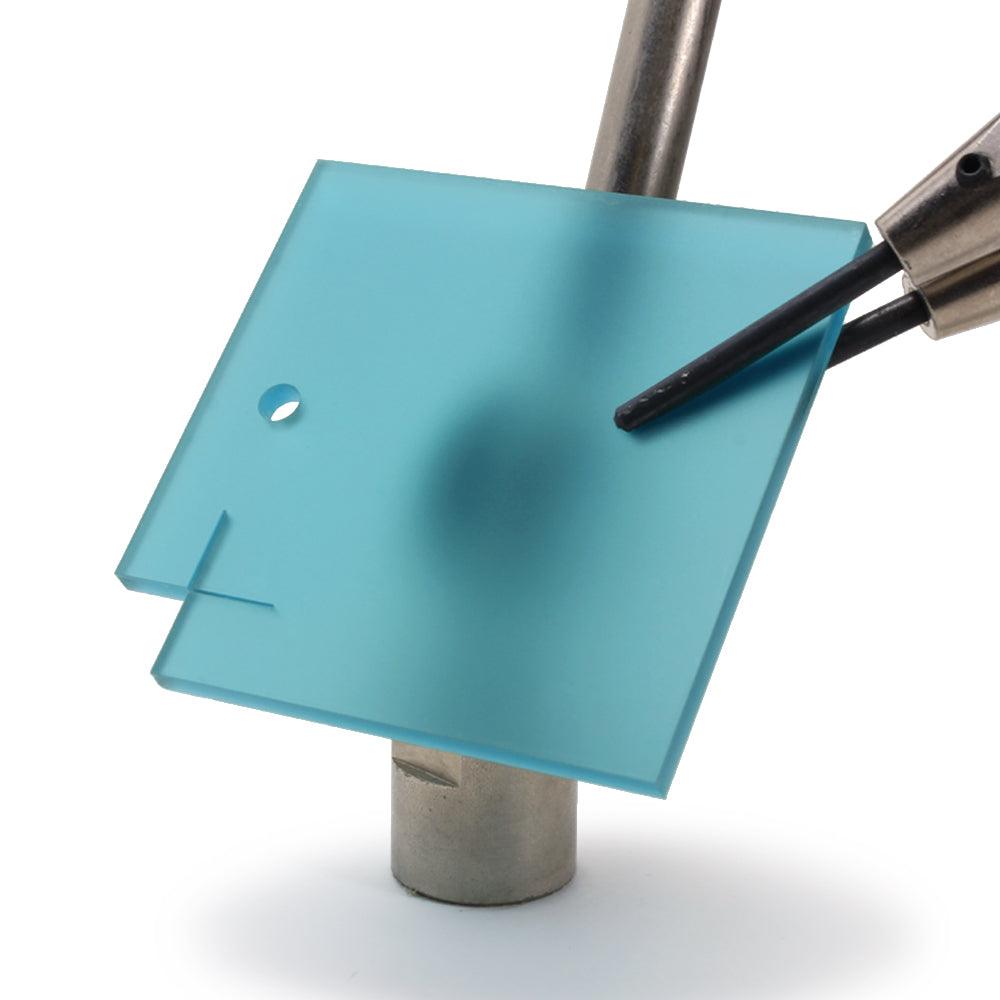

Laser cutting from frost acrylic

After uploading your design, you will receive an instant, no-obligation price. If you want, you can then order securely online.

In print runs as low as €0.05 per part!

| Material information | |

|---|---|

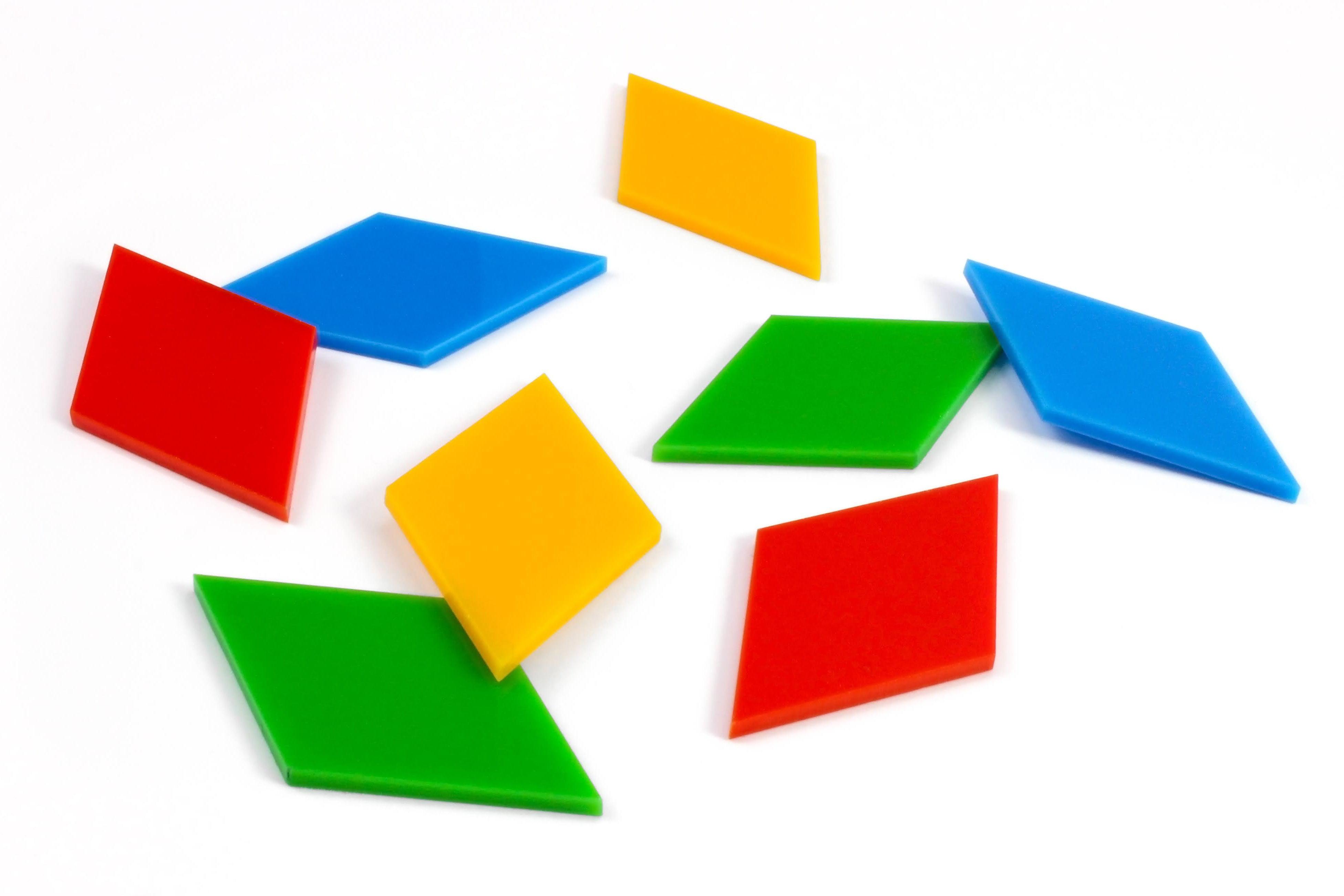

Available colors |

colorless, cyclamen red, peacock blue, water

|

Available thicknesses |

3.0 mm

|

| Technical specs | |

Density (Kg/m³) The specific weight per volume in kg / m³

|

|

Heat Deflection Temperature (°C) Heat Deflection Temperature indicates the temperature up to which a material remains rigid under load.

|

|

E-modulus (MPa) The modulus of elasticity or stiffness of the material. This indicates how much the material deforms under a given stress.

|

|

Moisture absorption(%) The degree to which a material absorbs moisture from the environment. A material that has absorbed moisture expands.

|

|

Tensile strength (MPa) The tensile strength is the maximum stress the material reaches just before it fails (permanently deformed). In practice, a material is used well below this limit.

|

|

Elongation to fracture (%) |

|

Impact strength (Charpy) Impact strength indicates how well the material can absorb shocks and blows. In the test, the material is held at two ends and struck in the middle with a special impact hammer.

|

|

Hardness (Shore °D) Hardness of the surface measured on a scale of Shore. For comparison, at shore D, a car tire is 15, a skateboard wheel is 50 and a construction helmet is 80.

|

|

Coefficient of friction The coefficient of friction indicates how much resistance a material provides to friction. Simply put; the lower this number the better the material glides.

|

|

Heat capacity (Kj/Kg°C) Indicates how much heat energy is required for the material to heat up. Or viewed another way, how much heat can the material store?

|

|

Breakdown voltage (kV/mm) The breakdown voltage is important when the material is used as an insulator and indicates the voltage at which the material ceases to insulate and begins to conduct.

|

|

Coefficient of thermal conductivity (W/mK) |

|

Coefficient of thermal expansion (mm/m°C) |

|

Maximum operating temp. short-term (°C) |

|

| Chosen variant | |

Material number |

MS0160

|

Thickness |

3.0 mm

|

Color |

colorless

|

Panel weight (kg/m²) |

0.08 kg

|

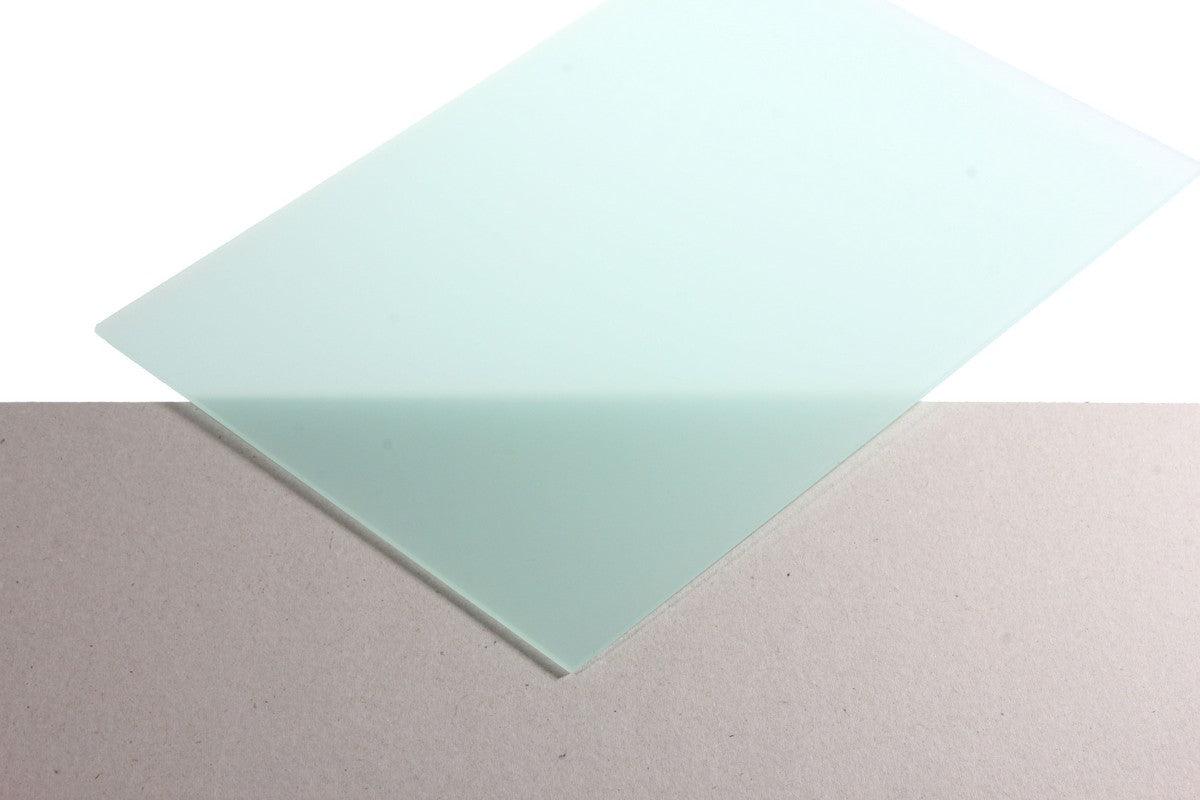

Description

Features

The frosted surface keeps the material looking good for a long time. This is because scratches and marks from use are much less visible than on glossy materials. Furthermore, acrylic is impact resistant, weather resistant and easy to work with.

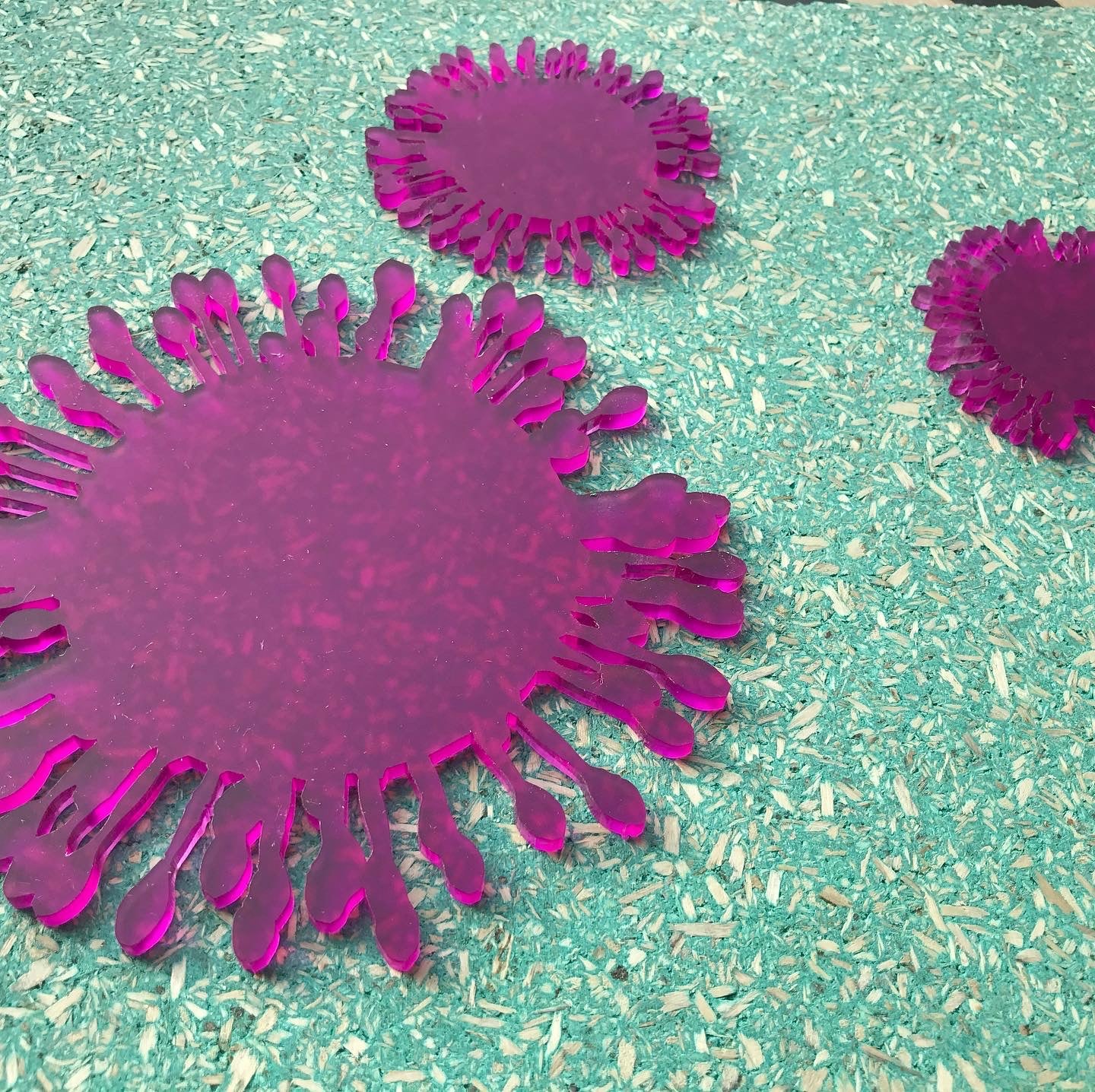

Applications

This material lends itself well to products that are handled frequently and need to look good without having to be cleaned. For example, in appliance housings, front panels, mounting plates, privacy windows, etc. Its light transmission also makes it very suitable for unique lamps and fixtures. In model making, it can be used as a substrate or for eye-catching facades. This acrylic is also widely used decoratively in artwork, in the advertising industry for logos, promotional items and lettering.

See Frost acrylic In real life, order a sample

To the samplesStill a different material?

Related materials

Vergelijkbaar met Frost acrylic

| Name | Thickness | Color | Max. size |

|---|

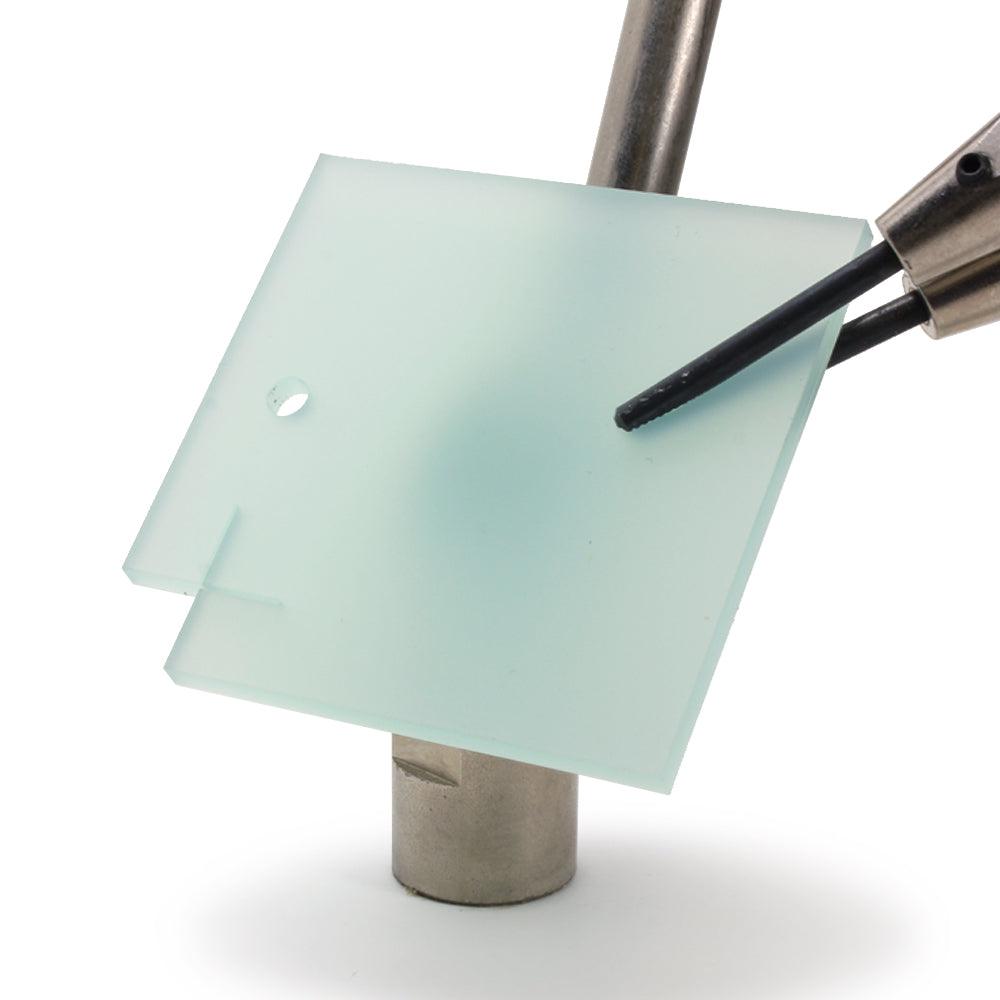

The advantages of laser cutting Frost acrylic

By Frost acryliclaser cutting, you can create complex designs with little effort and high quality. And that can be at any stage of production; research, prototyping, (on-demand) production or volume production. Laser cutting offers a range of advantages for machining Frost acrylic including precision, speed, low cost and no minimum order.

How does laser cutting work?

Laser cutting and engraving order online. Create an account and upload your drawing. Prices are calculated instantly, and quotes you download yourself.

We are here for you if you have any questions.

Contact us via chat, phone or mail.

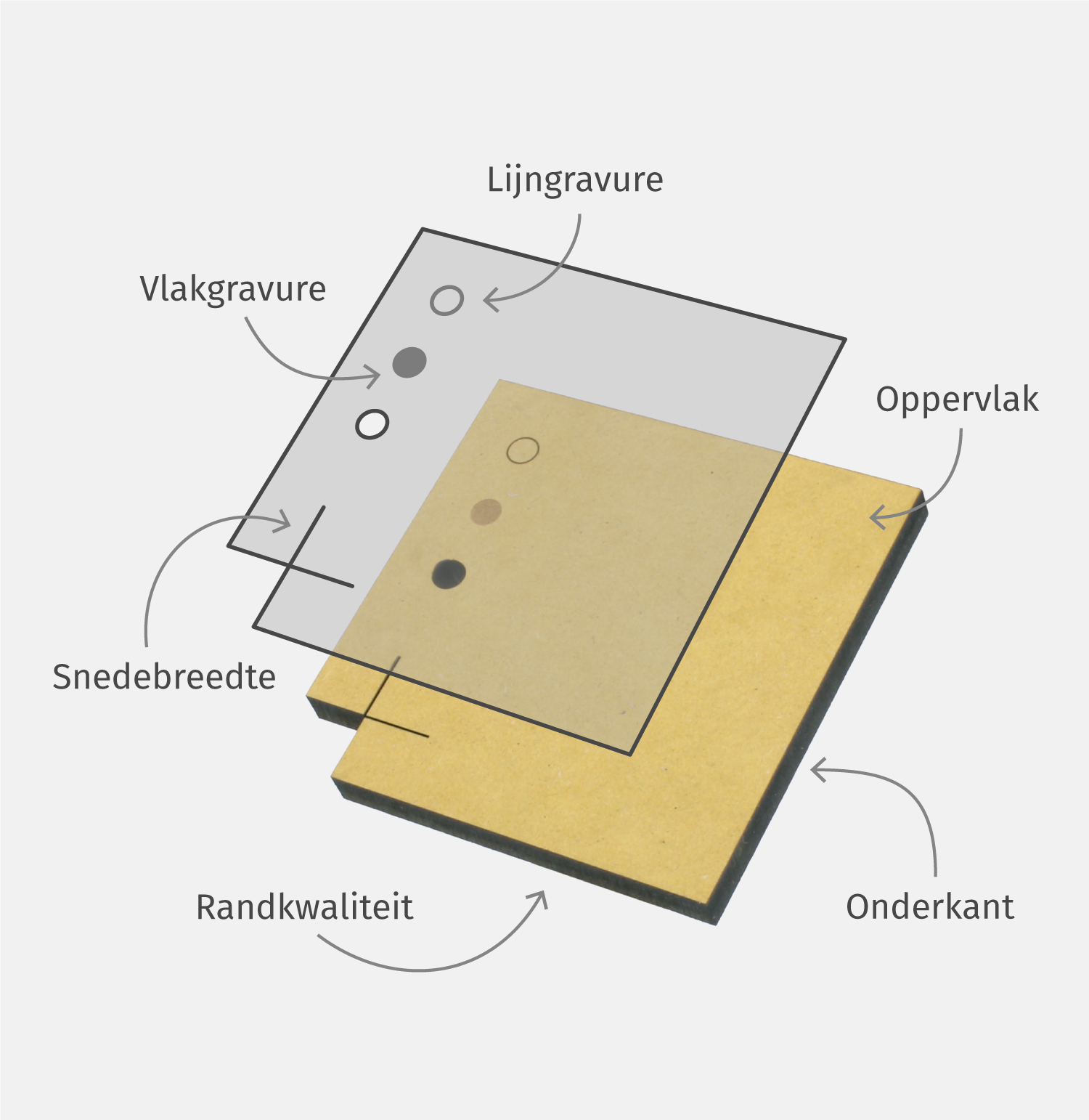

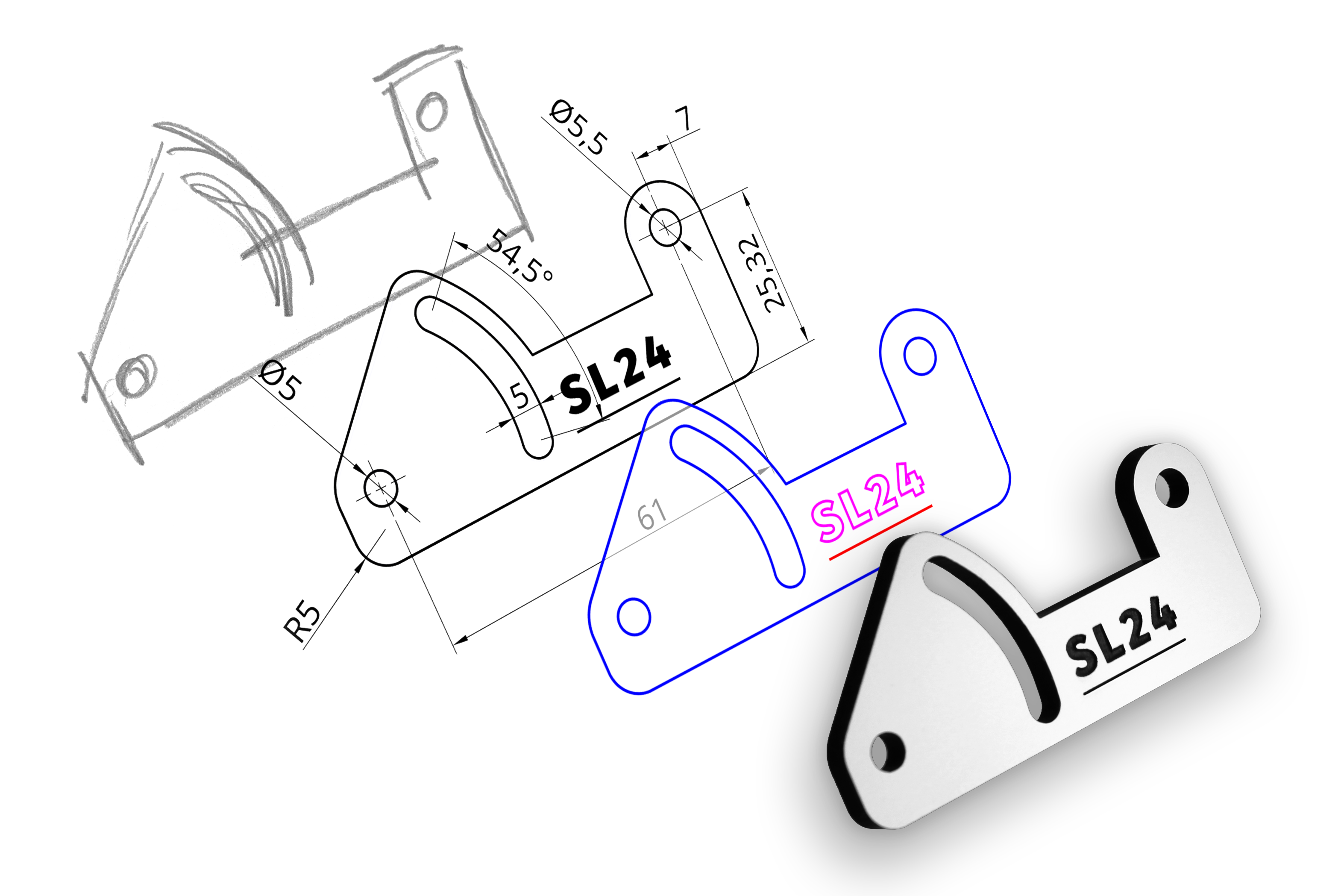

Layout drawing

- DXF, DWG, AI, PDF files

- Blue line = cutting

- Red line = line engraving

- Magenta line = plane engraving

Choose a delivery time

- Speed (ordered before 12:00 noon, delivered tomorrow)

- Fast (2 business days

- Standard (4 business days)

- Expensive (13 business days)

Secure online payment

How do you order laser cutting?

Upload your drawing, choose a material and delivery time and we will make it for you.

Try it now, uploading is free!

What does Frost acrylic laser cutting cost?

The price for laser cutting your design is automatically calculated in the shopping cart. Upload your drawing, choose a material and delivery time, and see the price instantly.

1 medium design ≈ €24.99*

1 full sheet ≈ €65.43*

1000 small parts ≈ €0.05/pc.*

*These are indicative prices incl. btw to give you an idea. Once you upload a design upload you will see the exact price.

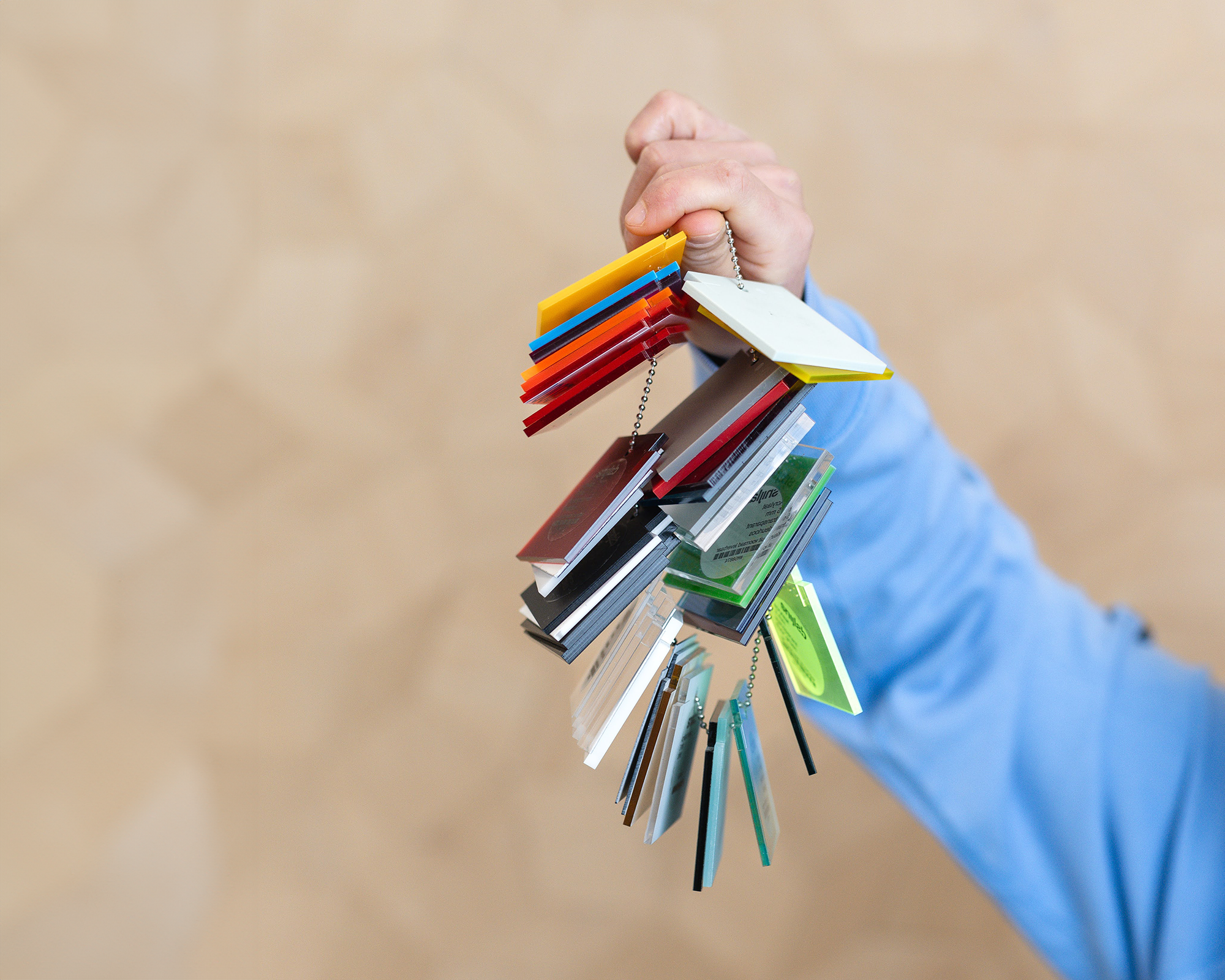

Want to see materials in real life?

Order one material sample chain. Samples provide a representative picture of the quality Snijlab delivers. This also allows you to compare materials so that you can make a good design decision.

To the sample chains