Laser cutting from mirror acrylic

After uploading your design, you will receive an instant, no-obligation price. If you want, you can then order securely online.

In print runs as low as €0.05 per part!

| Material information | |

|---|---|

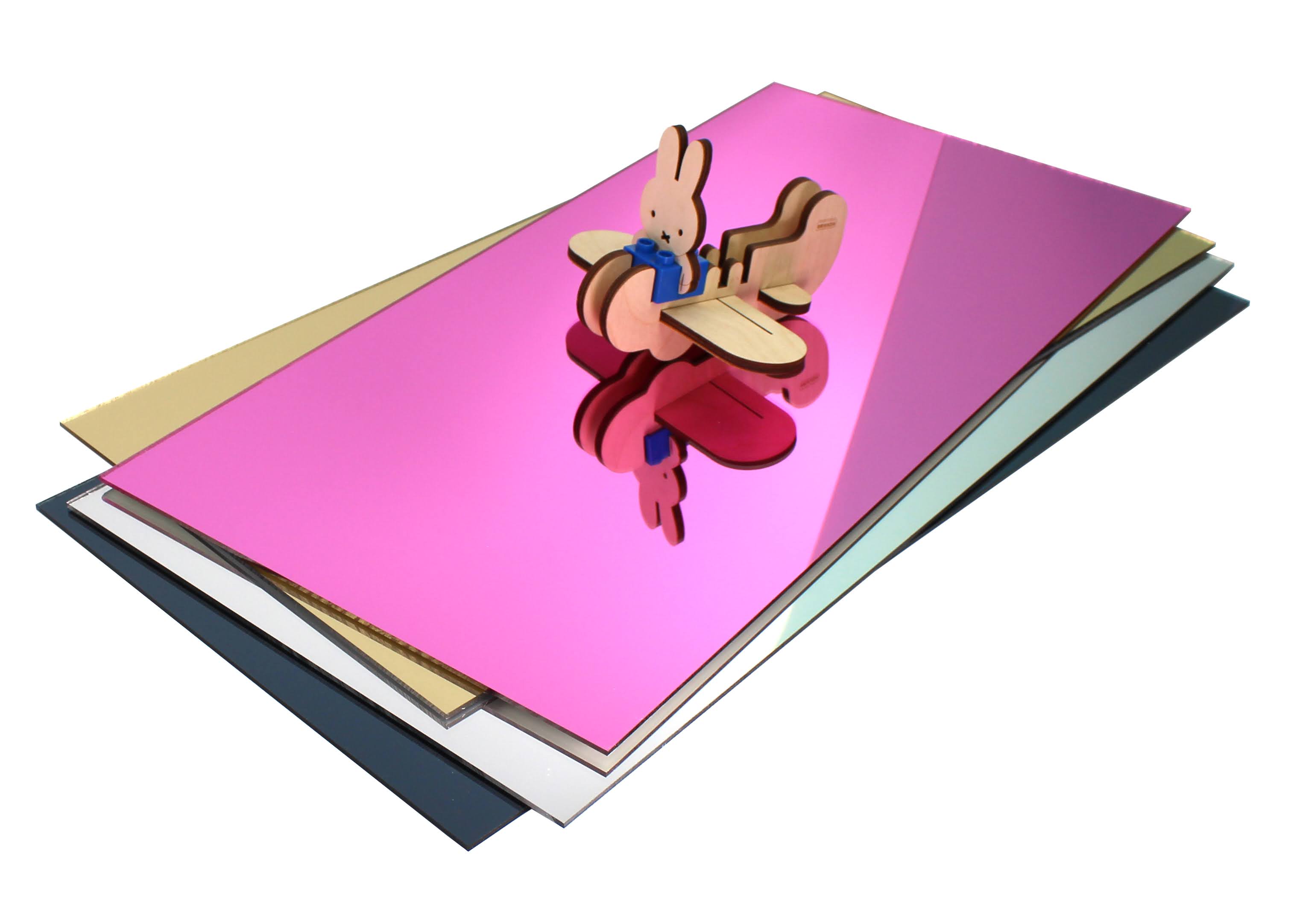

Available colors |

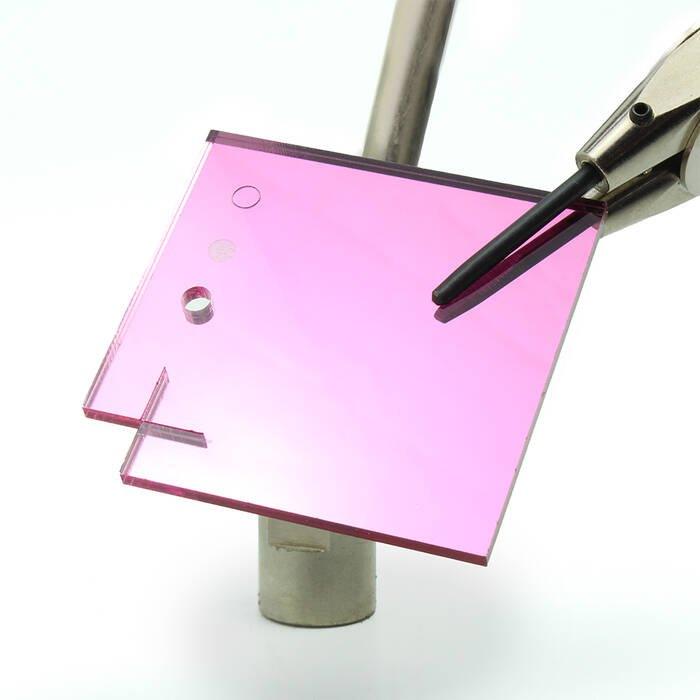

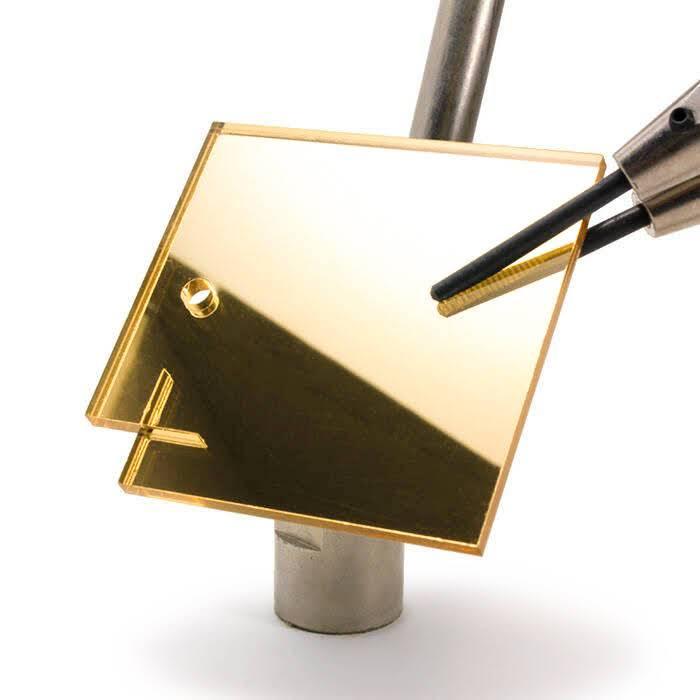

Silver, Gold, Anthracite, Pink

|

Available thicknesses |

3.0 mm

|

| Technical specs | |

Density (Kg/m³) The specific weight per volume in kg / m³

|

|

| Chosen variant | |

Material number |

MS0036

|

Thickness |

3.0 mm

|

Color |

Silver

|

Panel weight (kg/m²) |

0.08 kg

|

Description

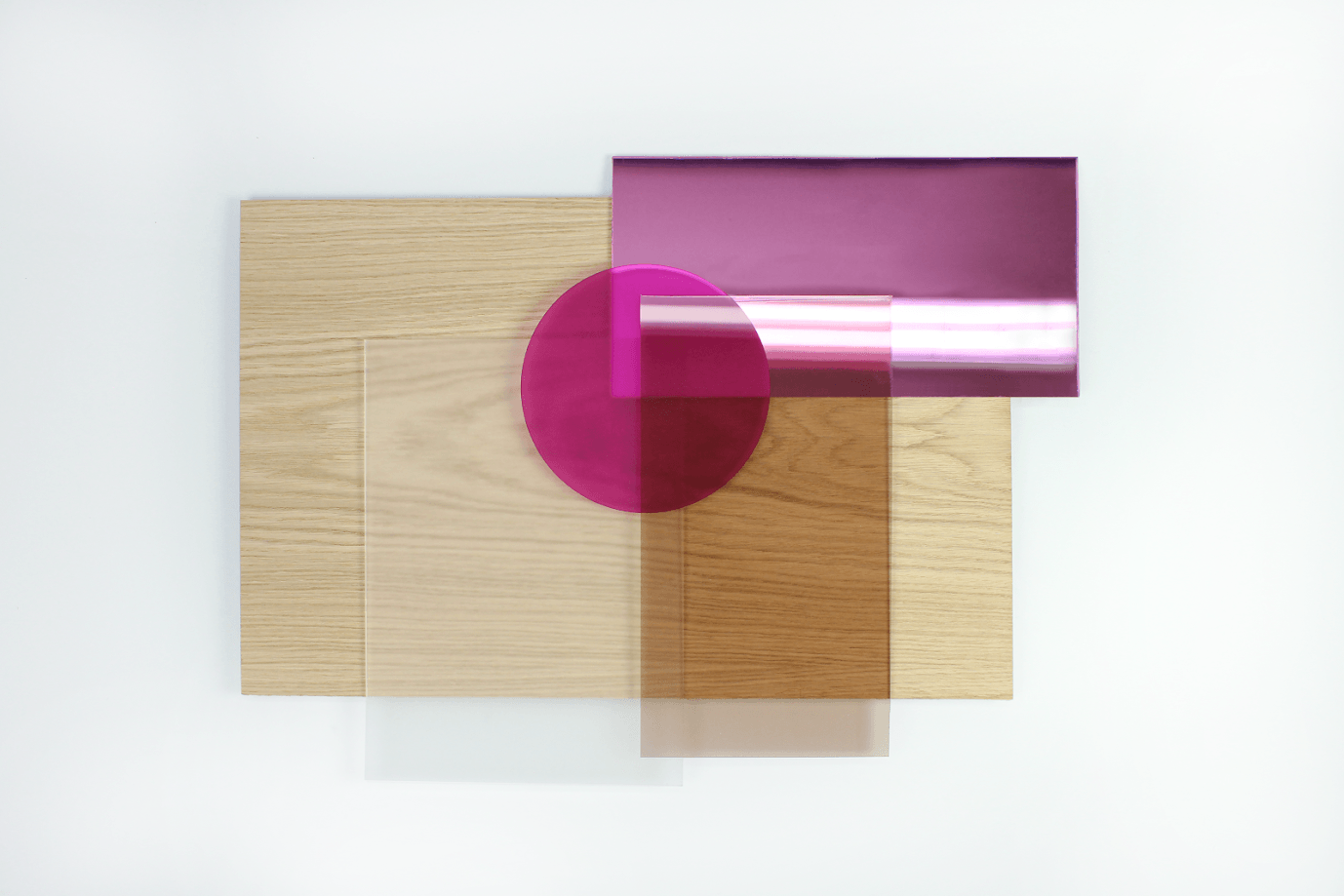

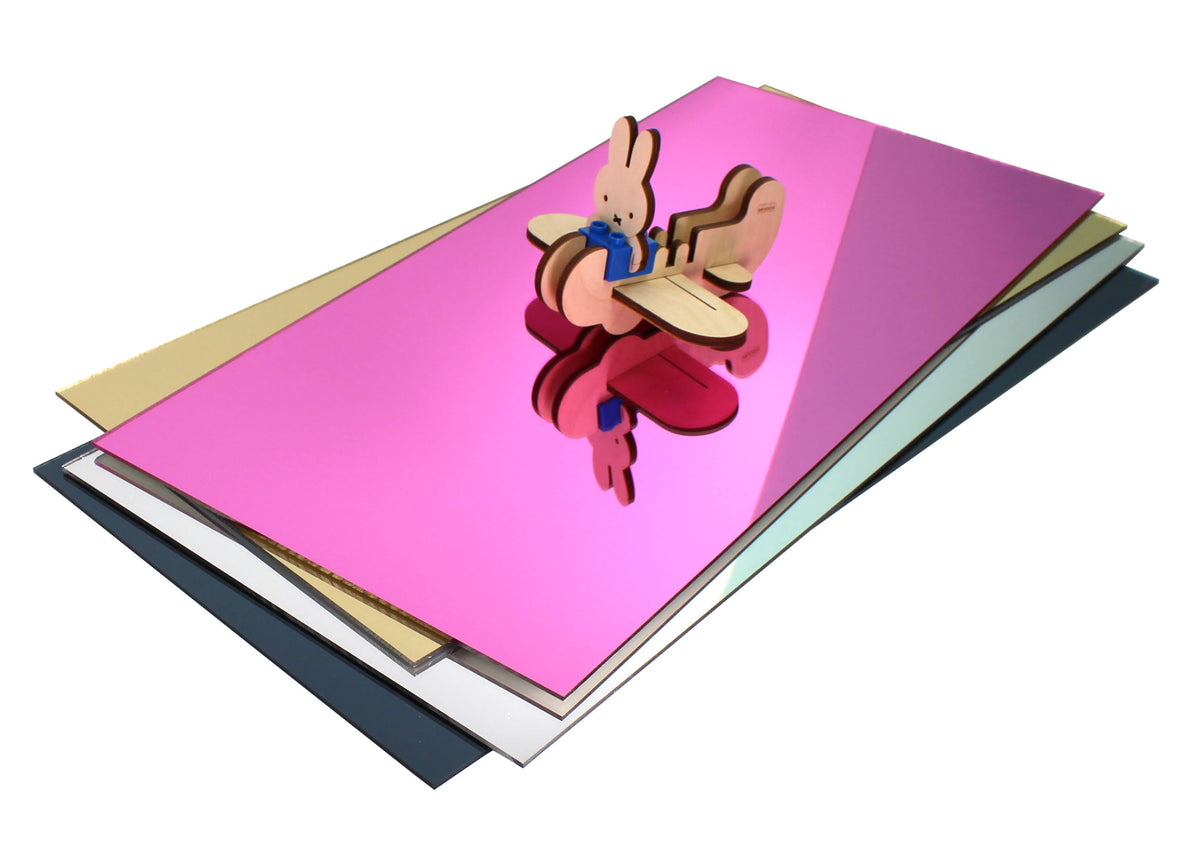

Laser-cut mirrors, indistinguishable on sight from glass mirror, with numerous applications.

Material properties

Acrylic mirror is made up of a transparent acrylic backing with a reflective backing layer. The mirrors are crystal clear and free of wrinkles, creating a flawless mirror image. The mirrors are available in both natural (silver mirror) and gold mirror.

Appearance

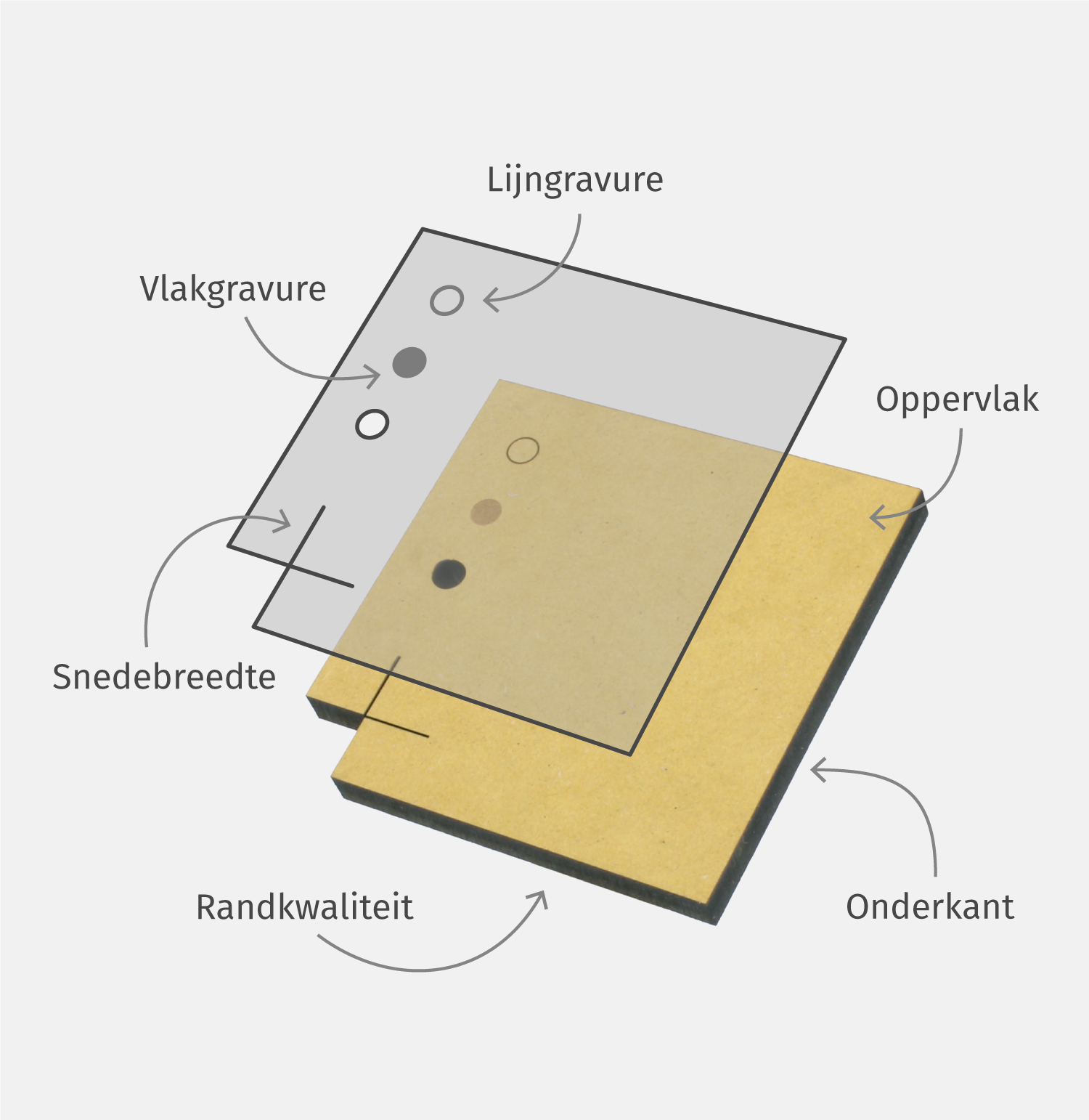

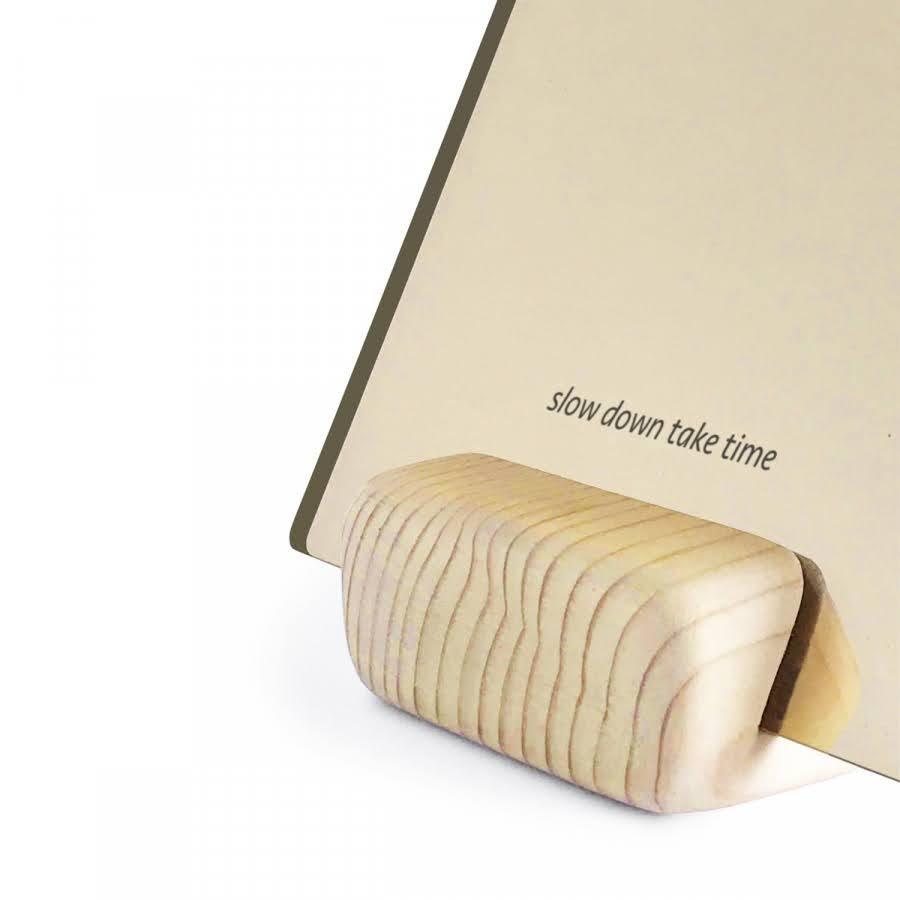

Mirror acrylic is good for laser cutting. The cutting edge does not discolor and the cutting process leaves no marks. Surface engraving is possible and is done by default on the reverse side. This makes the mirror layer disappear at the location of the engraving and the material becomes transparent there. This results in a good contrast, with the front of the mirror remaining smooth. Line engraving is also possible and also produces a high-contrast translucent line. Line engraving is also done from the back as standard.

Typical applications

With this material, mirrors can be made in any shape or pattern, or even mirror sculptures. It is used as an attention grabber in displays or billboards, and of course for lamps and lighting applications.

Finishing

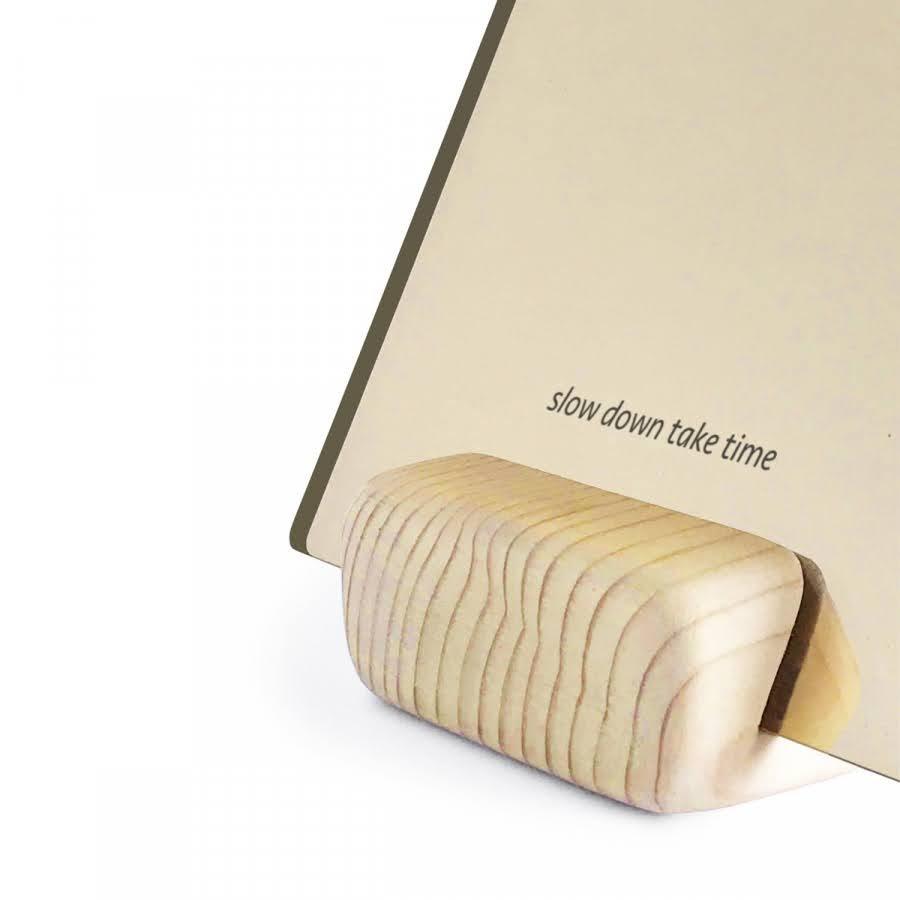

The material does not require finishing. The visible side is covered with protective film; the other side is gray or white.

Please note that acrylic is scratch-sensitive. Cleaning can be done with a soft cloth, but never use abrasive or scouring pads. Any scratches can be polished away with polishing compound.

Joints

Gluing acrylic is possible, but solvent-based glues are not recommended for laser-cut parts. Acrylic is easily attached with double-sided adhesive film.

See Mirror acrylic In real life, order a sample

To the samplesExamples of laser cut Mirror acrylic

Still a different material?

Related materials

Vergelijkbaar met Mirror acrylic

| Name | Thickness | Color | Max. size |

|---|

The advantages of laser cutting Mirror acrylic

By Mirror acryliclaser cutting, you can create complex designs with little effort and high quality. And that can be at any stage of production; research, prototyping, (on-demand) production or volume production. Laser cutting offers a range of advantages for machining Mirror acrylic including precision, speed, low cost and no minimum order.

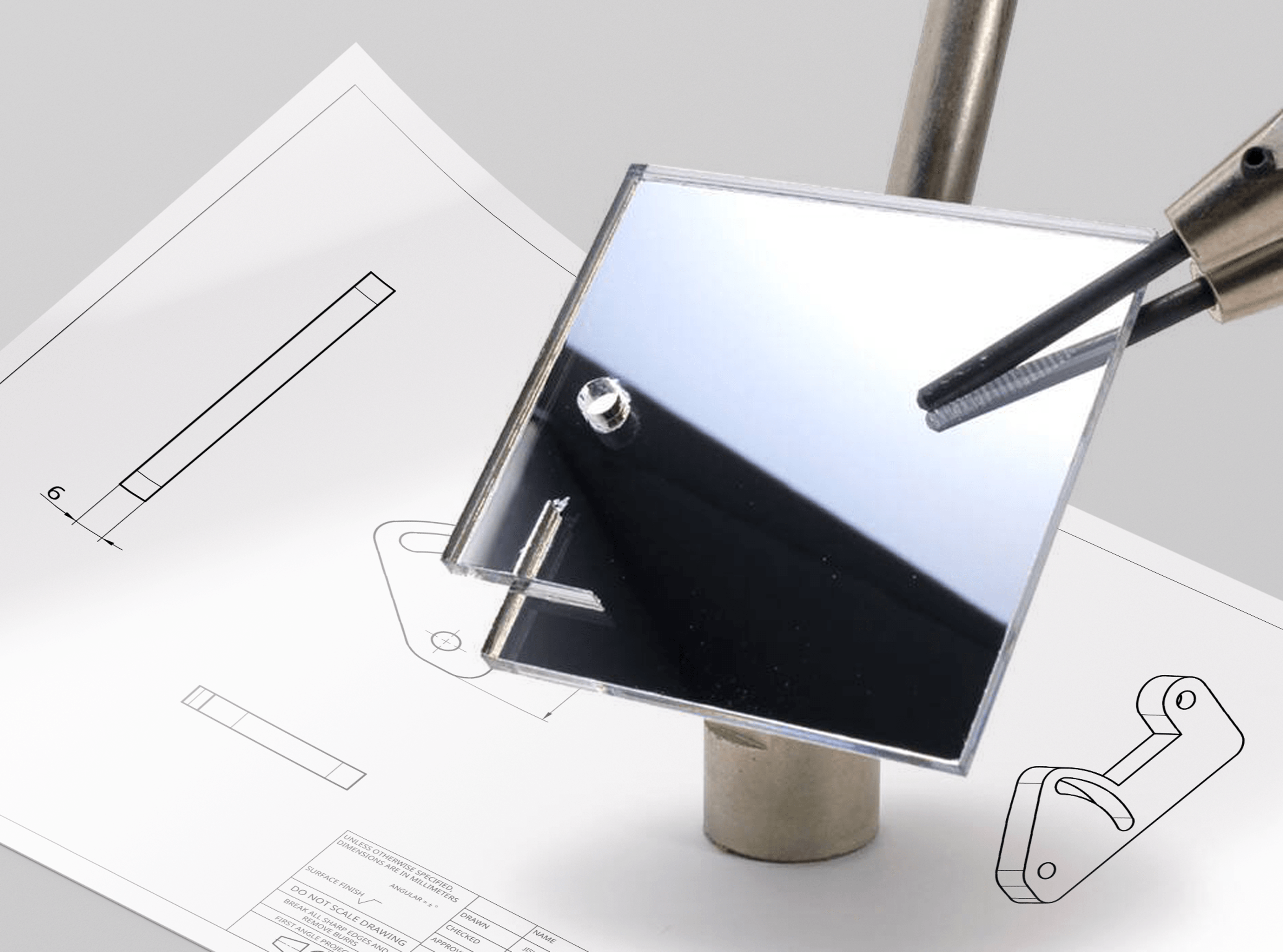

How does laser cutting work?

Laser cutting and engraving order online. Create an account and upload your drawing. Prices are calculated instantly, and quotes you download yourself.

We are here for you if you have any questions.

Contact us via chat, phone or mail.

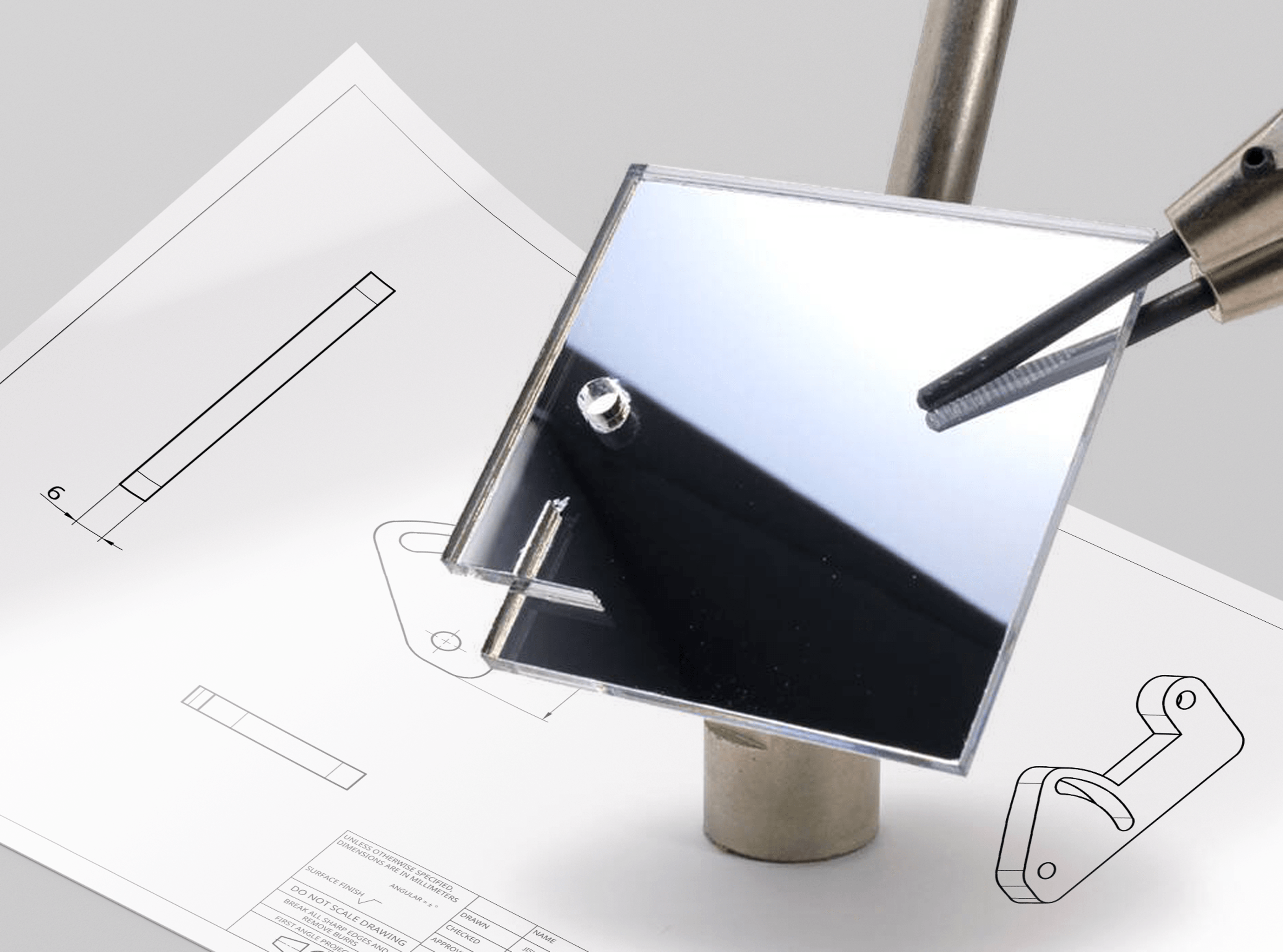

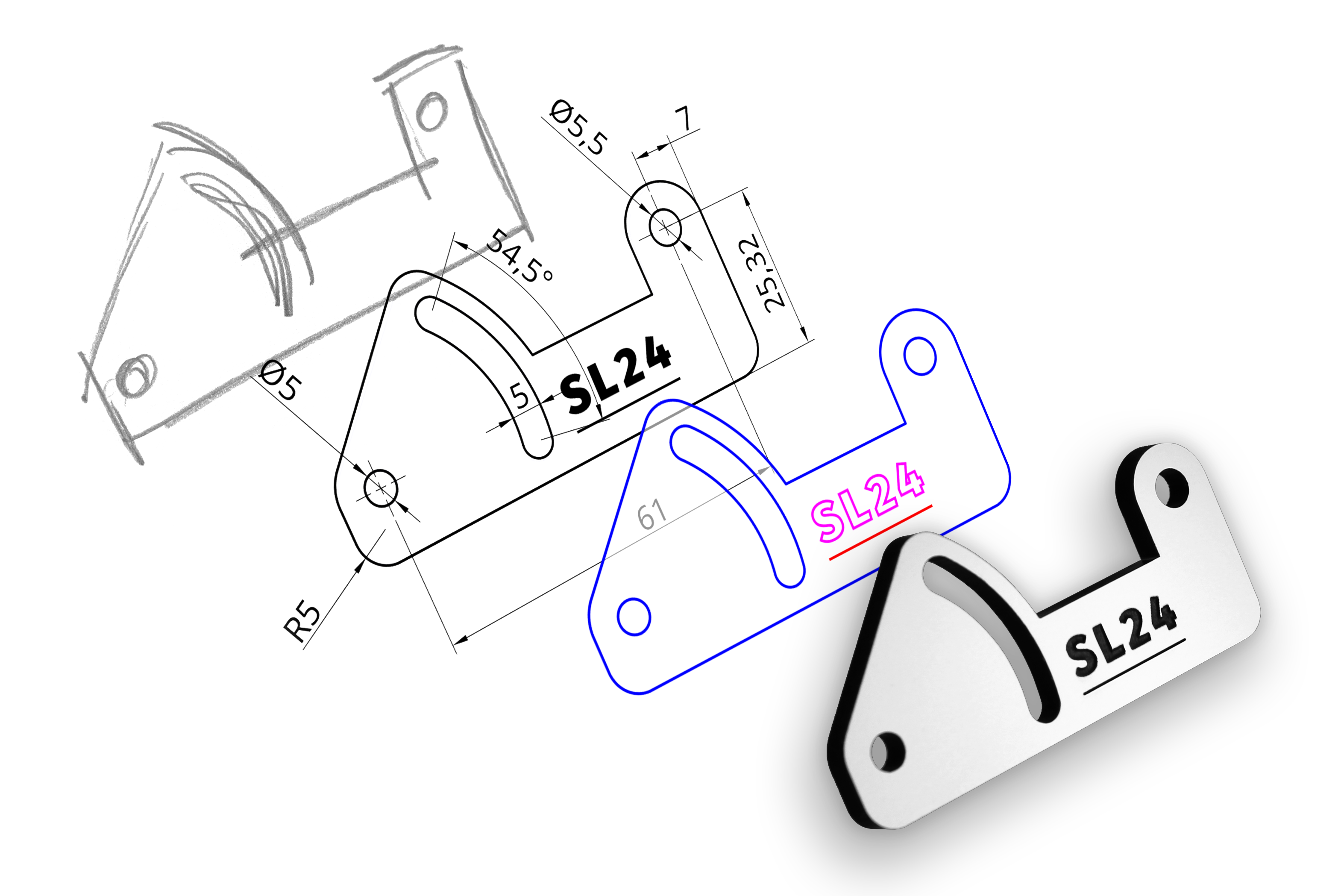

Layout drawing

- DXF, DWG, AI, PDF files

- Blue line = cutting

- Red line = line engraving

- Magenta line = plane engraving

Choose a delivery time

- Speed (ordered before 12:00 noon, delivered tomorrow)

- Fast (2 business days

- Standard (4 business days)

- Expensive (13 business days)

Secure online payment

How do you order laser cutting?

Upload your drawing, choose a material and delivery time and we will make it for you.

Try it now, uploading is free!

What does Mirror acrylic laser cutting cost?

The price for laser cutting your design is automatically calculated in the shopping cart. Upload your drawing, choose a material and delivery time, and see the price instantly.

1 medium design ≈ €24.99*

1 full sheet ≈ €65.43*

1000 small parts ≈ €0.05/pc.*

*These are indicative prices incl. btw to give you an idea. Once you upload a design upload you will see the exact price.

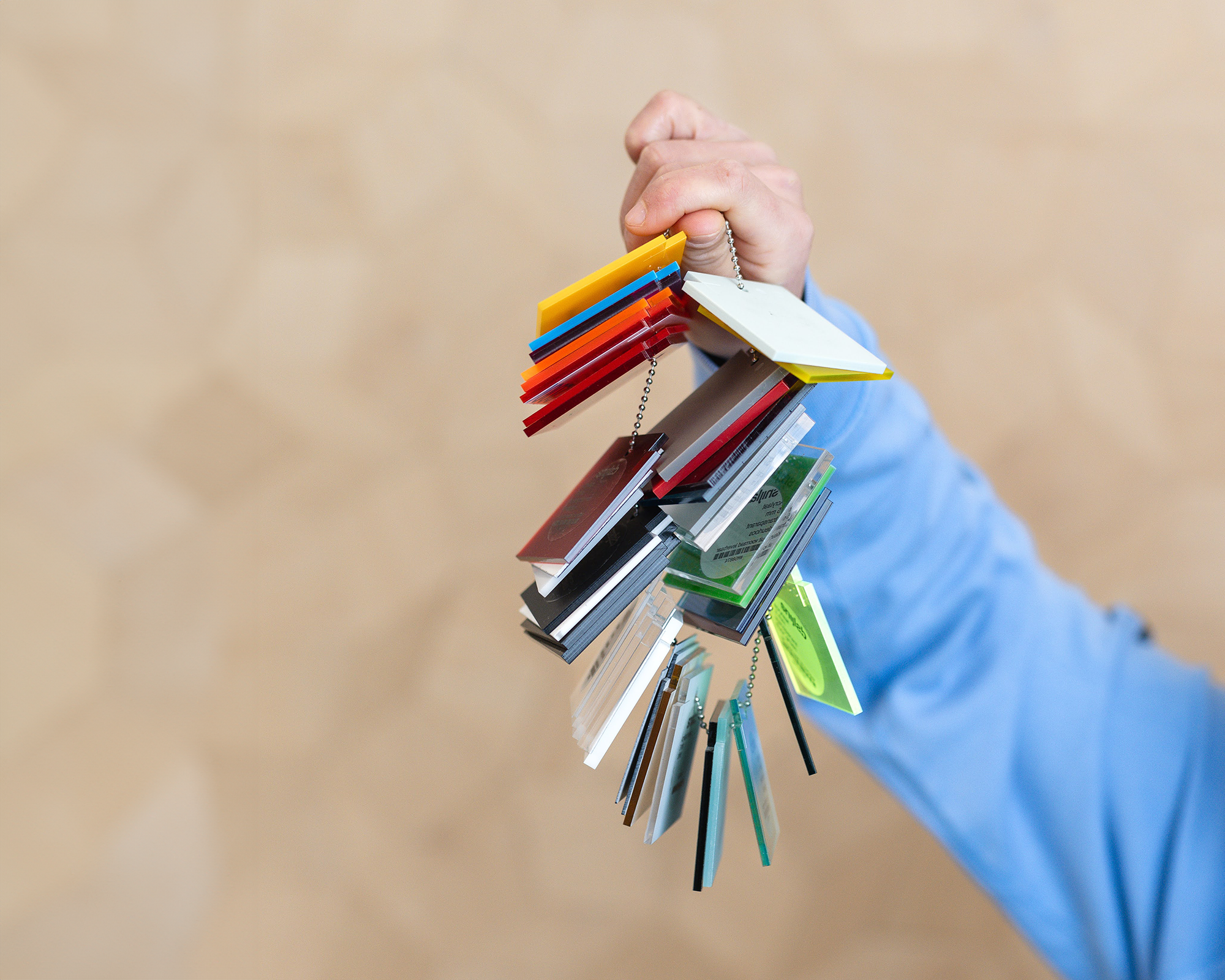

Want to see materials in real life?

Order one material sample chain. Samples provide a representative picture of the quality Snijlab delivers. This also allows you to compare materials so that you can make a good design decision.

To the sample chains