Types Technical plastics that you can have laser cut

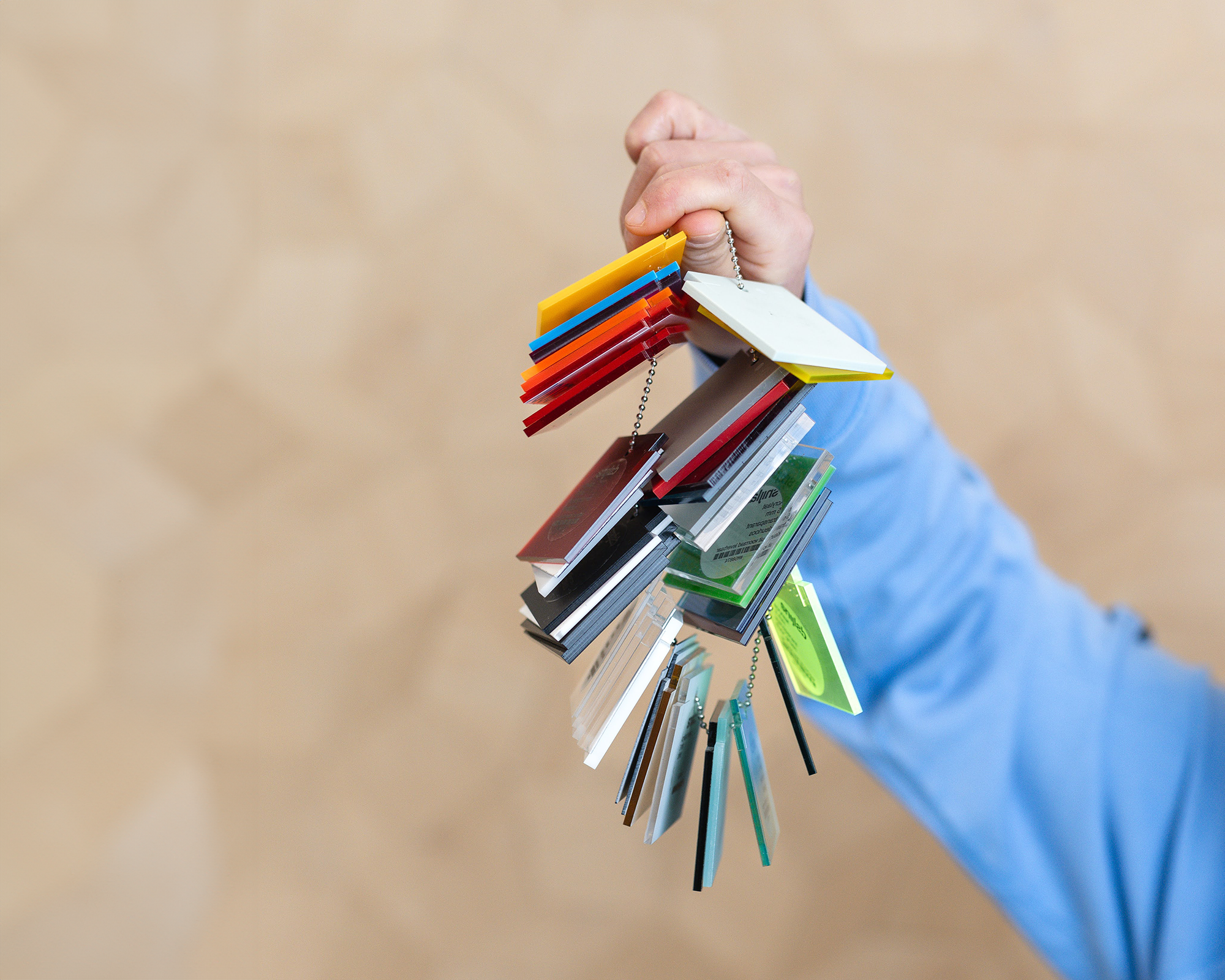

Samples of Technical plastics compare?

Order one material sample chain and compare all types Technical plastics in your own hand. This way you make a well-informed decision about your design.

Samples provide a representative picture of the quality Snijlab delivers.

To the samplesAlle soorten Technical plastics onder elkaar

| Name | Thickness | Color | Max. size |

|---|

Info about Technical plastics

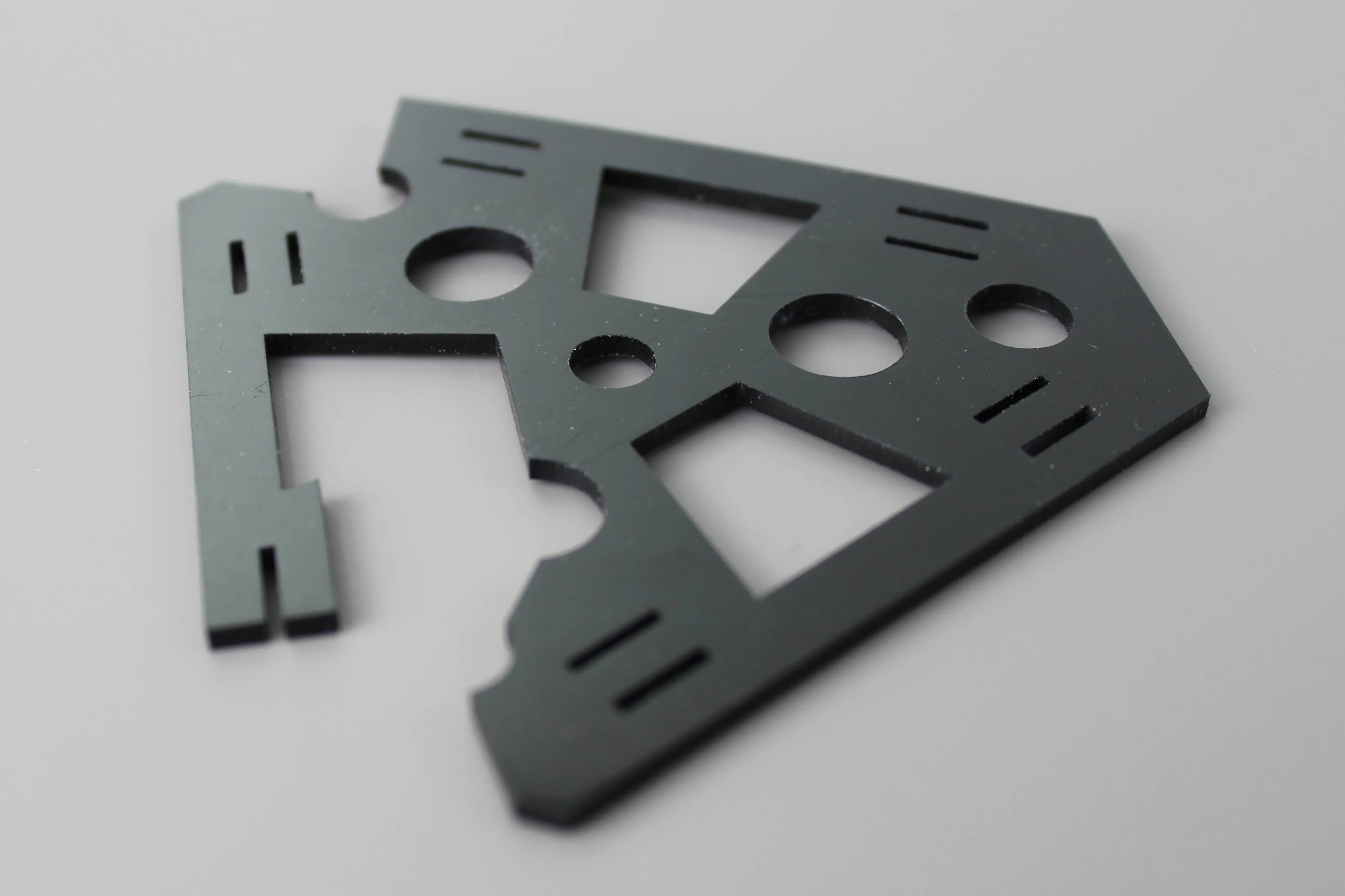

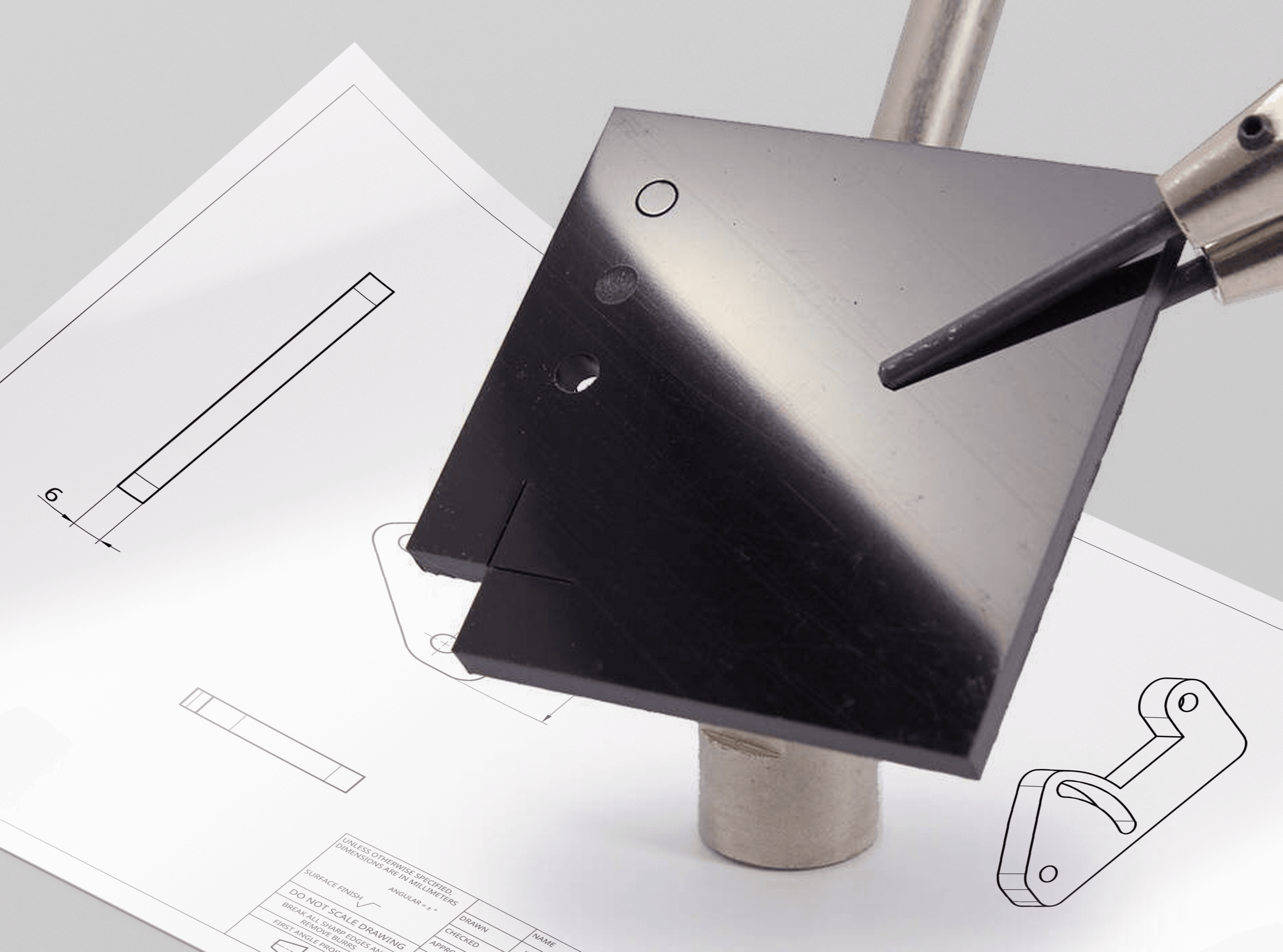

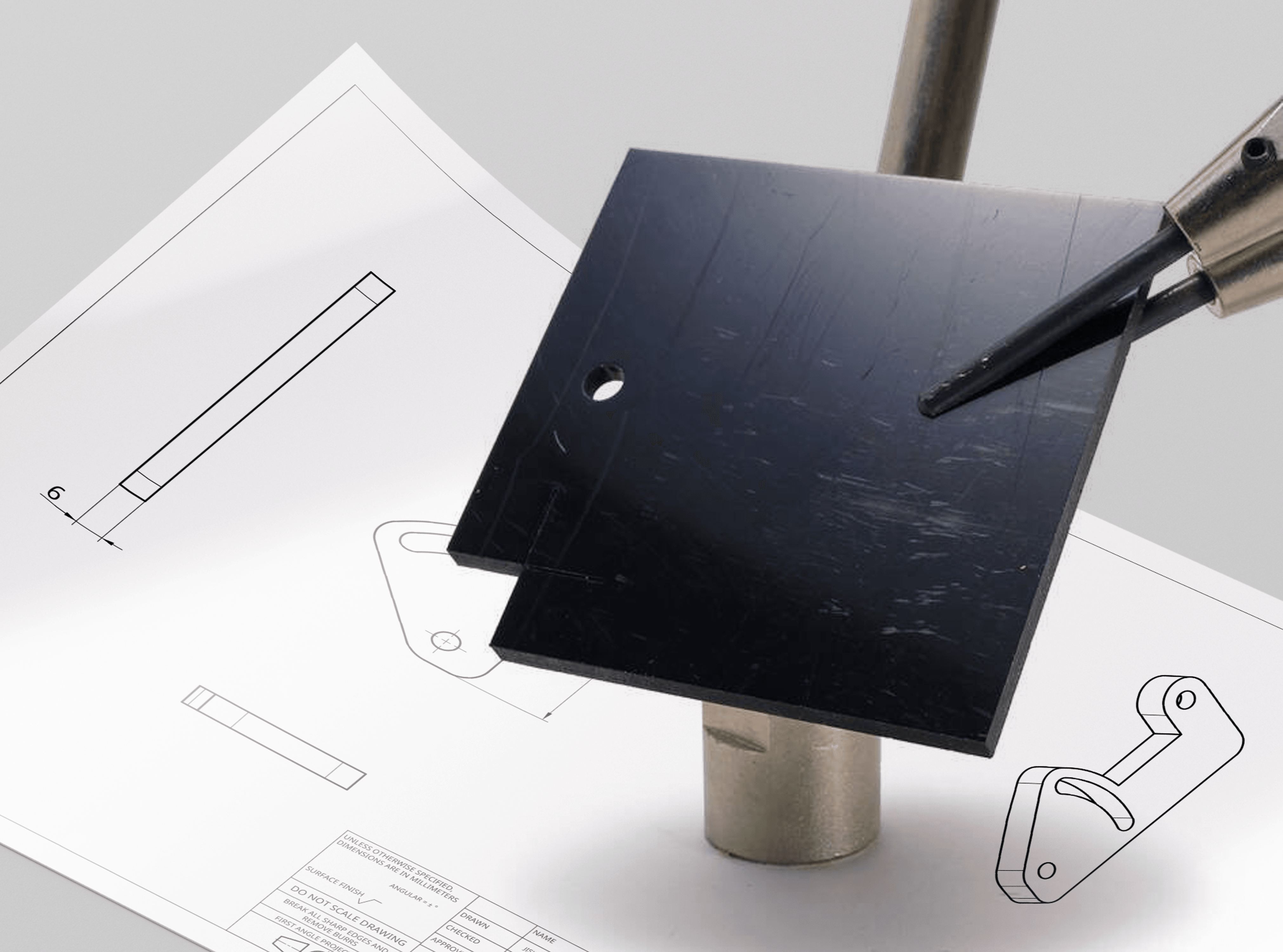

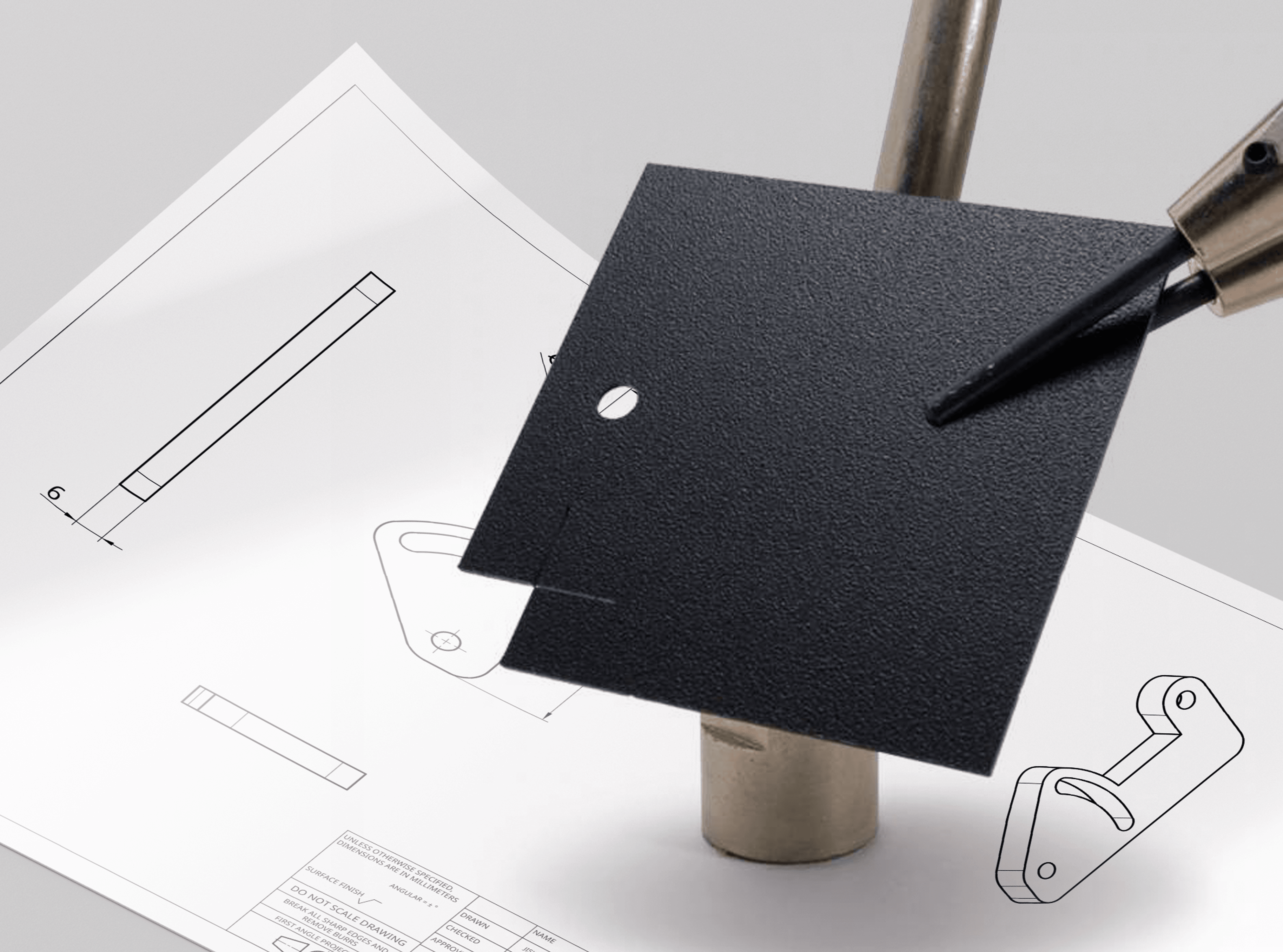

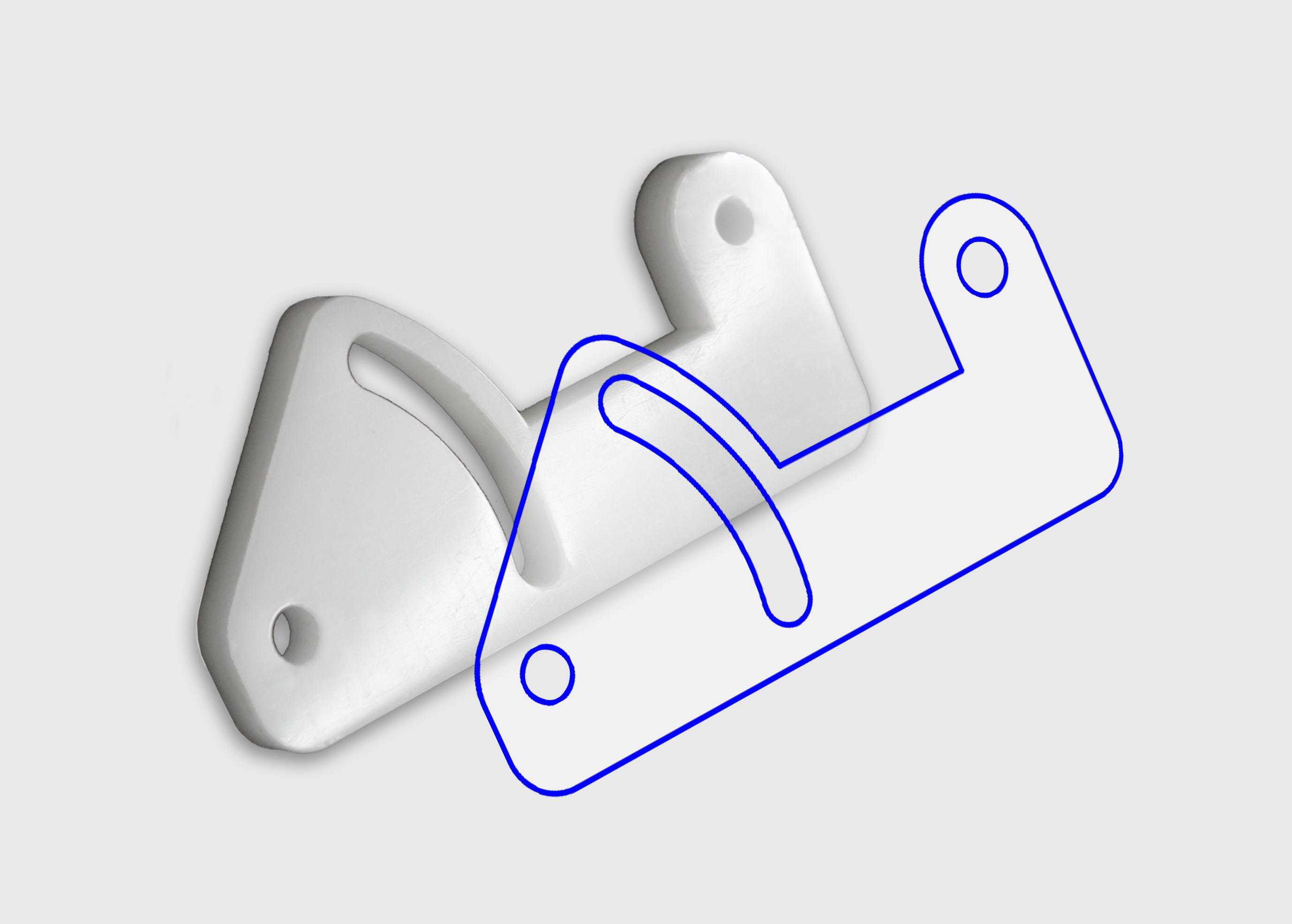

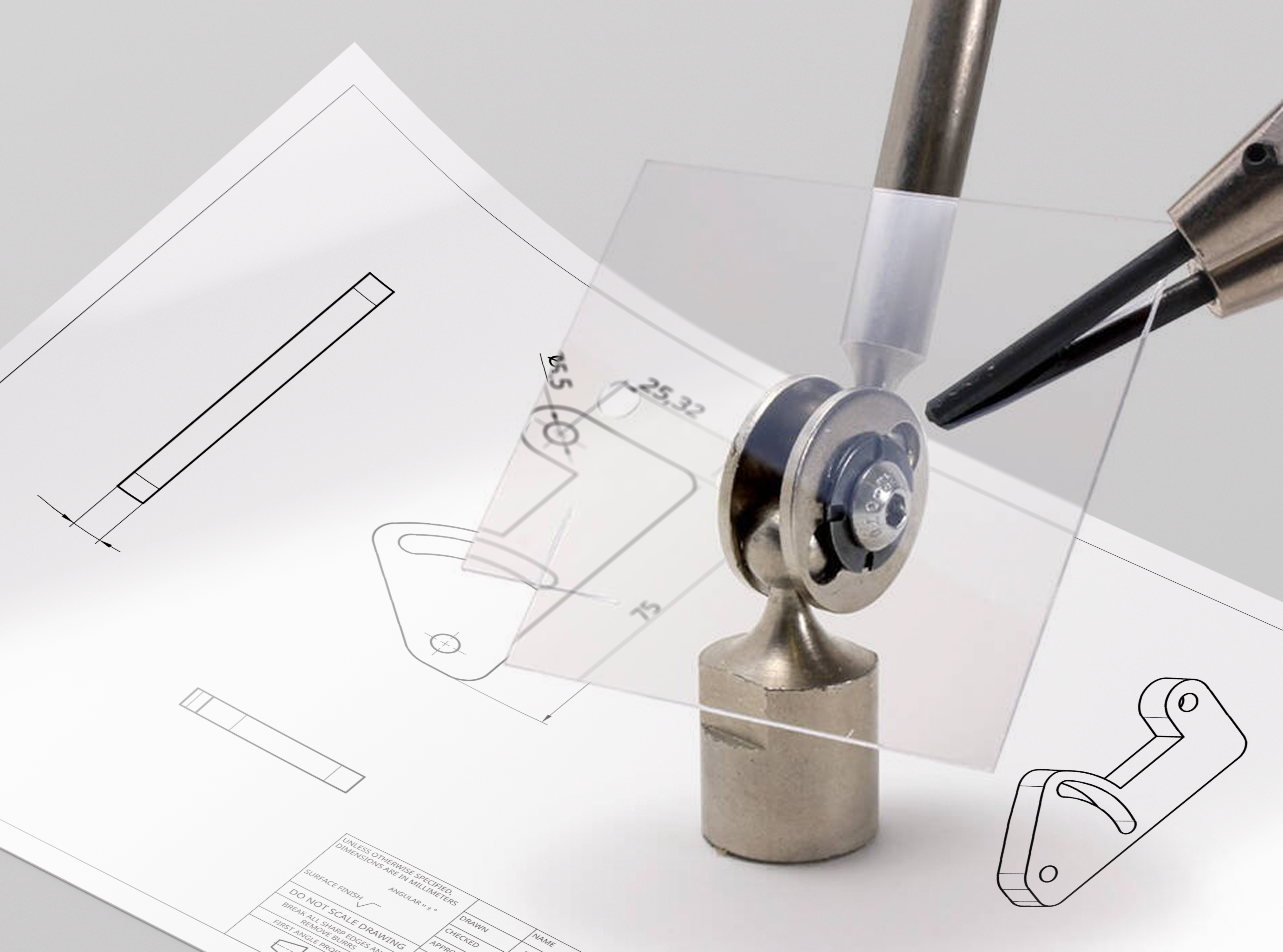

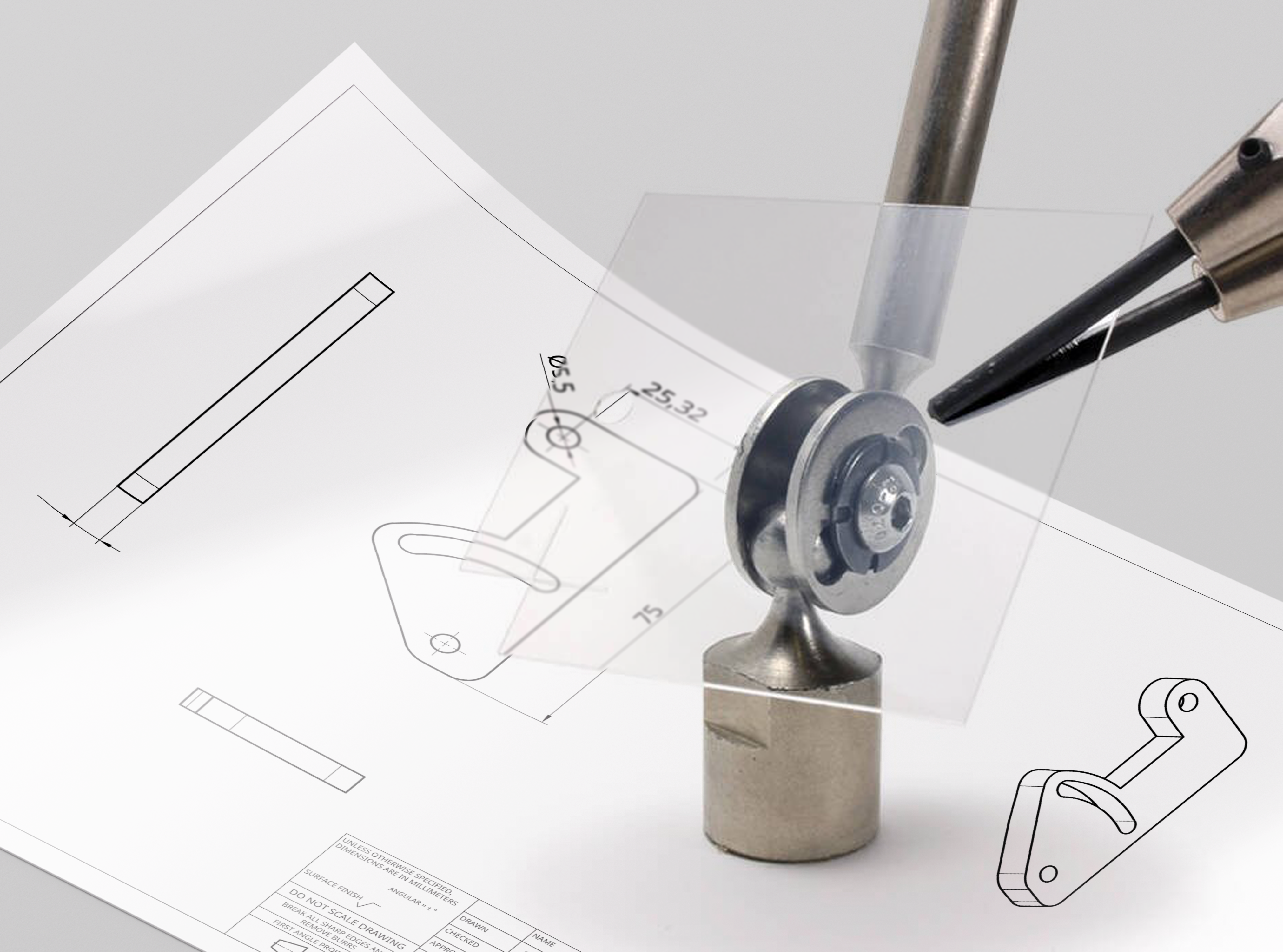

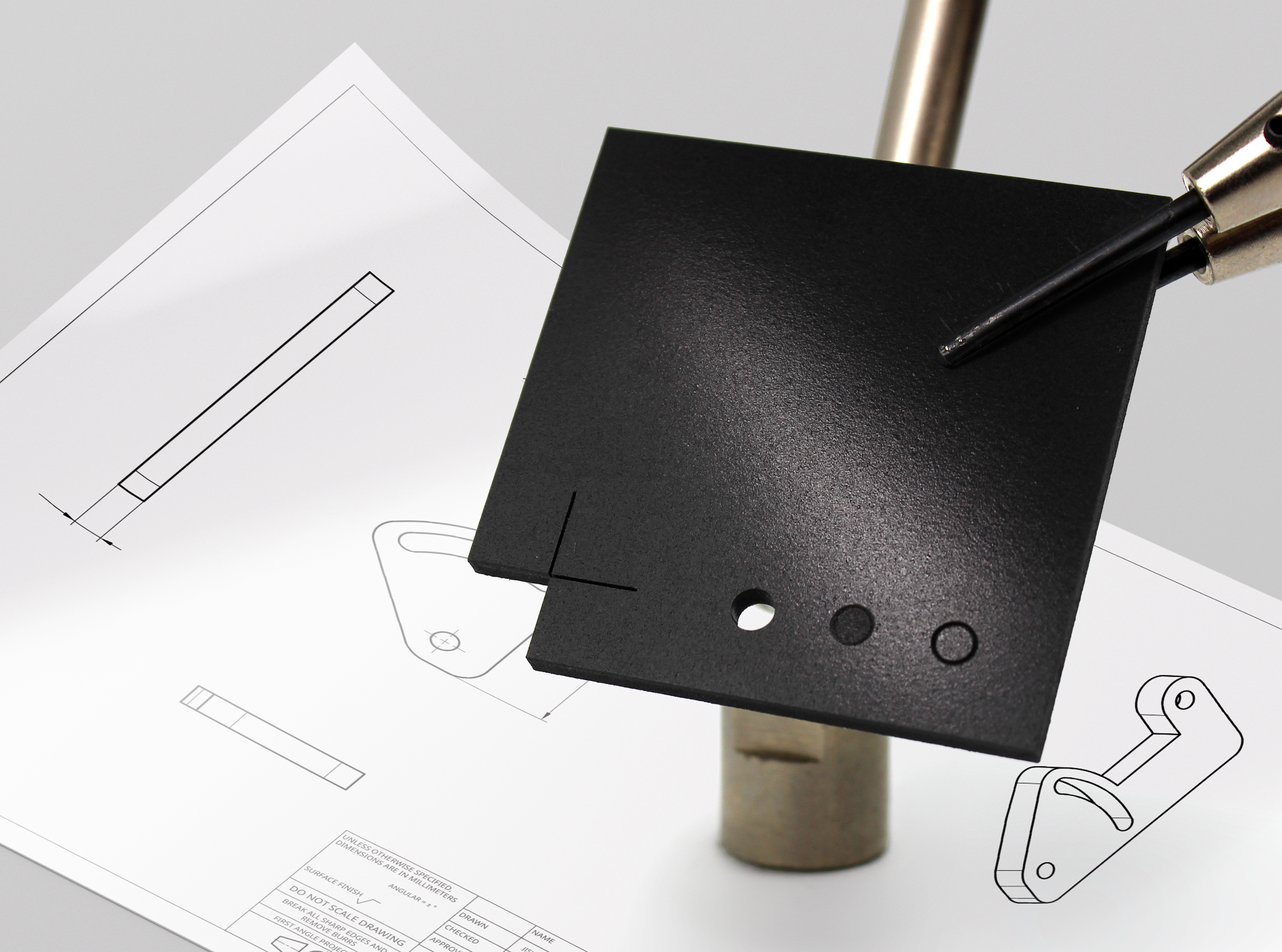

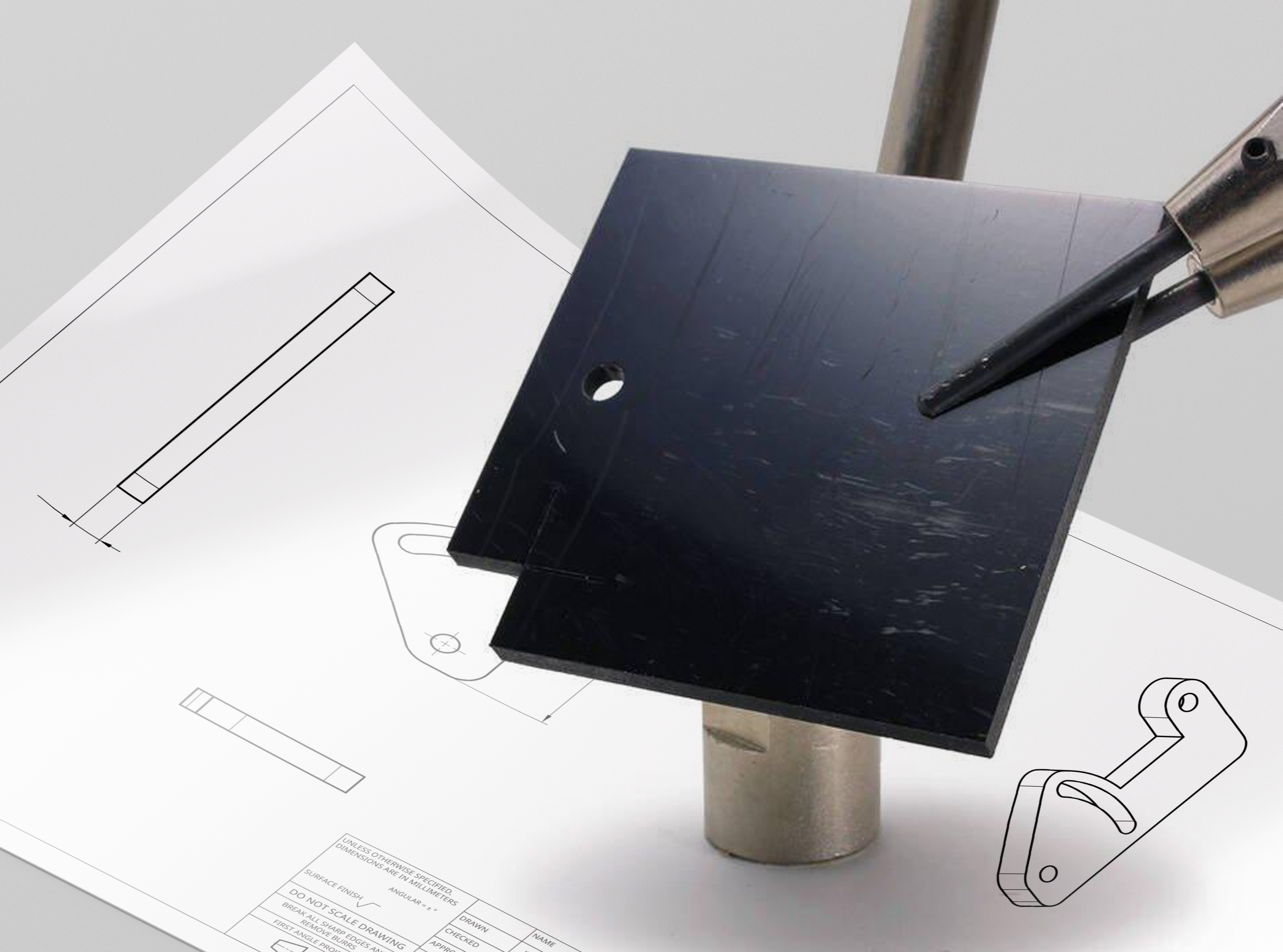

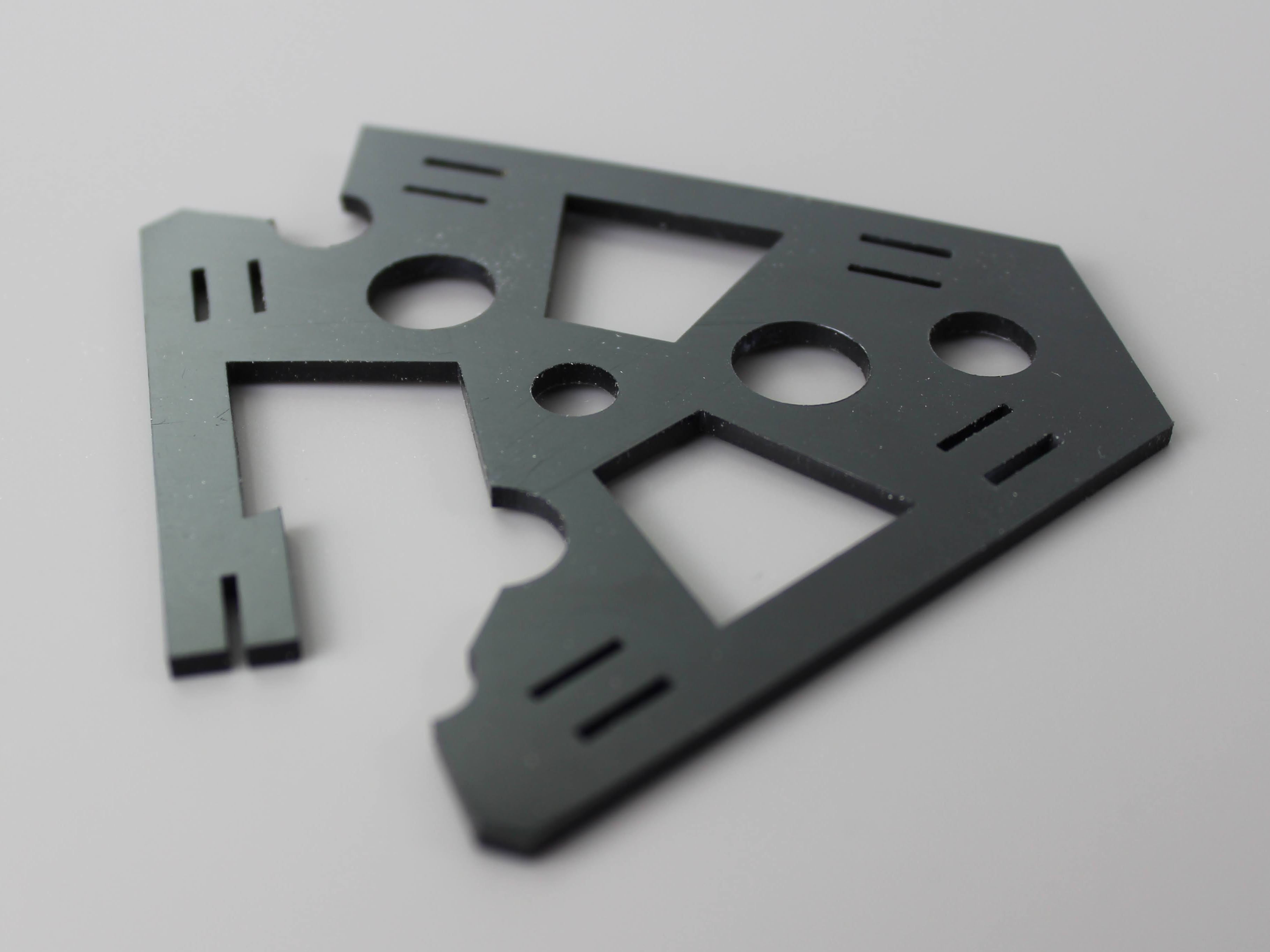

POM (Delrin), HDPE, HMPE, PET, PS, Nylon (PA6), ABS, etc. Plastic weak? Certainly not. Laser cutting is ideal for making high end plastic parts. It is precise, fast and repeatable. With our special laser for serial work we make clean parts without laser spots. Immediately ready for assembly.

Engineering plastics are strong, light and easy to machine.

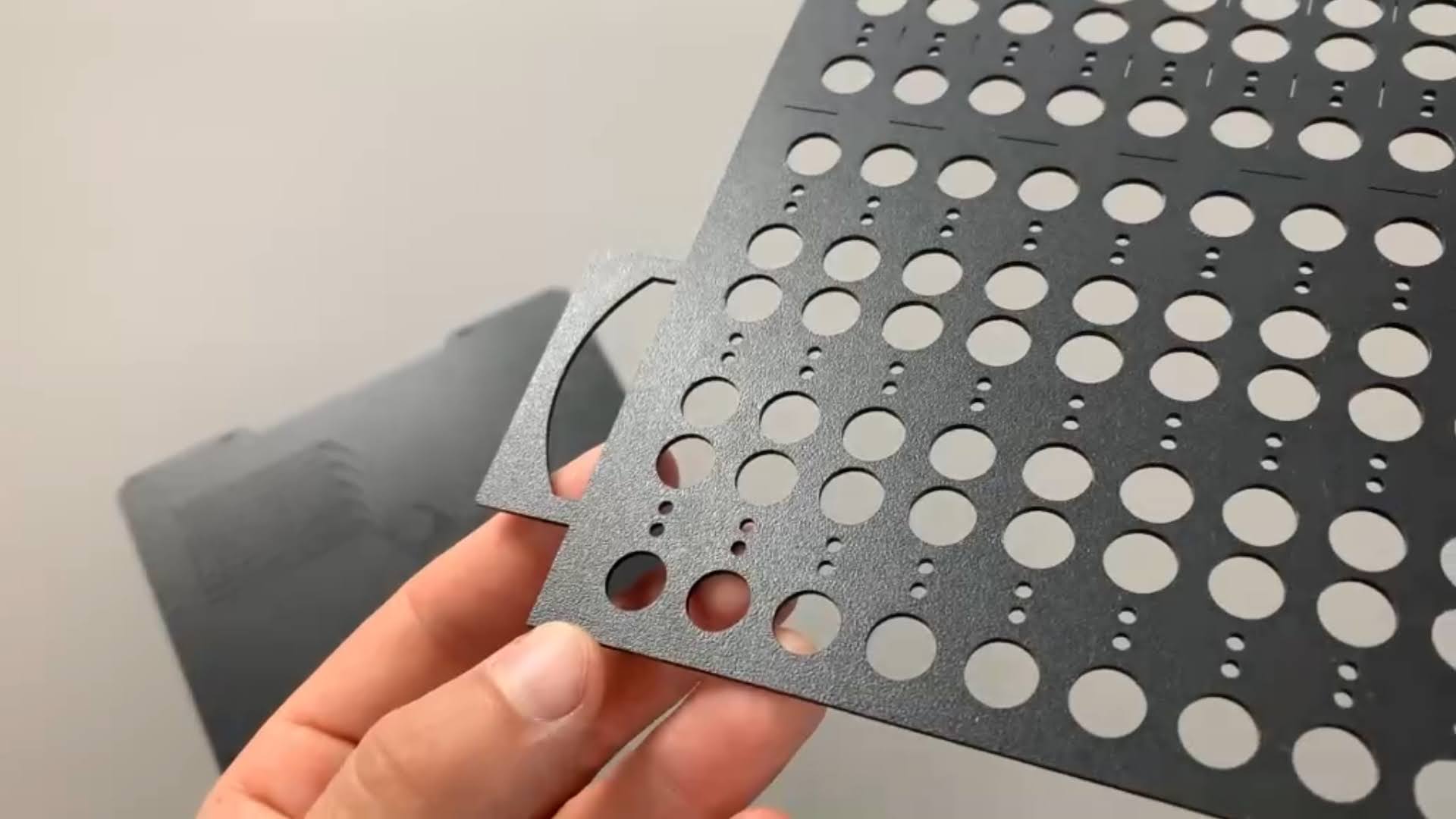

Laser cutting is often used for steel, aluminum and stainless steel, but most engineering plastics are also easy to laser cut. The laser cut is usually about 0.2mm so you can make small details, sharp corners well fitting joints.

POM, or polyacetal, also known by the brand name Delrin, is the most commonly laser-cut plastic. Not surprisingly; it is rigid and extremely tough. With an E-modulus of 3100 N/mm²and hardness of Shore D 81, it is a good choice for mounting plates, structural parts, brackets, mechanisms, etc. POM is chemically resistant and dimensionally stable. It absorbs little moisture.

HDPE excels in toughness. HDPE can stretch as much as 500% before breaking. It is less rigid with an E-modulus of 800 N/mm². The density of HDPE is 950 kg/m³ making it more or less weightless in water. HDPE is quite soft.

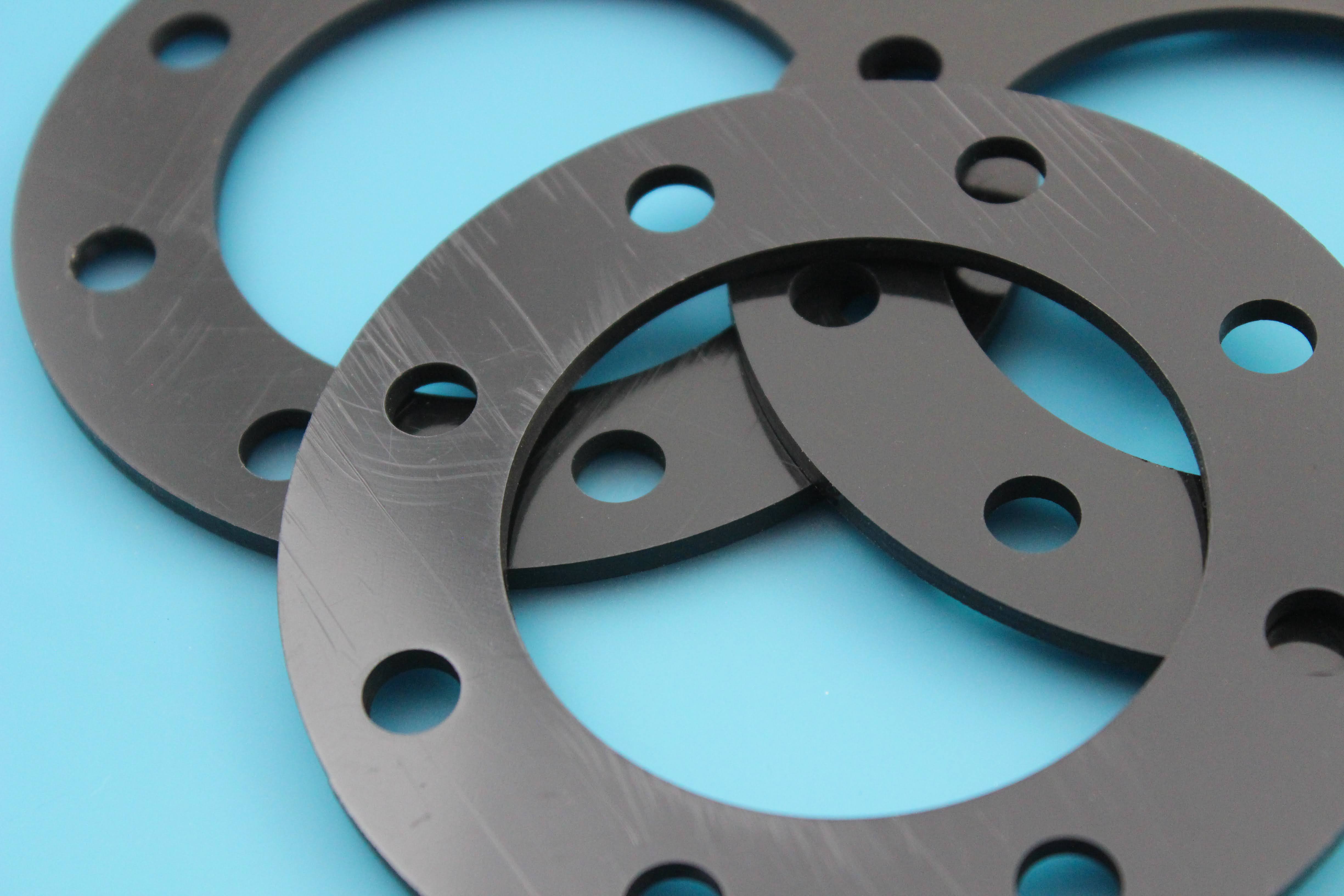

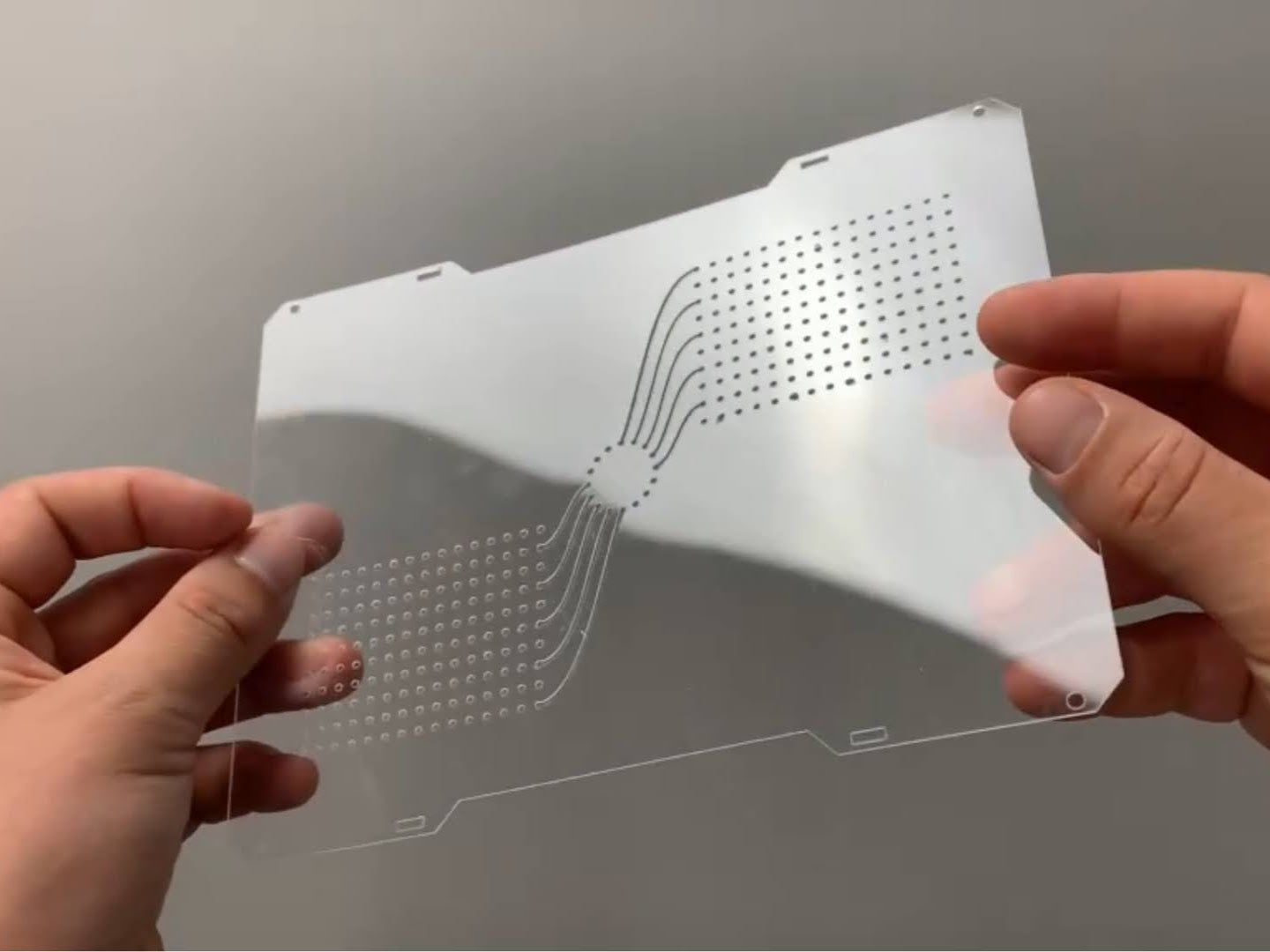

Polypropylene film is widely used for technical applications such as interlayers, insulators and other applications that require films. The surface is textured on one side which makes it scratch resistant and always looks neat.

PETG is transparent and flexible. It is used, for example, as visor in PPE or protective covers in machinery.

Do you make seals? then also check out laser cutting rubbers and laser cutting gasket paper.

At Snijlab you can upload your CAD drawing 24/7 on account.snijlab.co.uk. You will receive an instant quote and can then order online.. You choose your own delivery time, from 1 business day for shipping and same day for pick up in Rotterdam.

Questions? customer service.