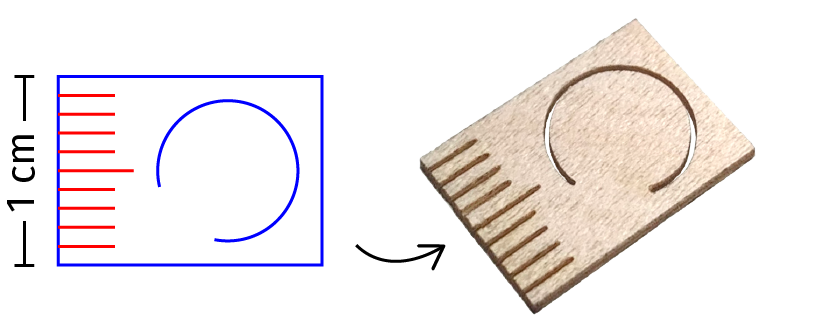

Laser cutting as a production technique requires reliable quality. To test this quality, we maintain the following standards.

Dimensional tolerances

We deliver our laser cutting work, unless otherwise specified, in accordance with ISO9013-1. This international standard specifies the limit tolerances to which the nominal dimensions of products with a thermal cutting operation (such as laser cutting) must comply.

Dimensional tolerances

We deliver our laser cutting work, unless otherwise specified, in accordance with ISO9013-1. This international standard specifies the limit tolerances to which the nominal dimensions of products with a thermal cutting operation (such as laser cutting) must comply.

Linear dimensions (ISO 9013-1).

The international standard ISO9013-1 prescribes the boundary tolerances to which nominal dimensions of products with thermal cutting operations, such as laser cutting, must comply.

In the table below, the nominal dimensions of laser cutting are plotted against the sheet thickness. Al values in the table are expressed in millimeters (mm).

|

Nom. size Sheet thickness |

up to 3 | > 3 to 10 | > 10 to 35 | > 35 to 125 | > 125 to 315 | > 315 to 1000 | > 1000 to 2000 | > 2000 |

| 0 to 1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,2 | ± 0,3 | ± 0,3 | ± 0,3 |

| > 1 to 3 | ± 0,1 | ± 0,2 | ± 0,2 | ± 0,3 | ± 0,3 | ± 0,4 | ± 0,4 | ± 0,4 |

| > 3 to 6 | ± 0,3 | ± 0,3 | ± 0,4 | ± 0,4 | ± 0,5 | ± 0,5 | ± 0,5 | ± 0,6 |

| > 6 to 10 | ± 0,5 | ± 0,6 | ± 0,6 | ± 0,7 | ± 0,7 | ± 0,7 | ± 0,8 | |

| > 10 to 50 | ± 0,6 | ± 0,6 | ± 0,7 | ± 0,8 | ± 1 | ± 1,6 | ± 2,5 |

Clean cutting

Laser cutting causes soot deposits, depending on material and drawing. This can be sanded down in many cases.

Deposits can be prevented in two ways. By foil and by innovative cutting technology.

- Protective film ensures that the deposit does not remain on the material. A good option for smaller runs.

- AutoSPOT is our innovative laser cutter that cuts without a stop, by cutting without a lower bed. Parts come out clean here.

Removing protective film on large quantities of small parts can be very labor intensive, which is why we recommend cutting on the autoSPOT for these orders.

Material quality

The range of materials has been carefully selected over the past 10 over the years. All materials are suitable for laser cutting, and tested to give good results.

Birch plywood is made especially for us. Here we use a glue that gives off less soot during laser cutting than regular glue.

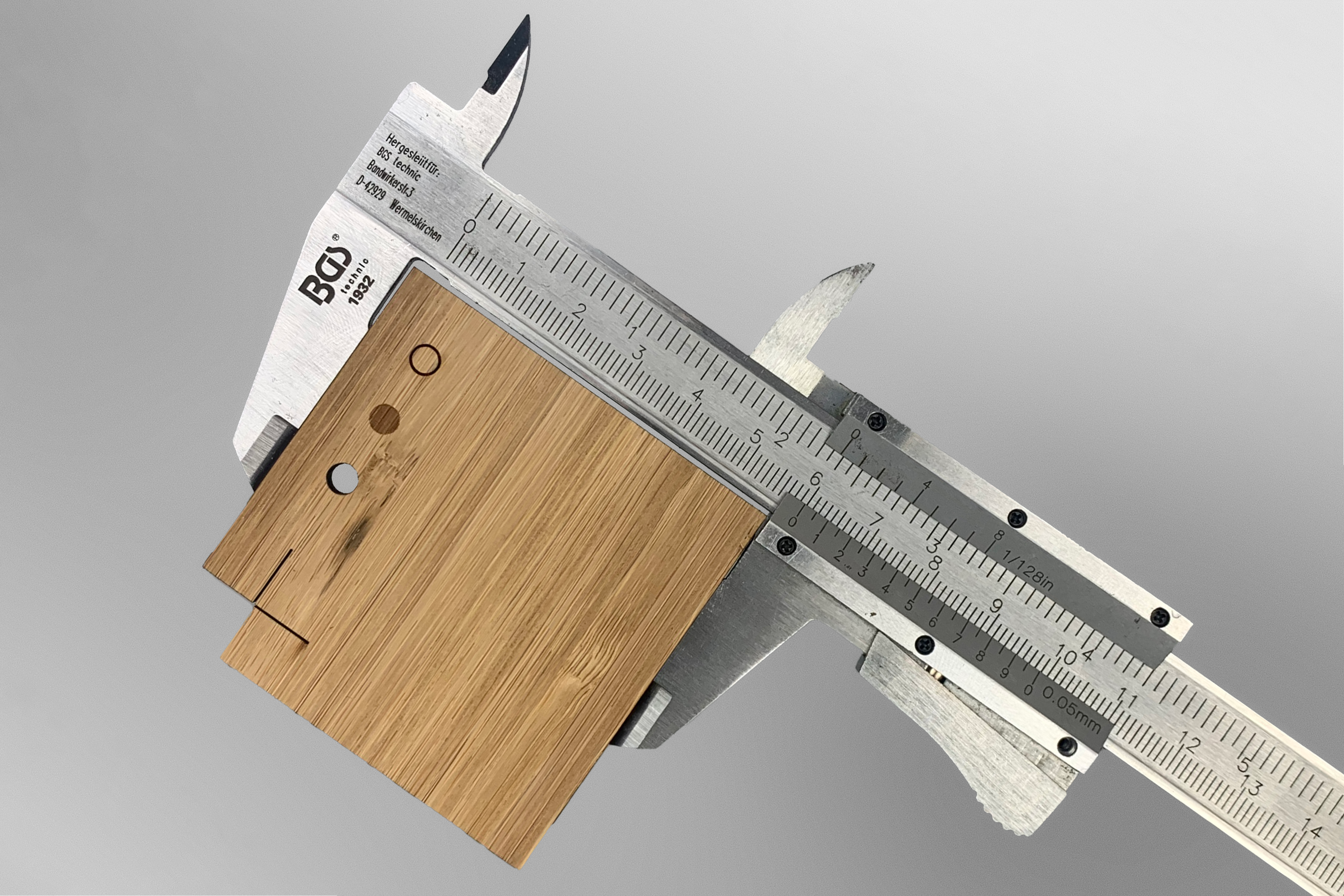

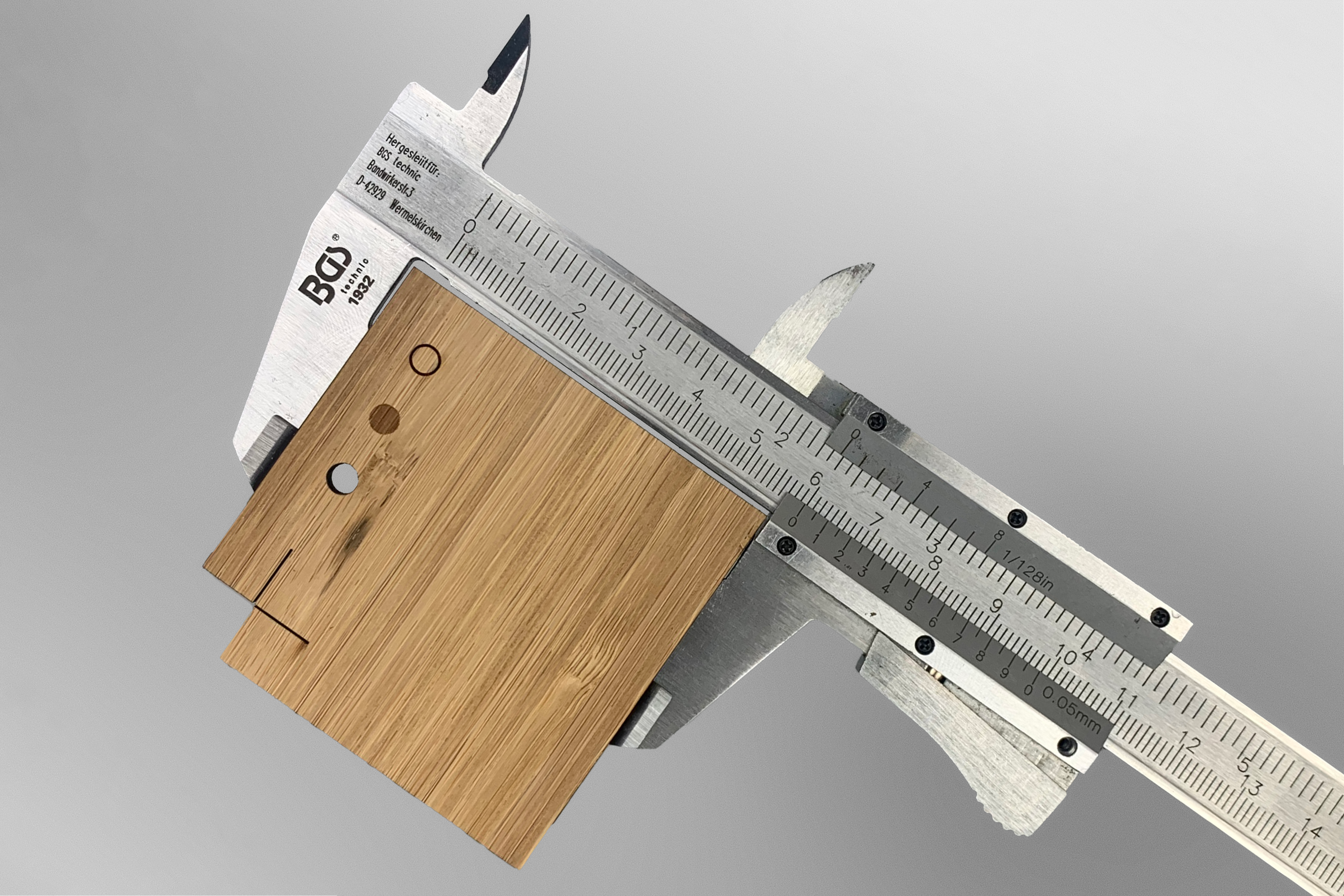

Thickness tolerance of the material

The sheet materials in the range have a stated thickness, of which they can deviate within a certain margin. We call this the thickness tolerance. For each material, the thickness tolerance is indicated in the specification table.

Cast acrylates have the highest thickness tolerance, and can therefore deviate the most from the indicated material thickness. Is precision important? Then extruded- and precision acrylic good options.

Thickness tolerance of the material

The sheet materials in the range have a stated thickness, of which they can deviate within a certain margin. We call this the thickness tolerance. For each material, the thickness tolerance is indicated in the specification table.

Cast acrylates have the highest thickness tolerance, and can therefore deviate the most from the indicated material thickness. Is precision important? Then extruded- and precision acrylic good options.