Types foam that you can have laser cut

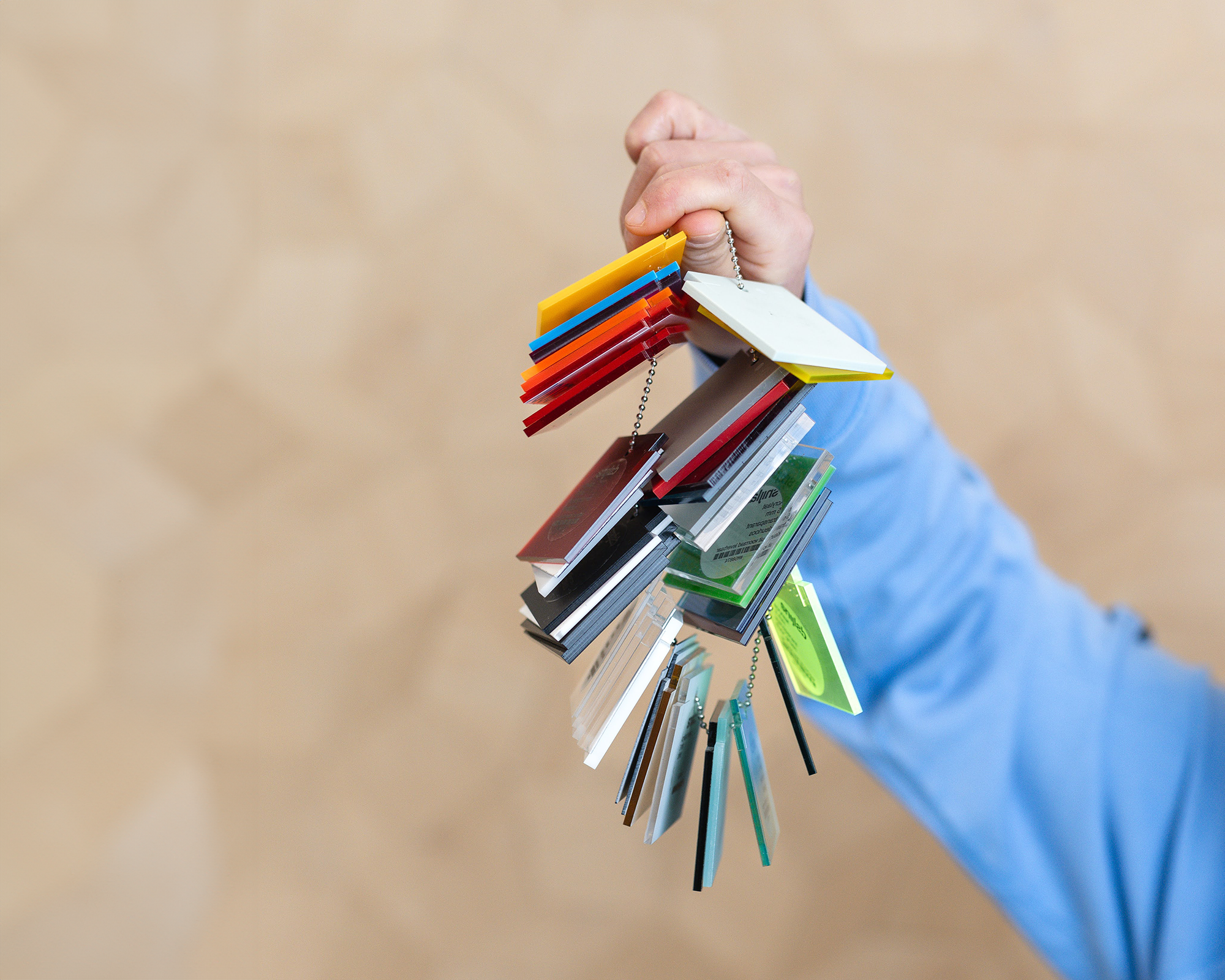

Samples of foam compare?

Order one material sample chain and compare all types foam in your own hand. This way you make a well-informed decision about your design.

Samples provide a representative picture of the quality Snijlab delivers.

To the samplesAlle soorten foam onder elkaar

| Name | Thickness | Color | Max. size |

|---|

Info about foam

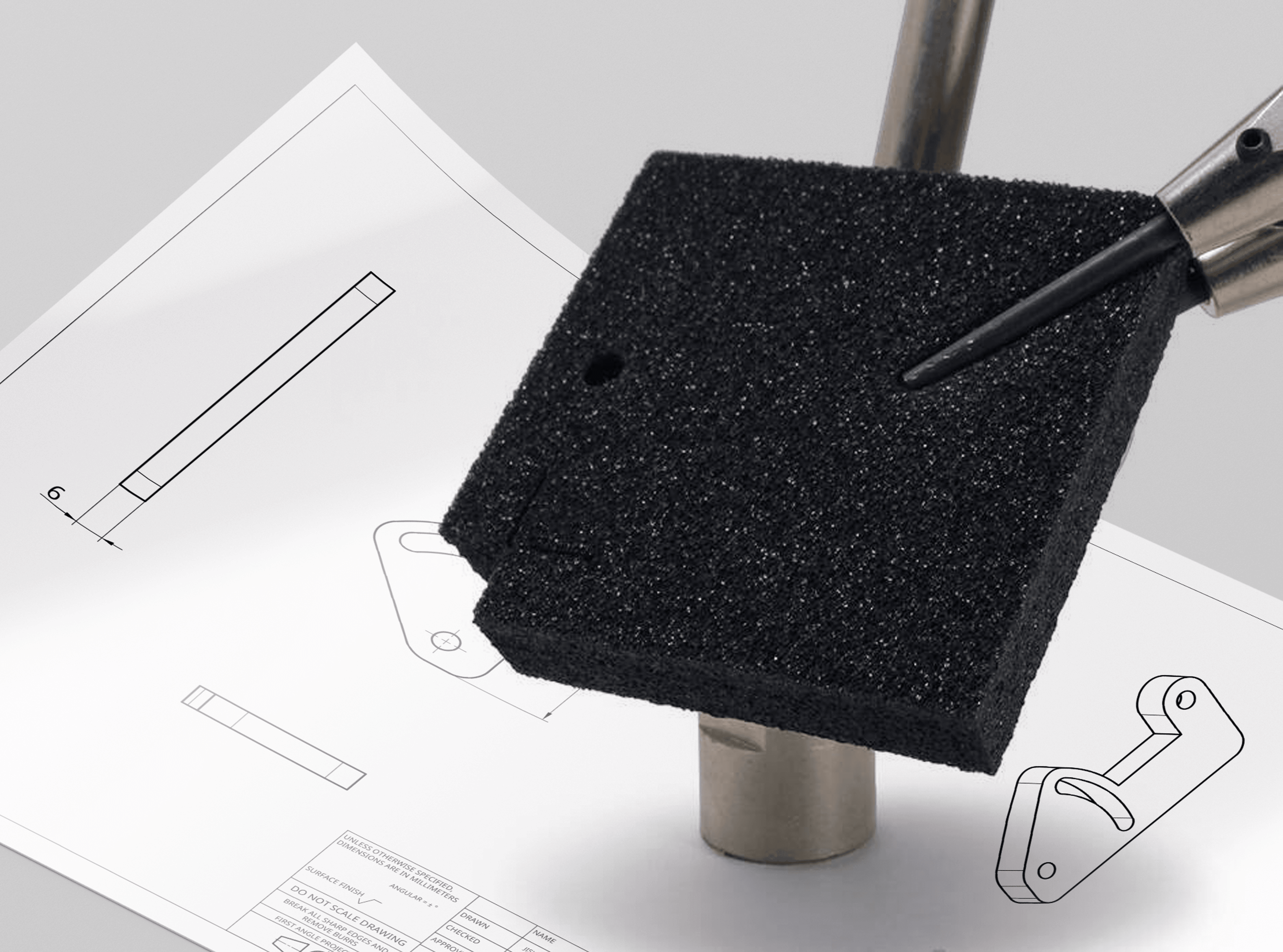

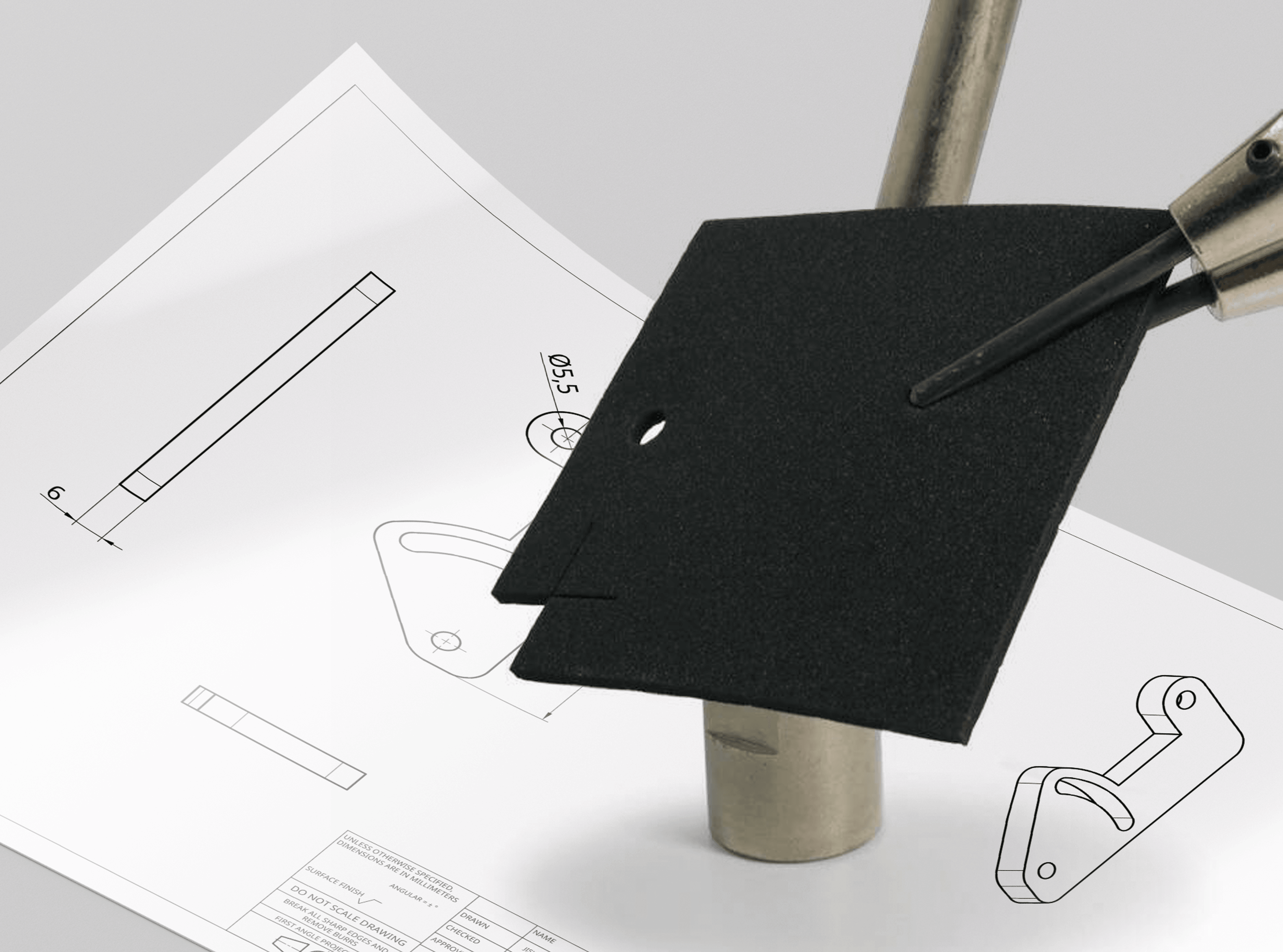

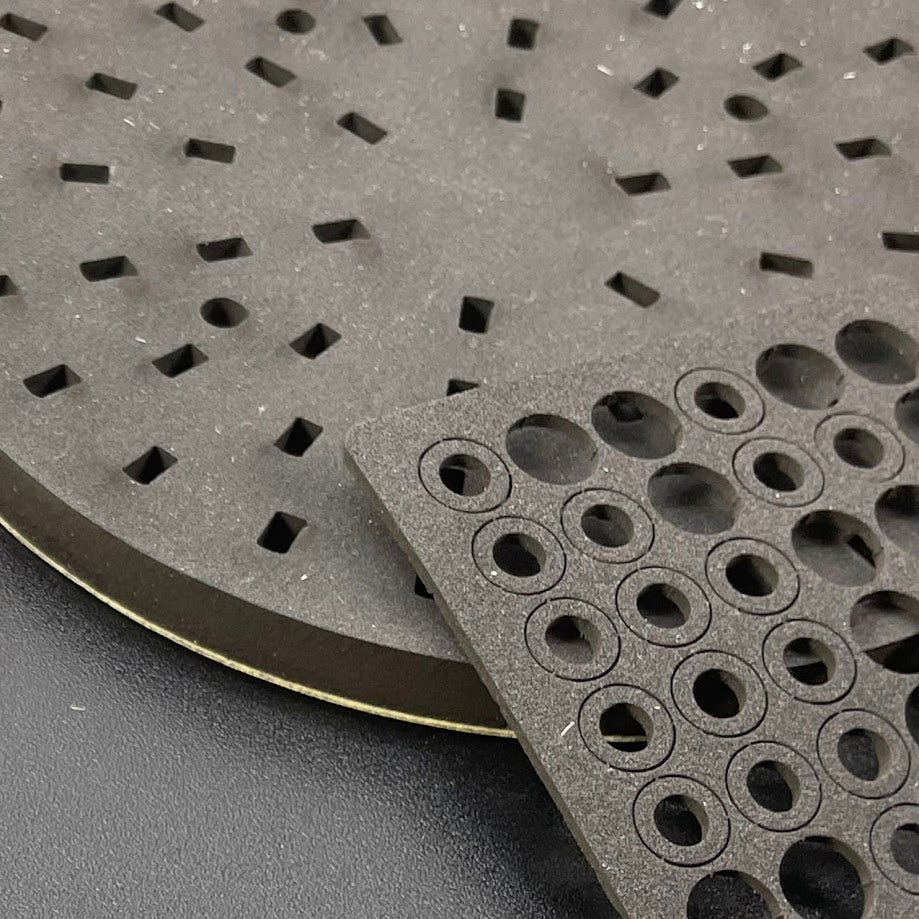

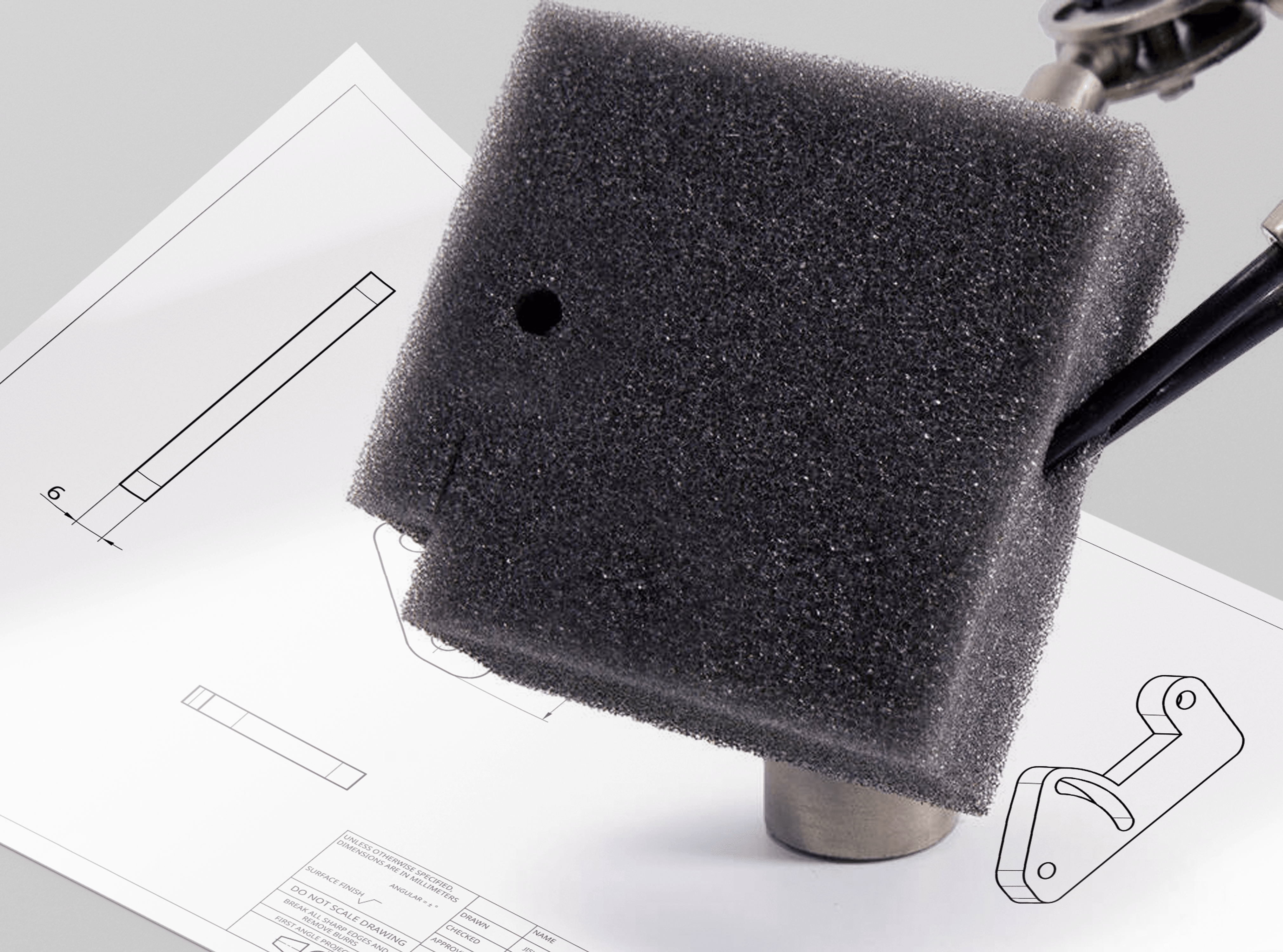

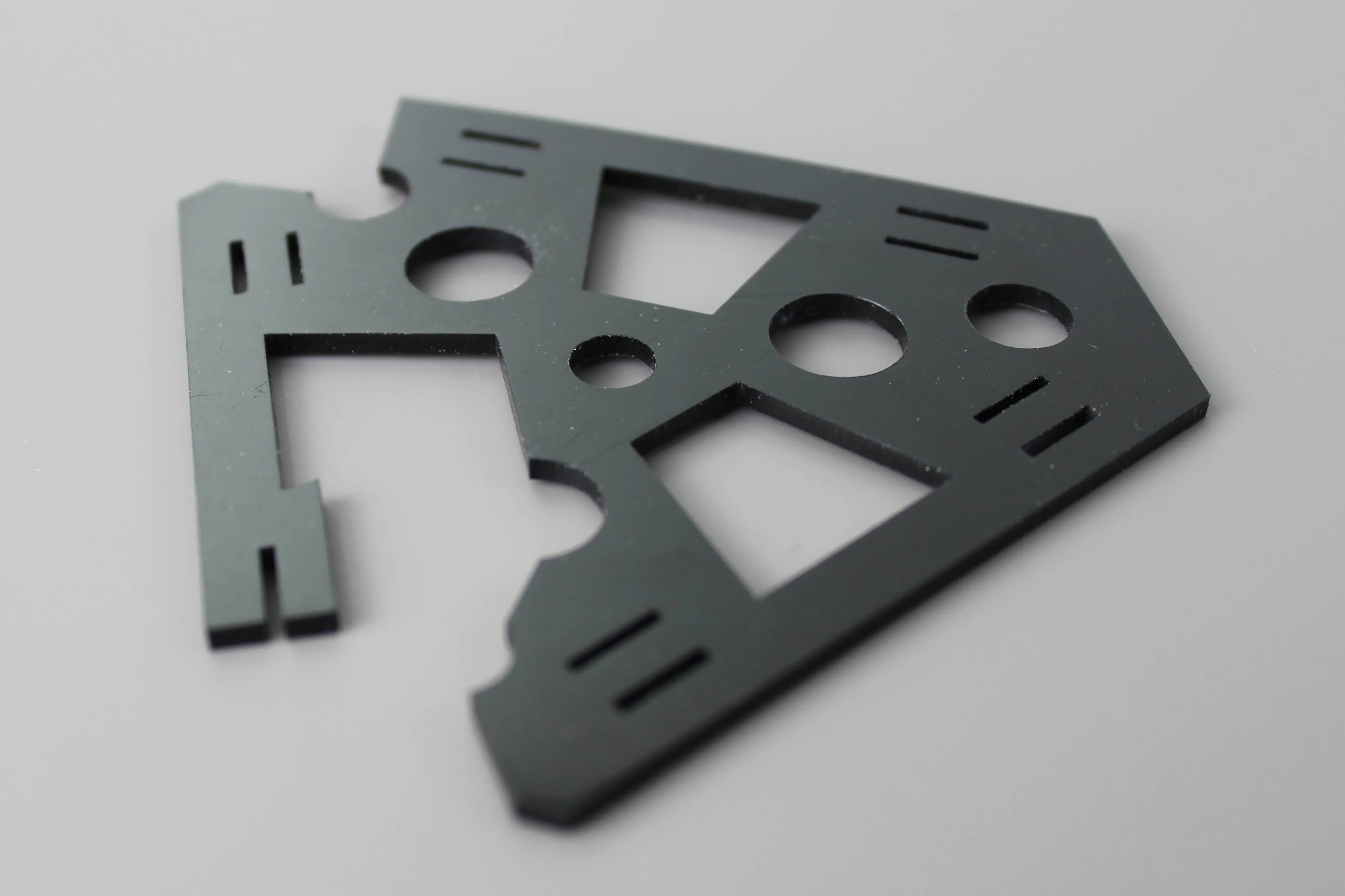

Have foam sheets laser cut into any shape you want. Very simply using your digital drawing as a basis. Small details are no problem and you can even engrave your logo and texts. Make case interiors, tool drawers and flight cases. Made to measure from one piece. Ordered online and delivered quickly.

Foam comes in many varieties

PE rigid foam or polyethylene foam is the most commonly lasered foam. It is a relatively firm foam of 39 kg/m³. It is the same foam you find on the insides of many flight cases. It is particularly neat to laser with tight edges that do not fade. By gluing several layers on top of each other, you can make complex inlays or packaging. Remember to make cutouts for fingers that allow you to easily grab small products. Besides protection, this foam is also suitable for making logos on the wall, for example, because it just looks very nice. You can also laser engrave in this foam. The engraving gets a few millimeters depth but does not discolor. This way you can indicate logos, names and part numbers. We recommend a minimum letter height of 10mm.

Soft foam (polyether foam) is more economical than PE rigid foam but suitable for the same applications. You can use soft foam for lighter products that require less load-bearing capacity. Engravings in soft foam are not as visible.

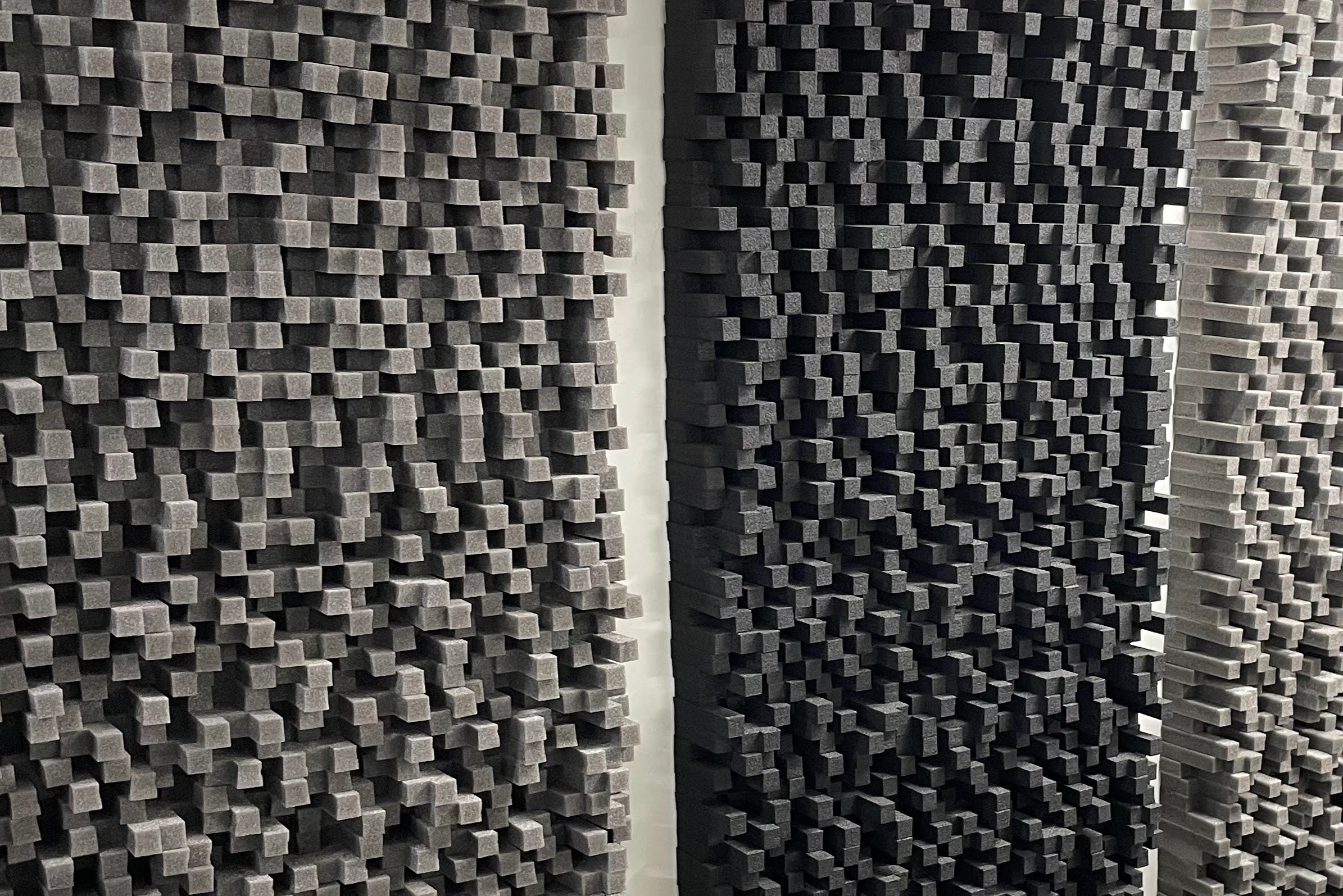

Acoustic foam is specially meant for de-dusting machines and sound attenuation. It is oil resistant. It has a strong adhesive layer so you can easily attach it to anything.

Foam online laser cutting

To laser cut foam, you need a drawing of your design. This can be in DWG, DXF or AI format. Create a free account at account.snijlab.nl and drag your drawing into the browser. You will then immediately see what it costs to have the foam cut and engraved. You can pay online and get the custom foam shipped to your home.

Questions? Our customer service is here to help.