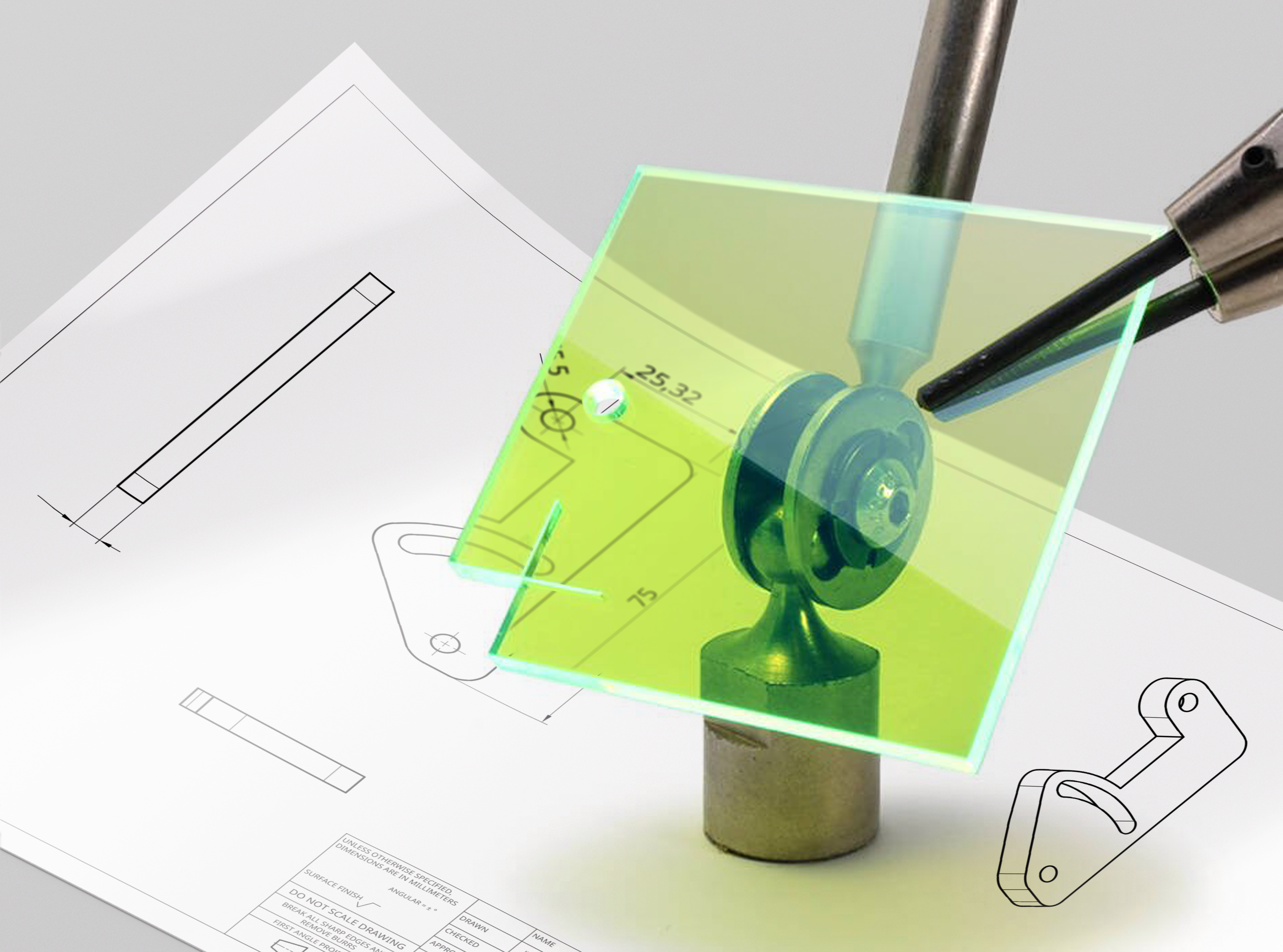

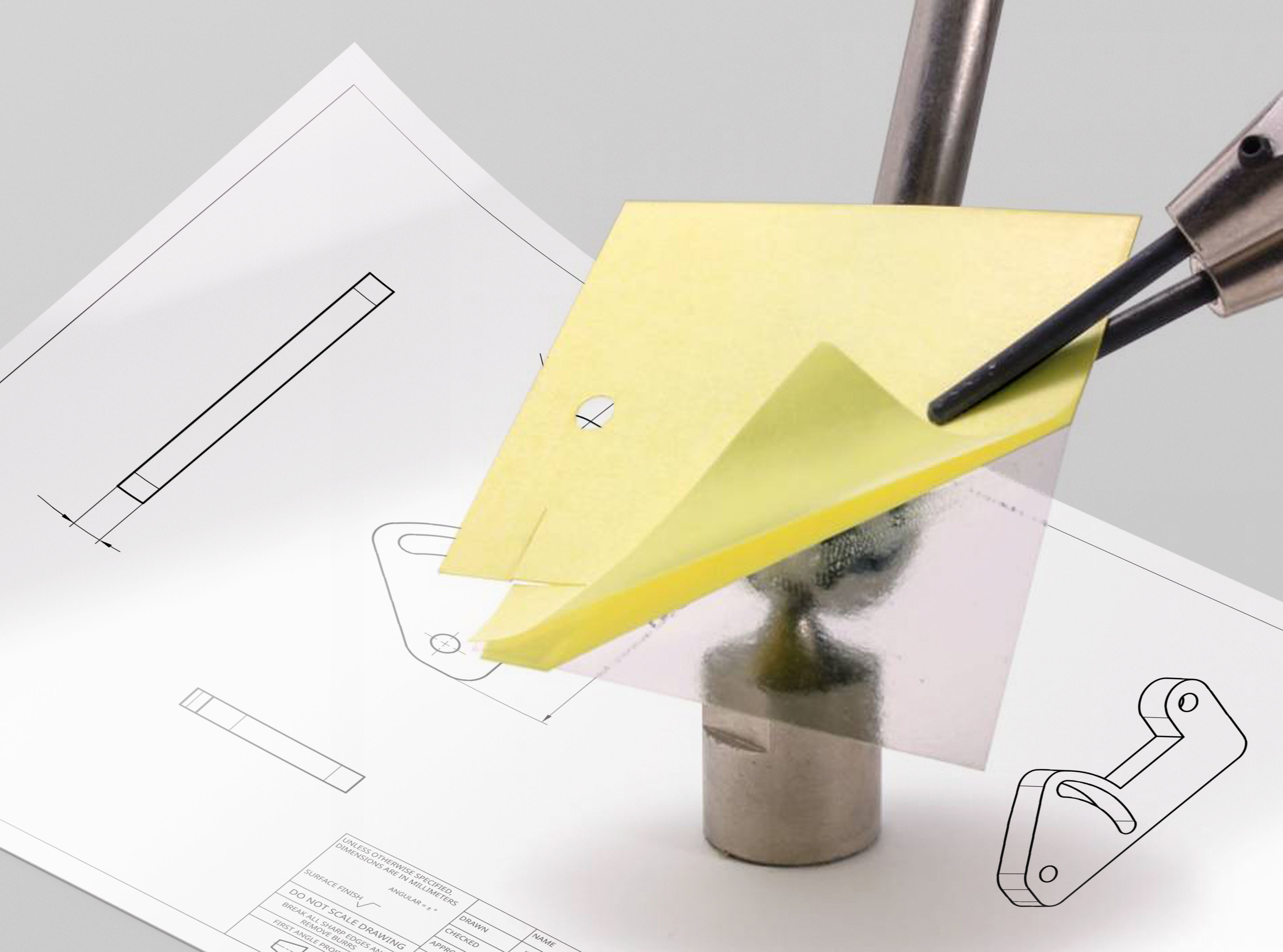

Discover the easiest and most cost-effective way to produce custom parts. With our expertise in laser cutting plastics, you get exactly what you need—when you need it.

Laser cutting is fast, flexible, and scalable.

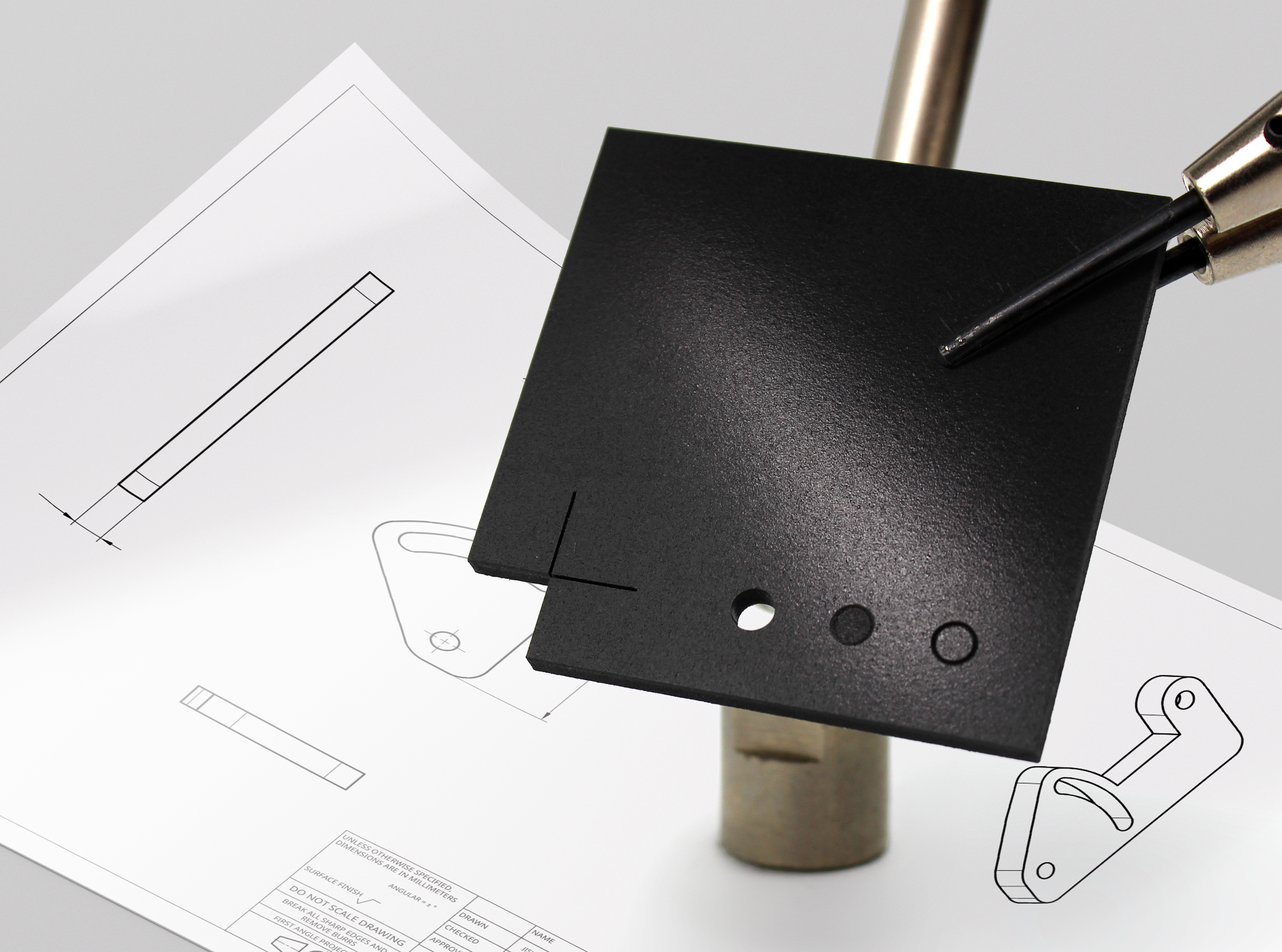

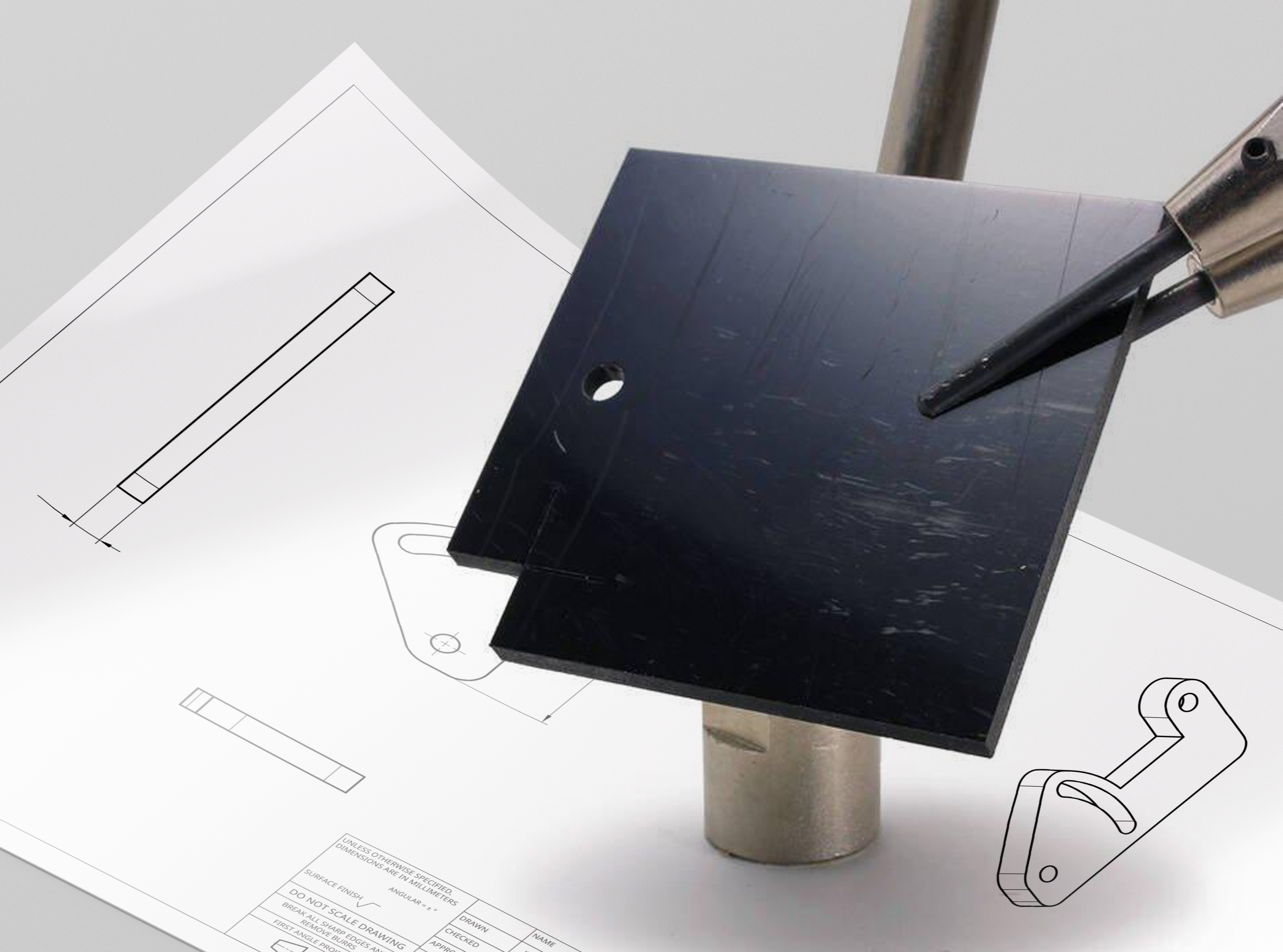

Create your parts quickly, accurately, and affordably

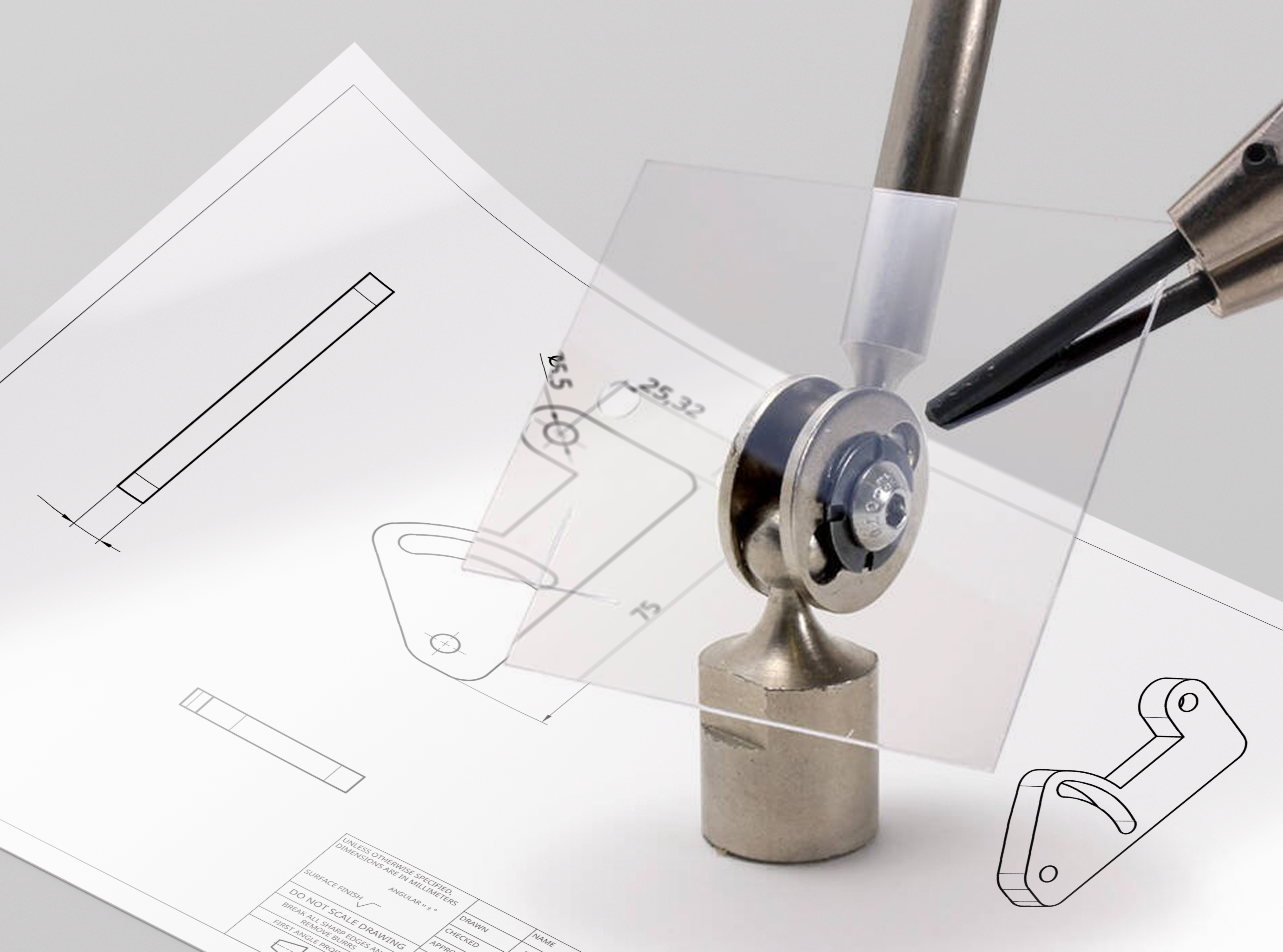

Looking for the easiest and most affordable way to create your parts? Choose laser cutting. This technique offers a level of precision, flexibility, and speed that traditional methods simply can't match. Cut intricate shapes and fine details without large upfront investments.

Surprisingly, laser cutting is cost-effective even at higher volumes. In many cases, it can even compete with injection molding!

The right material for every application

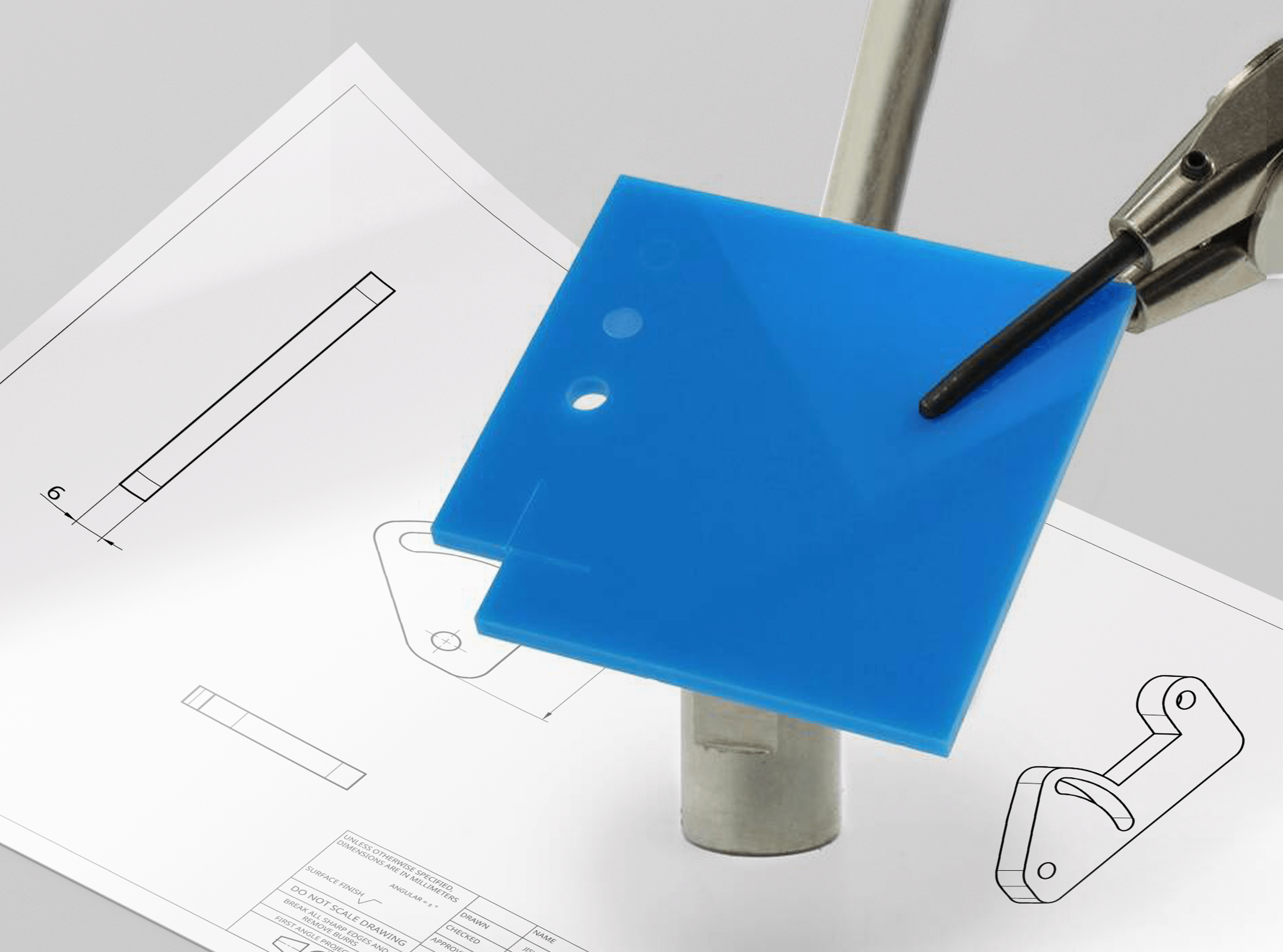

Take advantage of the wide variety of materials available for laser cutting. Choose from:

- Stunning colors and translucent options for decorative use

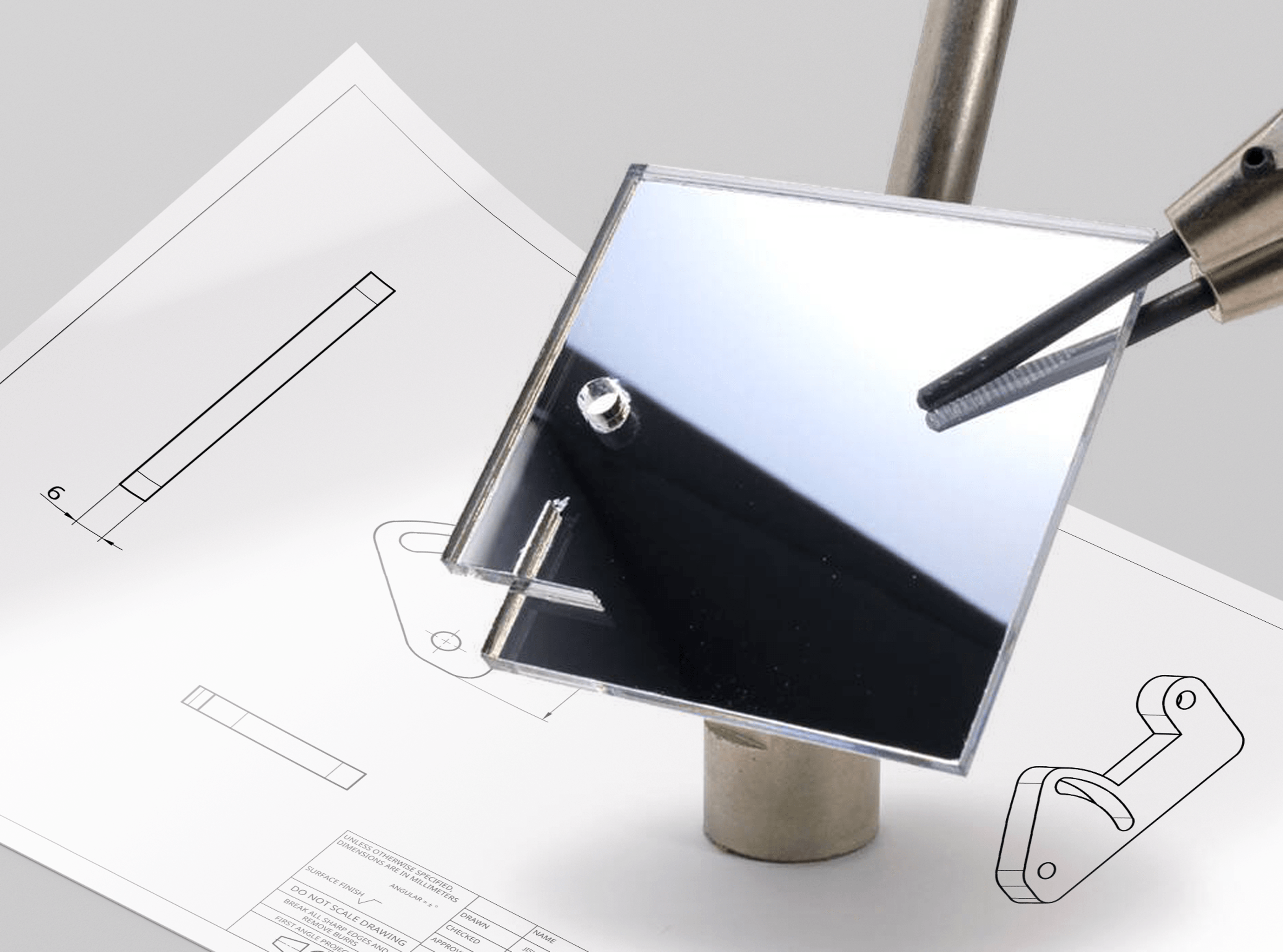

- Mirrored acrylics for a high-end look

- Engineering plastics for strong mechanical parts

- Foams and rubber for perfect seals

- Ultra-thin films for specialty applications

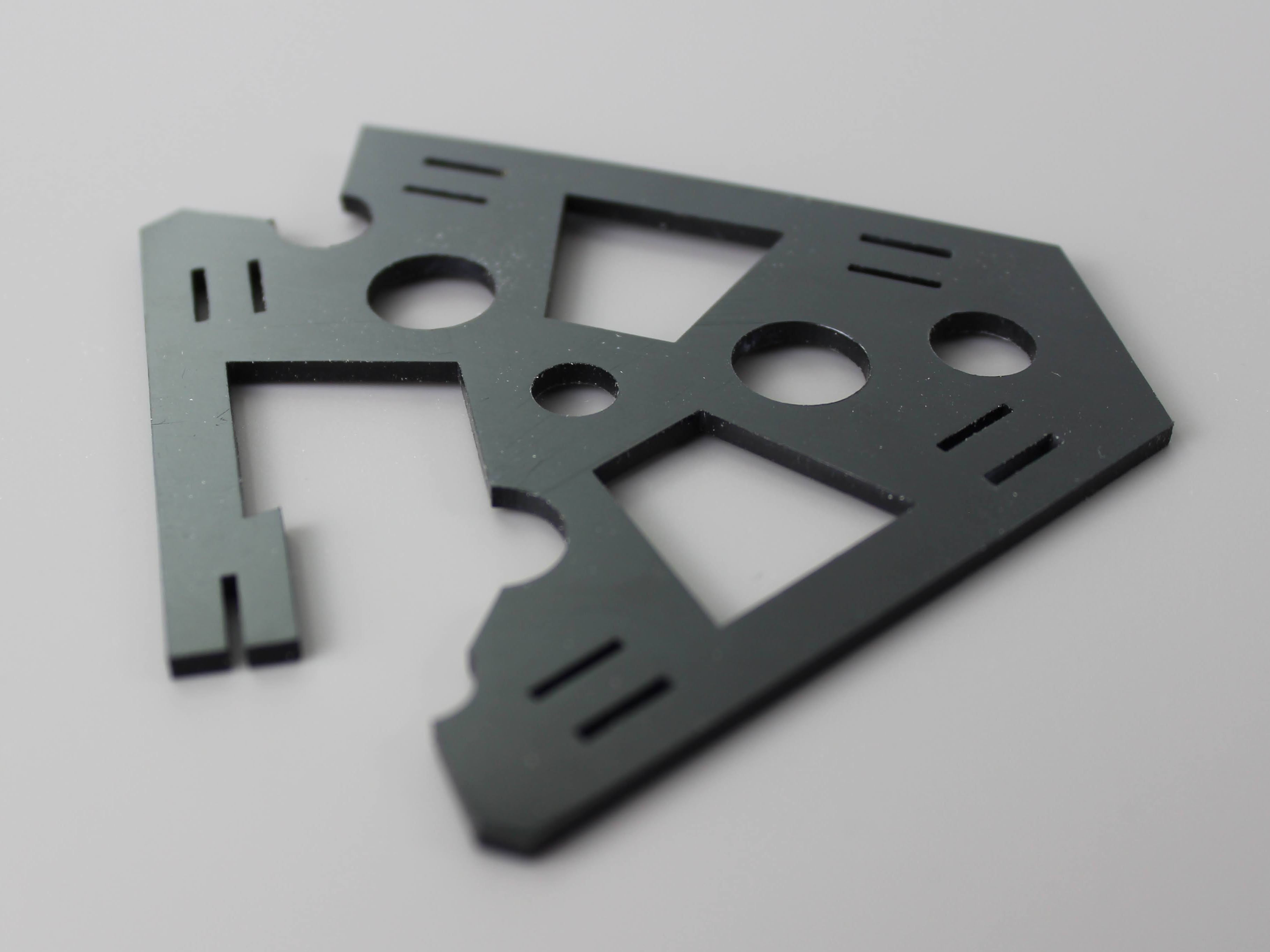

Laser cutting applies no force to the material, allowing for extremely fine detail in any type of plastic.

Perfect for both aesthetic applications and outdoor use.

Perfect for aesthetic applications and outdoor use.

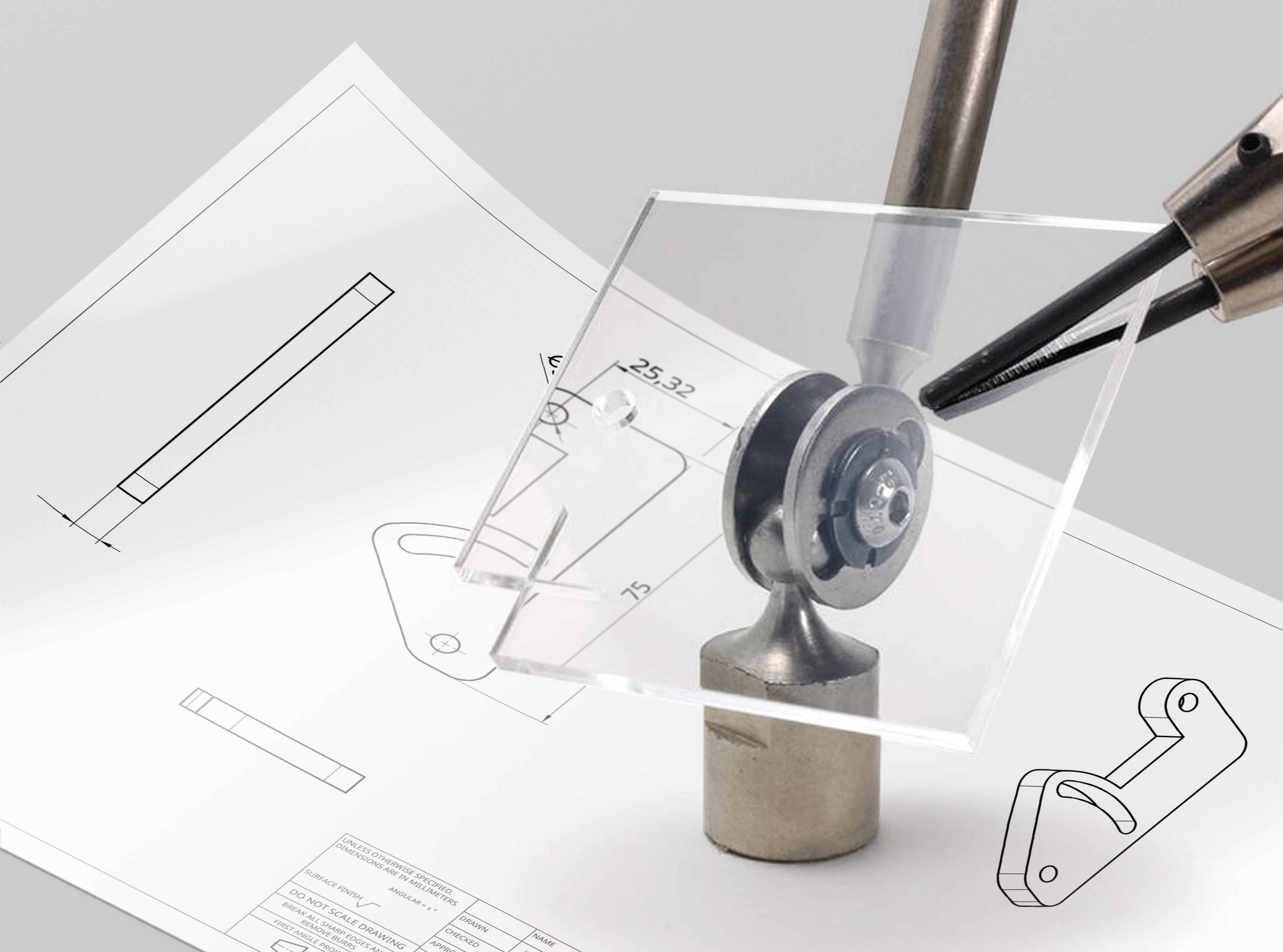

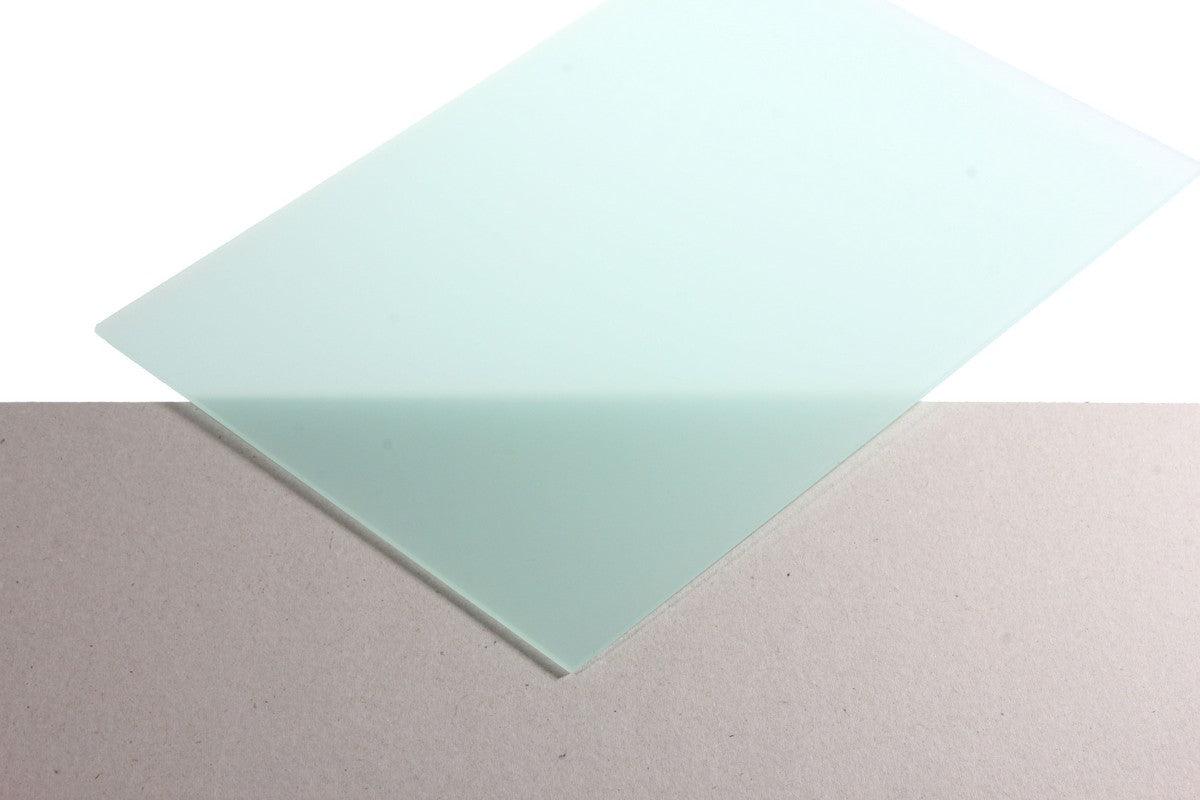

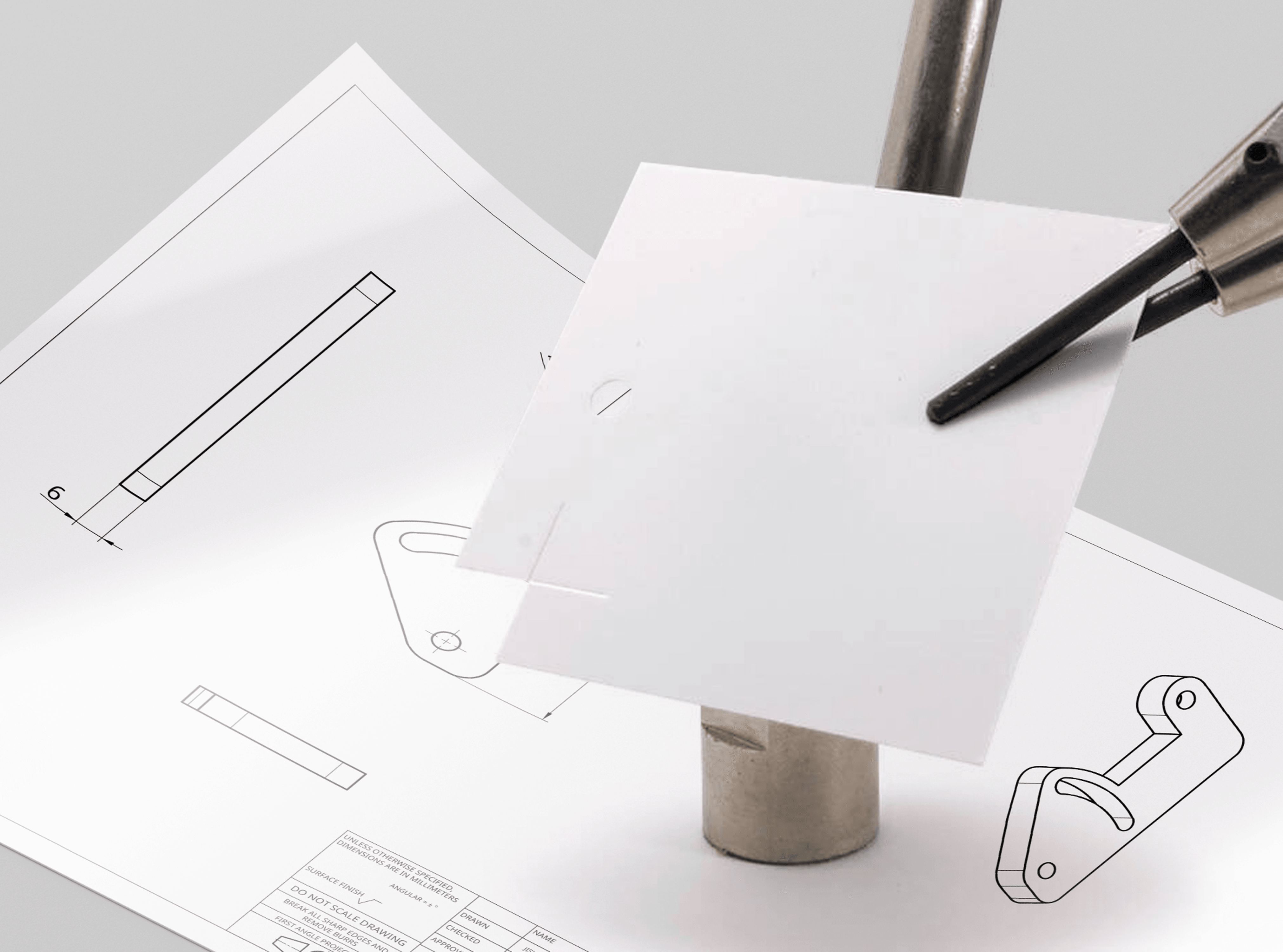

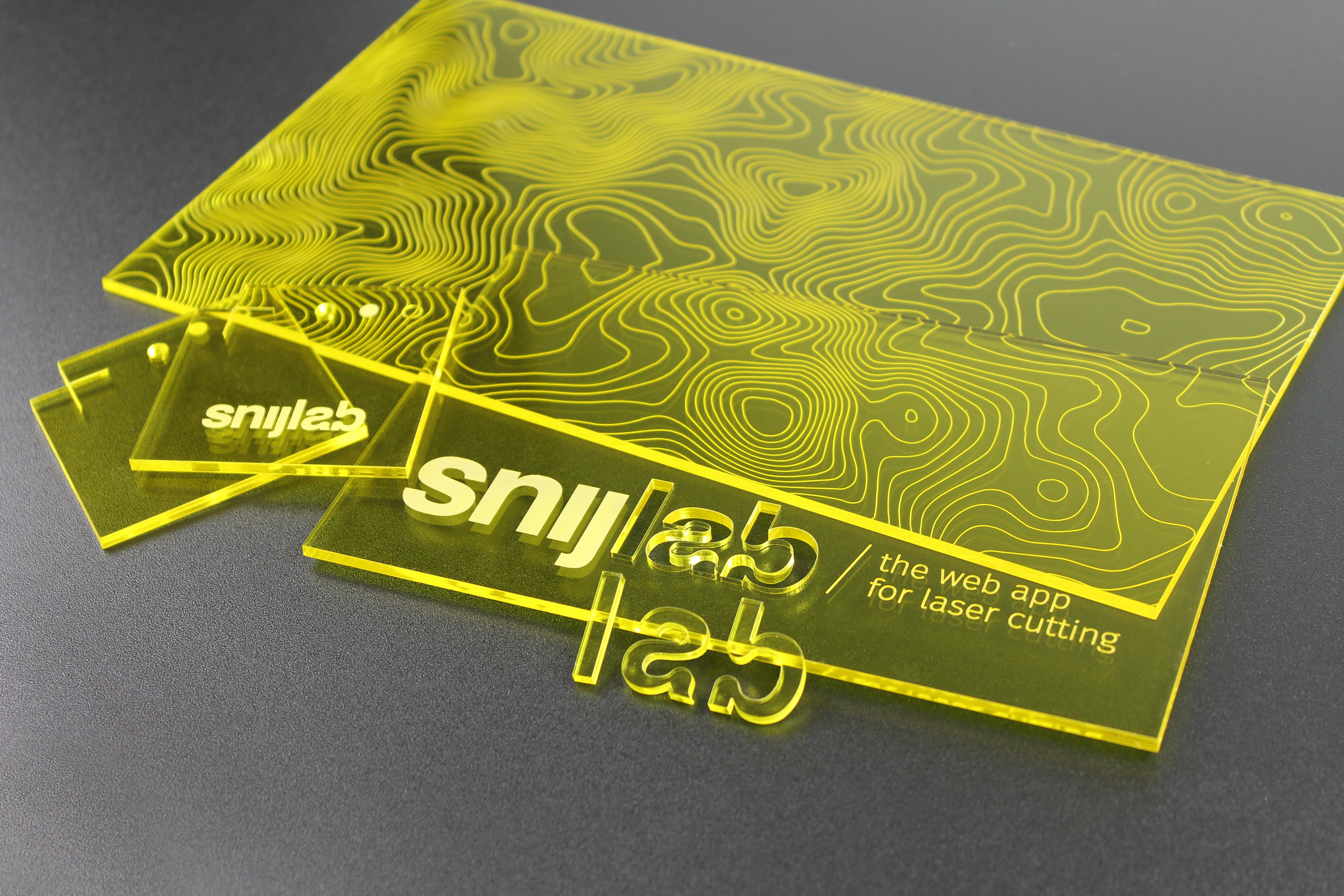

Acrylic (plexiglass)

Available in a wide range of colors—opaque, transparent, and crystal clear. Ideal for visual applications like logos, signage, retail displays, and product presentations.

Downside: acrylic is relatively prone to breaking and scratching.

Still, it’s one of our most popular plastic materials for laser cutting, thanks to its clean look and the fact that no post-processing is needed.

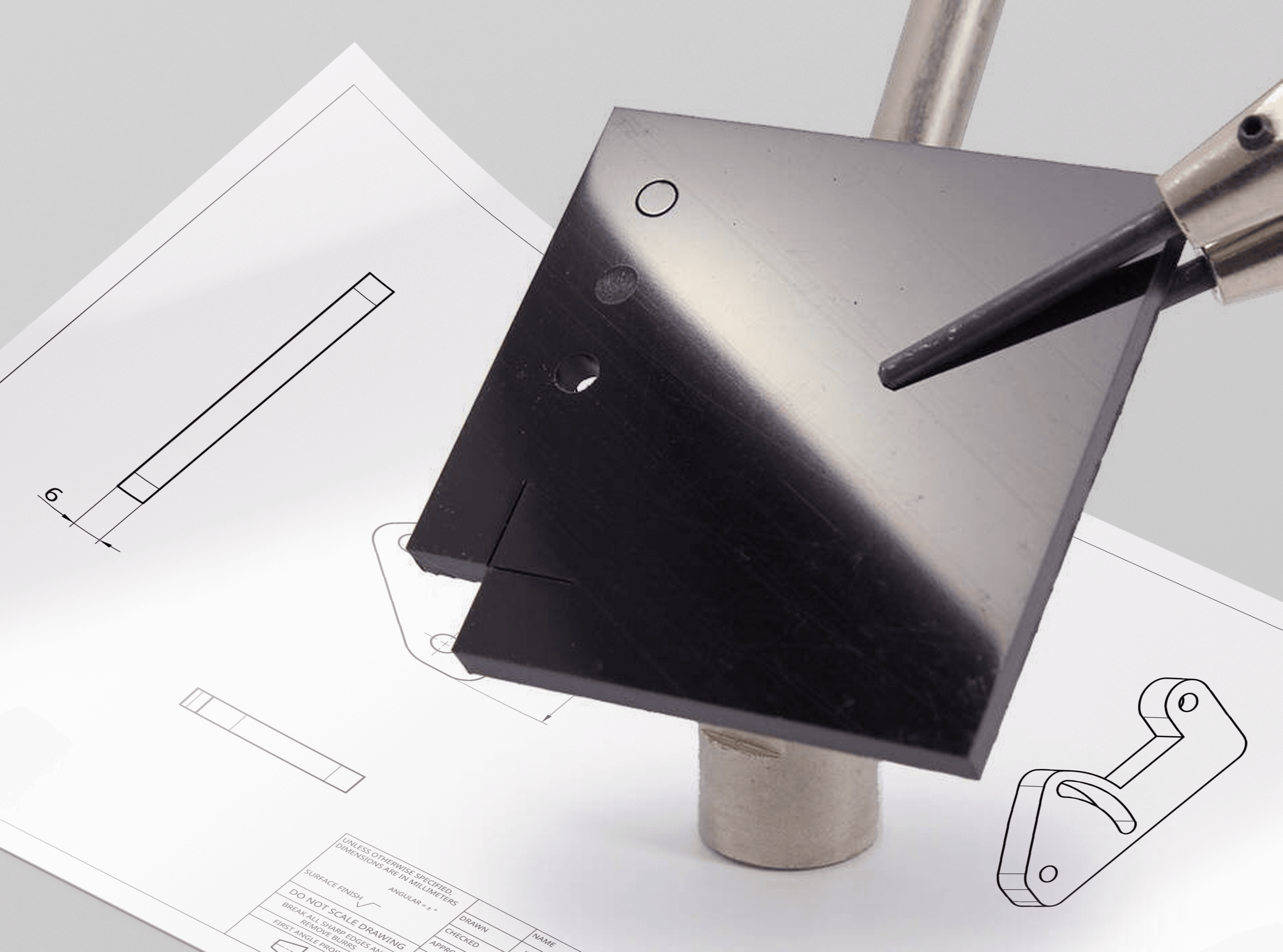

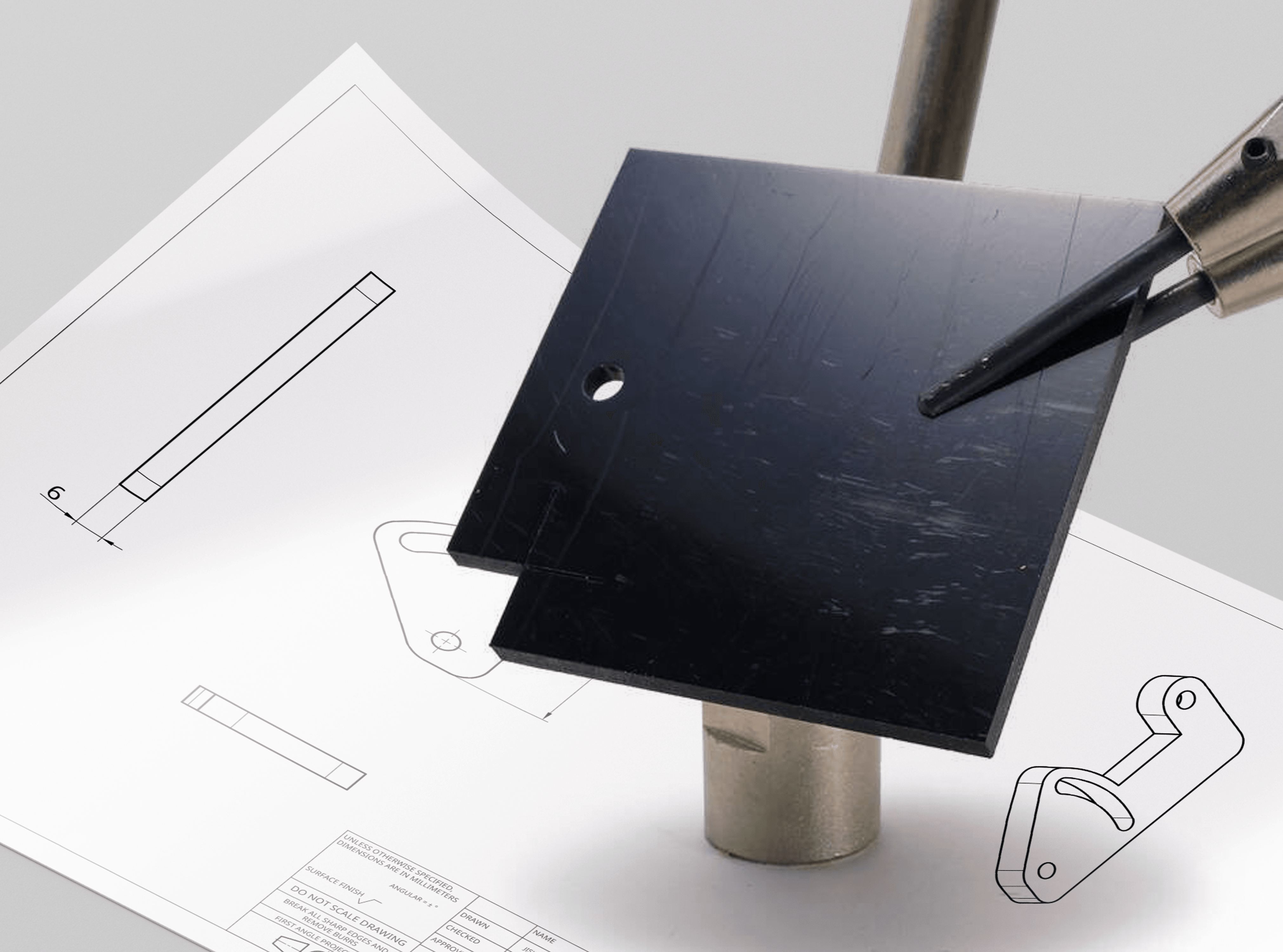

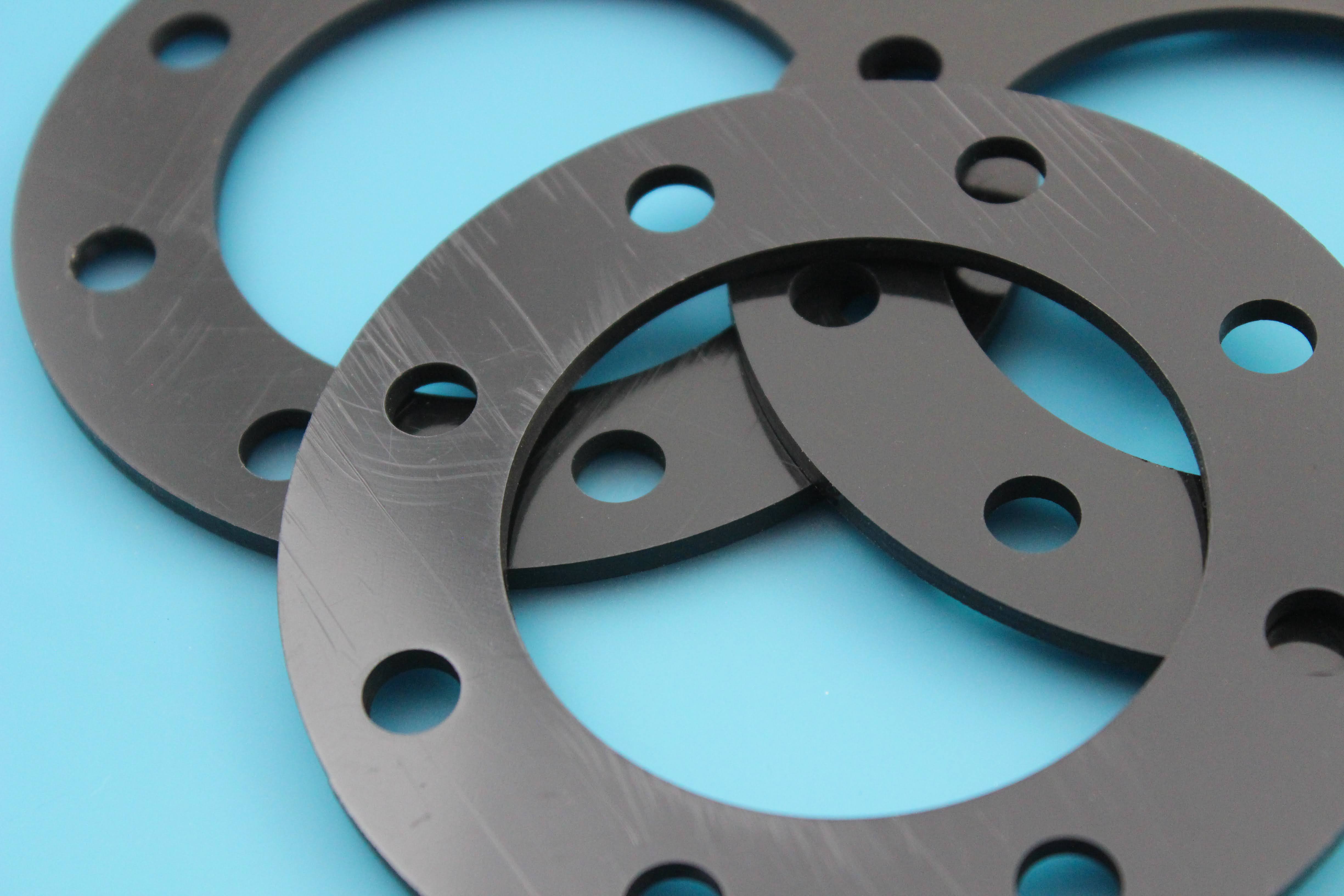

Strong and functional

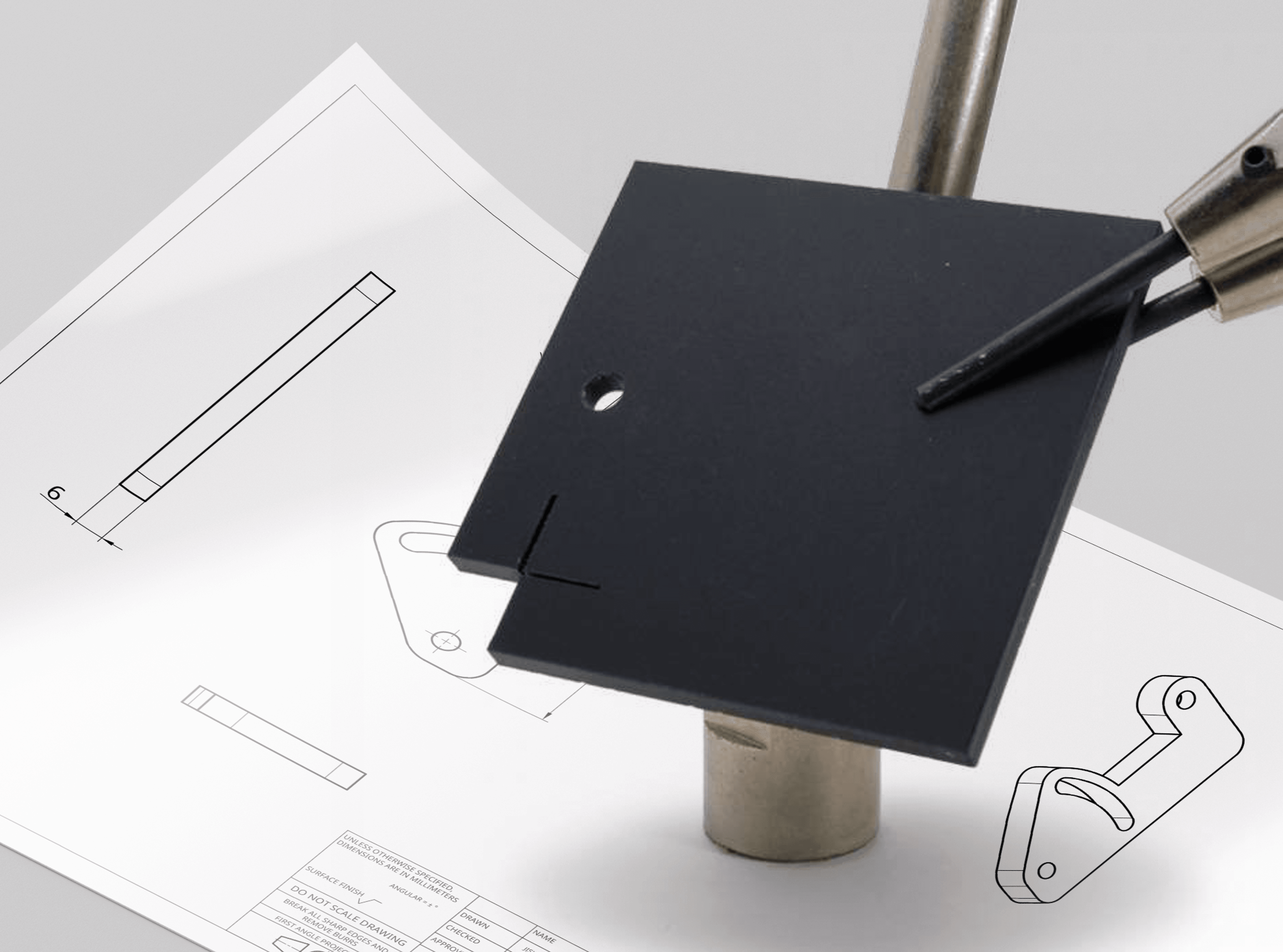

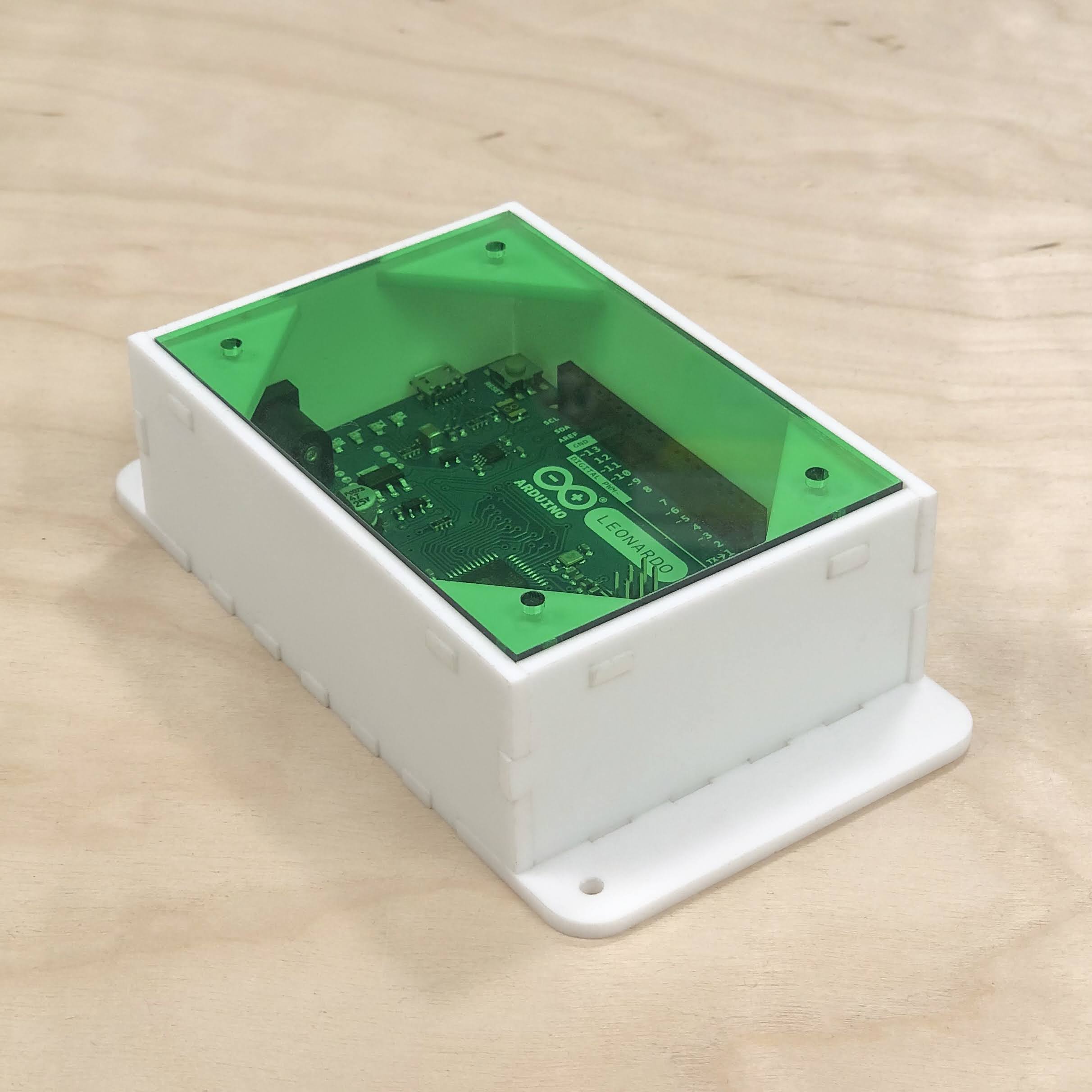

Engineering Plastics

From Delrin and Nylon to ABS and PEEK—each plastic type has its own strengths. Perfect for mechanical parts: structural components, seals, spacers, and more. Many variants can be laser cut with precision.

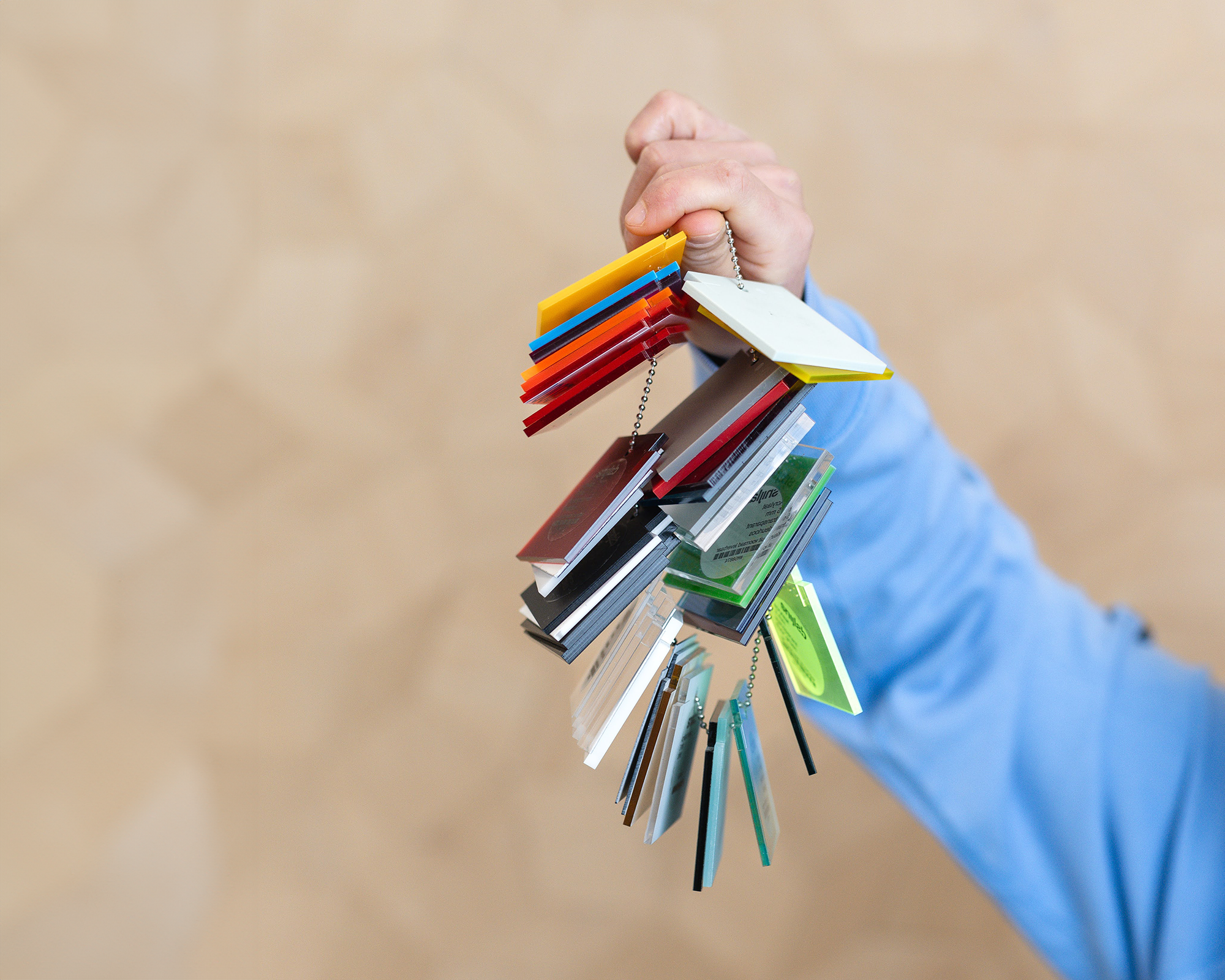

Compare plastics samples

Order a sample chain to compare plastic types in your hands. It’s the best way to choose the right material for your design.

Our samples give you a clear sense of the quality Snijlab delivers.

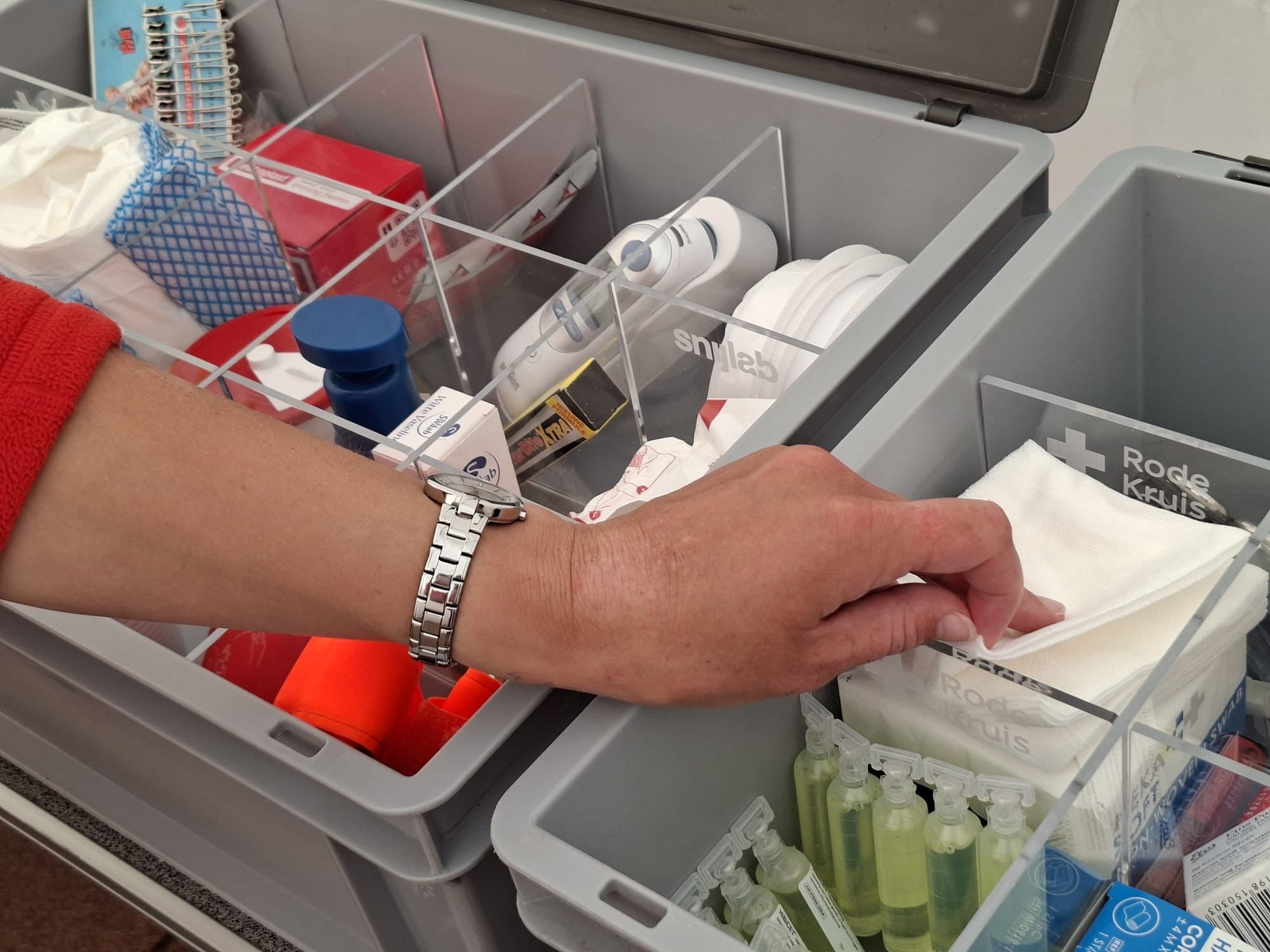

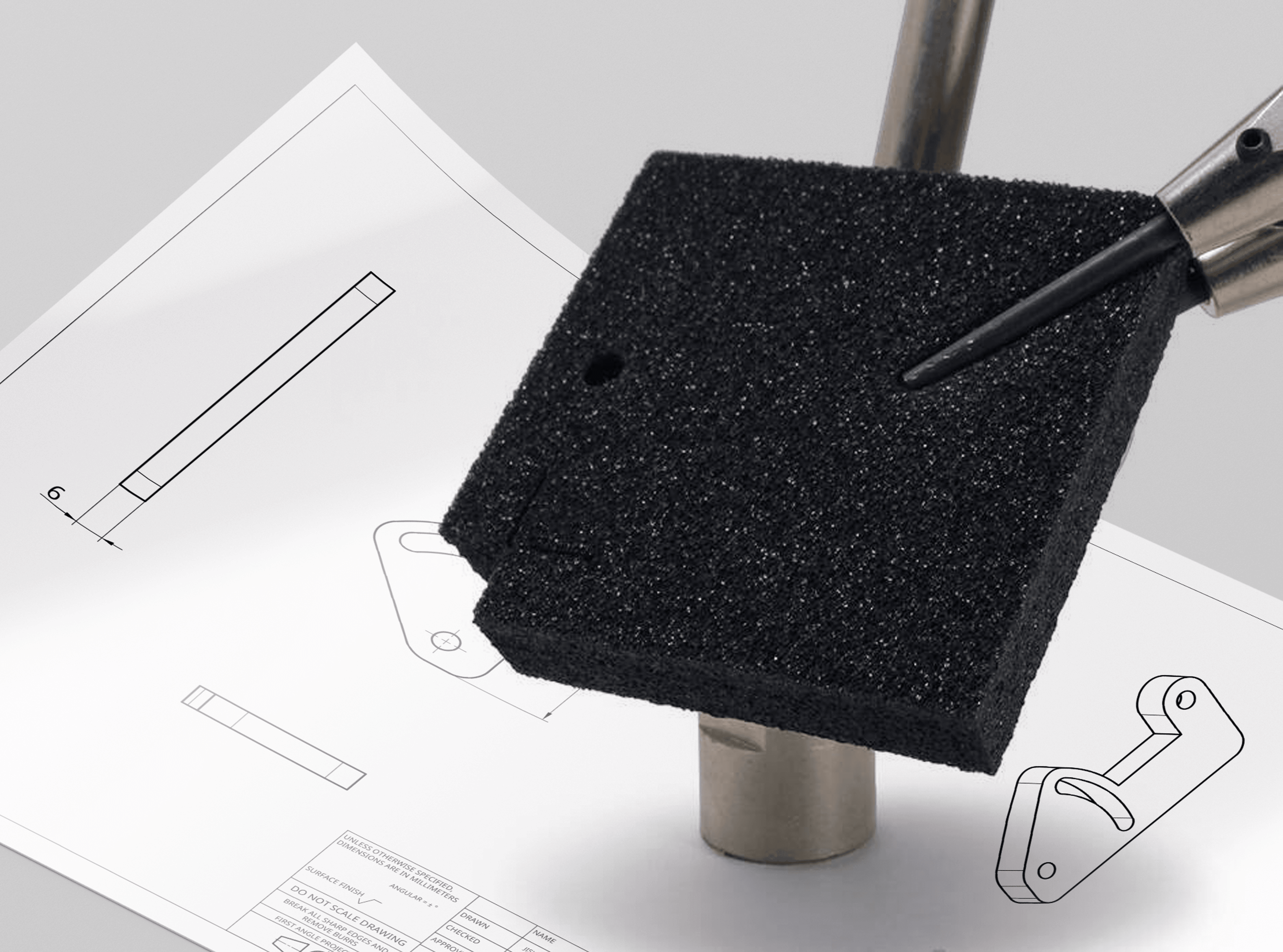

Order samplesFor inlays and seals

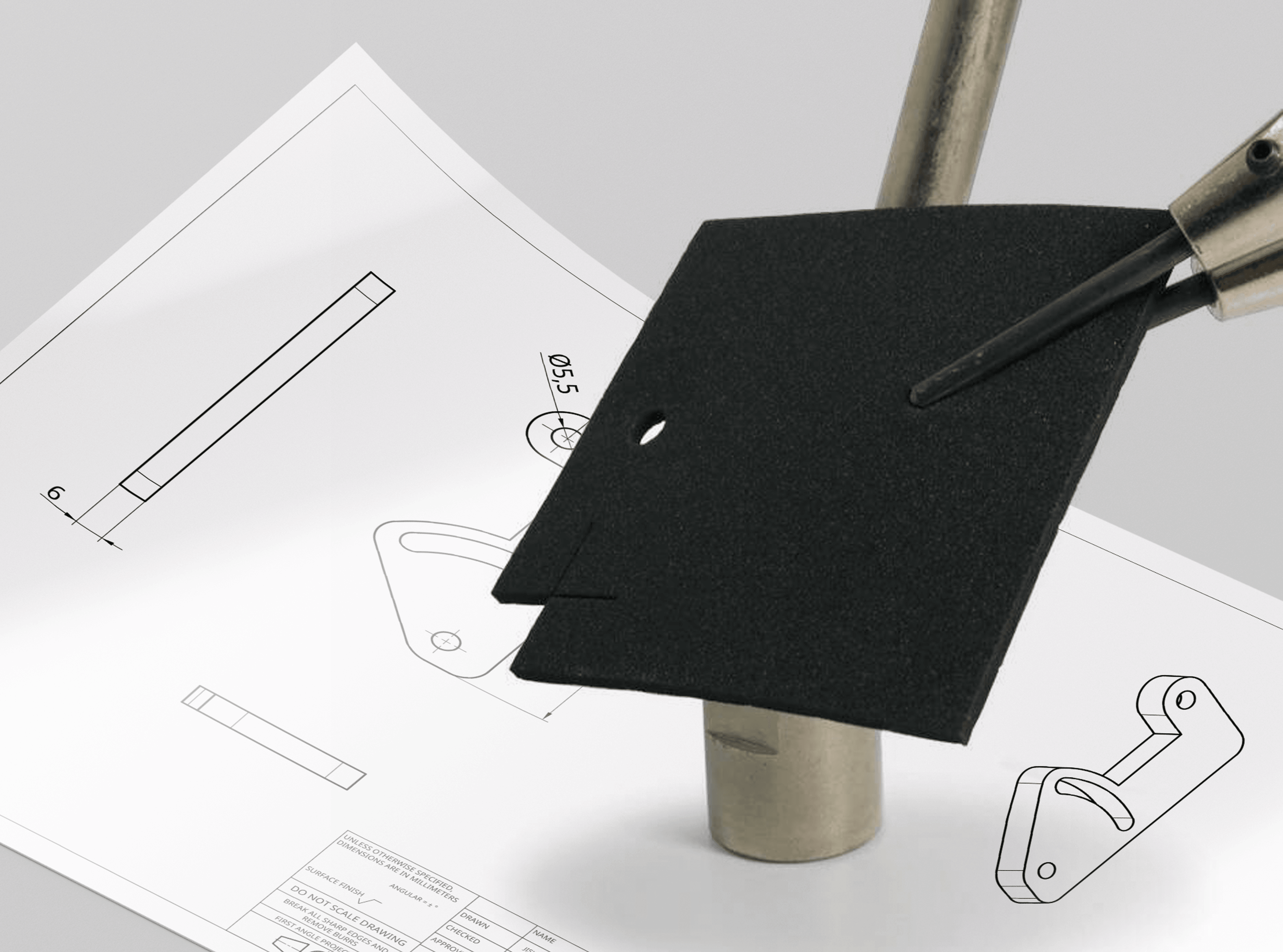

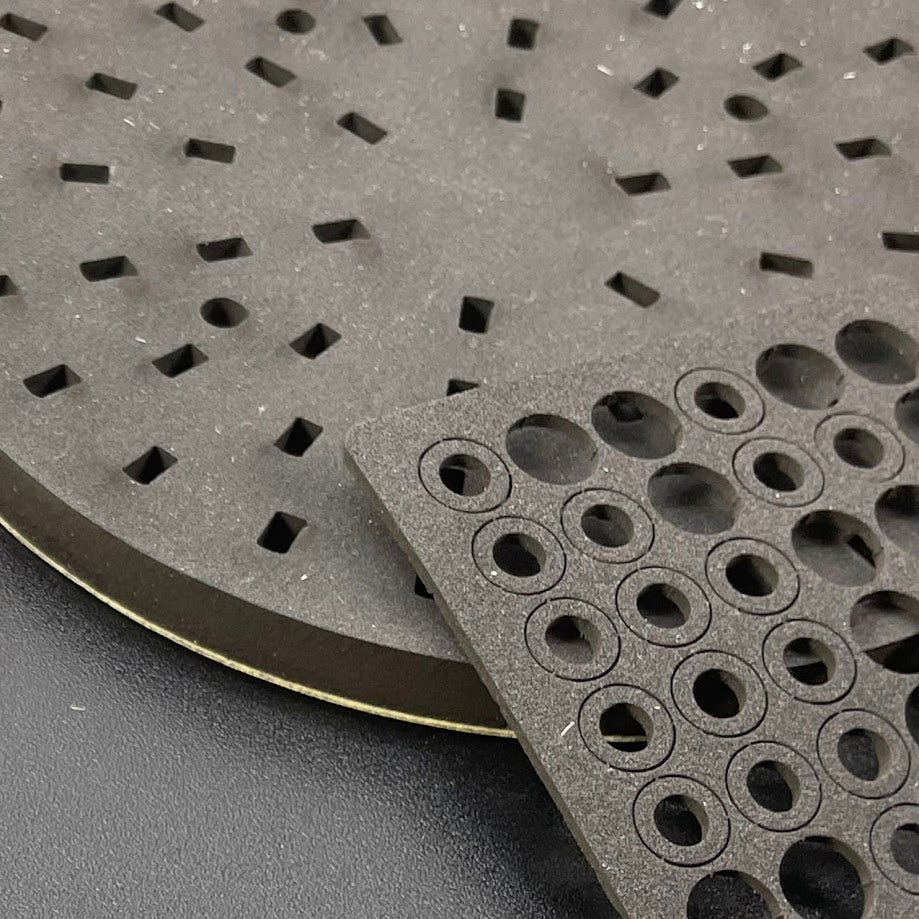

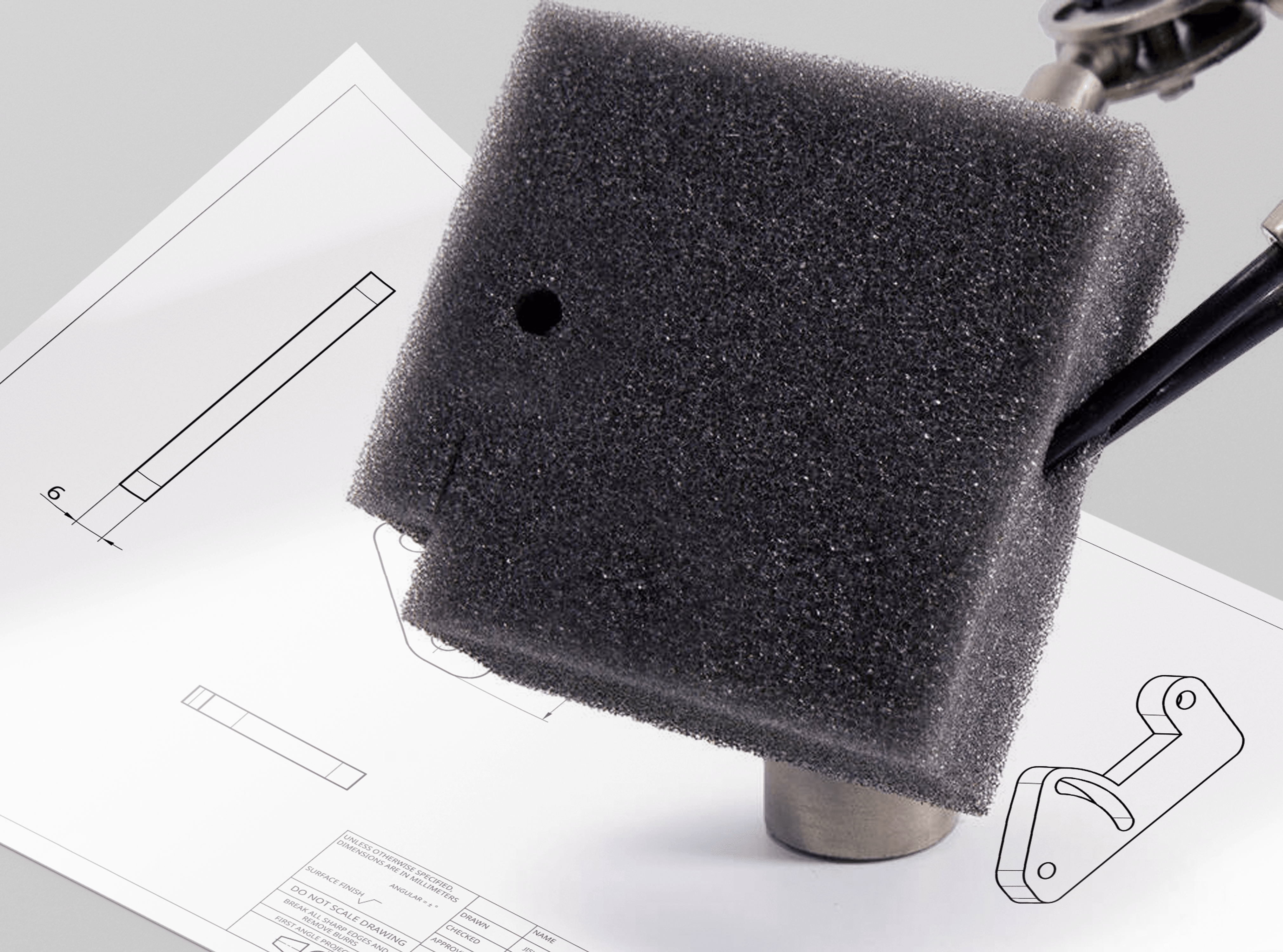

Foam

Foam materials are perfect for laser cutting. PE foam is great for tool drawer inlays, protective cases, or flight cases. Stack multiple laser-cut layers for a custom-fit solution. Soft foam is ideal for packaging; neoprene works well for seals and gaskets.

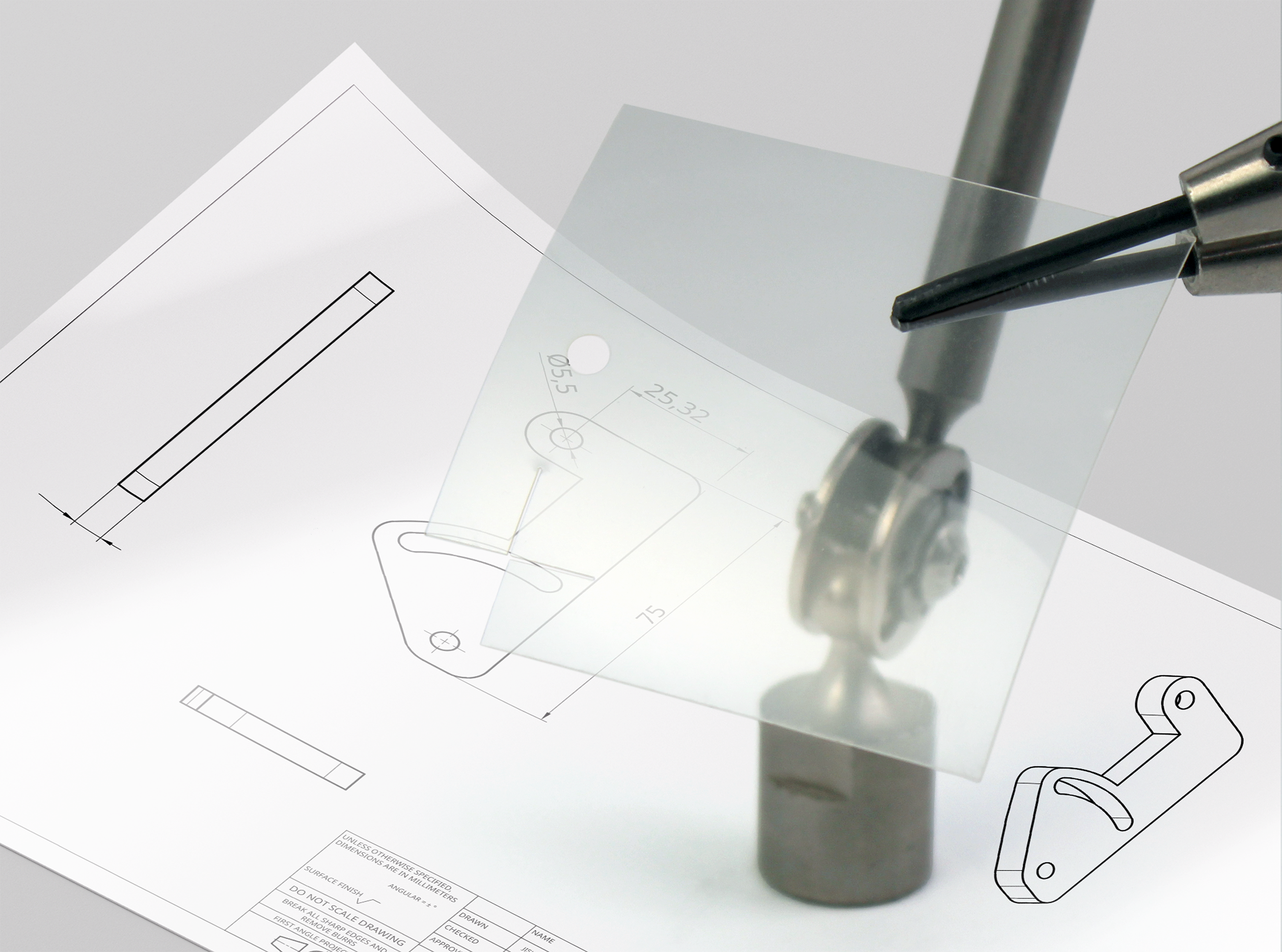

Plastic engraving

In addition to cutting shapes and holes, you can engrave lines and filled areas—perfect for visuals like text and logos.

More about engravingContour cutting and high contrast text and illustrations.

Engraving laminate

This ABS laminate features contrasting layers for easy, high-visibility signage with text and graphics. Ideal for directional signage, museum displays, nameplates, and branding.

Bonus: unlike printed signage, the contour can be cut into any shape you like.

Hairline detail possible

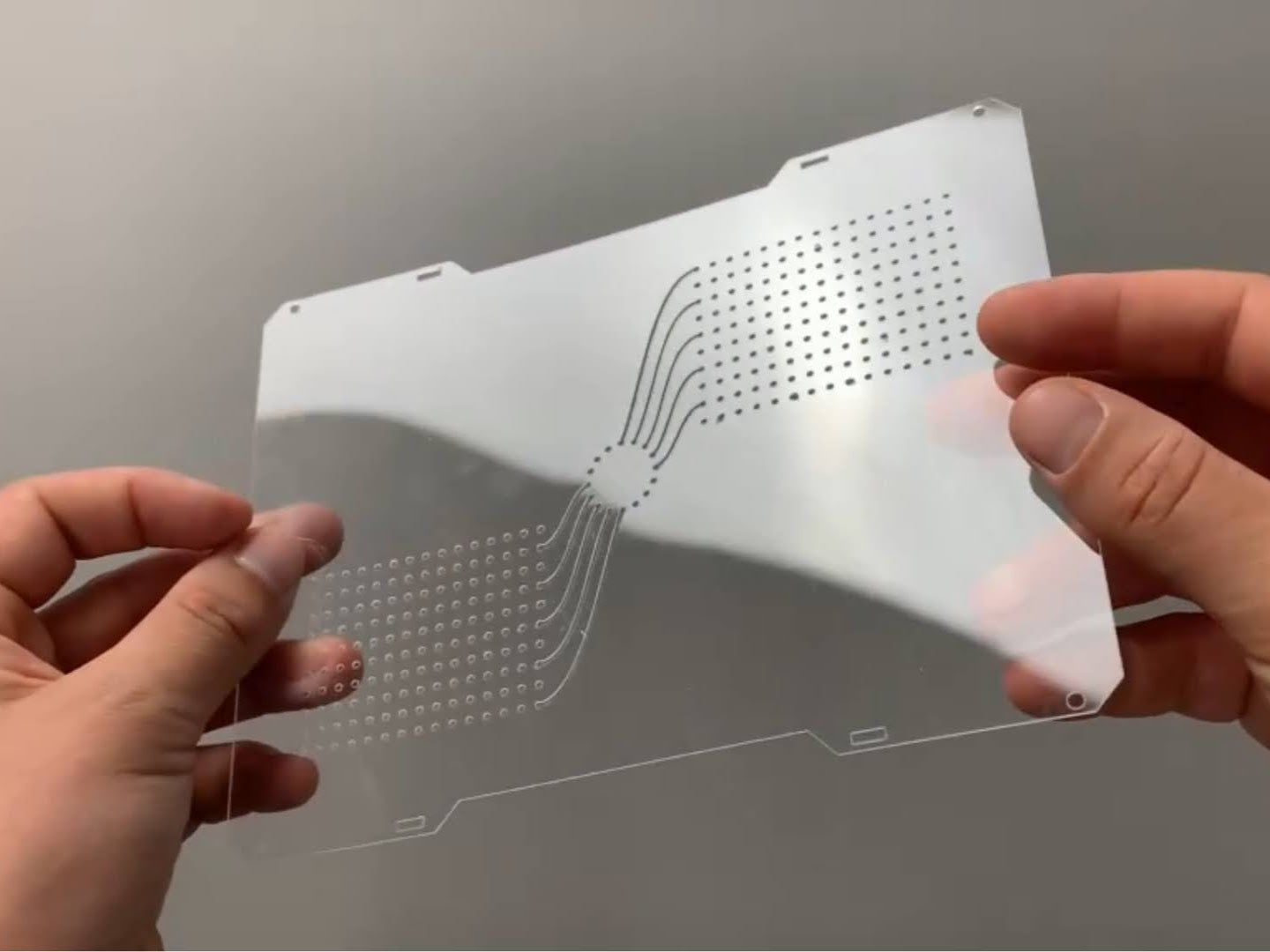

Foils

Laser cutting is extremely cost-efficient for plastic films. Achieve tiny details effortlessly—no need for custom dies.

Soft to the Touch, Lightweight & Strong

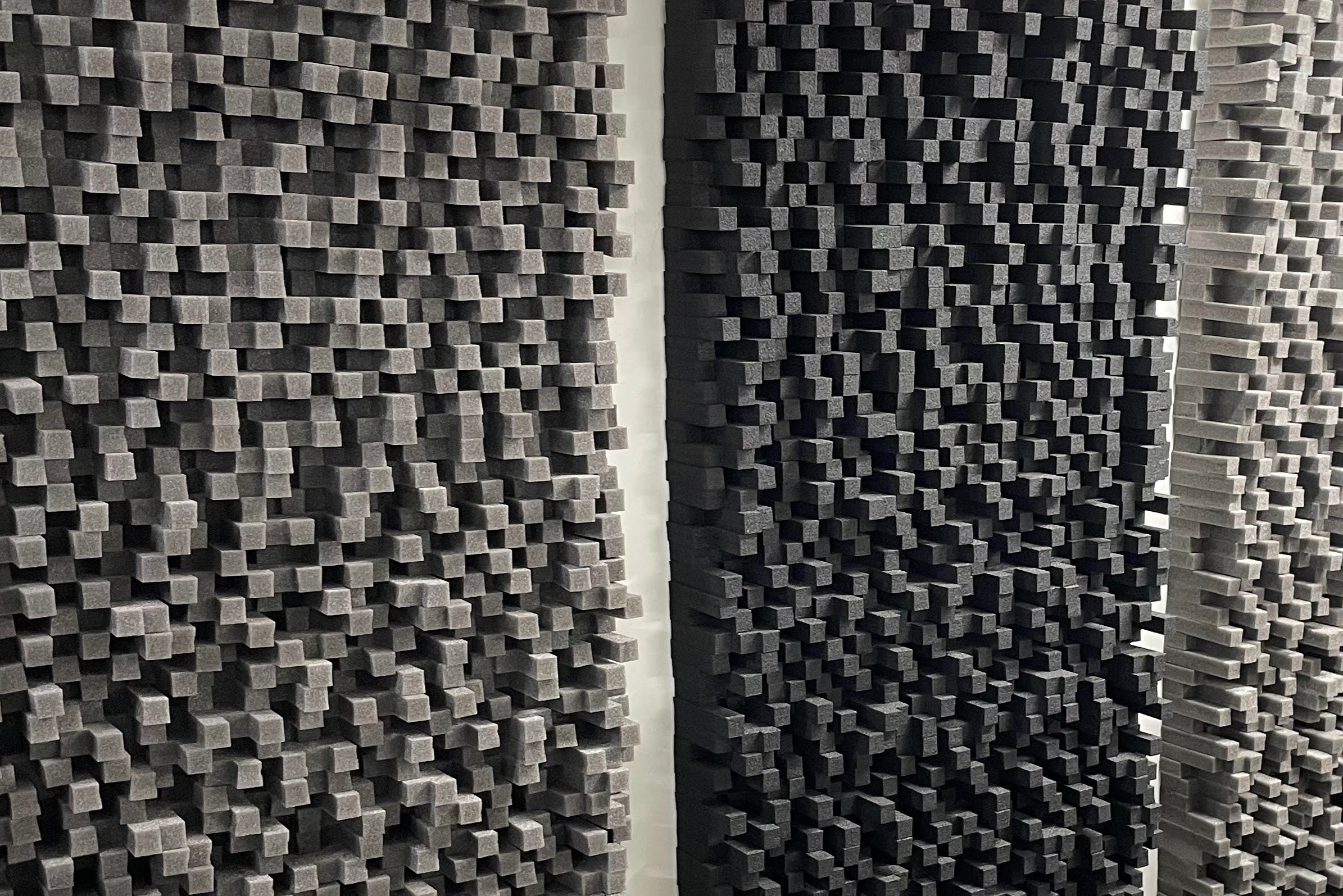

PET felt

An excellent material for acoustic and visual applications. PET felt is strong enough for large 2D or 3D elements like acoustic office panels. It’s soft to the touch, lightweight, and laser-cut edges have a subtle dark accent. Choose from 24 beautiful colors.

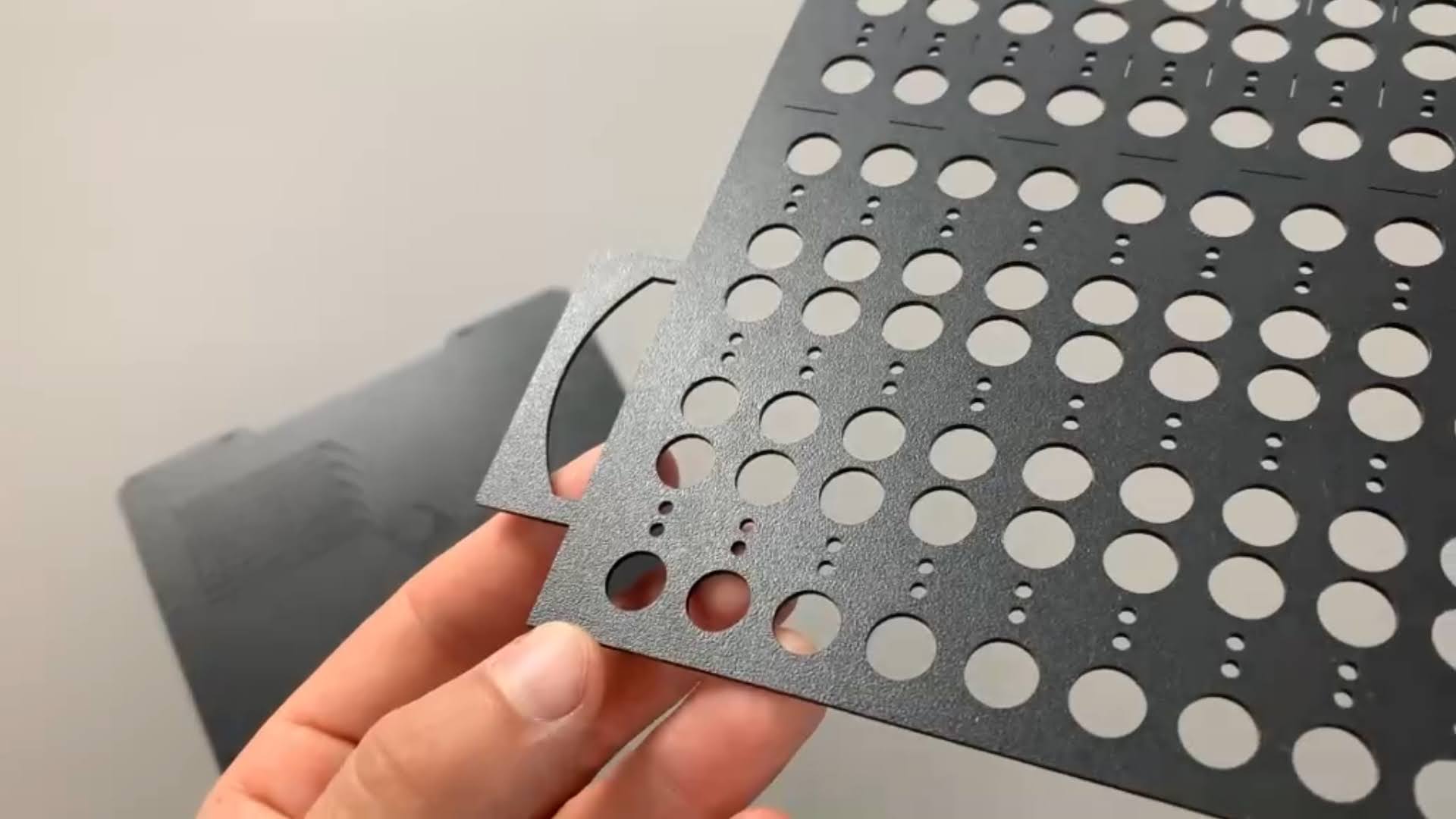

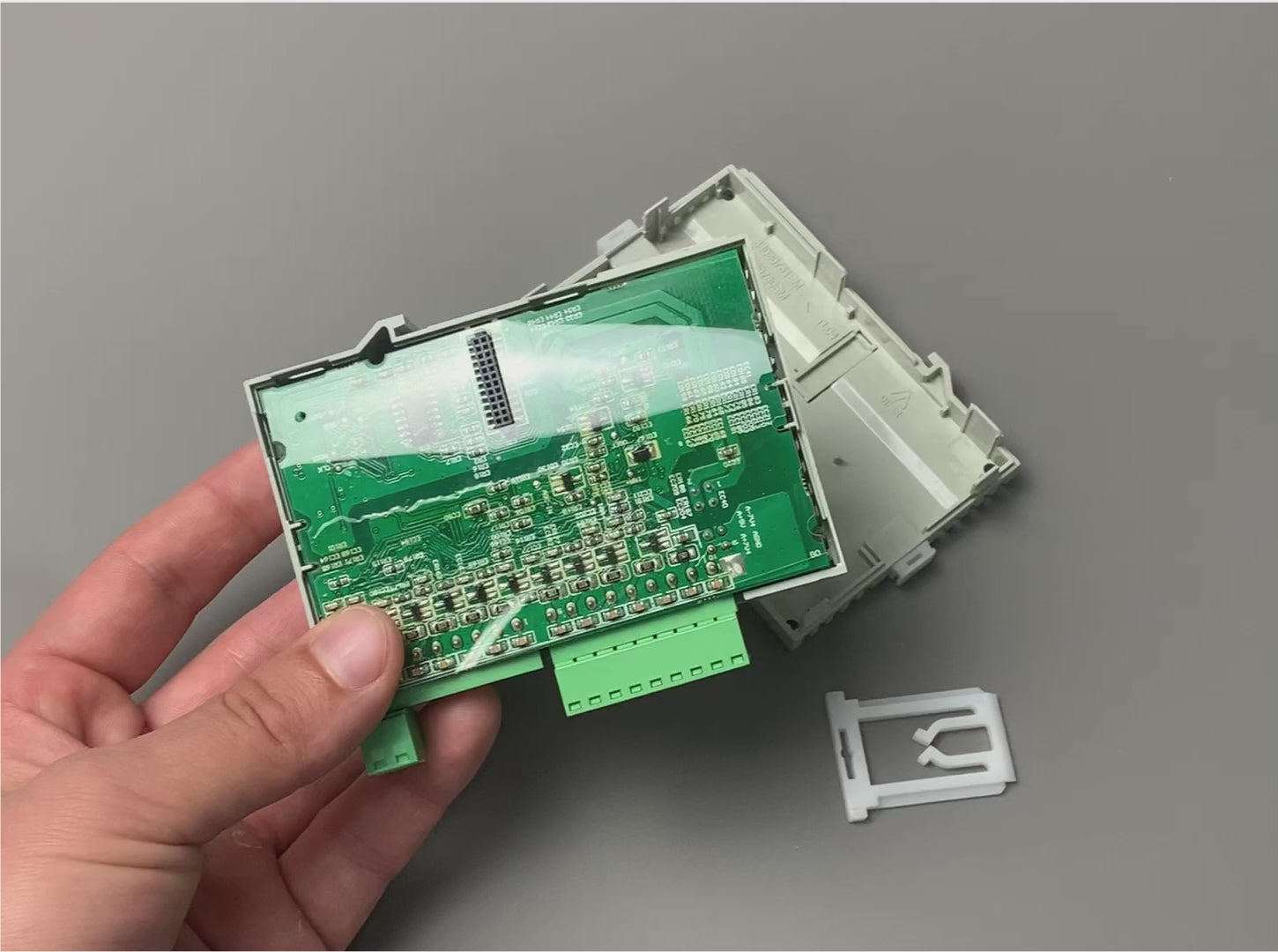

What can you laser cut from plastic?

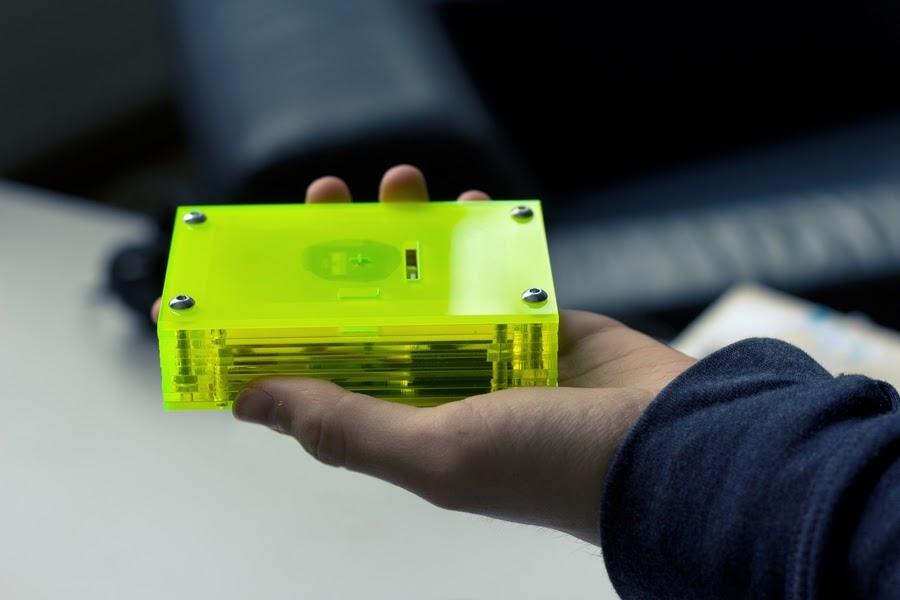

Laser cutting plastics unlocks endless possibilities for product designers, architects, and makers. Use it for signage, wayfinding, display elements, prototypes, interior parts, kiosks, lighting, medical devices, electronics enclosures, robot components, and consumer products.

Accelerate your design process by integrating functional features right into your part: snap fits, hinges, mounting points, locking tabs, and modular components.

Laser cutting gives you access to unique plastic properties like color options and transparency—perfect for both functional and aesthetic results. Choose the right material for the job, from crystal-clear acrylics to lightweight and tough ABS.

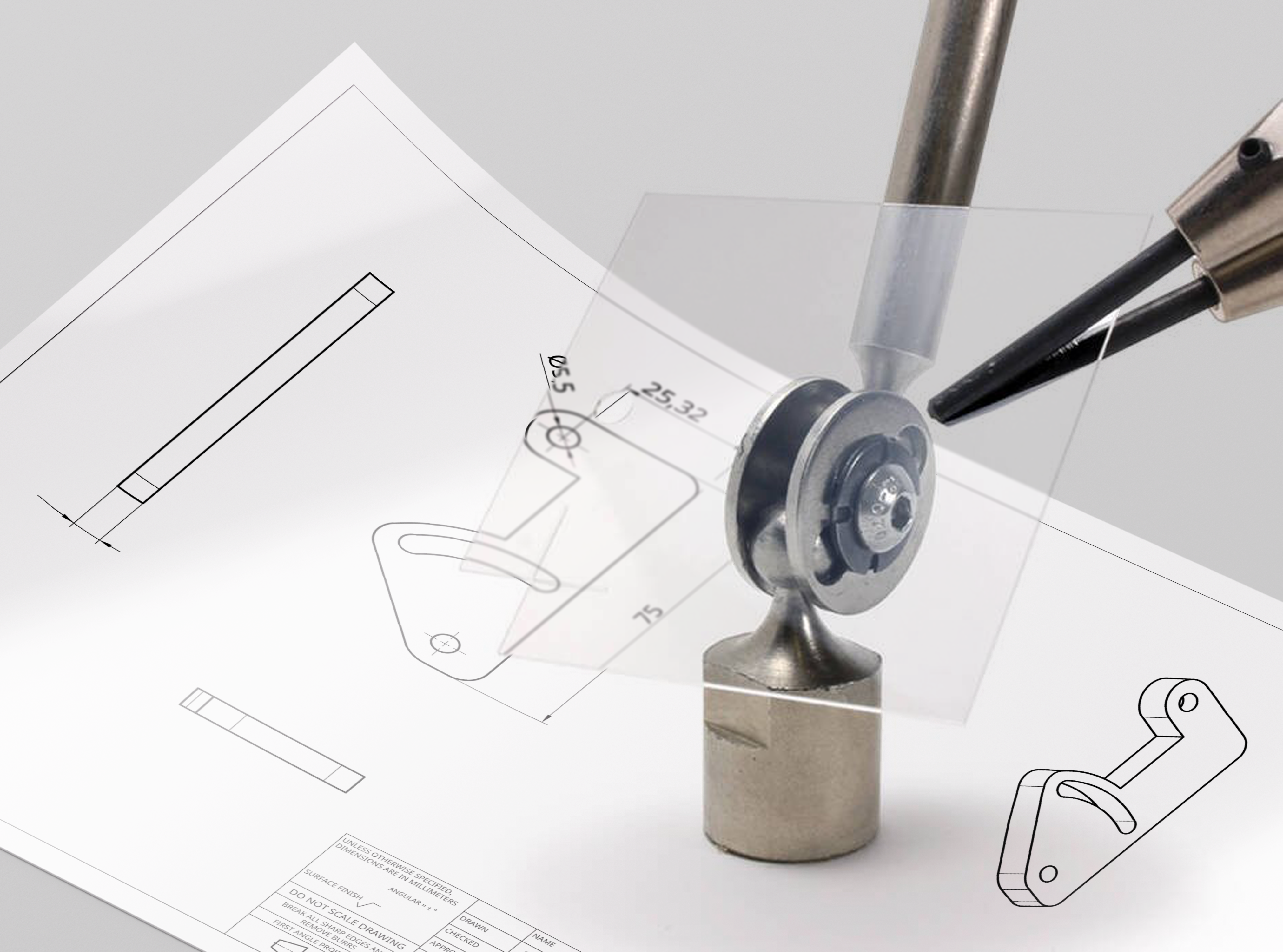

Engineering parts

Foam inlays

Signing

Stencils

Toward a future with renewable materials.

Sustainable plastics

Modern plastics are impressively strong, tough, and durable—vital for countless applications. At Snijlab, we use them responsibly by:

- Maximizing sheet usage to reduce waste

- Separately collecting plastic scraps for recycling

- Working with 100% recyclable materials like acrylic and POM

Choose the right material and create products built to last. Use laser cutting for quick prototyping and fine-tune your design before scaling up.

Stay ahead with the latest bio-based plastics. Try BioPanel, a promising blend of PLA and hemp that’s strong, weather-resistant, and a sustainable alternative to acrylic in many use cases.

GreenCast

Acrylic recycling

Sustainability comes in many forms. Take acrylic: originally a fossil-based plastic, but now 100% recyclable. Did you know we collect our off-cuts separately and have them reprocessed into new acrylic sheets?

Need help?

Let us help bring your ideas to life with laser-cut plastics. Feel free to reach out for advice on materials or support with your project.