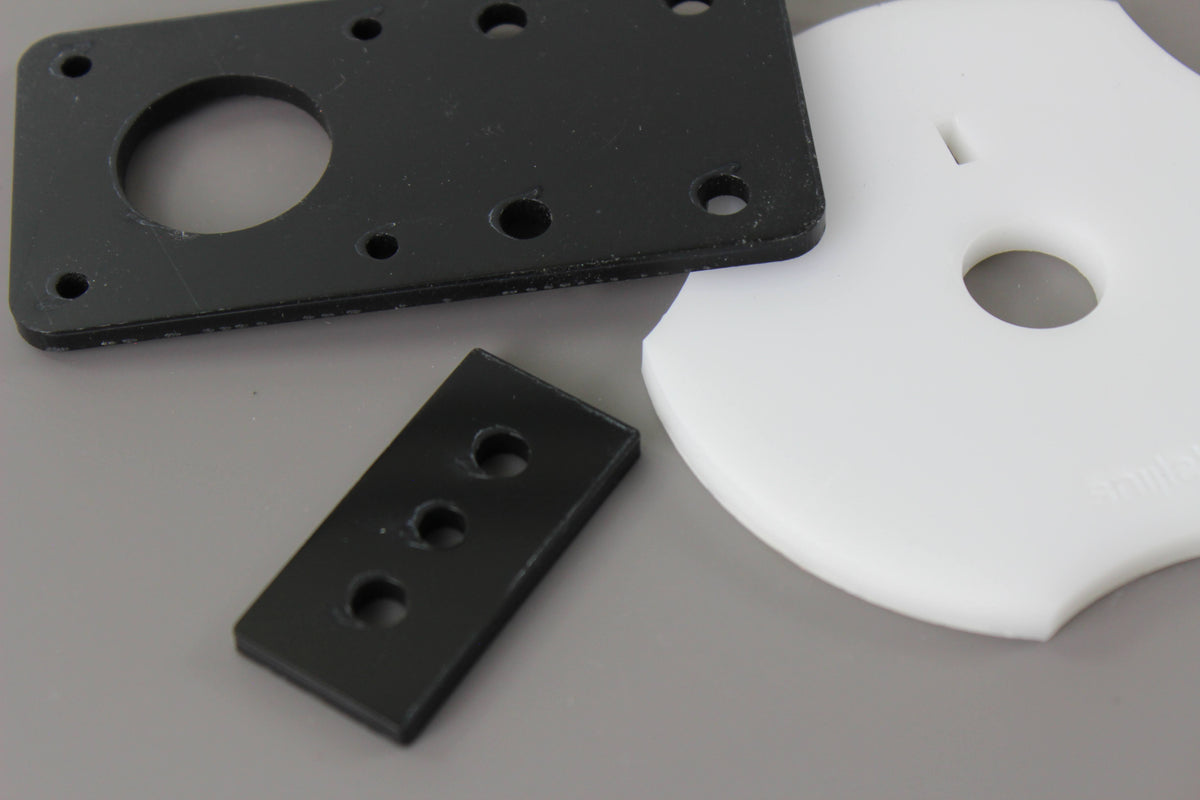

Laser cutting from pom (polyacetal)

After uploading your design, you will receive an instant, no-obligation price. If you want, you can then order securely online.

In print runs as low as €0.05 per part!

| Material information | |

|---|---|

Available colors |

black, white

|

Available thicknesses |

3.0 mm, 4.0 mm, 5.0 mm, 6.0 mm, 1.0 mm, 2.0 mm, 8.0 mm, 0.5 mm, 1.5 mm

|

Datasheet |

|

| Technical specs | |

Density (Kg/m³) The specific weight per volume in kg / m³

|

|

Heat Deflection Temperature (°C) Heat Deflection Temperature indicates the temperature up to which a material remains rigid under load.

|

|

E-modulus (MPa) The modulus of elasticity or stiffness of the material. This indicates how much the material deforms under a given stress.

|

|

Moisture absorption(%) The degree to which a material absorbs moisture from the environment. A material that has absorbed moisture expands.

|

|

Tensile strength (MPa) The tensile strength is the maximum stress the material reaches just before it fails (permanently deformed). In practice, a material is used well below this limit.

|

|

Elongation to fracture (%) |

|

Hardness (Shore °D) Hardness of the surface measured on a scale of Shore. For comparison, at shore D, a car tire is 15, a skateboard wheel is 50 and a construction helmet is 80.

|

|

Coefficient of friction The coefficient of friction indicates how much resistance a material provides to friction. Simply put; the lower this number the better the material glides.

|

|

Heat capacity (Kj/Kg°C) Indicates how much heat energy is required for the material to heat up. Or viewed another way, how much heat can the material store?

|

|

Breakdown voltage (kV/mm) The breakdown voltage is important when the material is used as an insulator and indicates the voltage at which the material ceases to insulate and begins to conduct.

|

|

Coefficient of thermal conductivity (W/mK) |

|

Coefficient of thermal expansion (mm/m°C) |

|

Maximum operating temp. short-term (°C) |

|

| Chosen variant | |

Material number |

MS0283

|

Thickness |

3.0 mm

|

Color |

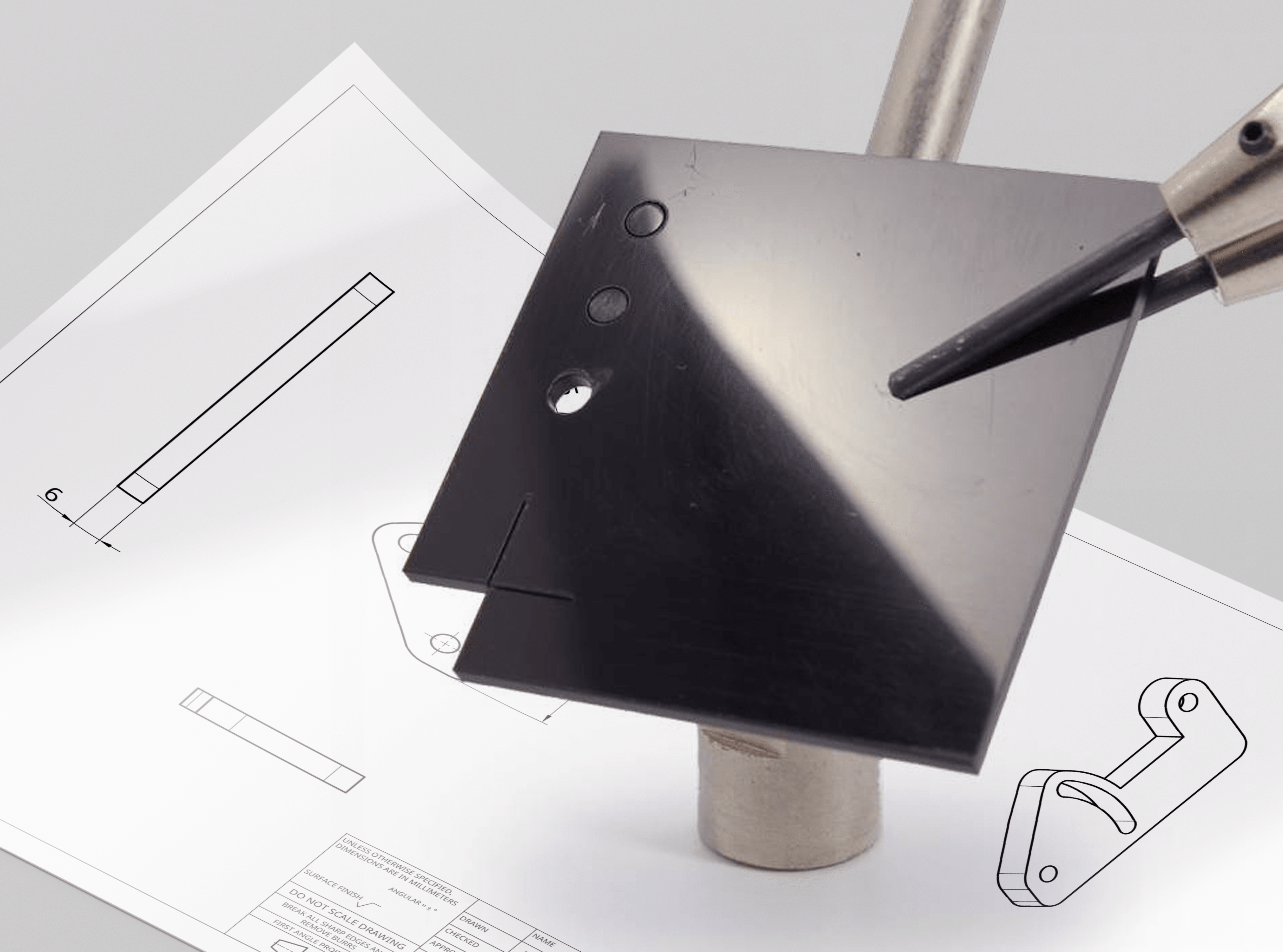

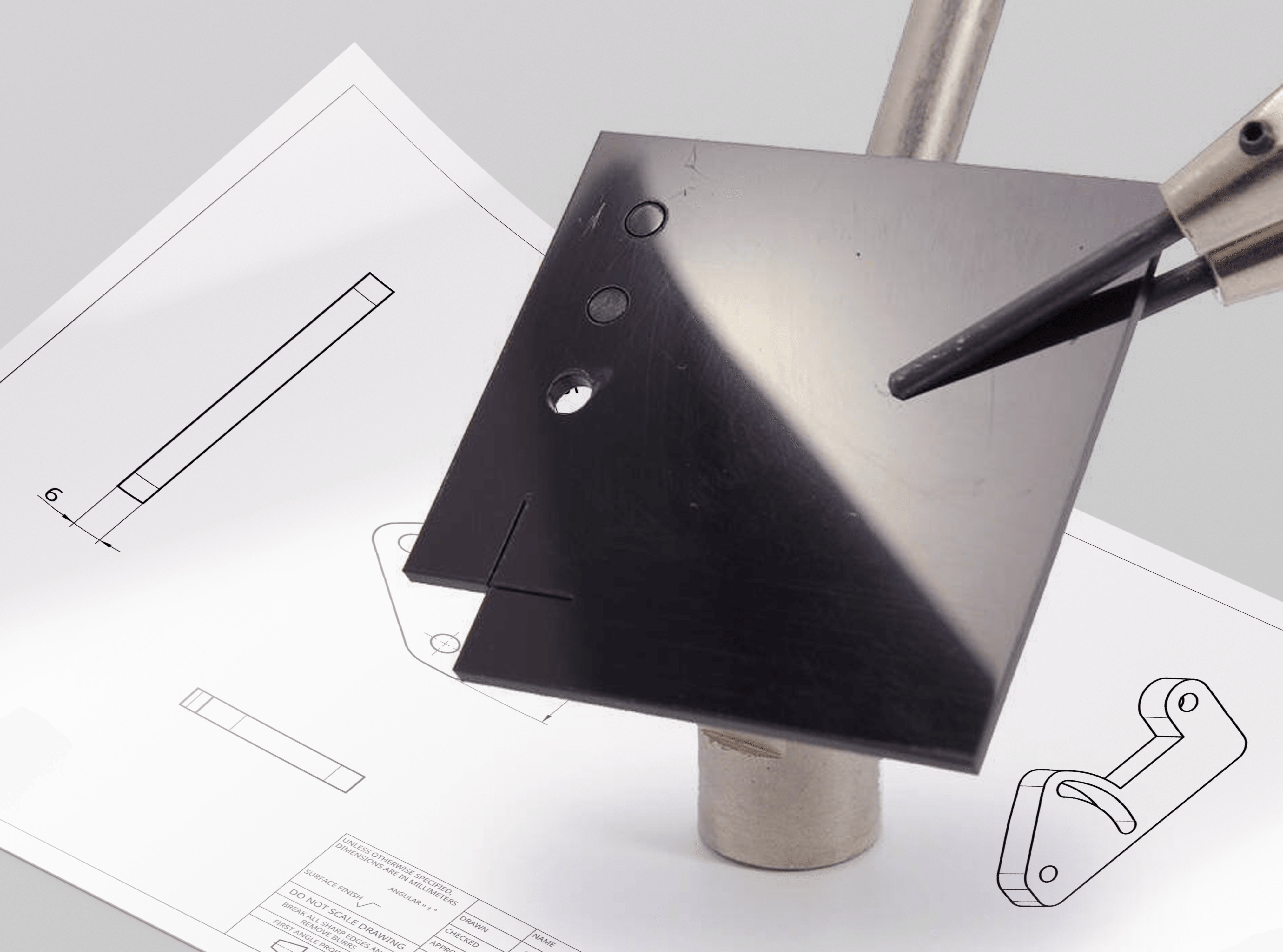

black

|

Panel weight (kg/m²) |

0.1 kg

|

Description

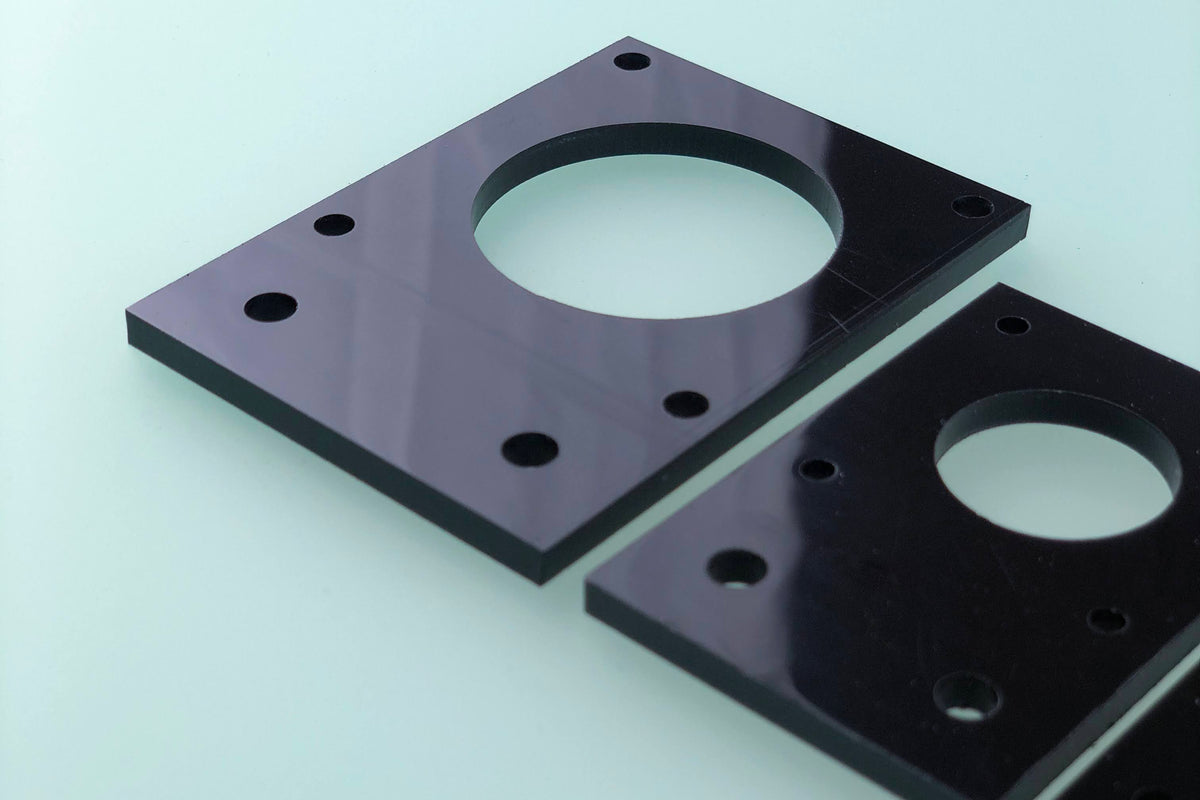

POM is one of the strongest plastics available. Tough, impact resistant and with good sliding properties.

POM or Polyacetal is a hard thermoplastic for engineering applications. You encounter POM in high-performance mechanical parts (gears, skis, plastic nuts and bolts, locks, etc). It is widely used in automotive and consumer products.

Properties

- Good resistance to chemicals

- High dimensional stability

- Low moisture absorption

POM has a hard surface (shore °D 81), a wide temperature range (-50 ... 100°C). It is so strong and tough that it is comparable to epoxy and polycarbonate, with the advantage that POM can be lasered.

POM has a low coefficient of friction of 0.36. The static and dynamic coefficients of friction are the same so there is no stick-slip. POM is also wear resistant and for both of these properties, POM is well suited for sliding or sliding parts. Polyacetal is also a good insulator with a breakdown voltage of 50kV/mm.

Production

Polyacetal is formed by injection molding or extrusion. The plates we laser cut are extruded. Please note; plates may vary in thickness. The thickness tolerance for a selected plate thickness is shown in the table.

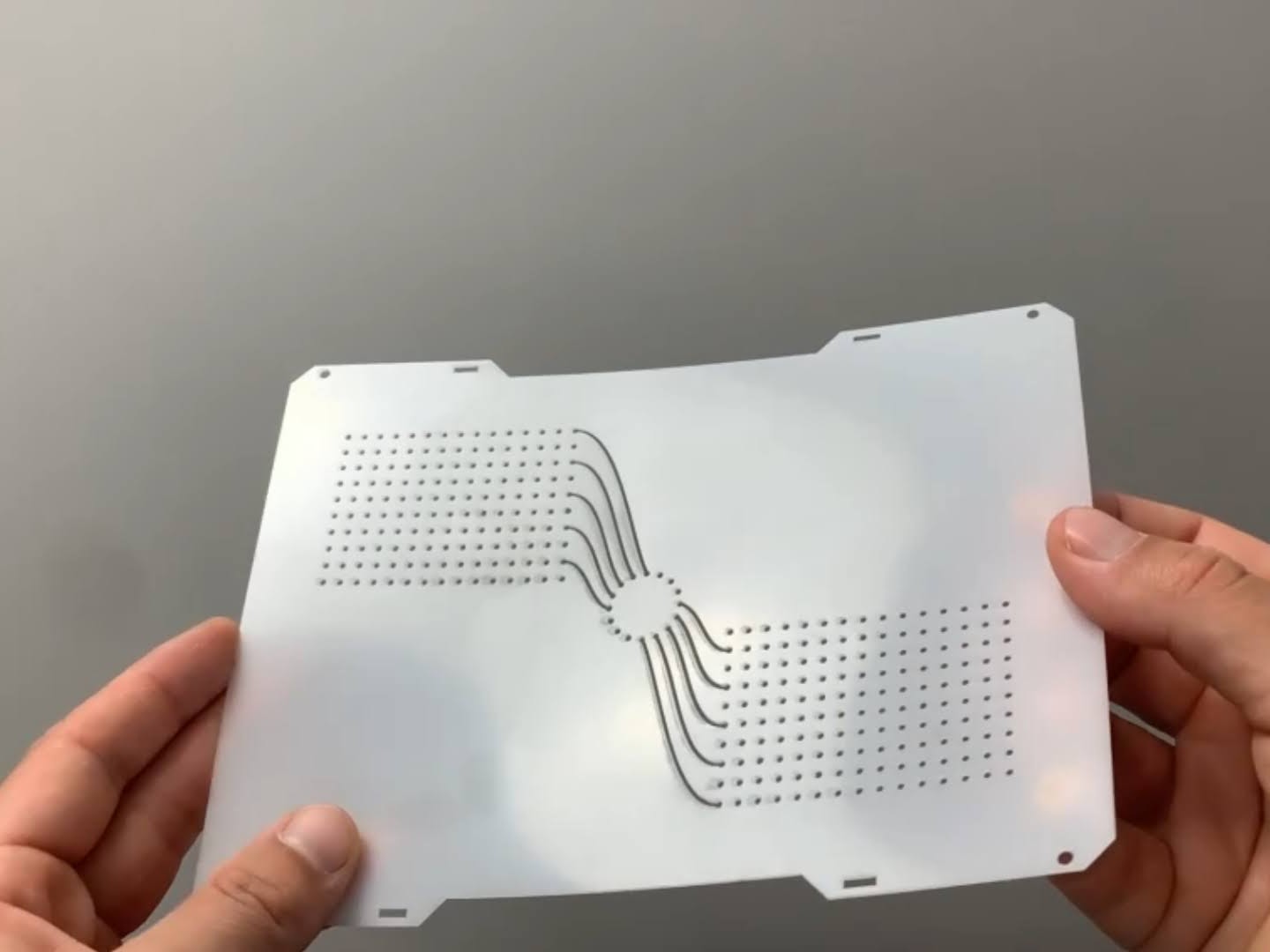

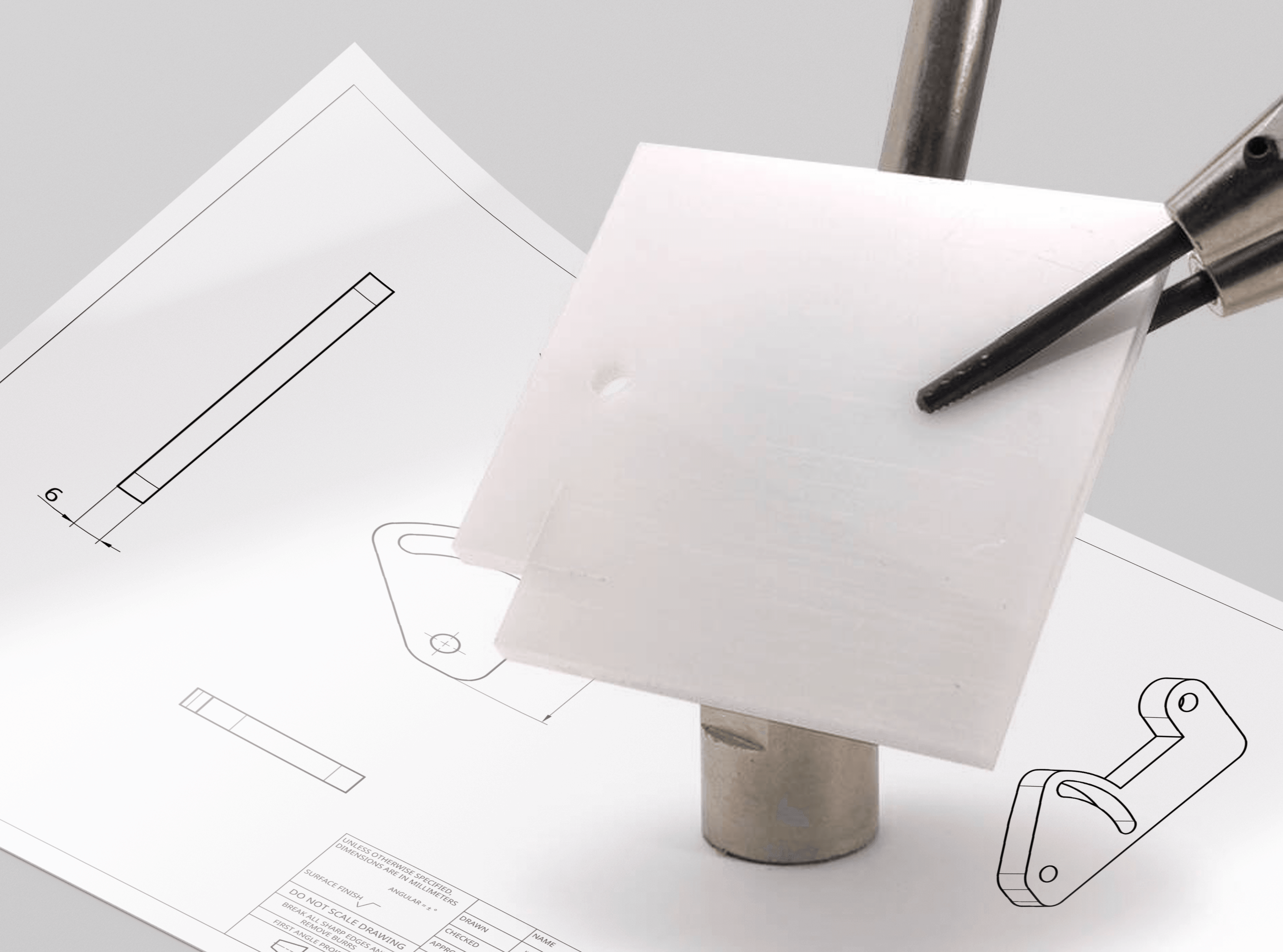

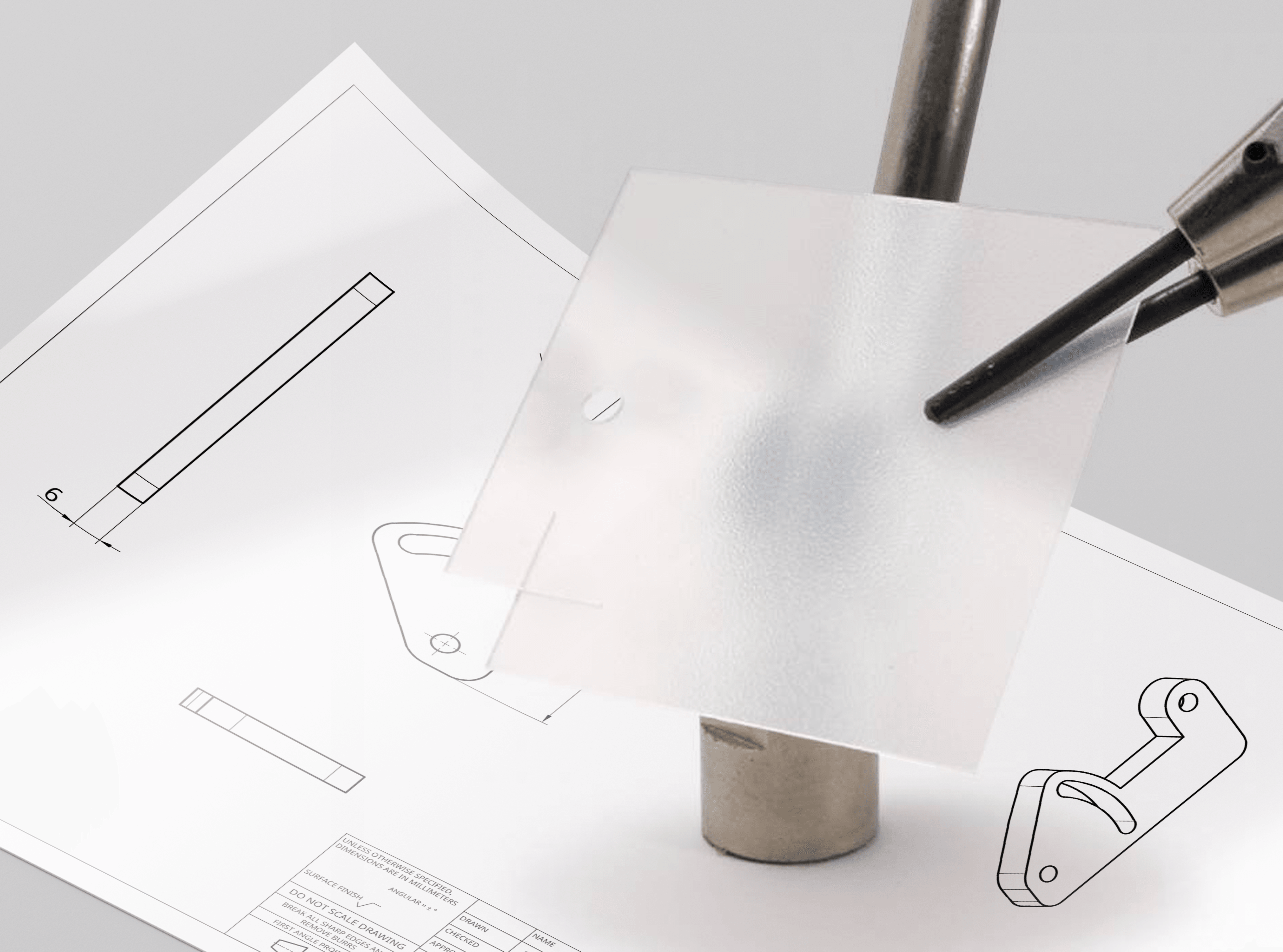

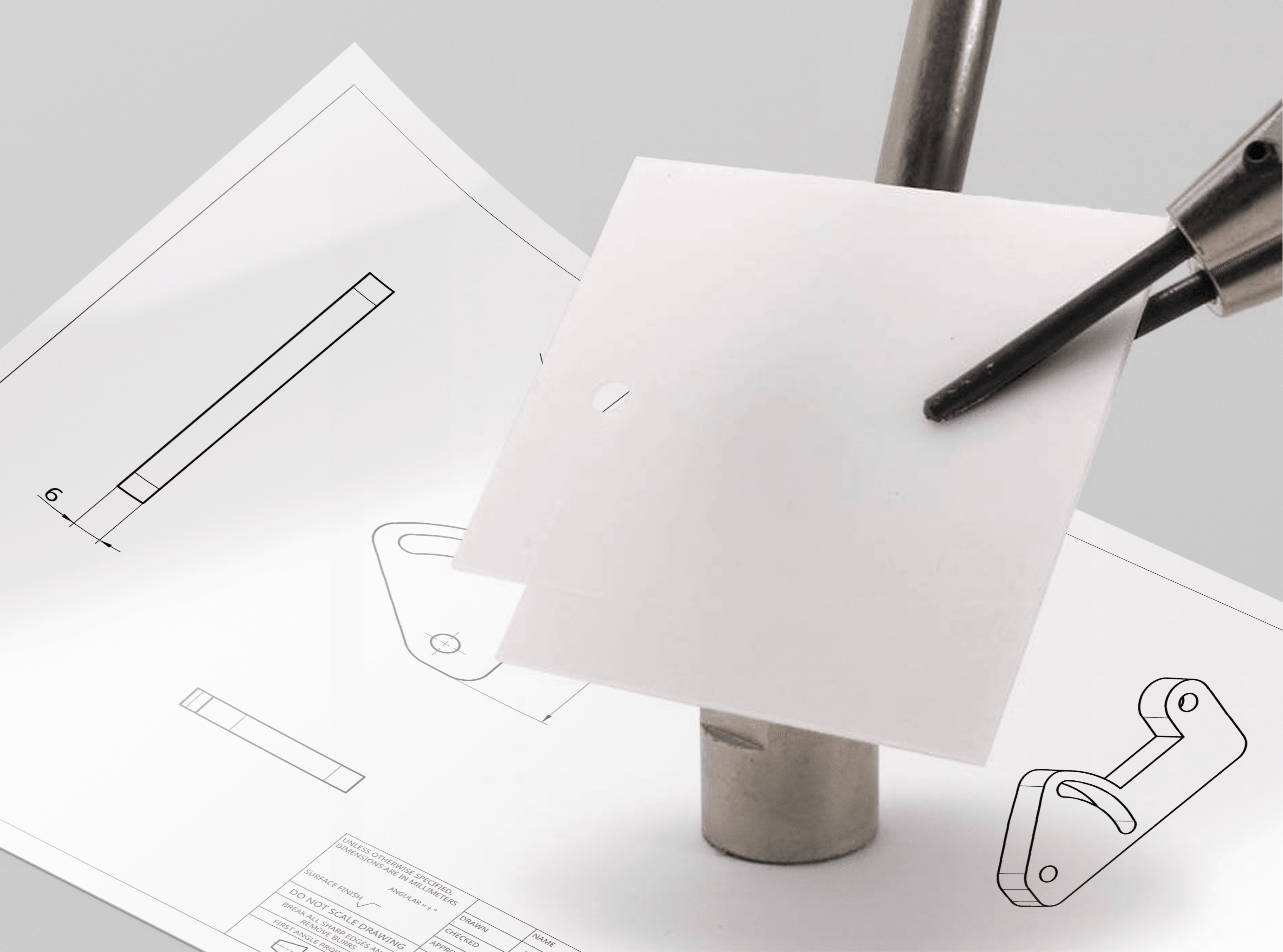

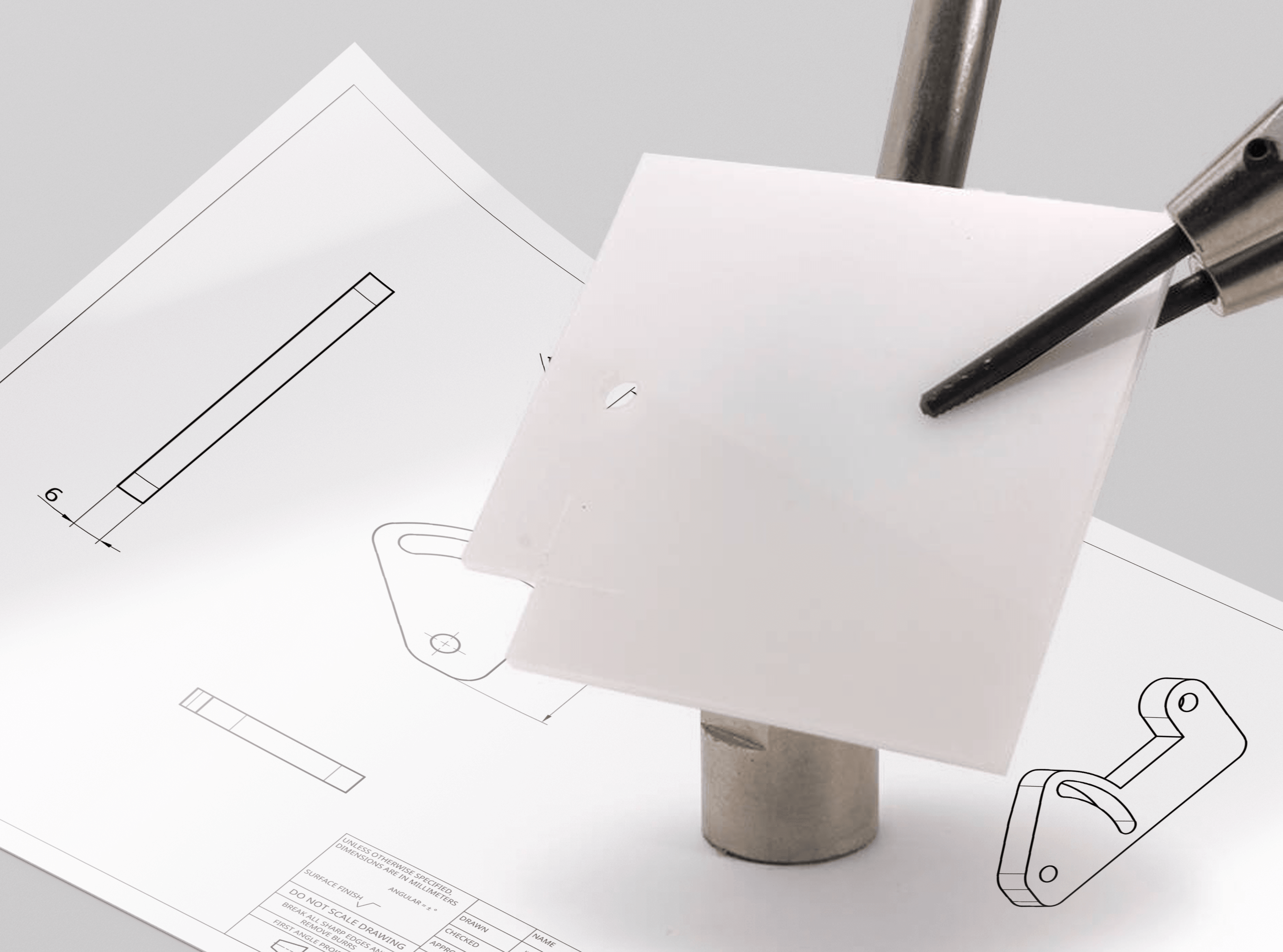

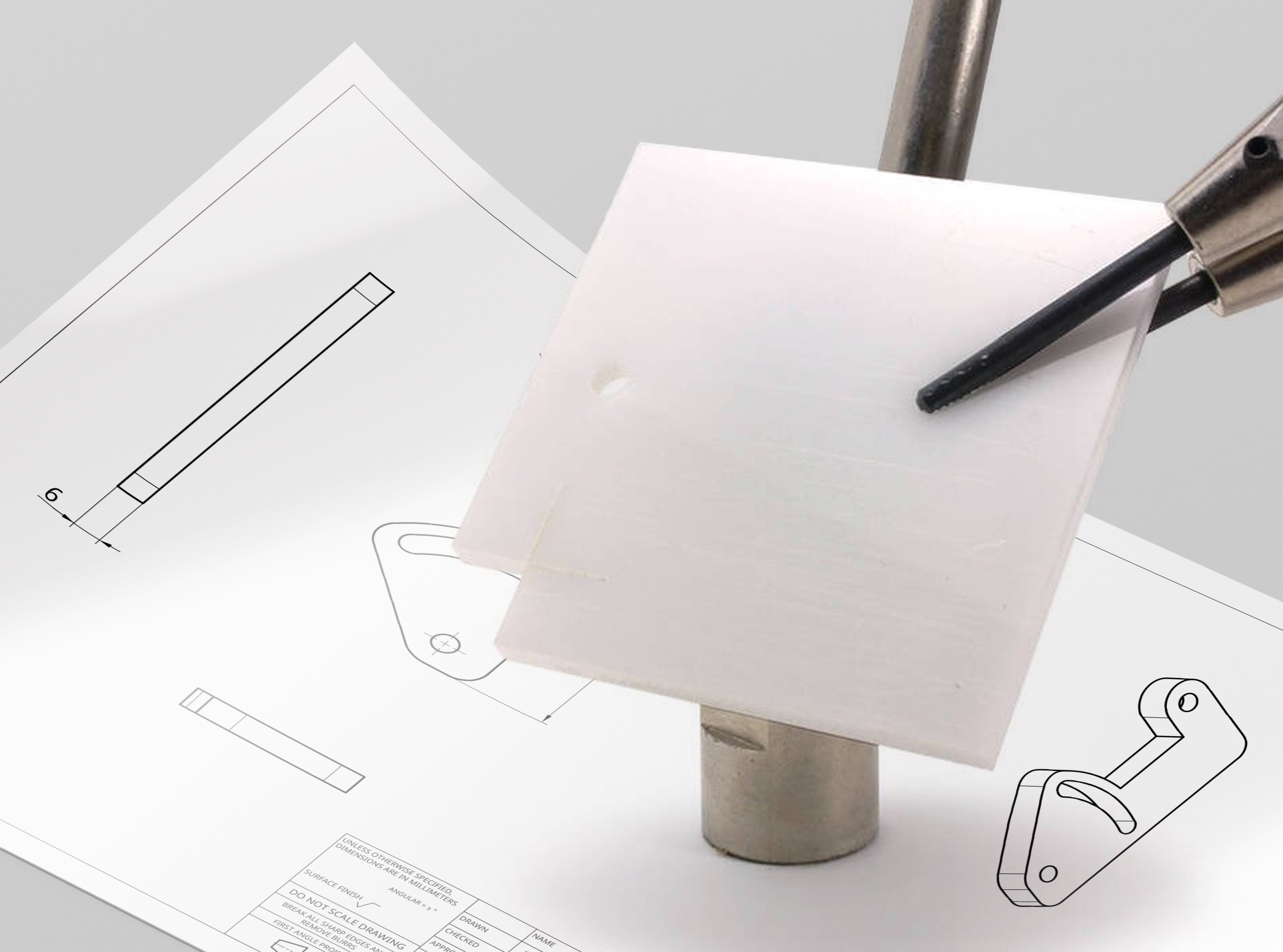

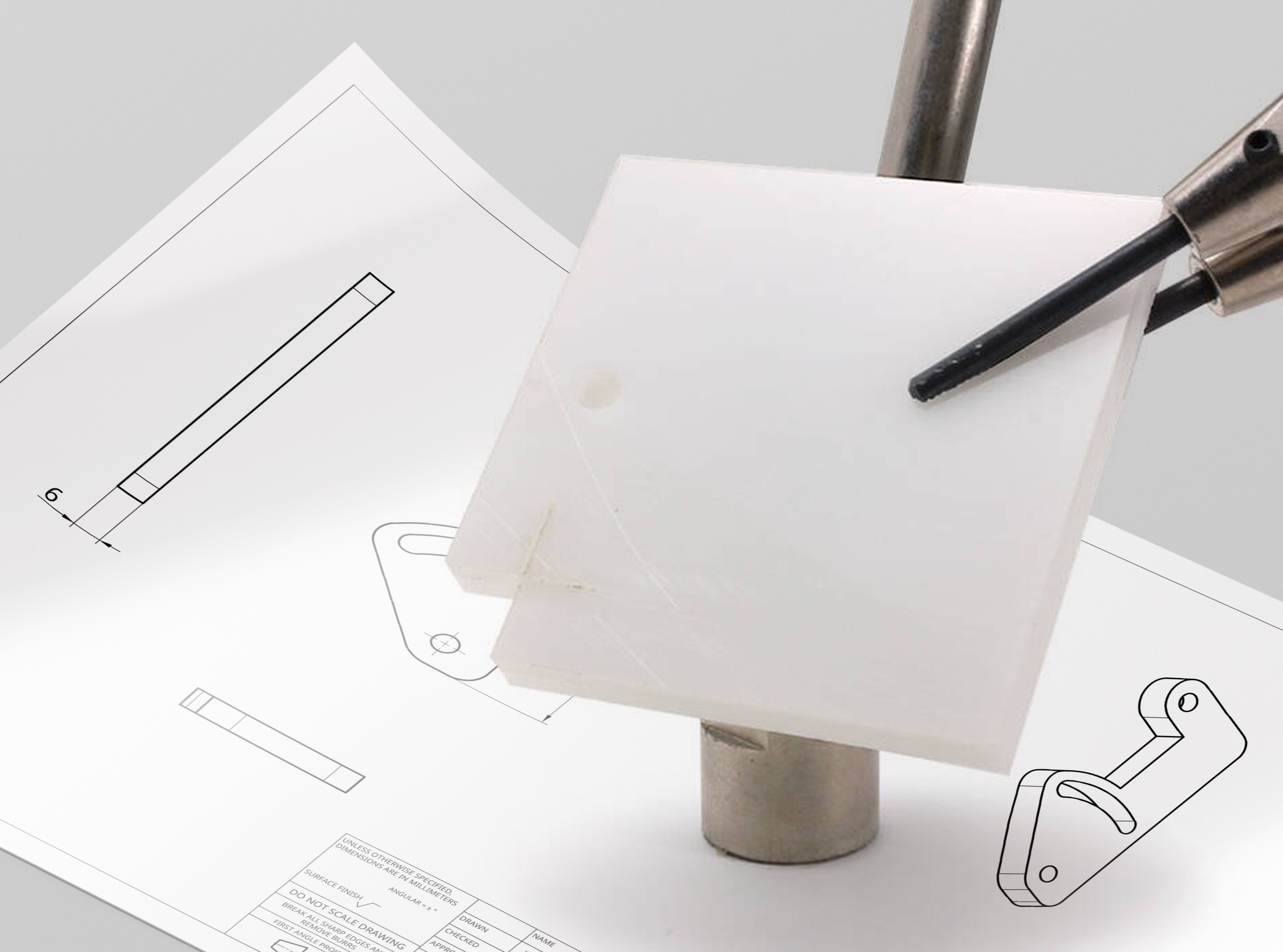

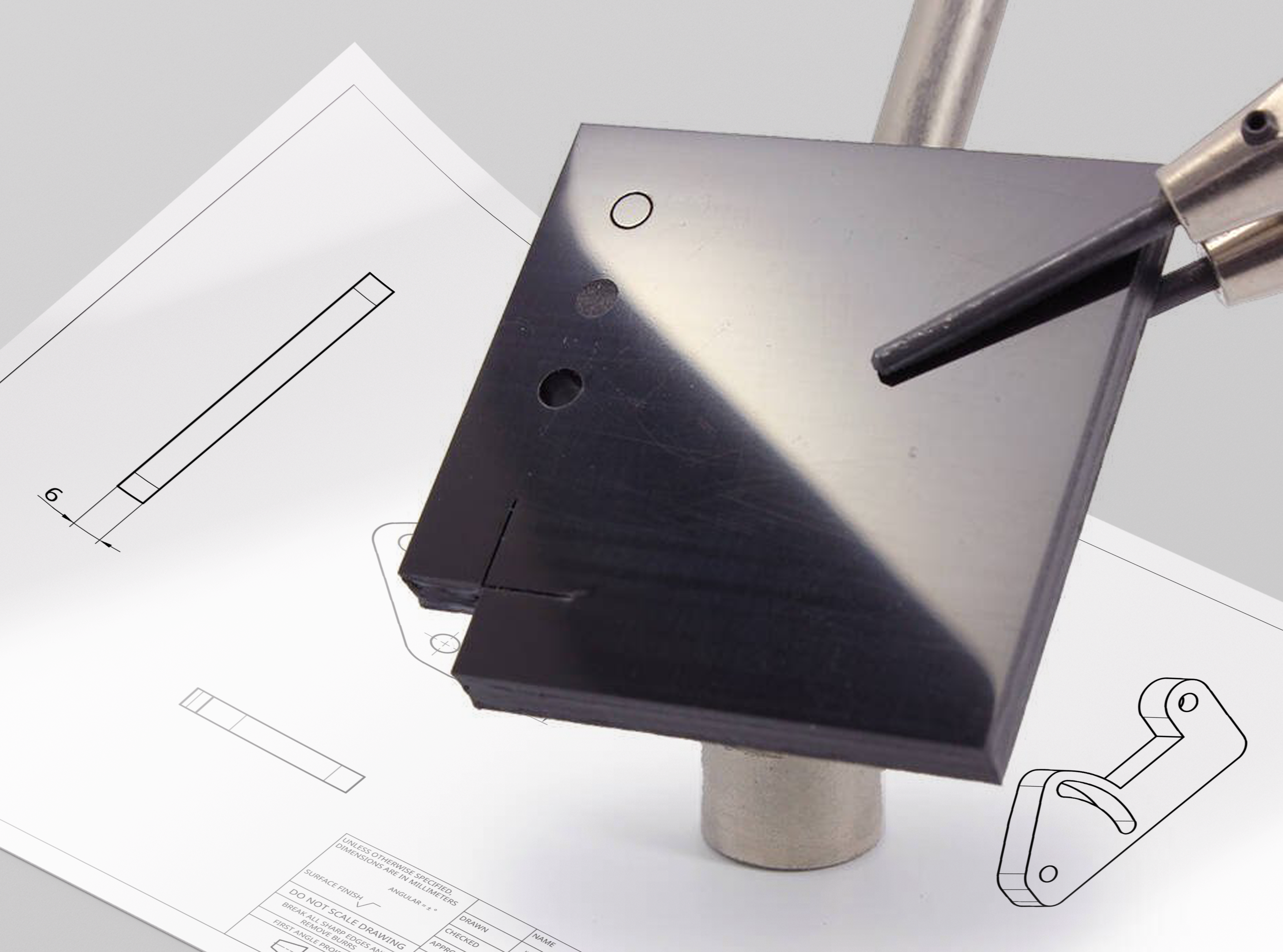

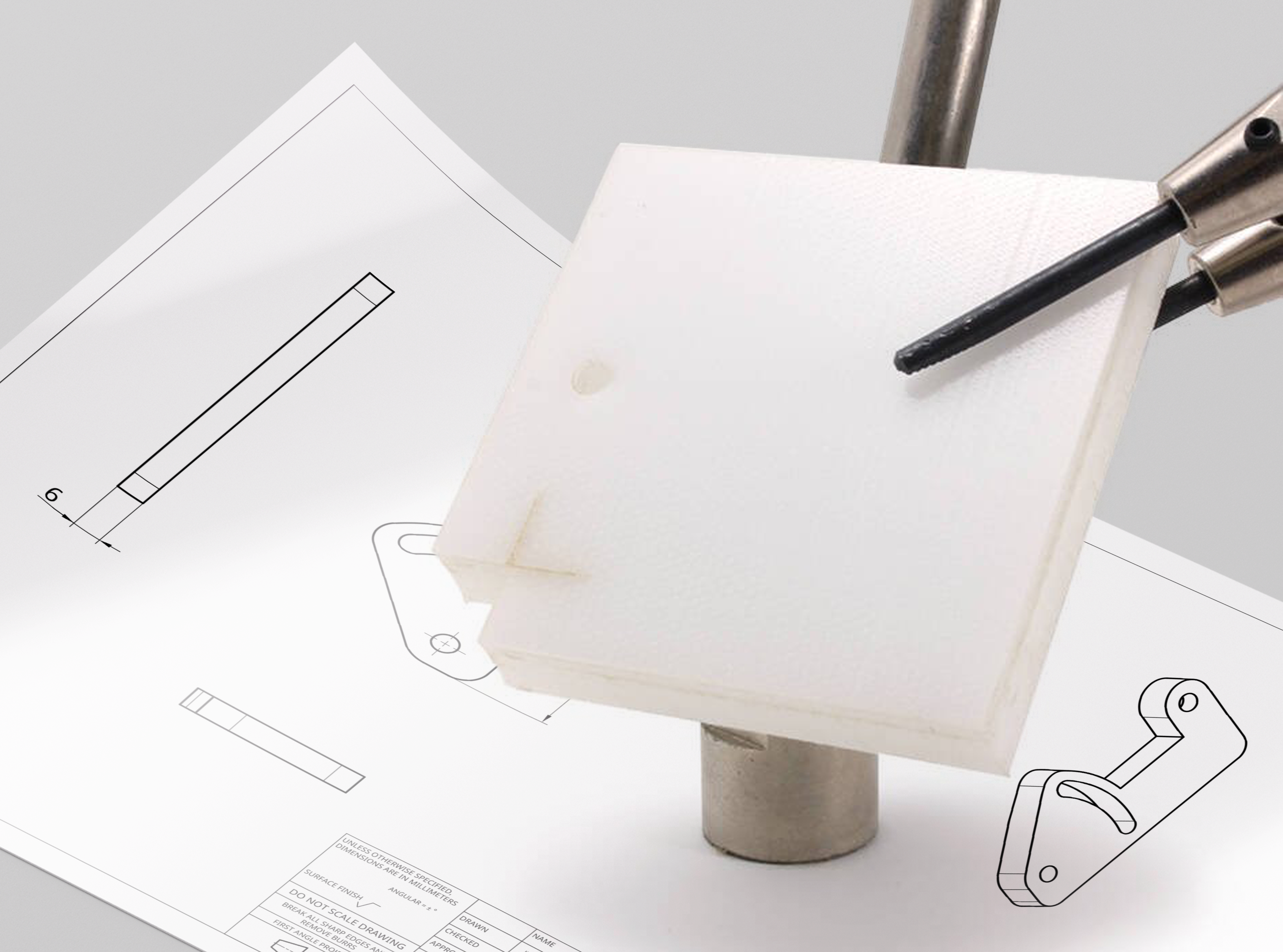

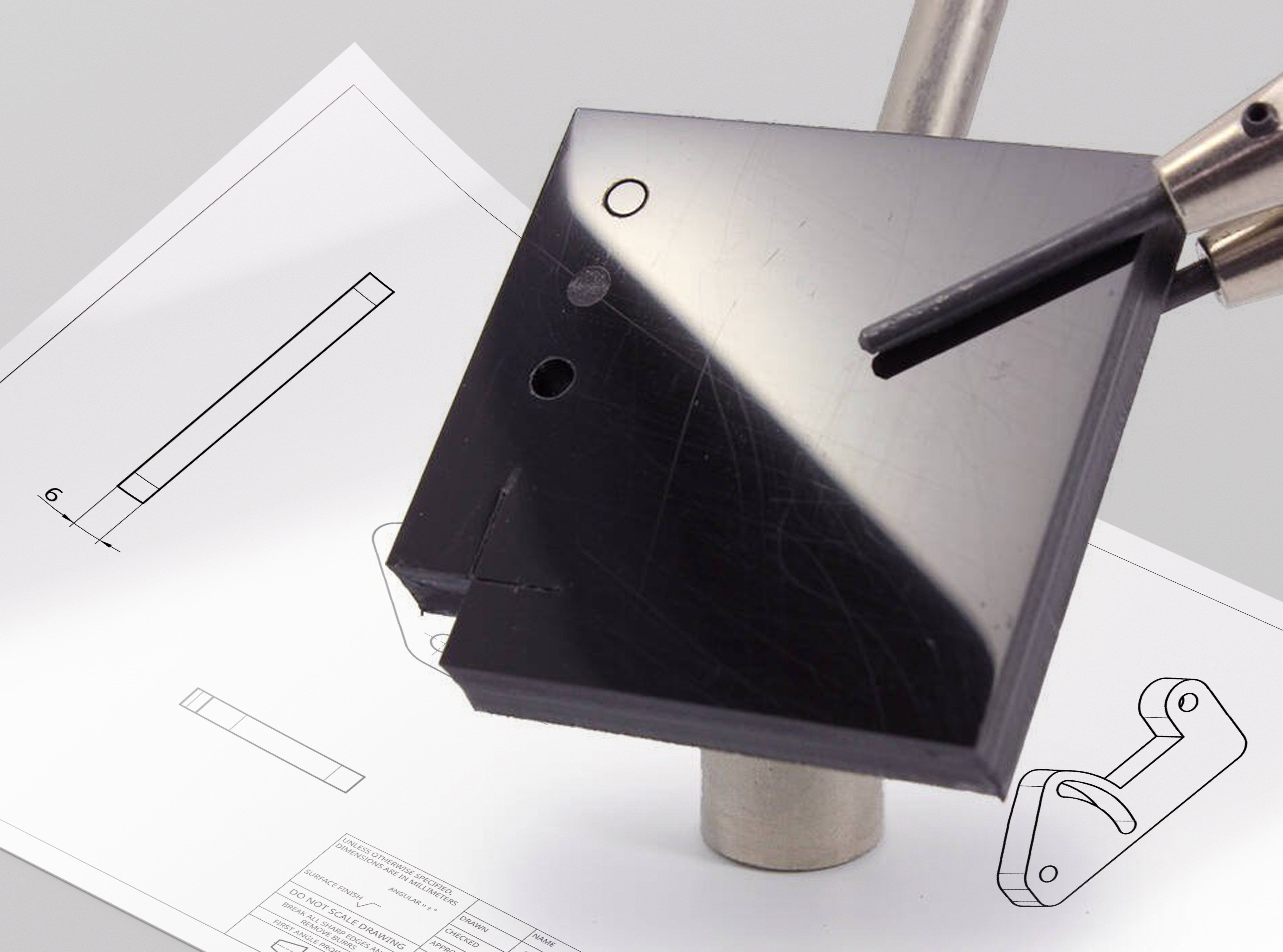

Our plates are available in black or natural. The natural variant is slightly translucent.

POM Processing

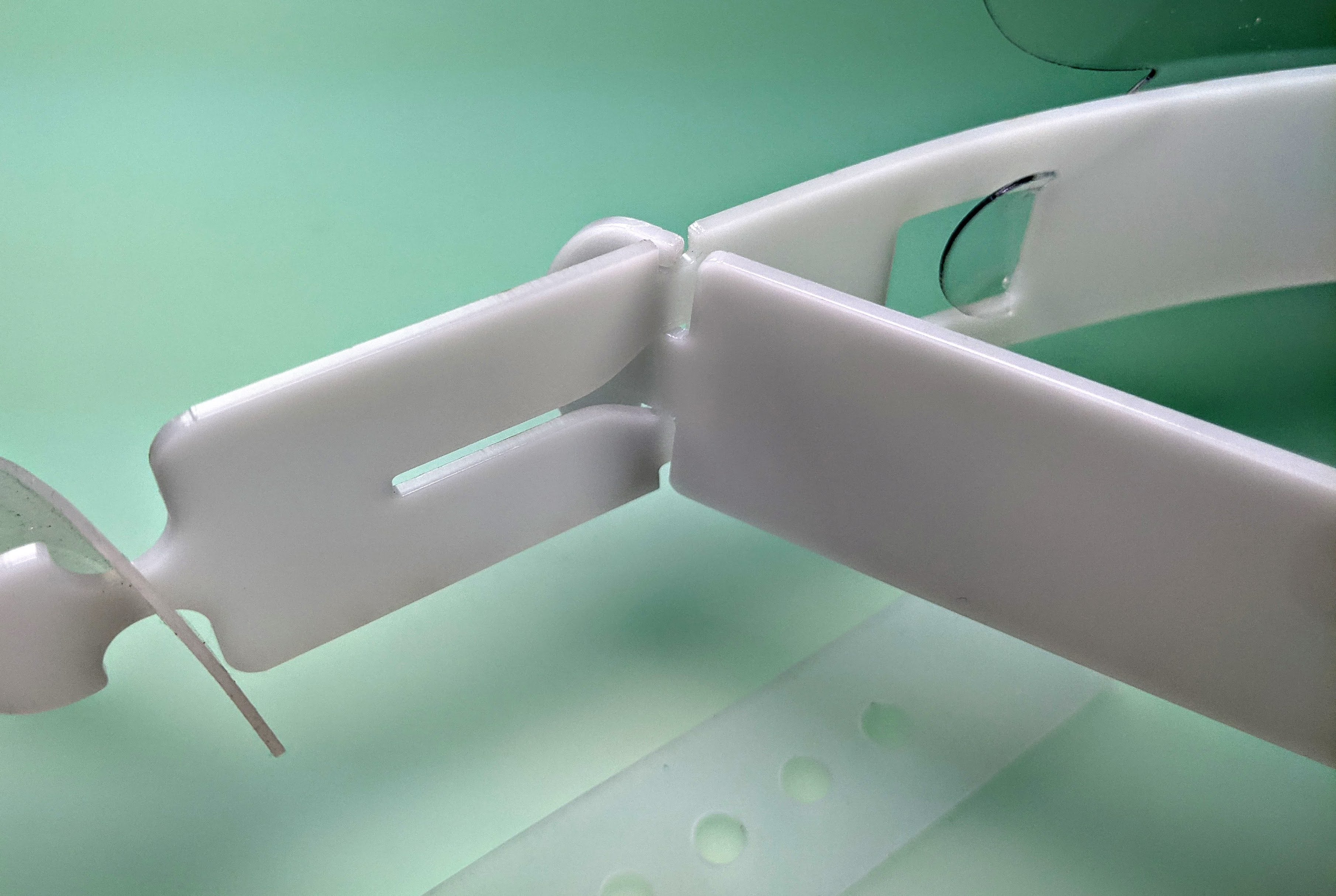

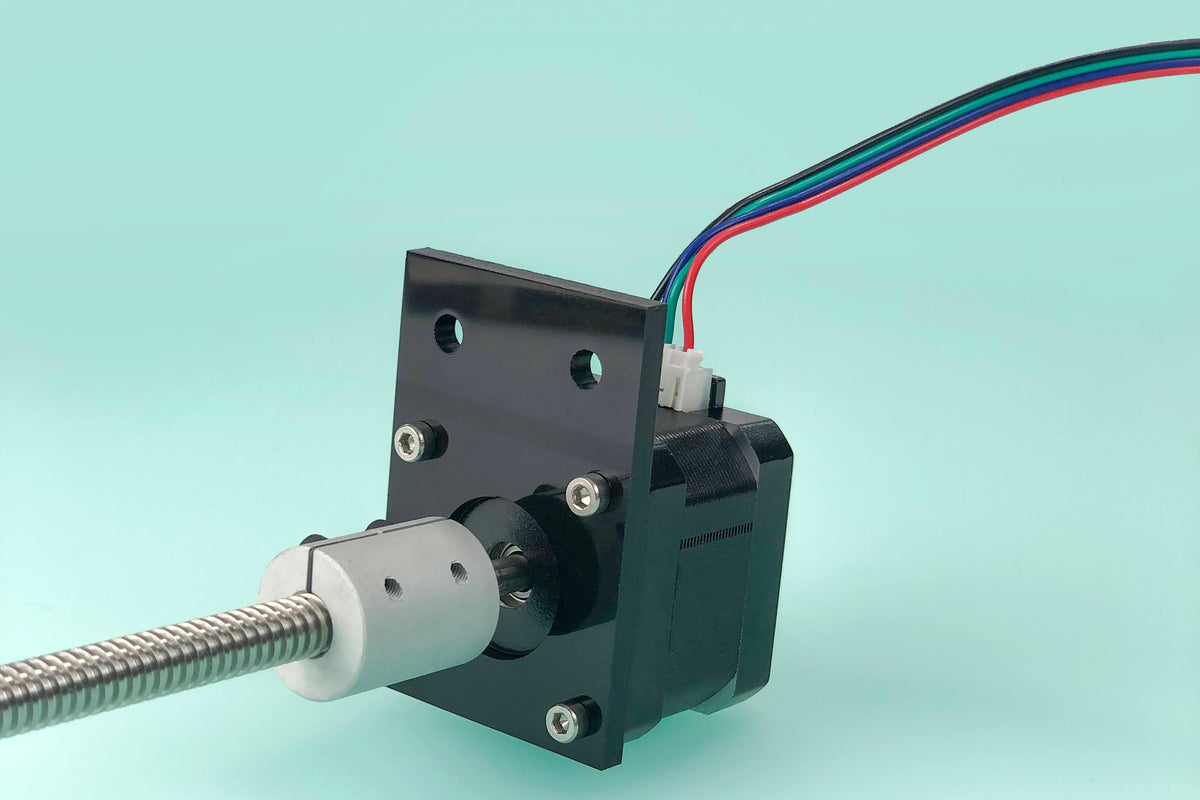

After lasering, parts can be machined (drilling, milling). If required, we can countersink holes and tap threads in POM.

POM can hardly be glued and painted. The surface is somewhat waxy and there are virtually no adhesives that adhere well. Various adhesive films do adhere well, however.

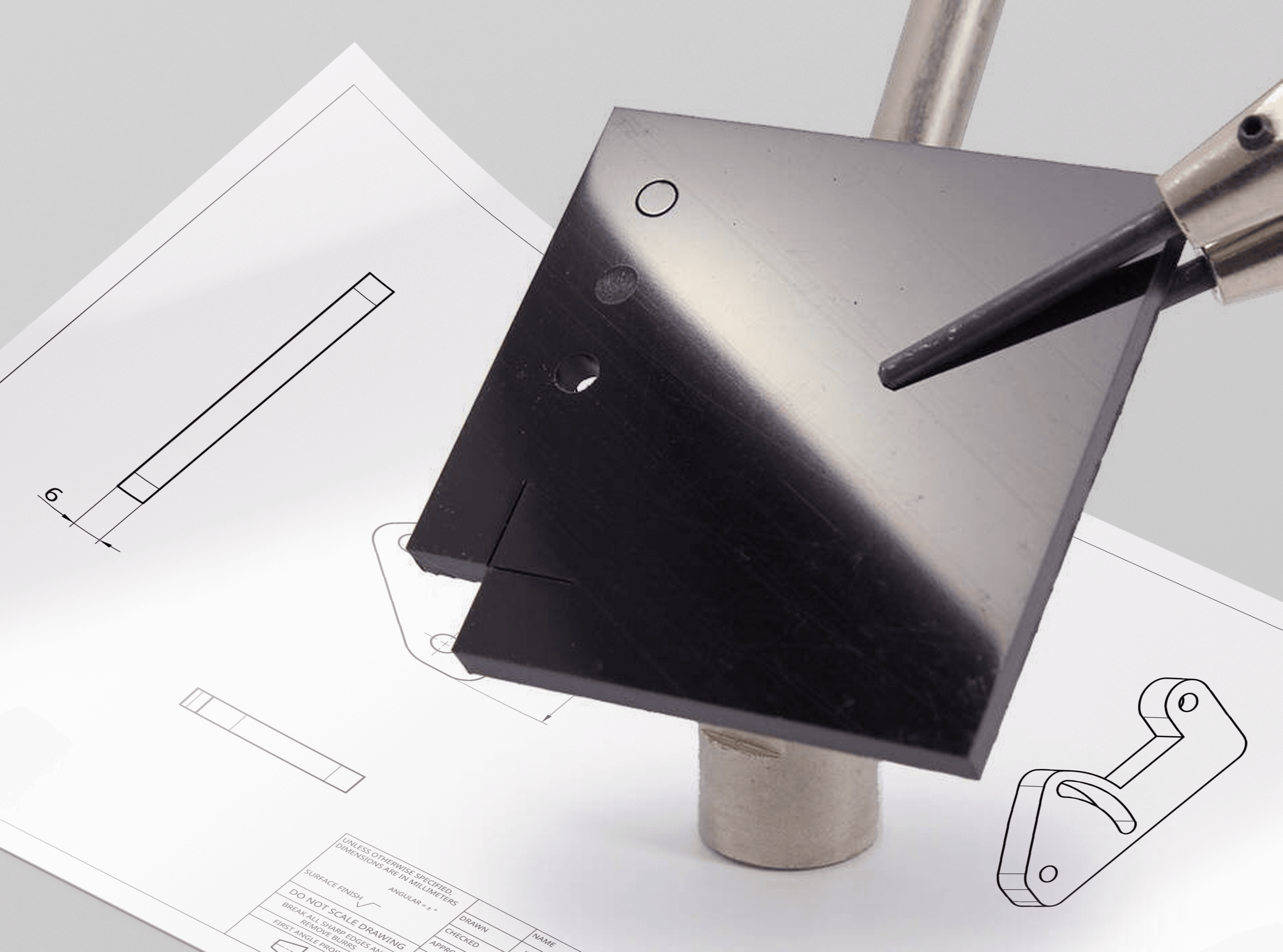

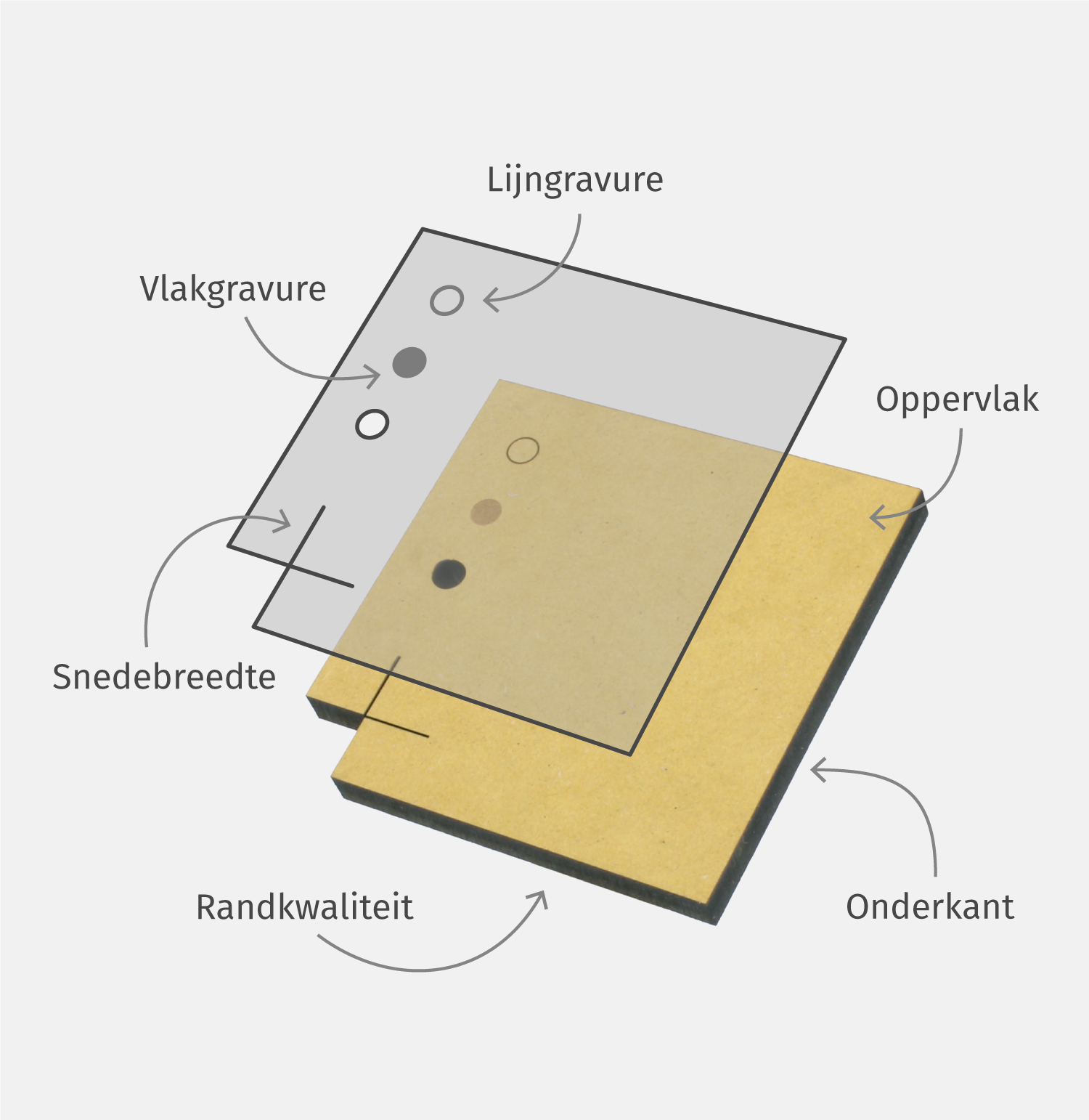

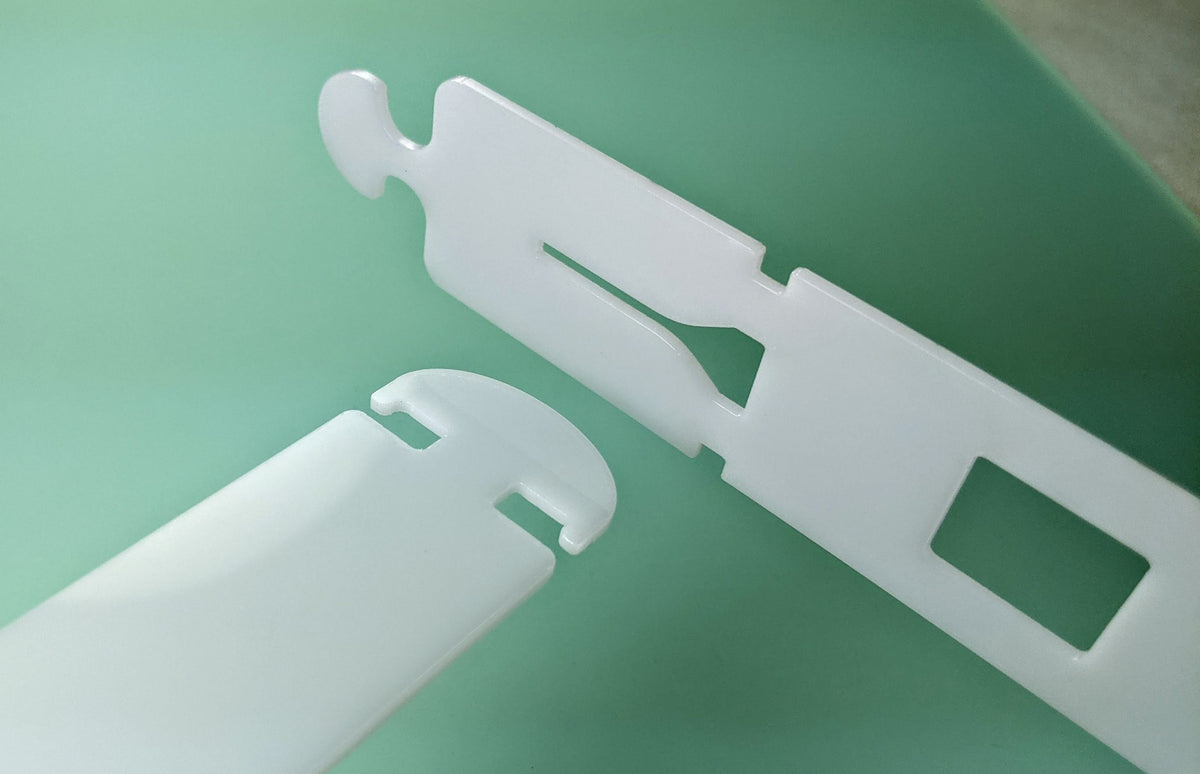

Edge quality of laser-cut POM

The laser cut in POM is neat and does not discolor. On thicker sheets (>6 mm), a small melting edge may occur on the underside of the sheet. This can be removed with a deburring knife or by sanding. The top side of the cut is clean and sharp.

If you prefer not to have to do any post-processing, you can also opt for protective film on the underside when ordering. You will then receive the parts with foil, and after removal the melting edge is also gone because it remains on the foil.

Applications of POM/polyacetal

Gears, plain bearings, housing parts, spring (compliant) mechanisms, rings, seals, Insulators, mounting plates, picks, keyboards, etc.

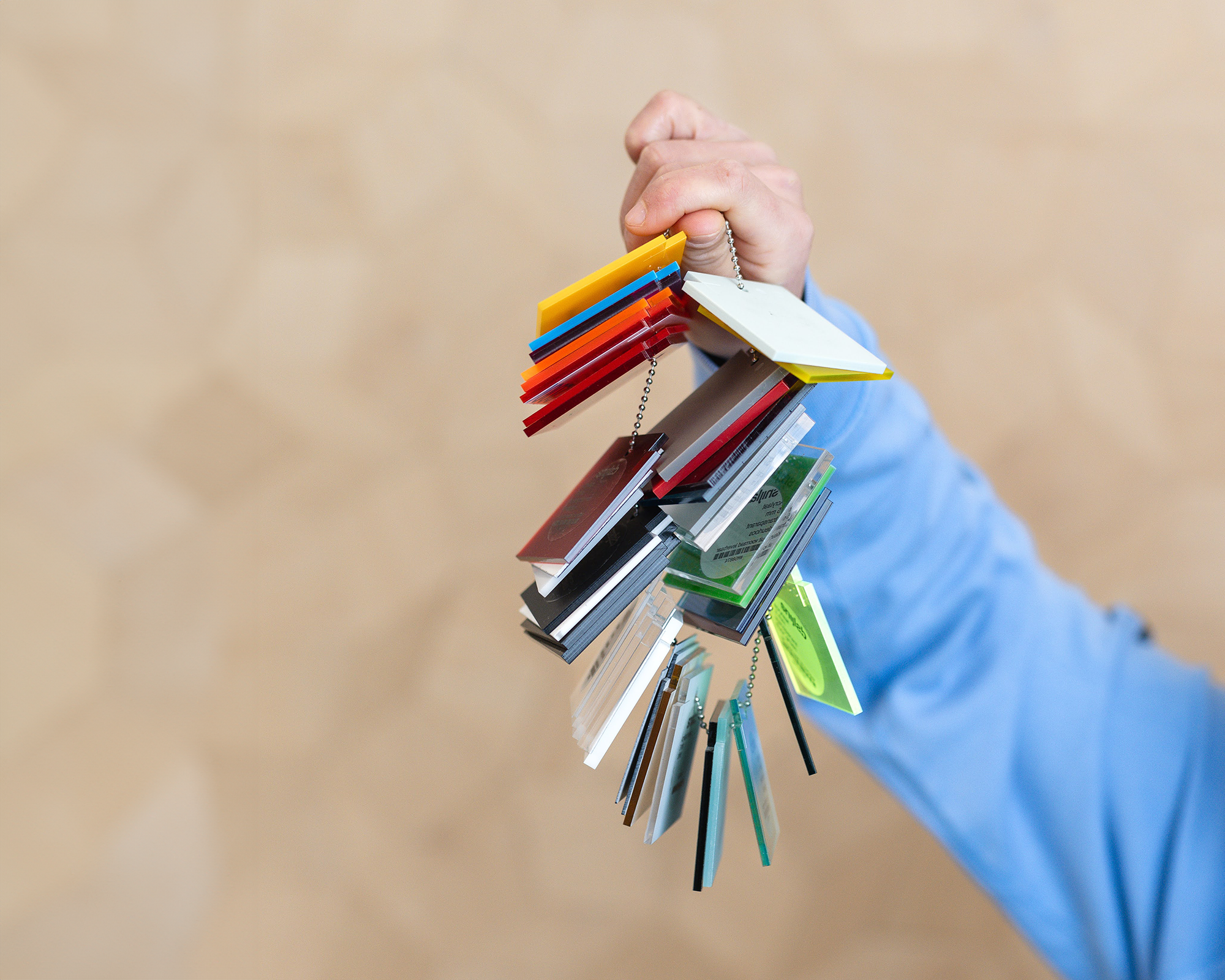

See POM (polyacetal) In real life, order a sample

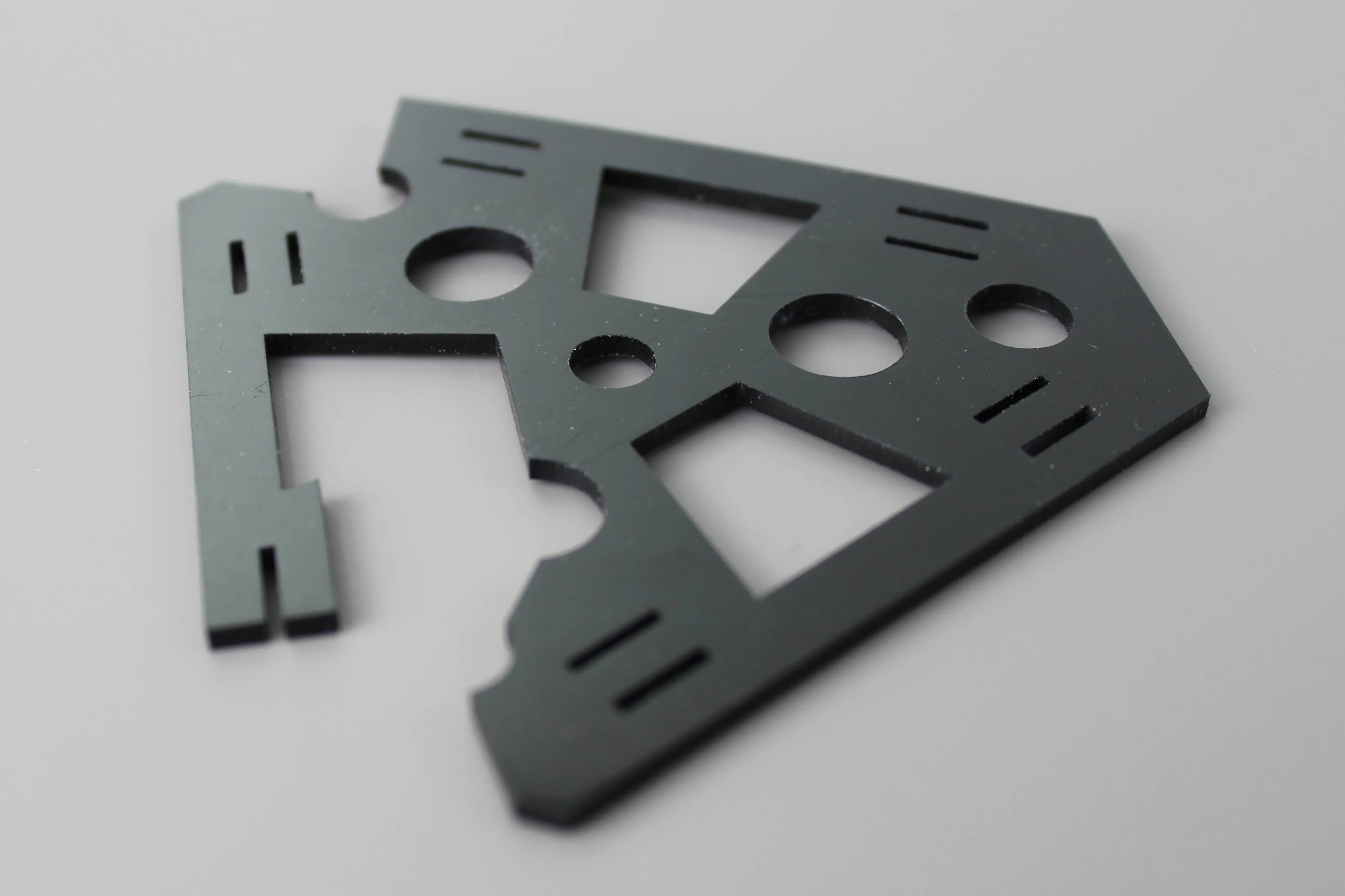

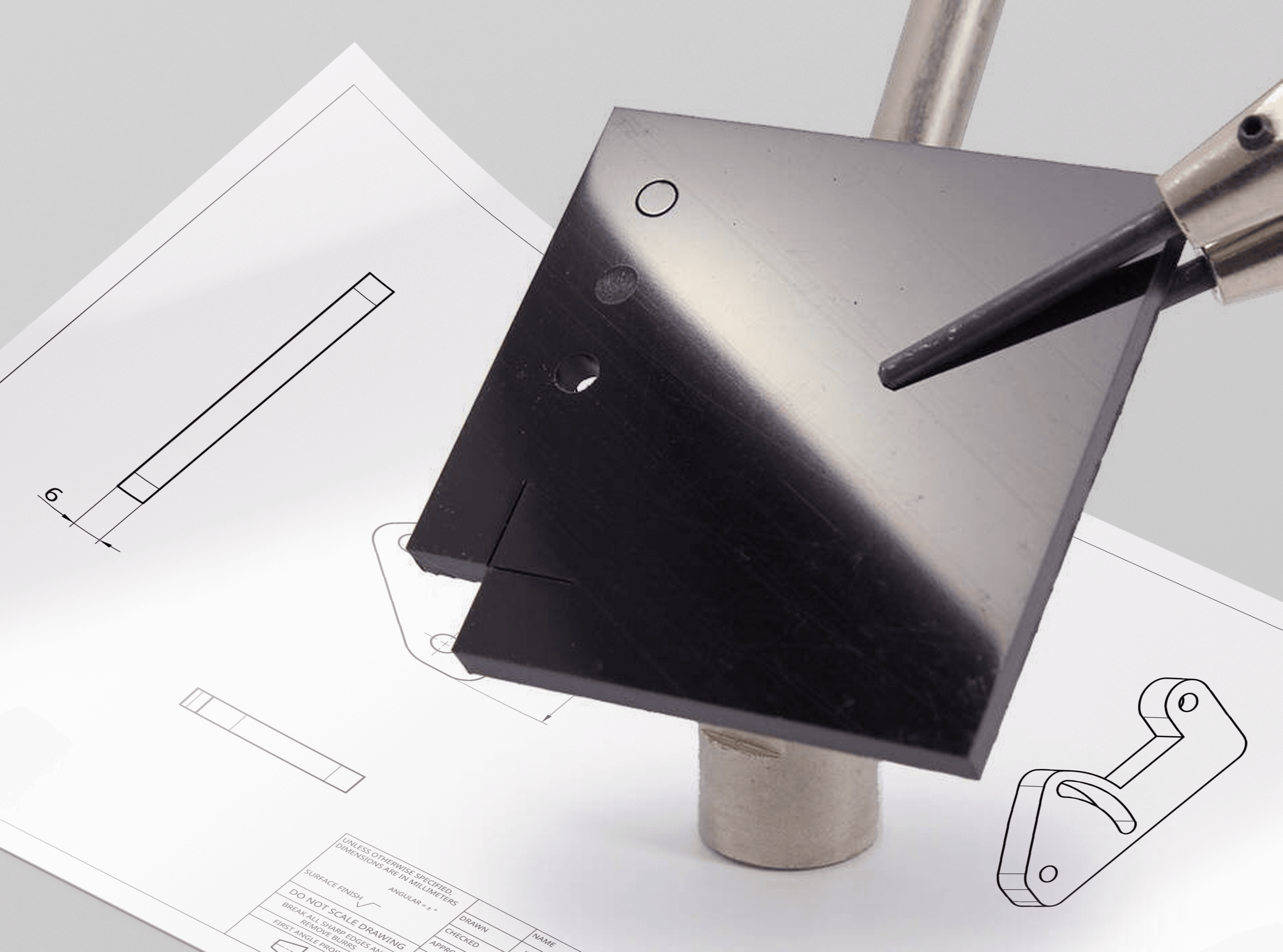

To the samplesExamples of laser cut POM (polyacetal)

Still a different material?

Related materials

Vergelijkbaar met POM (polyacetal)

| Name | Thickness | Color | Max. size |

|---|

The advantages of laser cutting POM (polyacetal)

By POM (polyacetal)laser cutting, you can create complex designs with little effort and high quality. And that can be at any stage of production; research, prototyping, (on-demand) production or volume production. Laser cutting offers a range of advantages for machining POM (polyacetal) including precision, speed, low cost and no minimum order.

How does laser cutting work?

Laser cutting and engraving order online. Create an account and upload your drawing. Prices are calculated instantly, and quotes you download yourself.

We are here for you if you have any questions.

Contact us via chat, phone or mail.

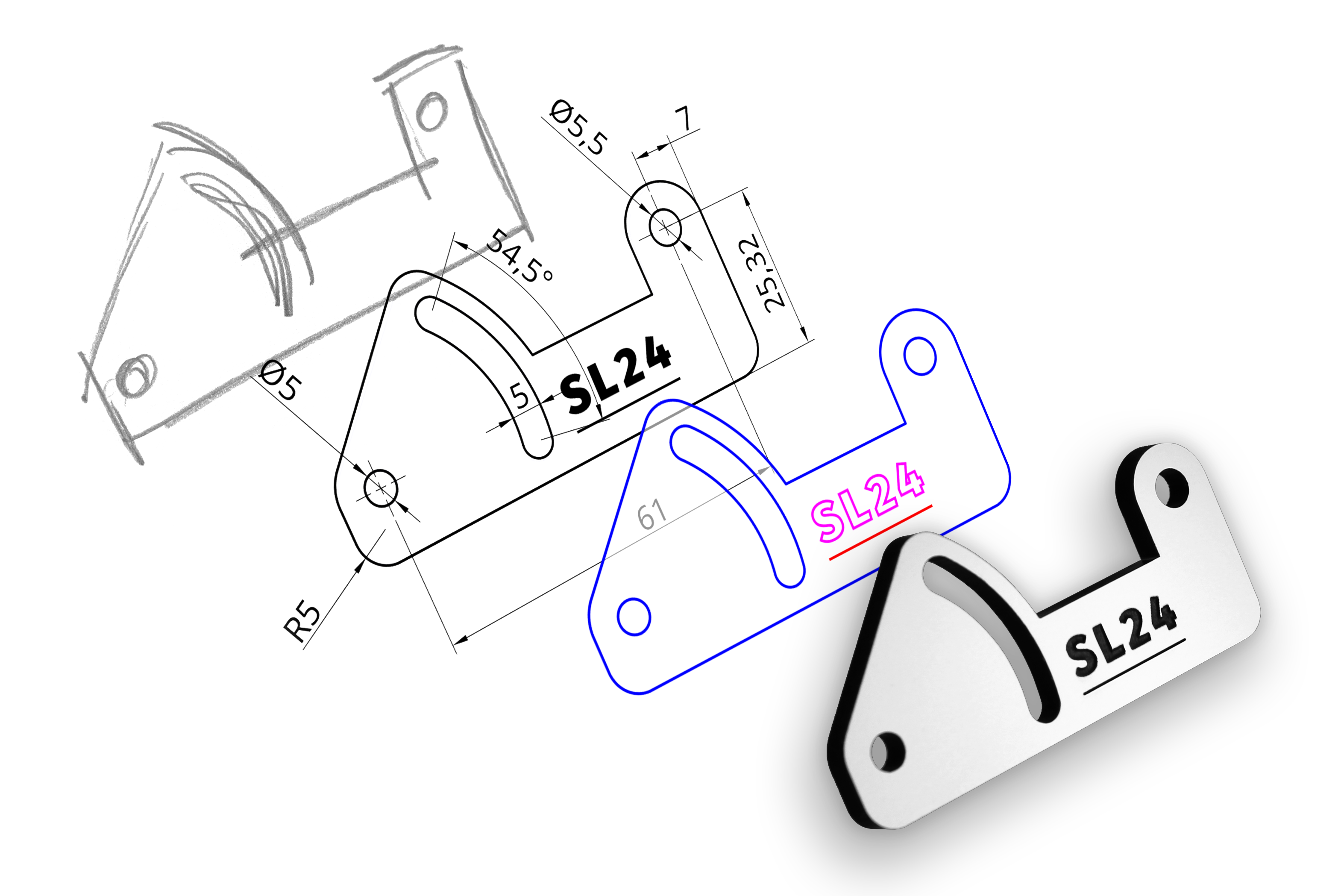

Layout drawing

- DXF, DWG, AI, PDF files

- Blue line = cutting

- Red line = line engraving

- Magenta line = plane engraving

Choose a delivery time

- Speed (ordered before 12:00 noon, delivered tomorrow)

- Fast (2 business days

- Standard (4 business days)

- Expensive (13 business days)

Secure online payment

How do you order laser cutting?

Upload your drawing, choose a material and delivery time and we will make it for you.

Try it now, uploading is free!

What does POM (polyacetal) laser cutting cost?

The price for laser cutting your design is automatically calculated in the shopping cart. Upload your drawing, choose a material and delivery time, and see the price instantly.

1 medium design ≈ €24.99*

1 full sheet ≈ €65.43*

1000 small parts ≈ €0.05/pc.*

*These are indicative prices incl. btw to give you an idea. Once you upload a design upload you will see the exact price.

Want to see materials in real life?

Order one material sample chain. Samples provide a representative picture of the quality Snijlab delivers. This also allows you to compare materials so that you can make a good design decision.

To the sample chains