Discover Cutting Lab's cutting-edge technology that expands the boundaries of digital manufacturing. We strive to make the possibilities of laser cutting accessible to engineers, designers and makers. Discover our innovative machines for high-quality, custom-made parts. Together with us, continue to challenge the boundaries of digital manufacturing.

CleanCut

Also known as AutoSPOT. This machine makes it possible to laser cut without underbed which normally causes weld spots. As a result, the parts autoSPOT cuts are free of stains and tarnish, providing much higher visual quality and saving finishing time. In addition, this machine operates fully automatically and can make many thousands of parts per day unattended. It includes an RF laser with a peak power of 440W. Linear motors on the X and Y axes provide micrometer precision and high acceleration.

Snijlab developed this technology in-house with R&D grant from the RFO. See her in action

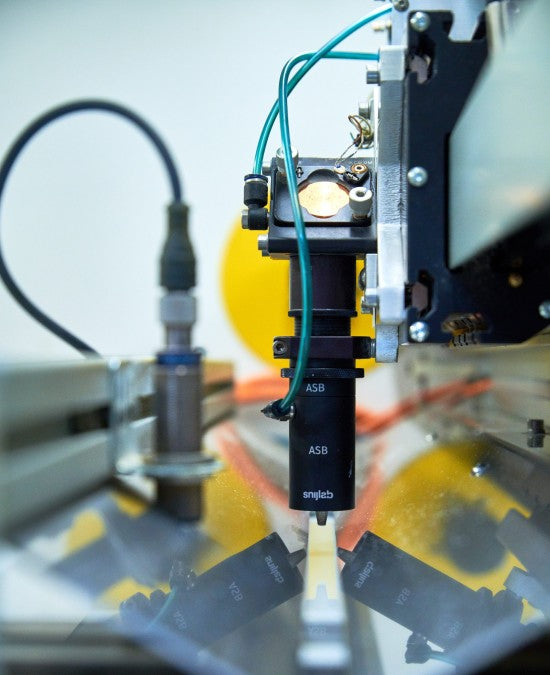

DuoNozzle

At snijlab we like sharp cuts and engravings without smoke stains. However, a nozzle for sharp cuts produces a lot of smoke deposits when engraving. And a good engraving nozzle, you understand, gives poor cutting results.

Most laser cutting machines on the market make a compromise in this, yielding mediocre quality. Or it is necessary to change nozzles during operations, which is inefficient and can introduce errors. Our duoNozzles completely solve this problem, offering optimal results in both cutting and engraving, without adding much extra weight or complexity.

autoLoad

To save operator time and thus reduce costs, we developed a system to automatically load sheet materials into the lasers.

This machine, also known internally as the sheet-o-size, can pick up and load almost all of our material types. From smooth plastics to soft foam. The sheets are automatically measured and validated so that it is possible to work with stacks of sheets of mixed sizes.

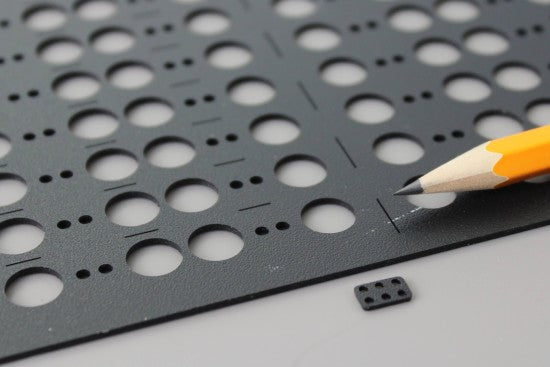

autoUnload

We like our people to be doing things that are as human as possible, and machines to do what is repetitive.

This innovation automatically separates the cut part and the residual sheet. This makes it possible to perform volume production efficiently, and we ensure that you, the customer, neatly receive only the parts without residual material.

Dynamic autoFocus

For good cutting and engraving quality, it is essential that the laser head be exactly the right distance from the material. A deviation of 0.2mm already gives visibly worse results.

For virtually all laser cutters on the market (muv. steel lasers), the operator must manually adjust the focus distance at the beginning of a production run. In practice, however, this produces only mediocre quality. This is because sheet materials are not the same thickness everywhere and rarely lie 100% flat. The laser then gets "out of focus" which causes a wider cut, loss of detail and unnecessary smoke deposits.

We developed a dynamic autofocus for this purpose. While cutting, a sensor measures the distance and continuously corrects the machine. This allows for the thinnest cutting lines and sharp engravings at all times and ensures superior quality parts.

ordBase

OrdBase is Snijlab 's advanced manufacturing software that allows us to accurately and efficiently produce thousands of unique parts per day. This state-of-the-art MRP system tracks every detail of the production process, from who is working on what to what part is where, so our team can deliver your job on time, every time. ordBase seamlessly connects our online ordering system to our laser cutting machines, streamlining the production process and ensuring you receive the highest quality customization possible.