Do you need a part or product but do not want to mass produce it? For example, because you make frequent updates to your product, because you want to keep low stock or simply because you only produce when you have sold?

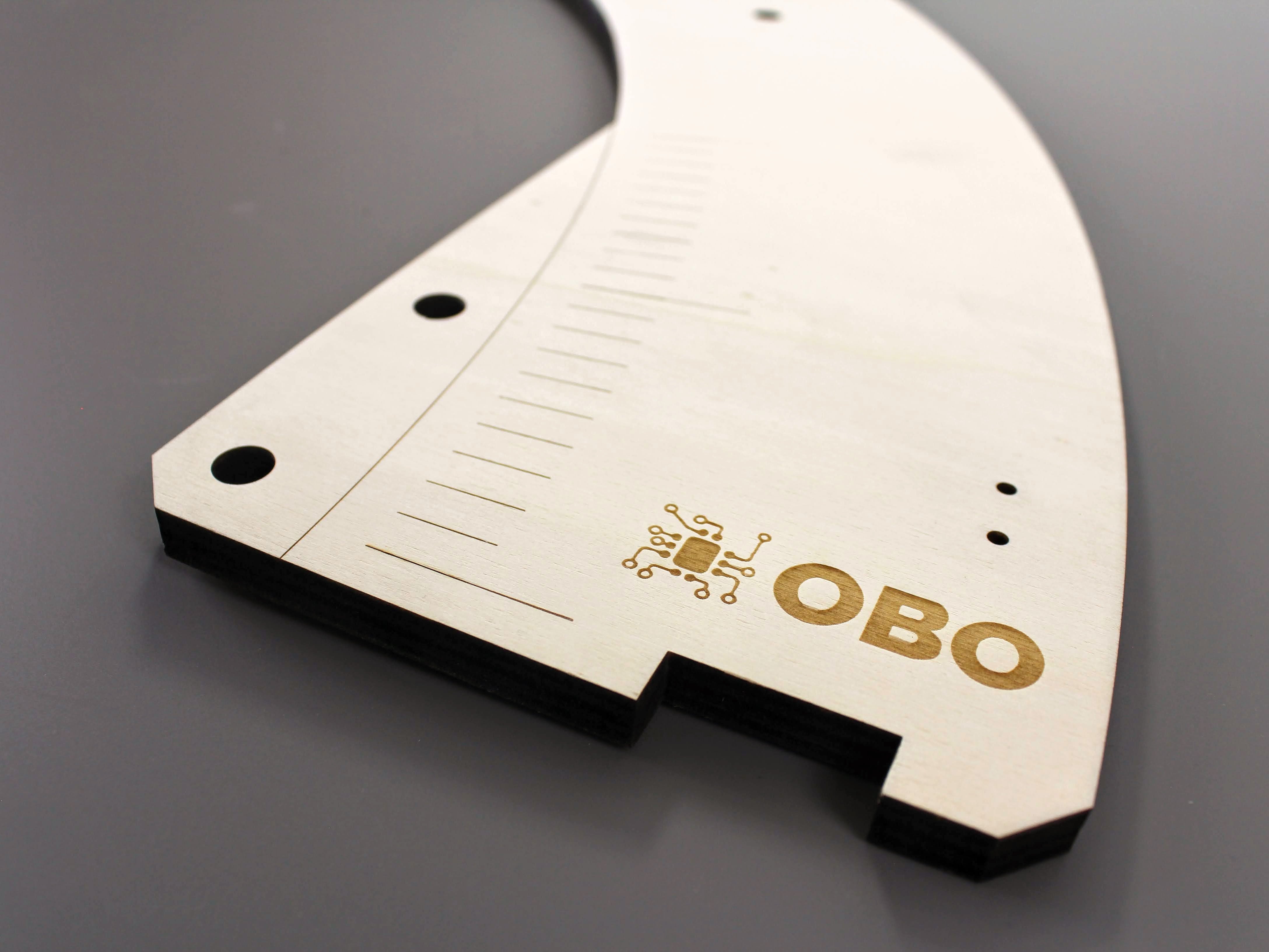

For both technical parts and products that you sell yourself through your web shop, laser cutting gives you flexibility and reliability.

What is production with laser technology?

Our online laser cutting service allows you to start and manage on-demand, i.e. on demand, productions of parts you have designed.

Manufacturing on-demand (MOD) is a system where you produce when you need something, and in the quantity you need.

That sounds logical, but it's a big change from more traditional mass production where large quantities are made that are then stored until needed.

Advantages

Customers from many different industries use Snijlab to produce their products "on-demand." What they have in common is that they exploit one or more of the following advantages:

Fast to market

No lengthy decision processes and mega-orders. Those who want can have a product on the market within a few weeks

Staying flexible

Is a product selling faster or slower than anticipated? Do you want to make adjustments in the interim? No problem.

Low risk

Explore new markets without large investments.

Personalization

Customize your products by market segment or even by customer.

Customer speaking

"Thanks to their online quotation tool, as a customer you can see for yourself which design adjustments affect the price. That way you can easily touch up."

- Sander Vieveen, Alphatron Medical

. read the customer case studyWhat does a production process look like?

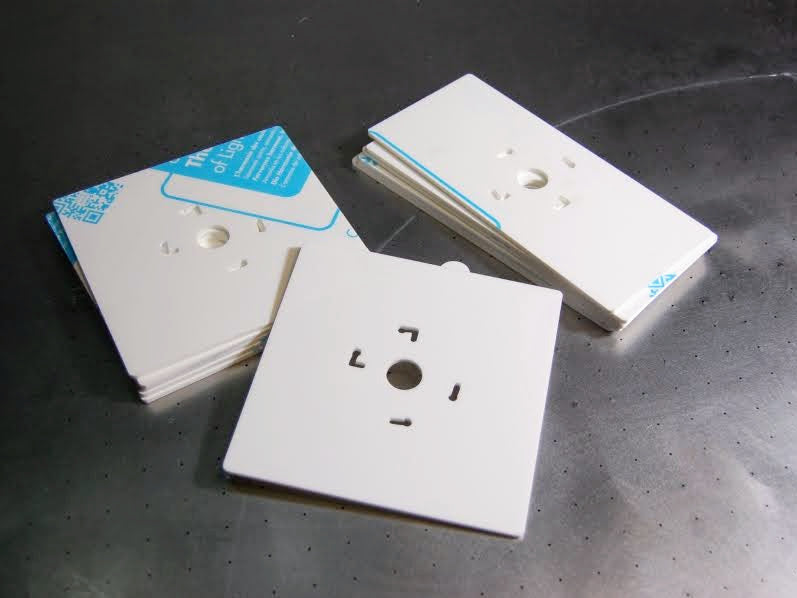

1. Prototyping

Some designs are right the first time, but most of us do a few rounds of prototyping to get the "i's" right.

Prototyping is fast and efficient through our online assumption system.

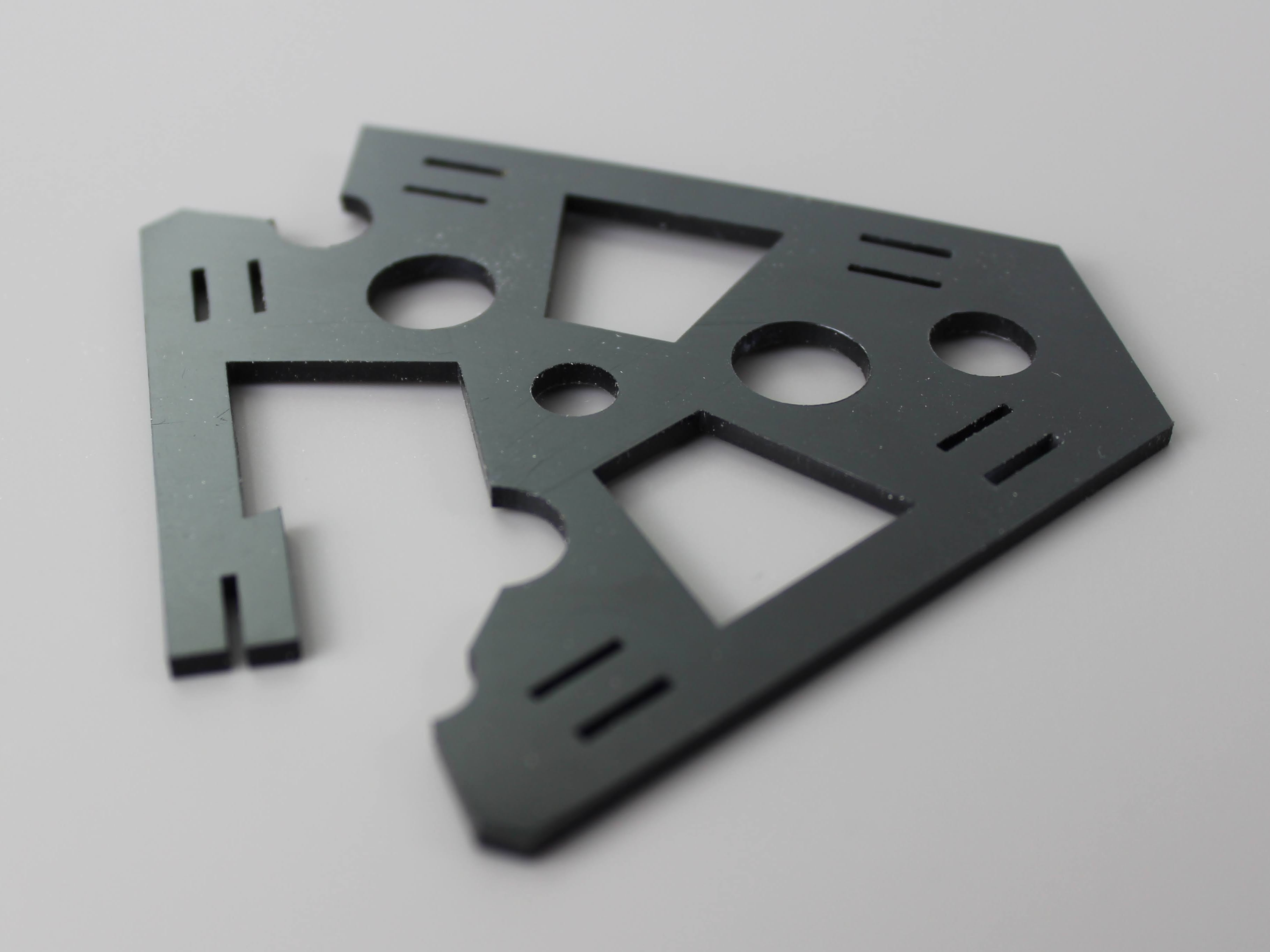

2. Optimization

If your product starts to run harder, then it's a good time to make sure we get the cost as low as possible.

We are happy to help you with advice and additional services.

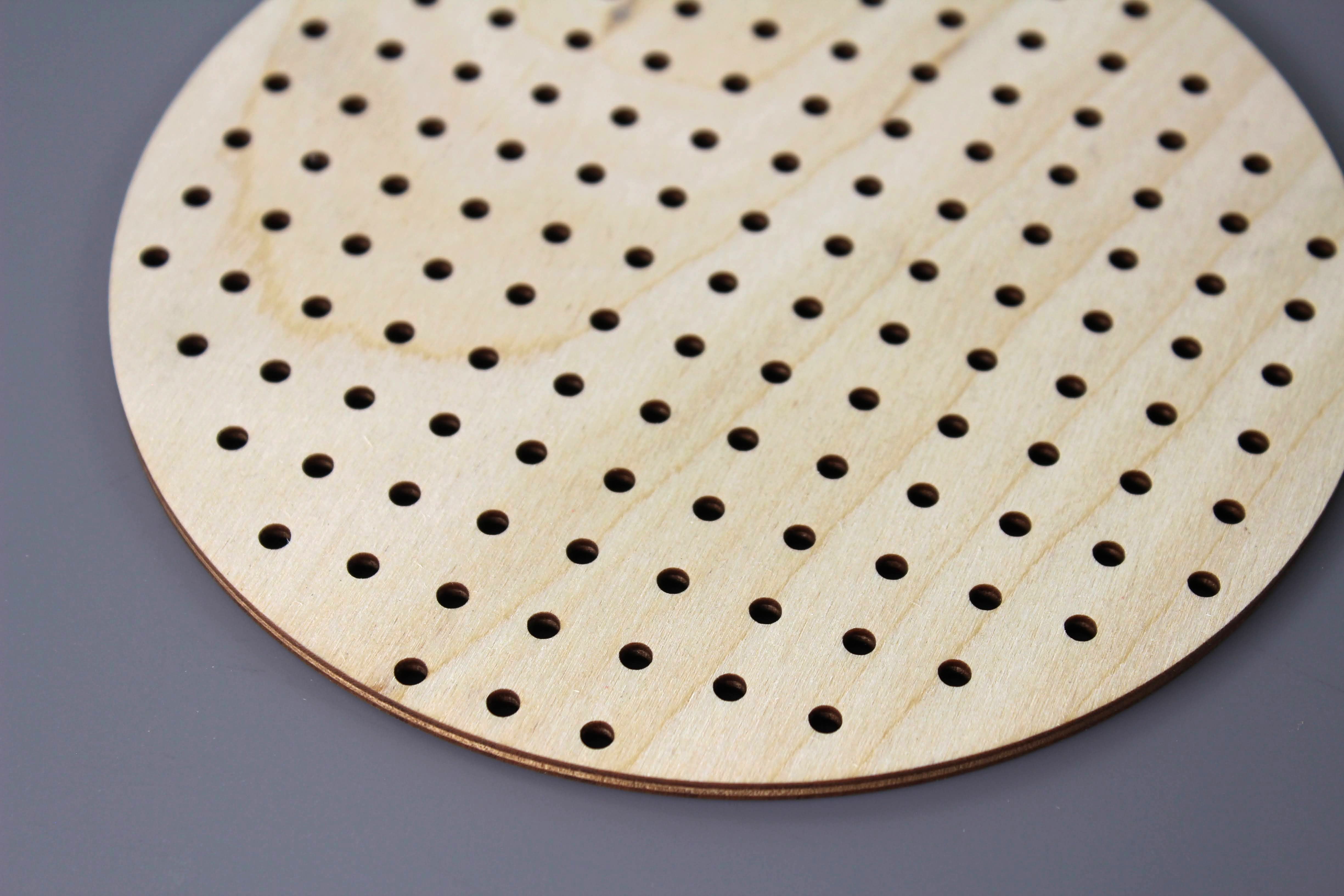

3. Economical reorder

Order yourself from your account, or delegate your production to your purchasing department.

(Personalized) tiered pricing is viewable online so you never have to wait for a quote. You are at the controls yourself.

Dutch quality

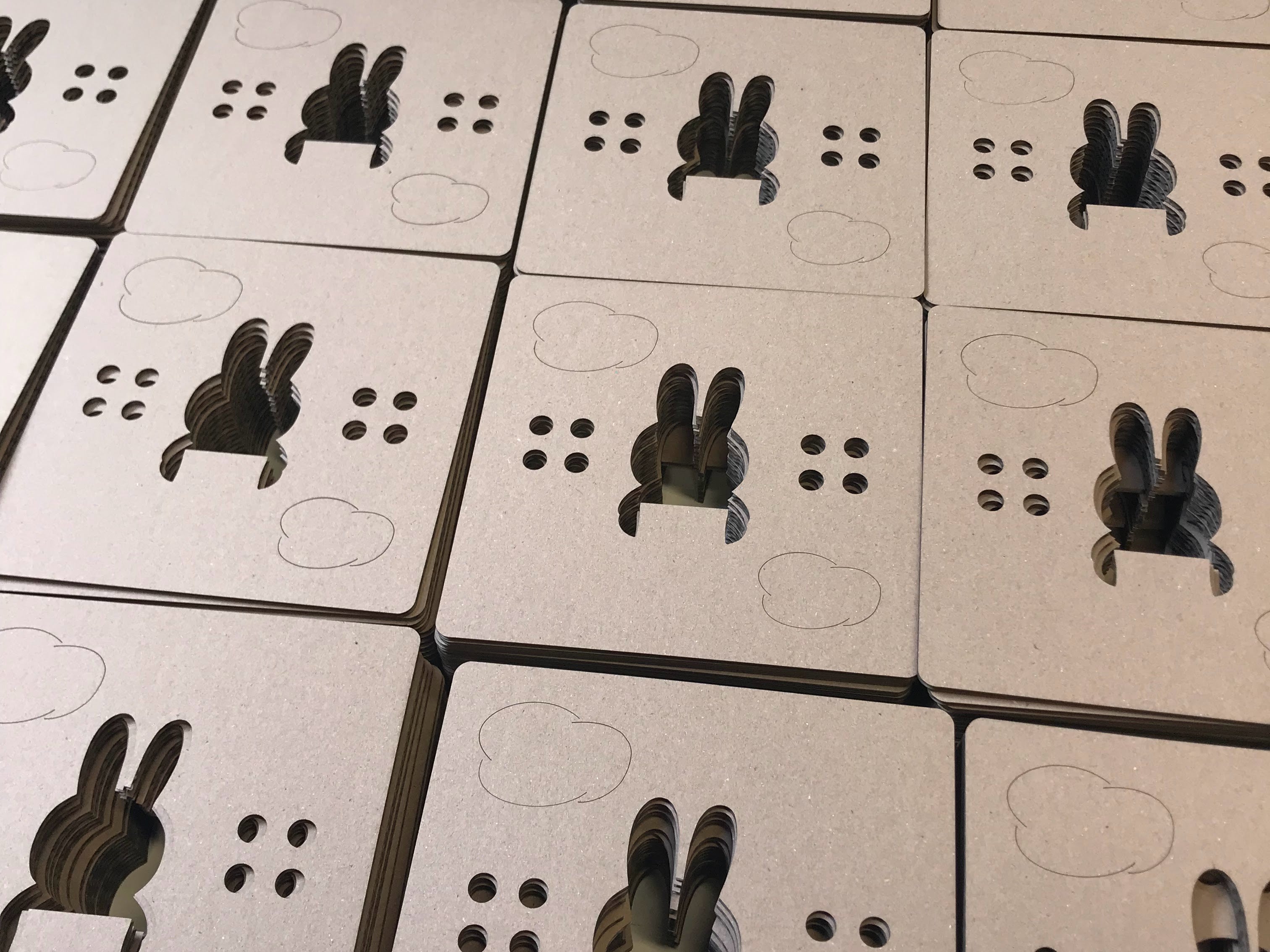

Our in-house developed automation enables high quality and low price

more about our technologyWhat is possible?

You can produce parts up to 1200x600mm in size and from 0.1 to 40mm thick. Maximum size and thickness depend on the material type.

Urders and prices

The minimum print run is 1 piece. With larger orders, the unit price drops. You can quickly see this price trend in your account.

Laser cutting is often very economical for relatively small runs!

read more about pricesAdditional Services

Process optimization

For large or regularly recurring productions, we can often optimize our production process. This reduces costs.

DFM

Design for manufacturing, or taking production into account in your design, often makes your product cheaper and better. We can advise you and draw for you.

Tapping thread

Some plastics can be threaded. We tap from M2 to M10

Sovereigns

Have screws countersunk and save yourself the trouble by having your parts sourced directly.

Our mission is to make manufacturing with laser technology easy and accessible so you can make better products.