Wood is one of the most beautiful materials to work with. Laser cutting and engraving allow you to create sharp corners, fine details, and clever wood joints. Add your logo or text and easily make stunning products—for yourself or your customers.

We offer laser cutting from a single piece, or cost-effective batch production. We even have a dedicated production line for clean wood cuts without burn marks. Perfect for high-quality wooden parts that need to look flawless!

What types of wood can you laser cut?

Strong, beautiful and natural

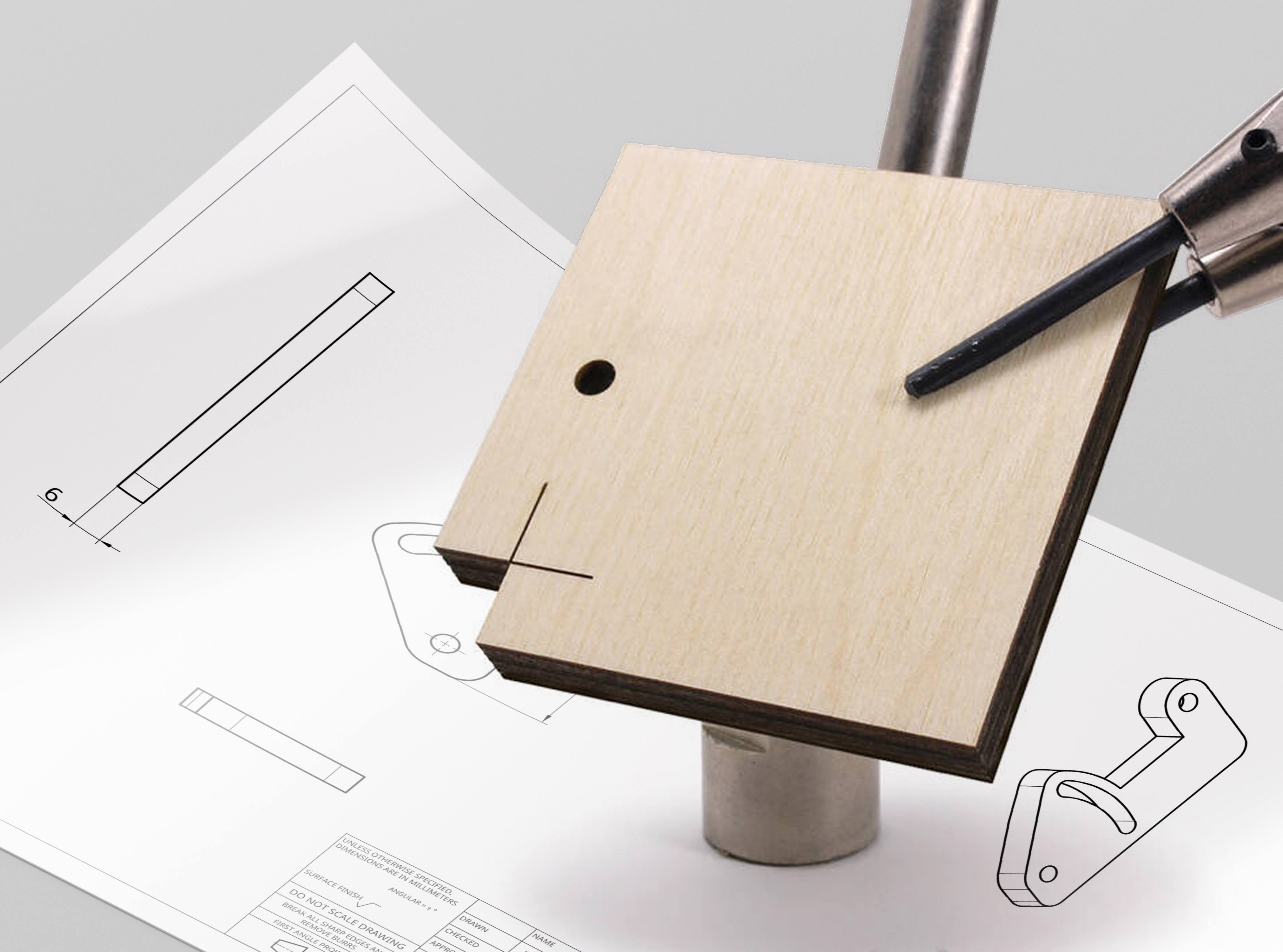

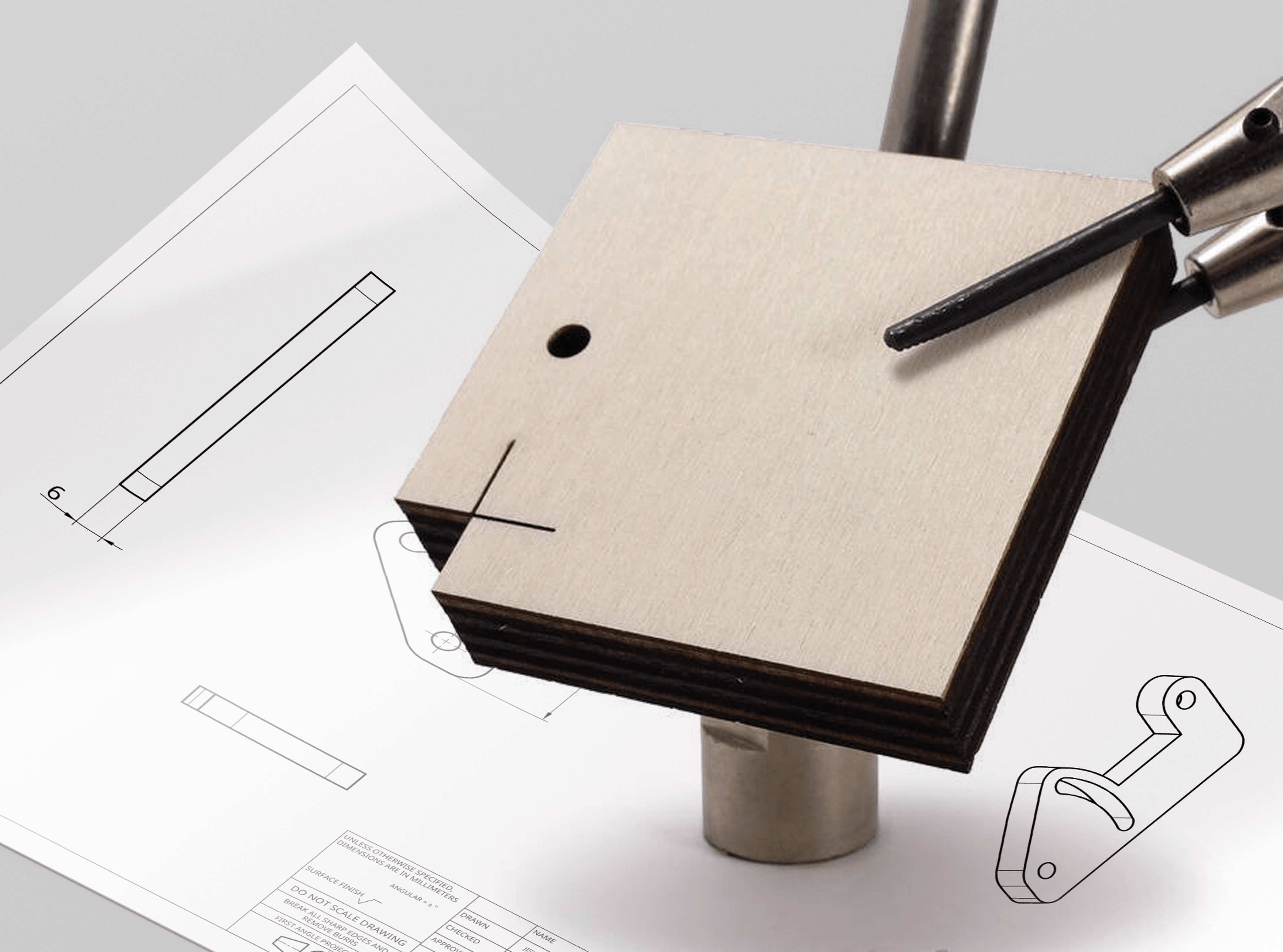

Plywood

Plywood is strong, stable, and has a clean, natural look. Because of the cross-laminated layers, it’s strong in all directions. We offer laser cutting in plywood from 0.5 mm to 15 mm thick.

- Birch plywood is the strongest. Ideal for furniture, panels, and structural parts.

- Basswood (Linden) plywood is the most cost-effective option. Slightly softer than birch, but still very strong.

- Poplar plywood (up to 12 mm thick) is lightweight and great for larger parts thanks to its many layers.

- Bamboo plywood is very dense and ideal for detailed or delicate designs. Available from 0.5 mm to 5 mm.

All types of plywood

| Name | Thickness | Color | Max. size |

|---|

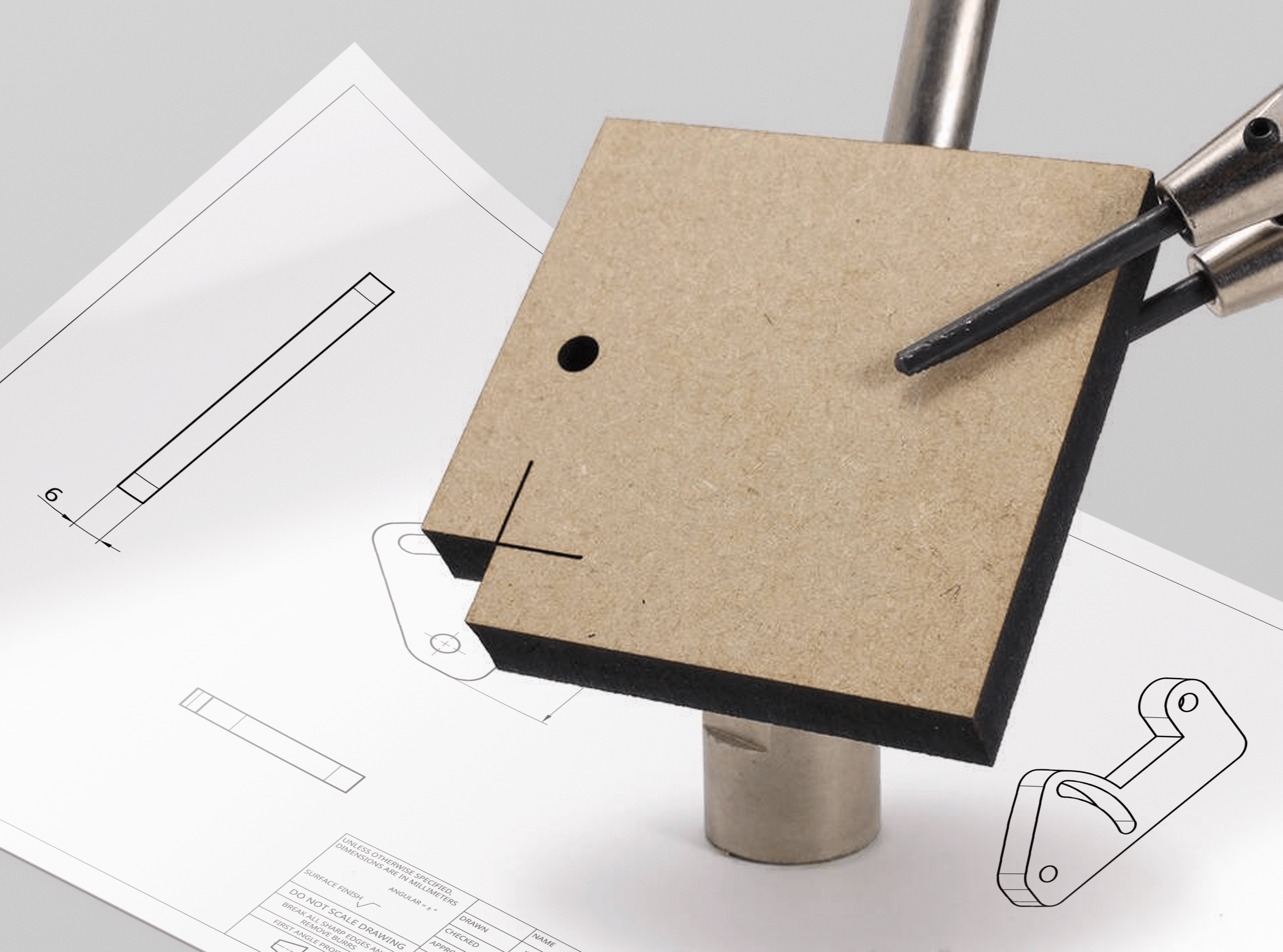

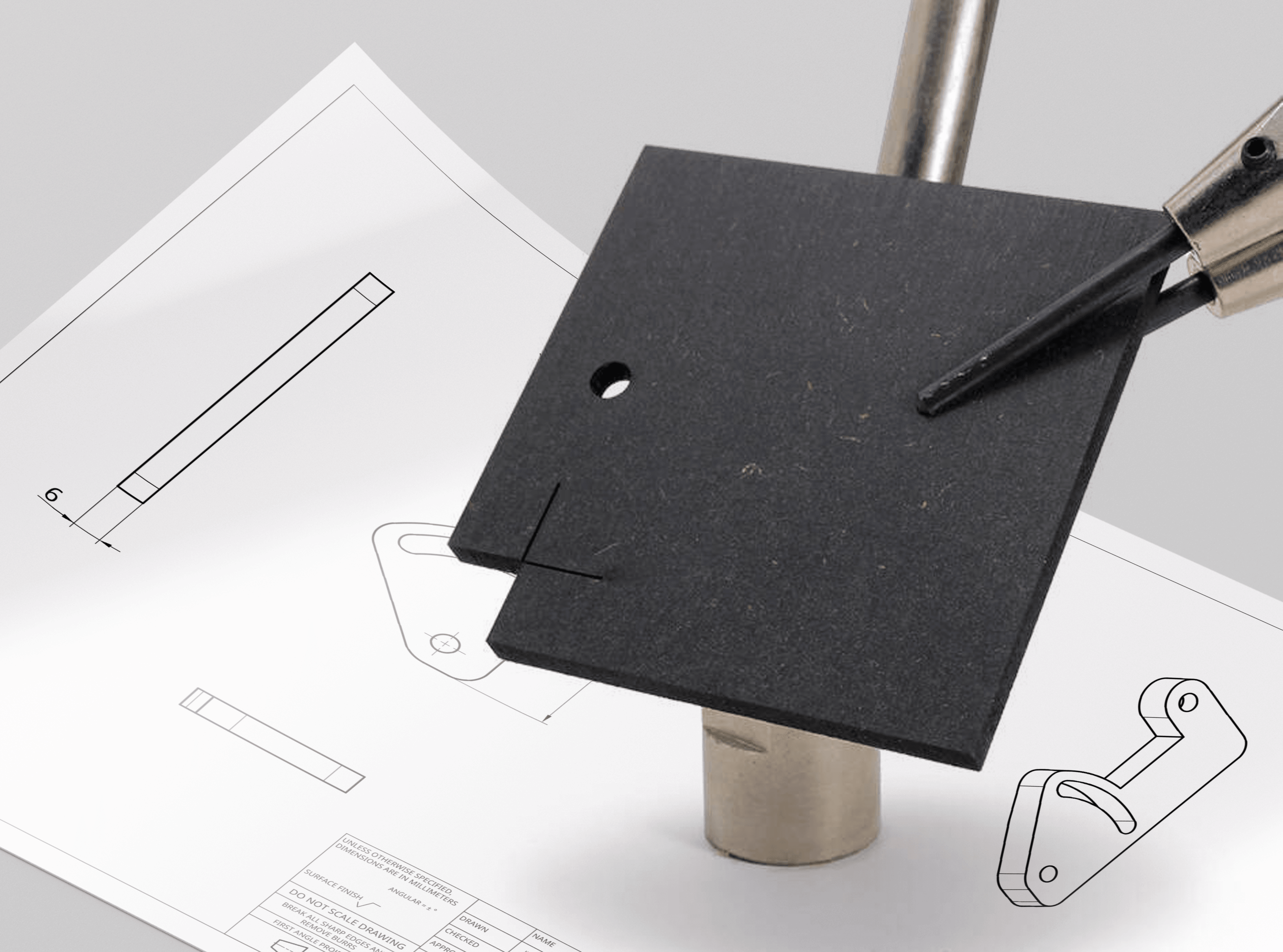

The most budget-friendly wood option

MDF

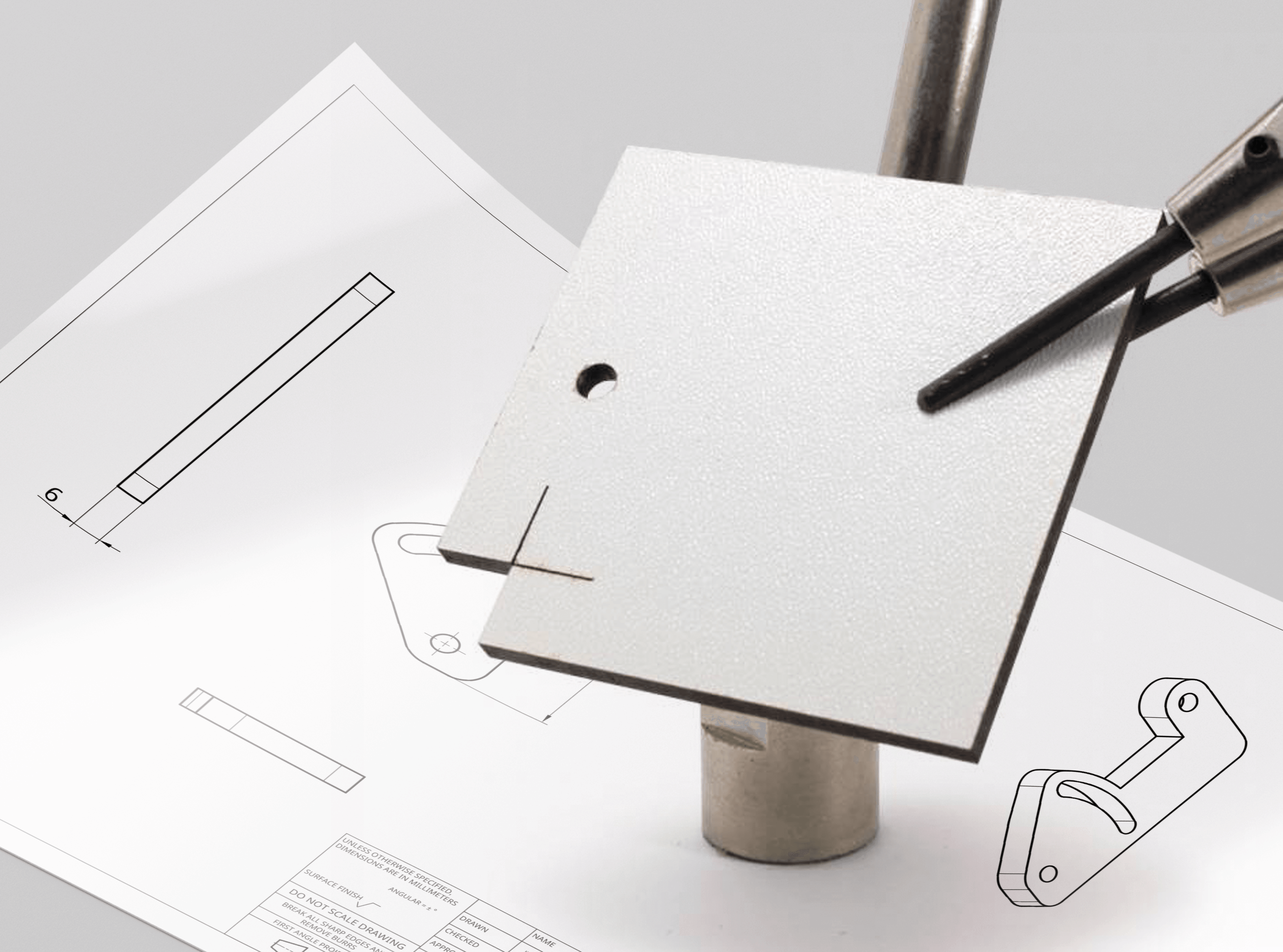

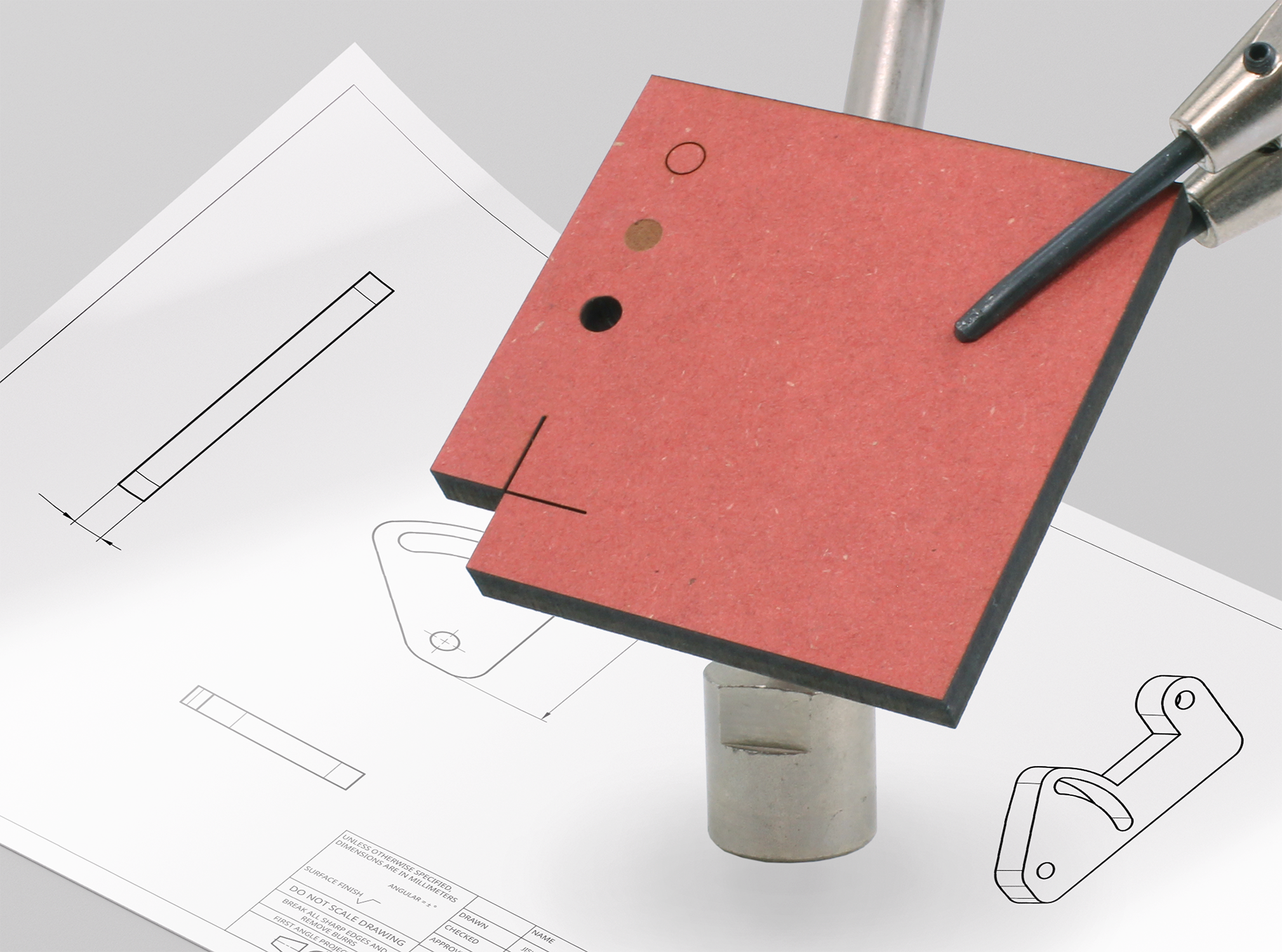

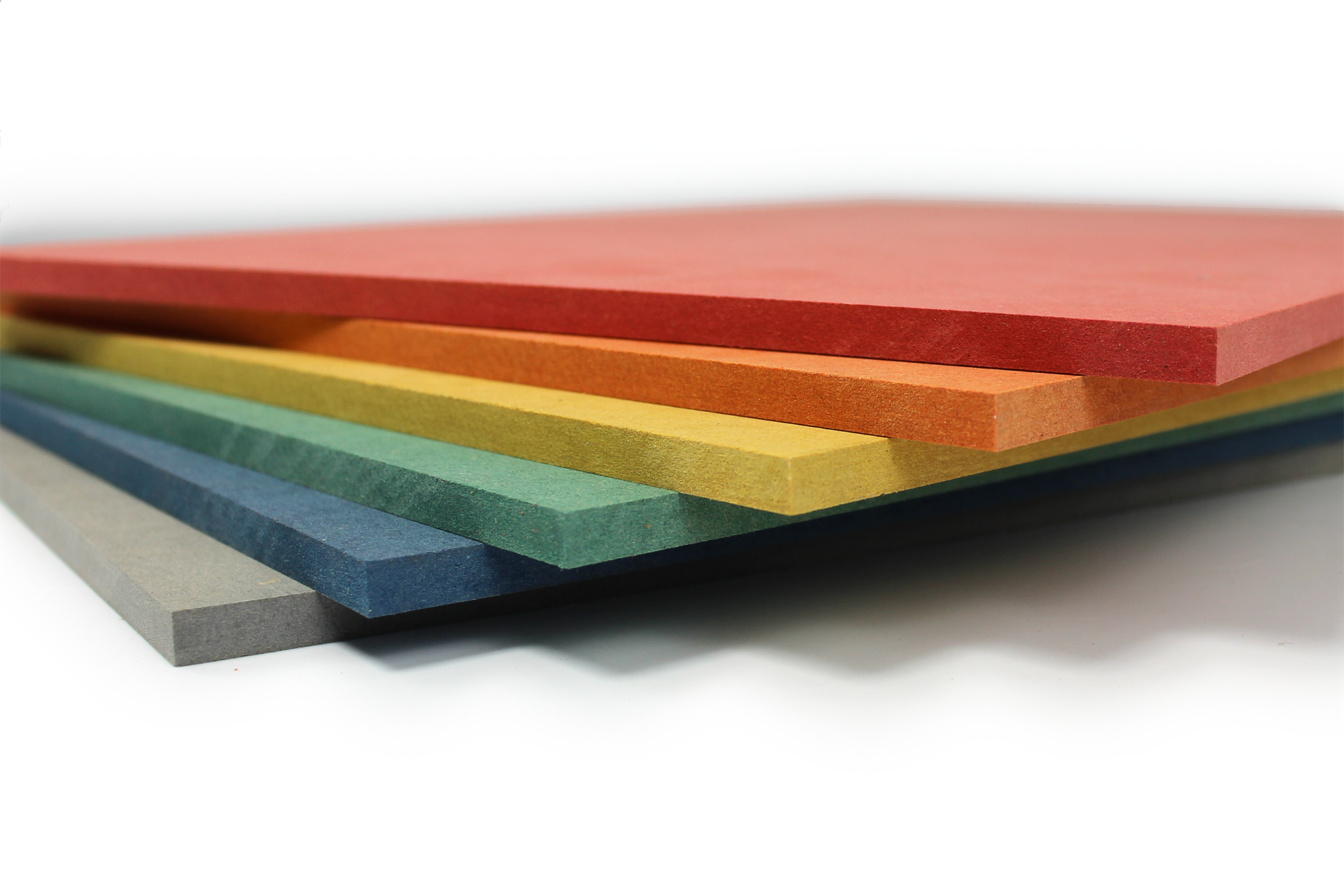

MDF is one of the most affordable wood materials to work with—and still very durable. It’s completely homogeneous, which means clean, consistent cuts and edges.

Its uniform thickness makes it great for precise, tight-fitting joints.

- Brown MDF 3 mm is the most economical.

- Black and colored MDF is fully colored throughout, so the laser-cut edges look clean and finished. Available in 3 mm and 6 mm.

- Coated MDF doesn’t need post-processing but note—it’s not water-resistant!

All types of MDF

| Name | Thickness | Color | Max. size |

|---|

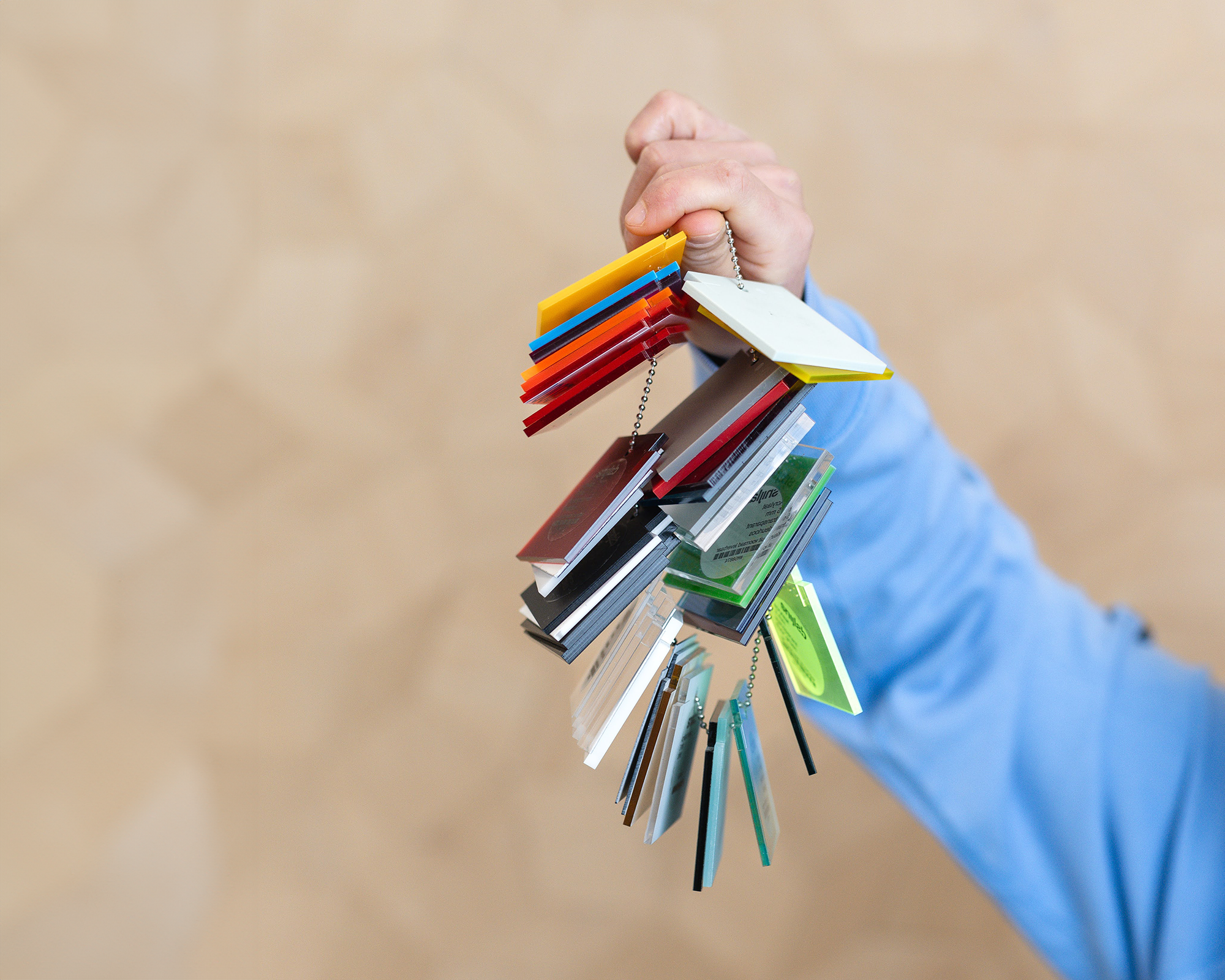

Compare wood samples

Order a sample chain to feel and compare every type of wood in your hands. This helps you make informed design choices.

Our samples reflect the high quality Snijlab delivers.

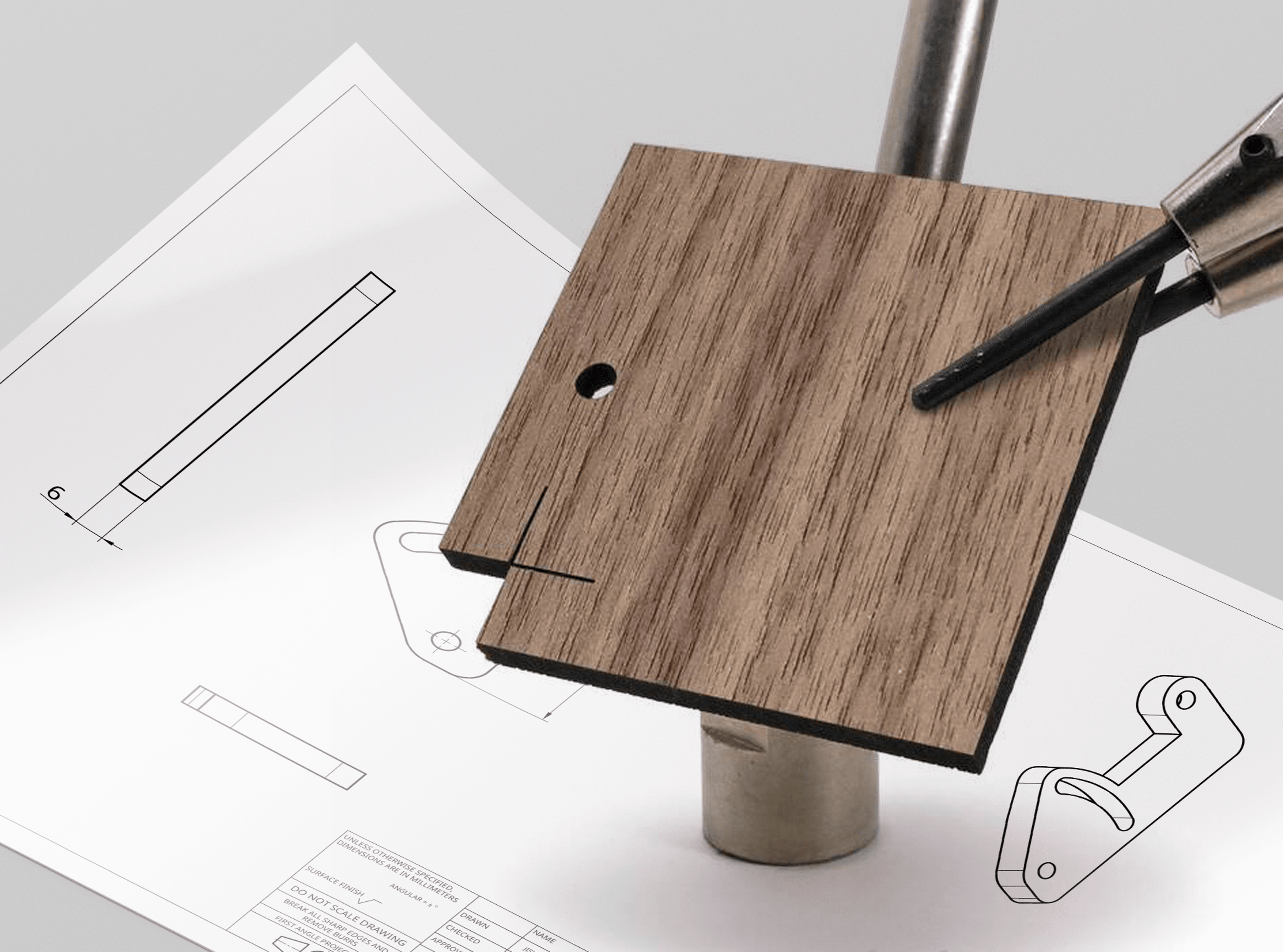

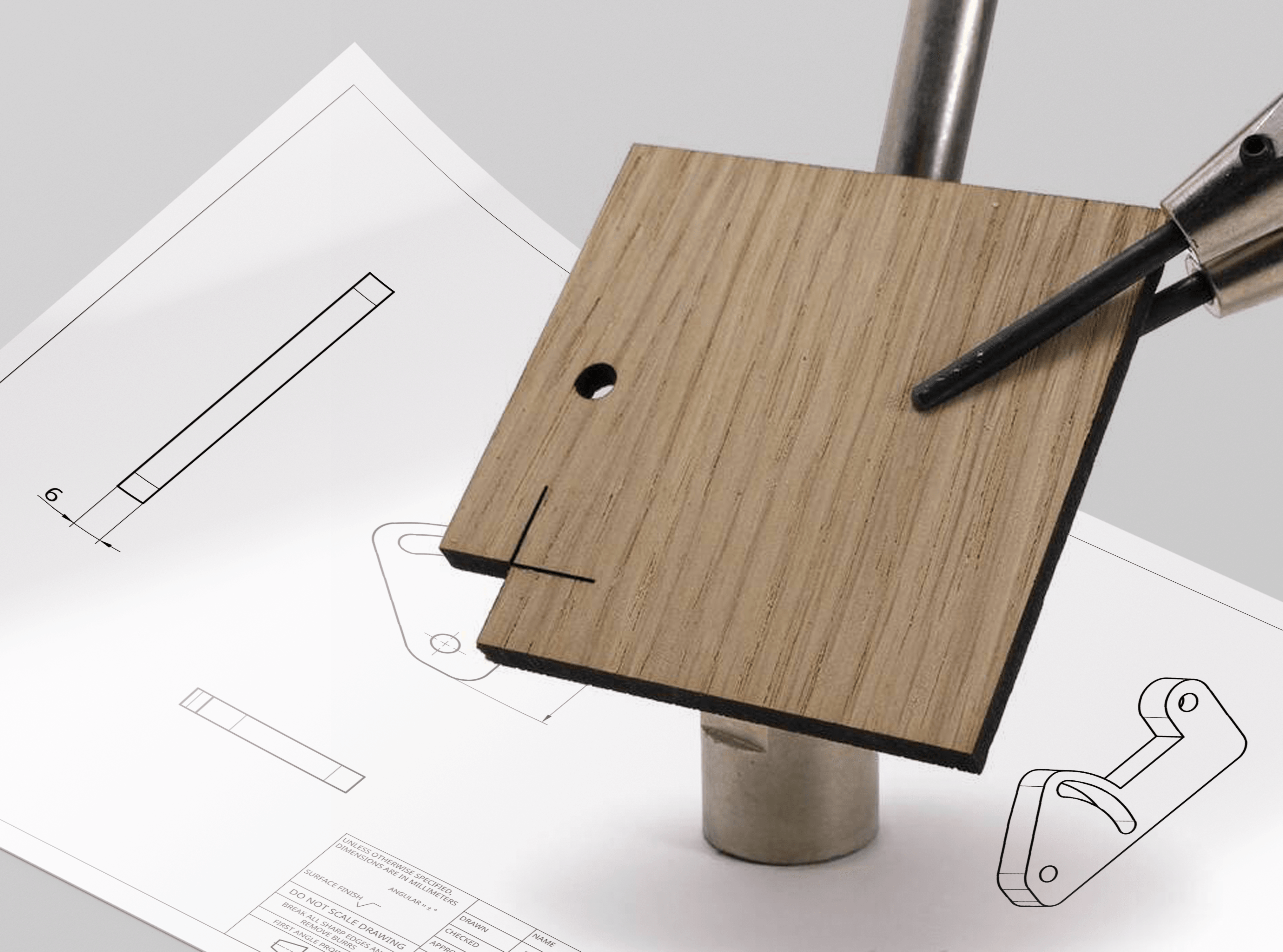

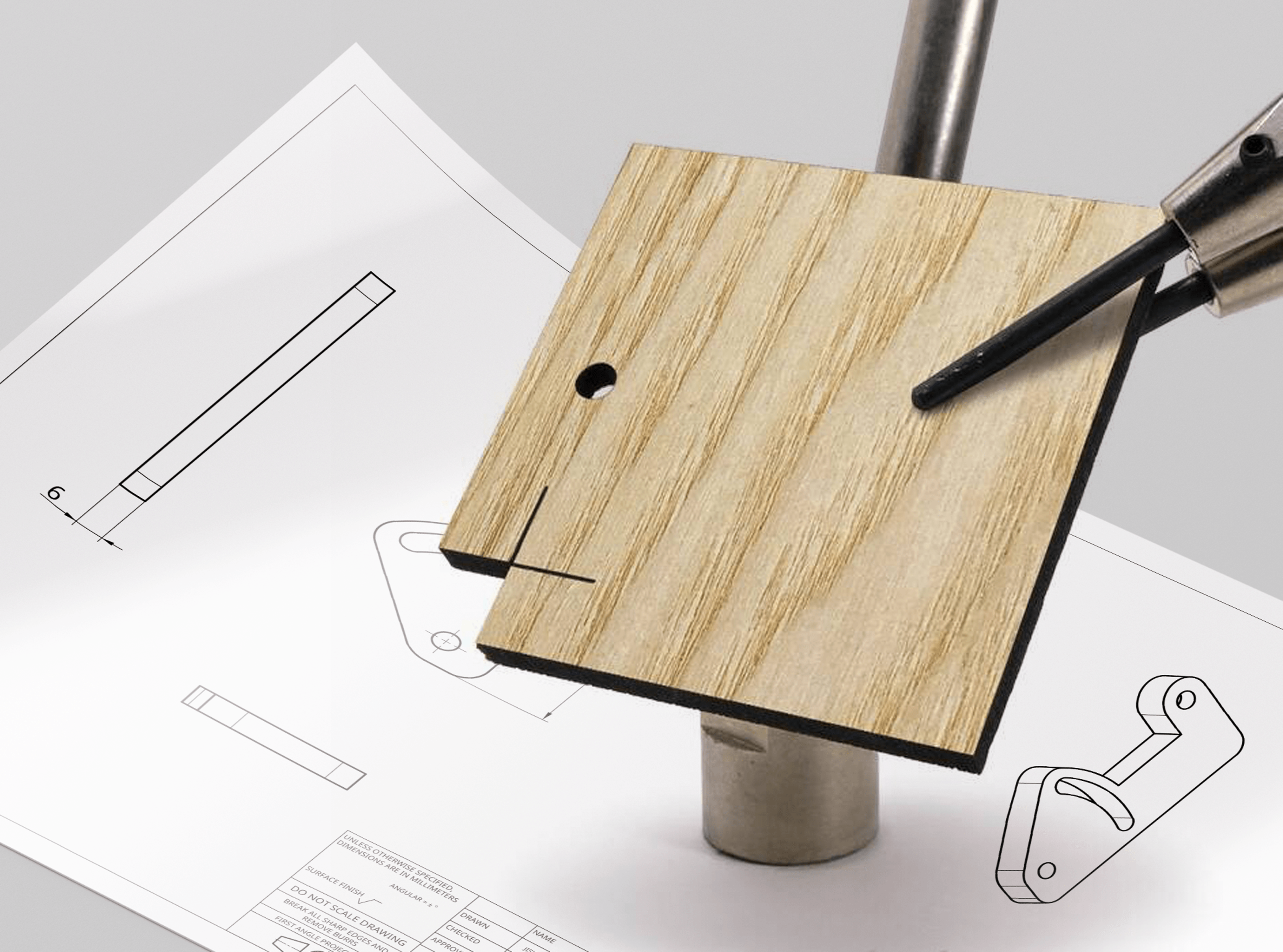

Oak, Walnut, Ash and Mahogany with MDF core strength

Wood veneer panels

These sheets feature real wood veneer on both sides, with an MDF core. You get the beautiful look of solid wood without the downsides like cracking or warping. The MDF core keeps the sheet strong and stable.

Laser-cut edges turn a dark brown and look clean. Veneered MDF is often used for furniture, interior products, lamps, and decorative items.

All types of MDF

| Name | Thickness | Color | Max. size |

|---|

Solid bamboo

Solid bamboo—also called side-pressed—is extremely hard, which allows for a clean finish. It’s strong along the grain but can be brittle across it. Be careful to avoid thin sections in your design.

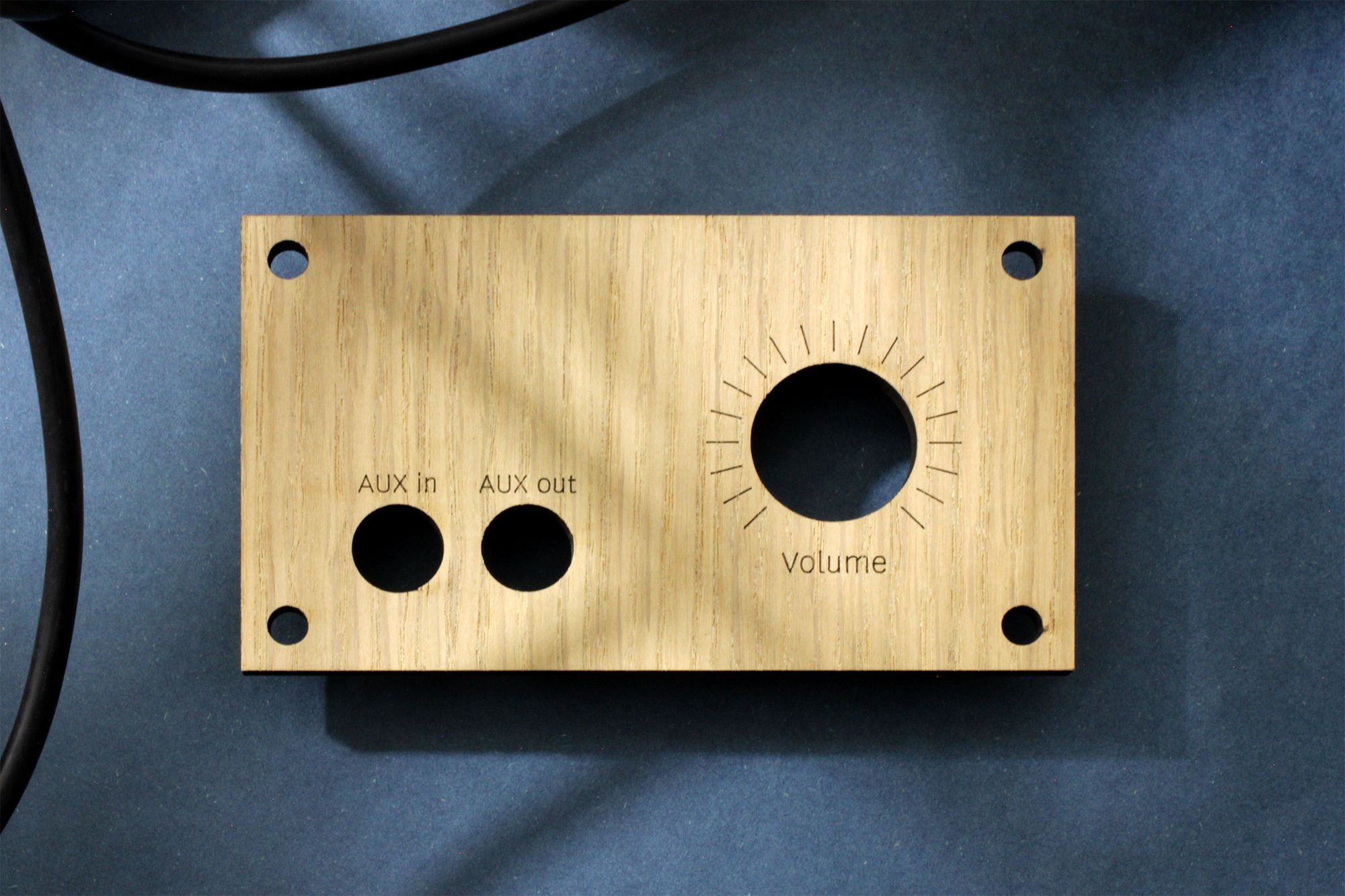

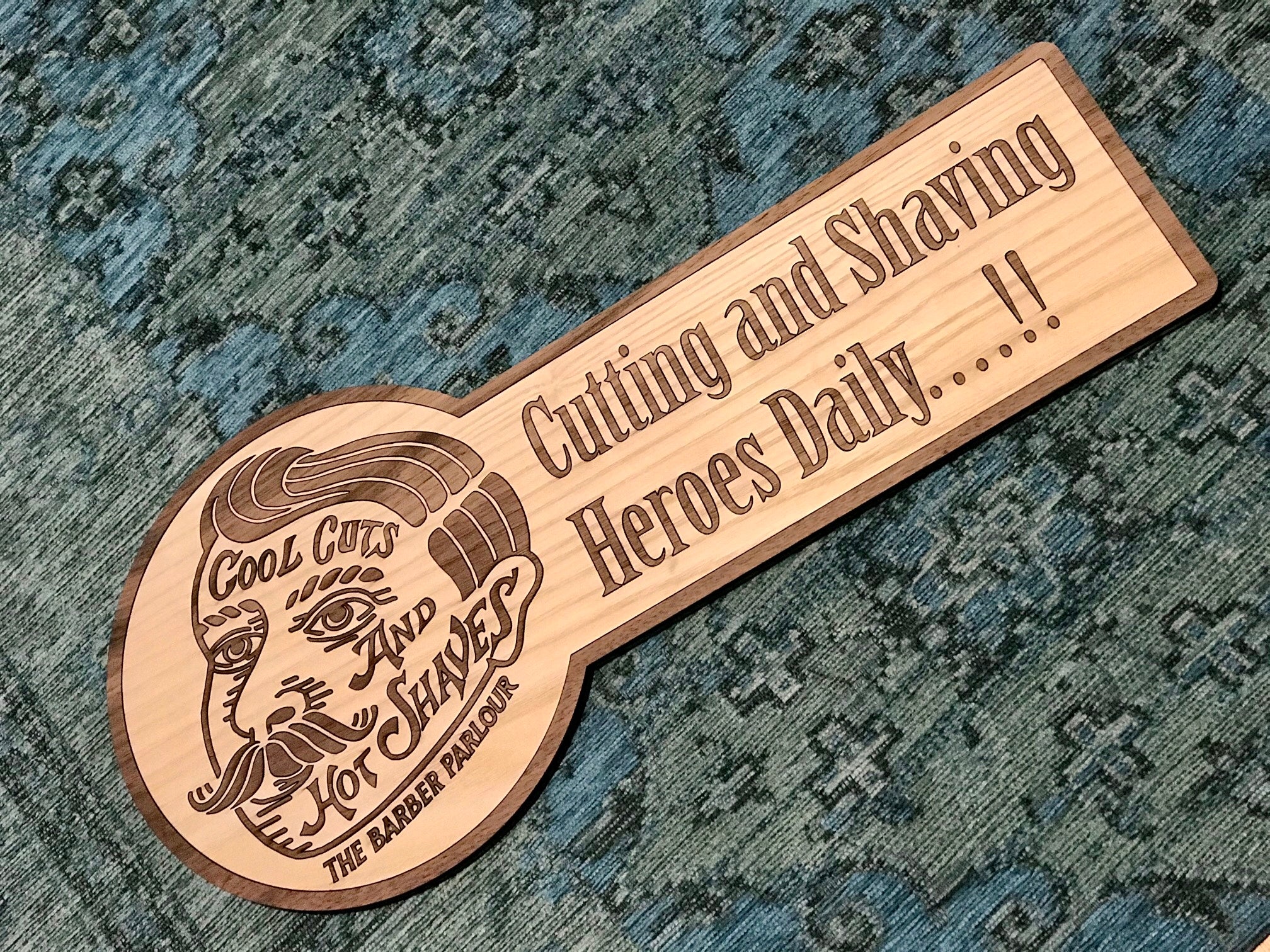

Laser engraving

Besides cutting, you can also engrave. Add graphics, logos, text, instructions, or decorative touches.

Engraving is available on parts we cut, or on your own materials.

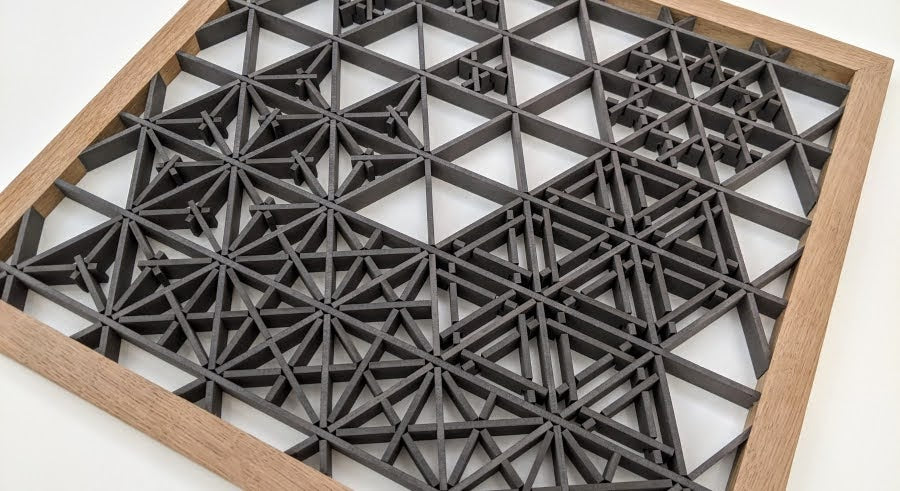

more about engravingWhat can you laser cut from wood?

Laser cutting is perfect for furniture, instruments, puzzles, toys, art, lamps, models, decor, enclosures, test setups, assembly tools, jigs, templates—you name it.

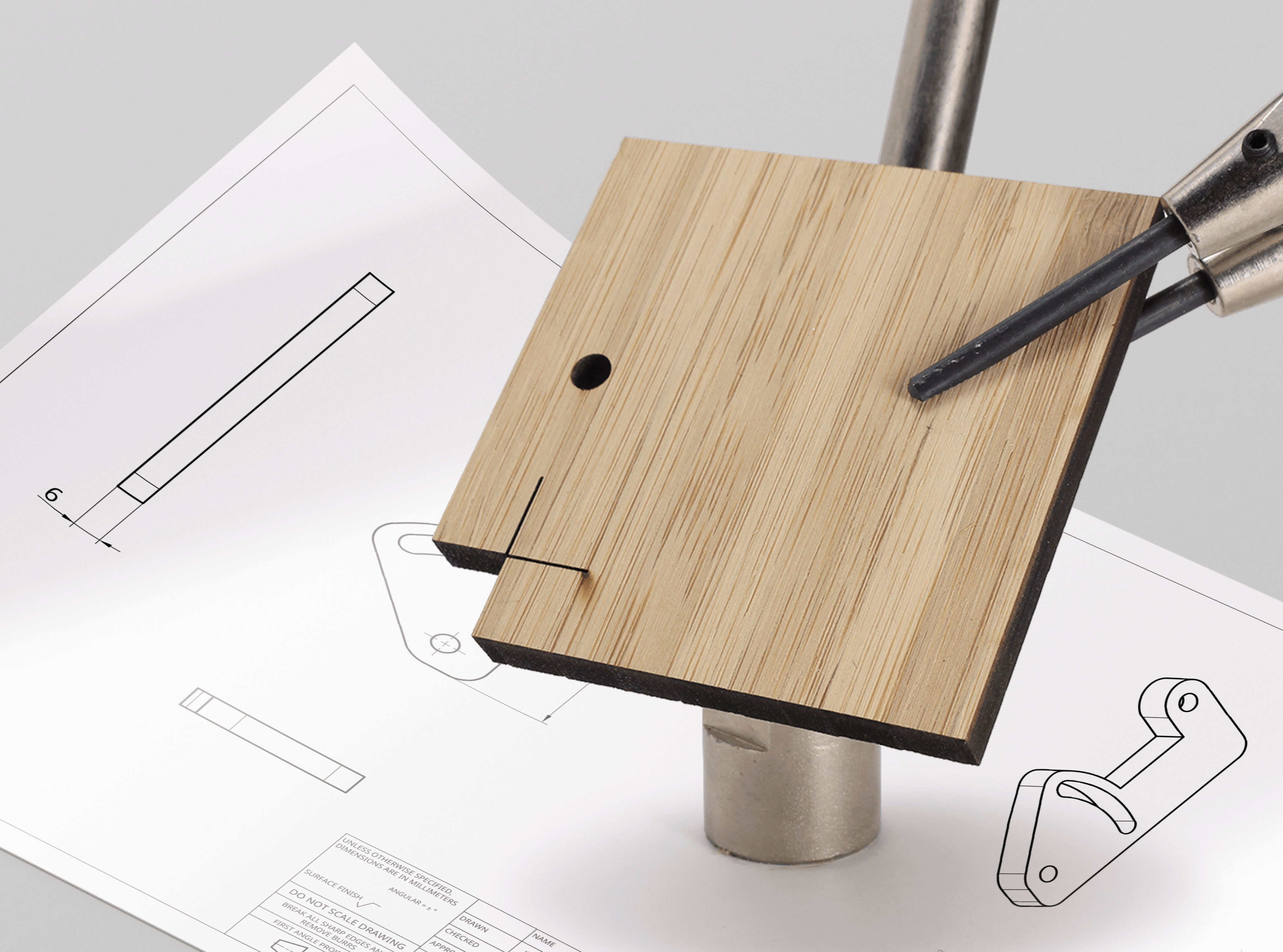

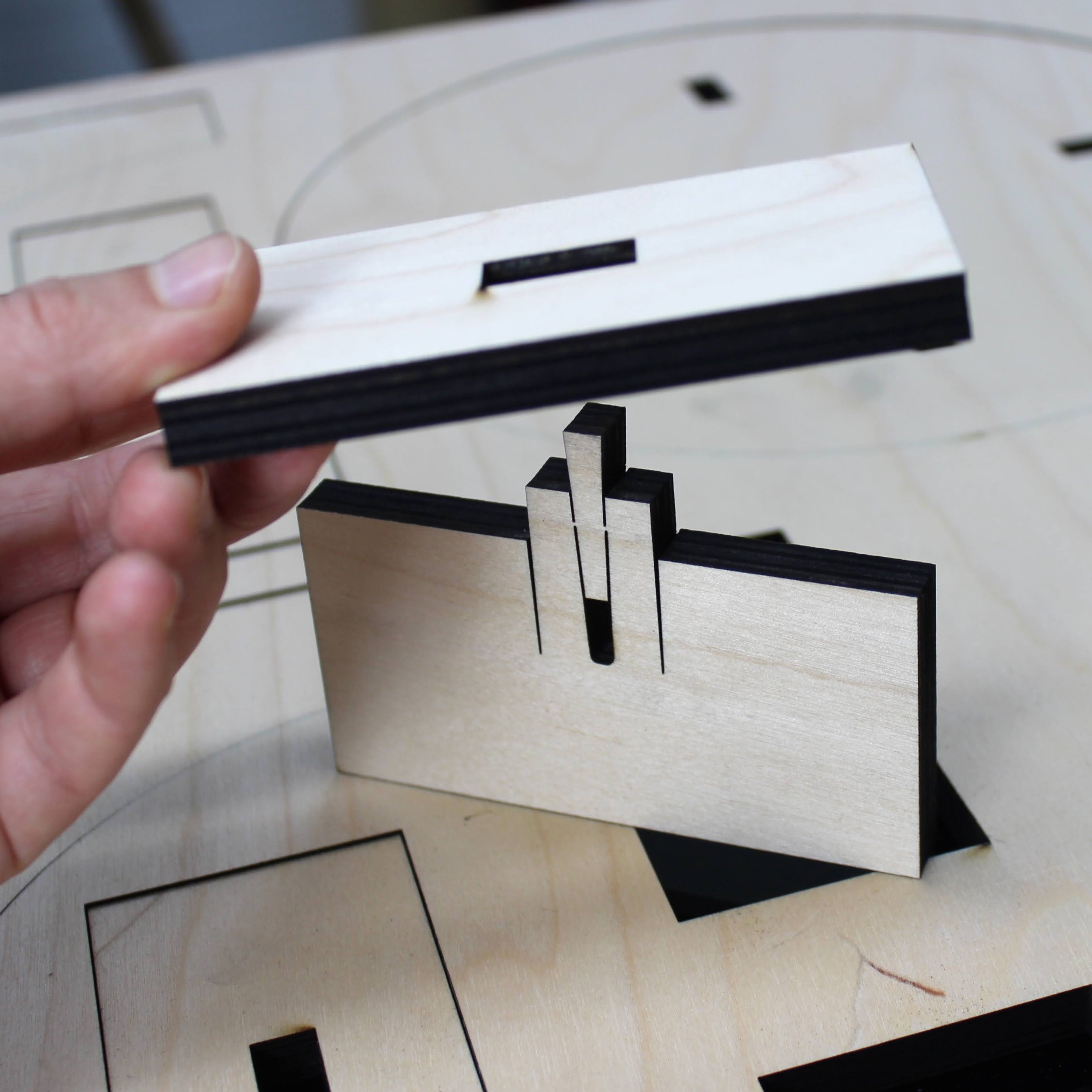

It saves loads of time by letting you integrate functional features into your design, like:

- Screw holes

- Mortise and tenon joints

- Box and finger joints

- Laser cutting even enables flexible, spring-like joints or bendable sections (aka sninges, snijlab-hinges).

Sustainability

Snijlab is FSC® certified (C117418), which means we offer our most popular wood types with FSC® certification:

This guarantees the wood comes from responsibly managed forests.

Only products marked as such are FSC® certified.

View FSC productsAll you need to know

Frequently asked questions

In our online platform, you can order laser-cut wood using your own design files. Upload your design 24/7 and get an instant quote. Order from just a single piece and choose next-business-day delivery if needed.

We serve professionals who design and often sell their own products. We also specialize in series production and on-demand manufacturing.

Students and hobbyists are welcome too—create a free account to get started on your home, hobby, or school project.

Need help? We're happy to assist!

Upload your design

See instant pricing

Order online

How does laser cutting work?

We have an online environment where you can order your design.

- Upload your design

- See the price

- Order online

See also How it works and Drawing rules

What does wood laser cutting cost?

Pricing Example (ex. VAT):

- A small design starts at €15

- A full 1200×600 mm file with many cuts may exceed €100

- A small part in a batch of 500 can cost as little as €0.10 per piece

How thick wood can you laser cut?

We stock wood from 0.5 mm up to 12 mm thick.

The thickest plywood we offer is Basswood. In special cases, we can cut up to 18 mm—contact us if you're interested.

Maximum sheet size: 1200 × 600 mm (a quarter sheet of standard furniture panel).

Up to what size can you laser cut wood?

We cut up to 1200 x 600 mm in size (one quarter furniture board).

Can I supply wood myself?

It depends. Many types of plywood and MDF aren’t great for laser cutting, which is why we strongly recommend using our in-stock materials—they’re made specifically for laser cutting and are high-quality throughout.

Solid wood usually cuts well up to about 9 mm. You can select "self supplied material up to {thickness}" when ordering, and then send or drop off your wood. Your delivery time starts once both the file and material are received.