Types Cardboard and paper that you can have laser cut

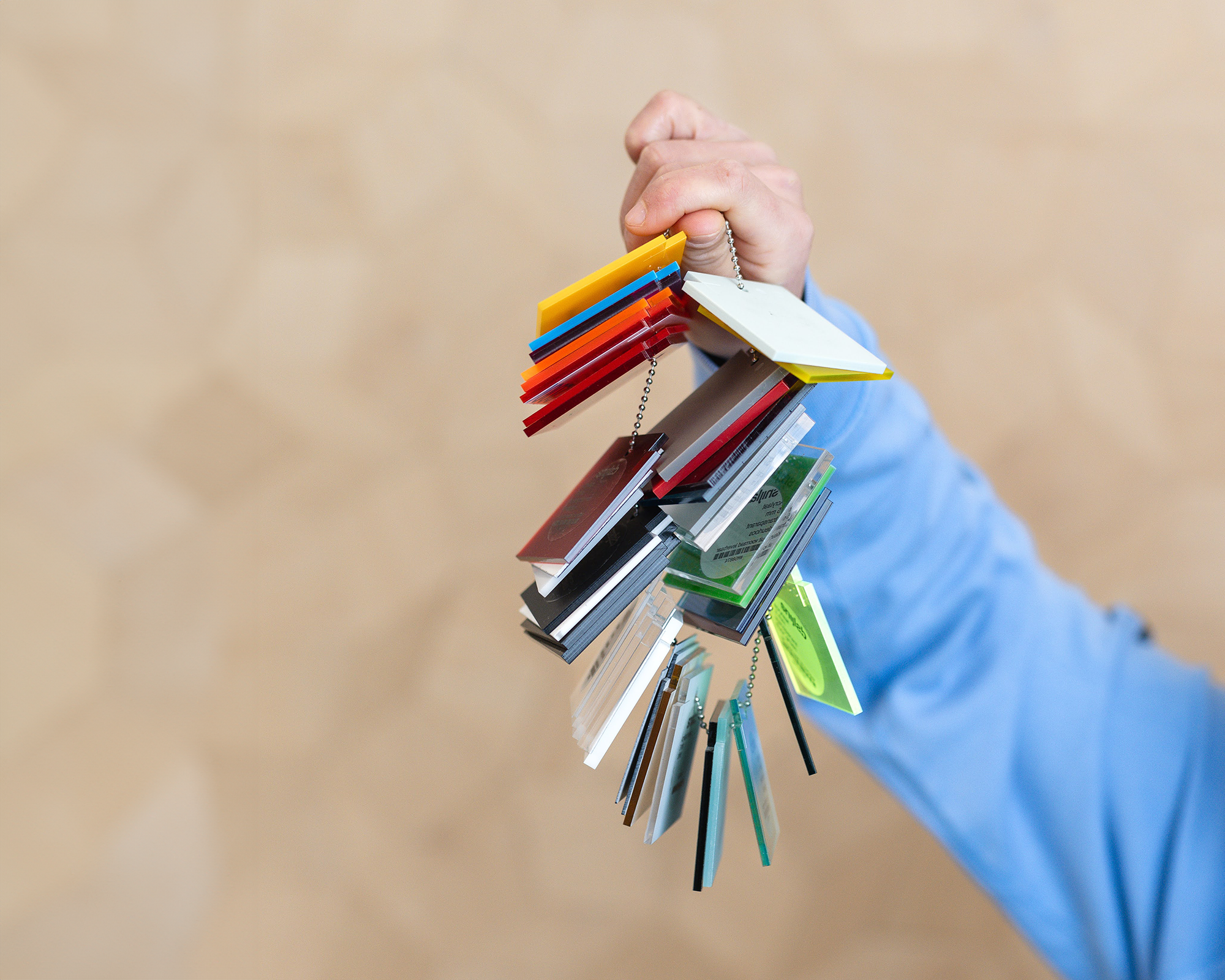

Samples of Cardboard and paper compare?

Order one material sample chain and compare all types Cardboard and paper in your own hand. This way you make a well-informed decision about your design.

Samples provide a representative picture of the quality Snijlab delivers.

To the samplesAlle soorten Cardboard and paper onder elkaar

| Name | Thickness | Color | Max. size |

|---|

Info about Cardboard and paper

The easiest way to cut paper and cardboard into any shape! Laser cutting or laser punching is inexpensive and very precise. Make a drawing on your computer, order online and get the laser cut cardboard or paper delivered quickly. Choose from museum board, felt board, laser board and more. The ideal service for any creative mind!

How does laser cutting in paper and cardboard work?

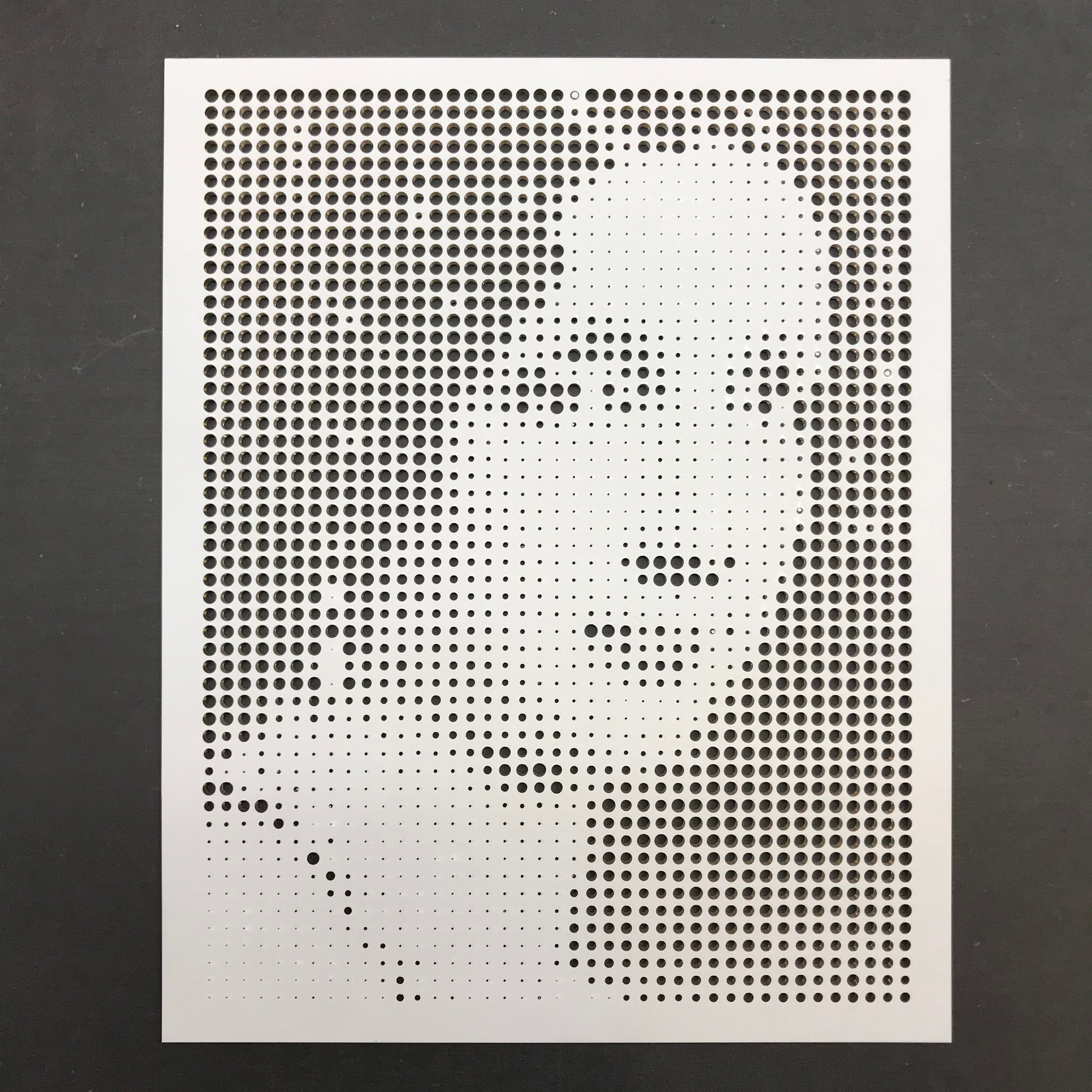

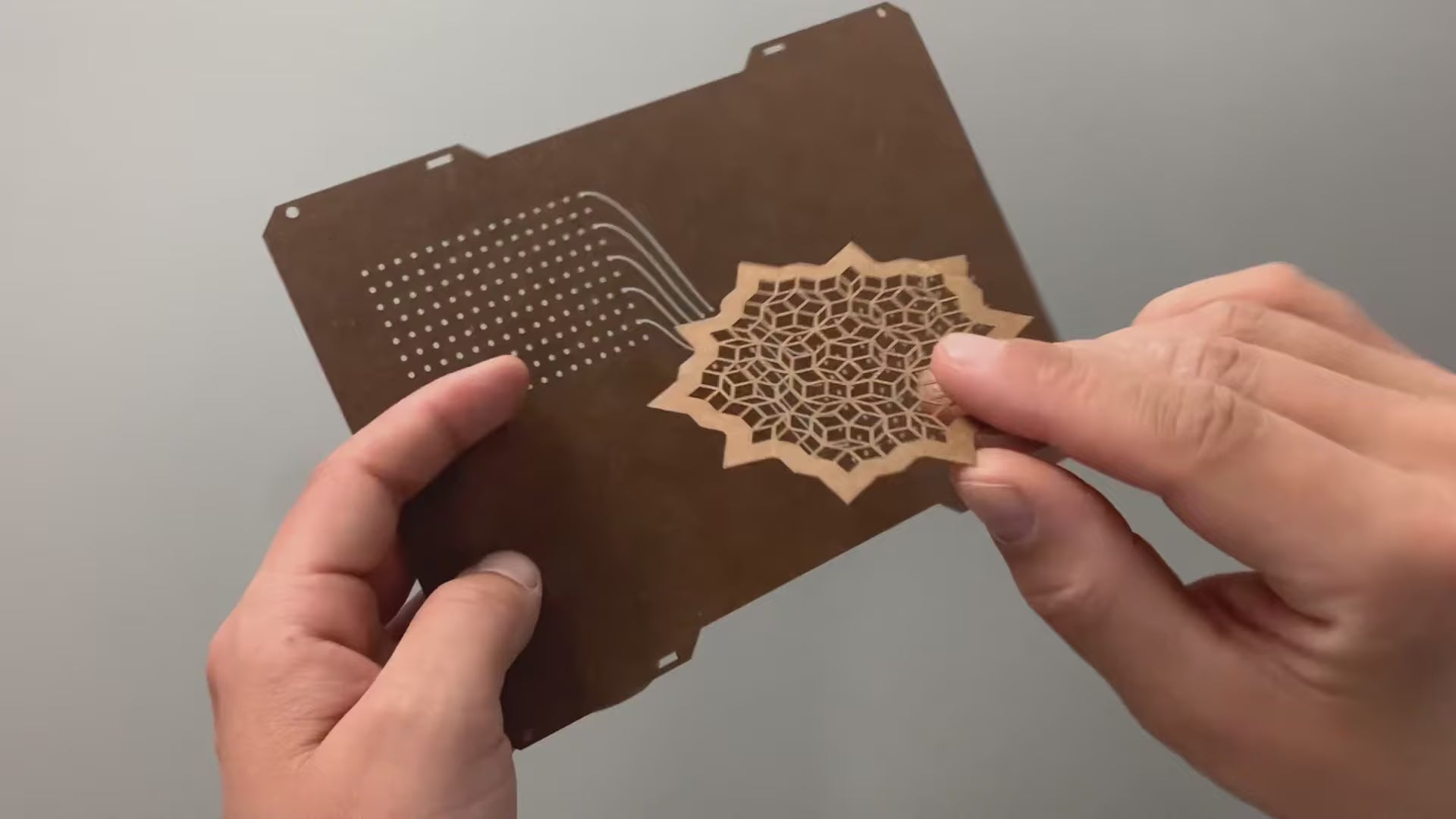

The laser (simply put, a strong beam of light) cuts through the material with a very thin tip. The smallest holes you can make this way are about half a millimeter in size. The laser-cut edges are usually light brown, but this varies depending on the type of cardboard. This is laser cutting or laser punching.

The laser can also engrave. This involves discoloring the surface (usually brown/black, but light brown/white in the case of corrugated cardboard). This allows you to add text and graphics without the need for ink.

Creasing is not possible. Instead, you can laser a stripe or dotted line and fold over it. Please note that not all types of cardboard can be folded. Especially corrugated cardboard does fold well.

Because laser cutting does not require a mold, there are few start-up costs. You can already have a small design lasered for €15 ex. vat.

If you order more than one piece, the price drops significantly, by up to 95%.

Welding is inexpensive up to medium-sized series. If you need even more, then mechanical punching is more economical. With this, however, you can make fewer small details and cannot engrave.

What can you make with laser-cut paper or cardboard?

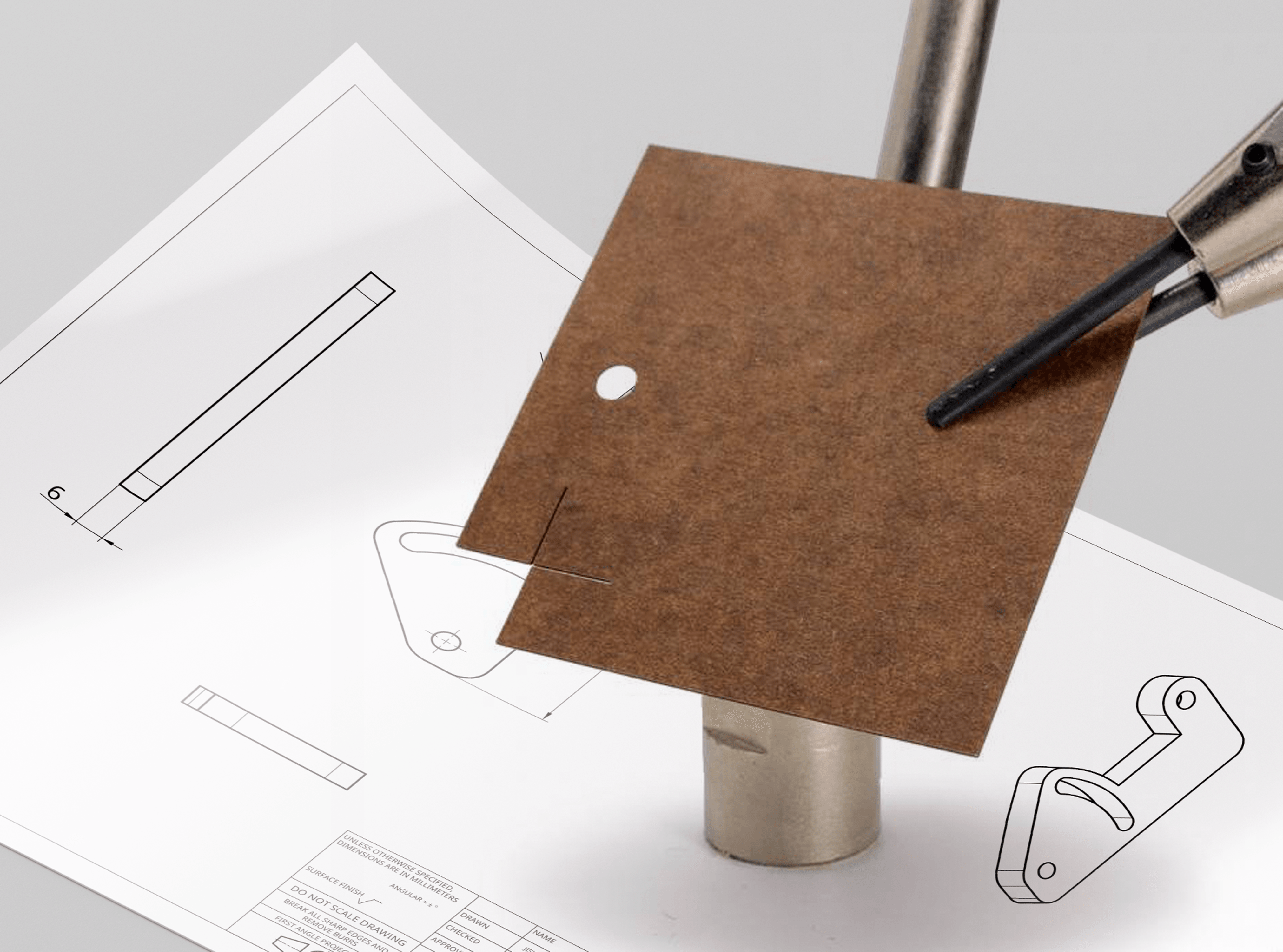

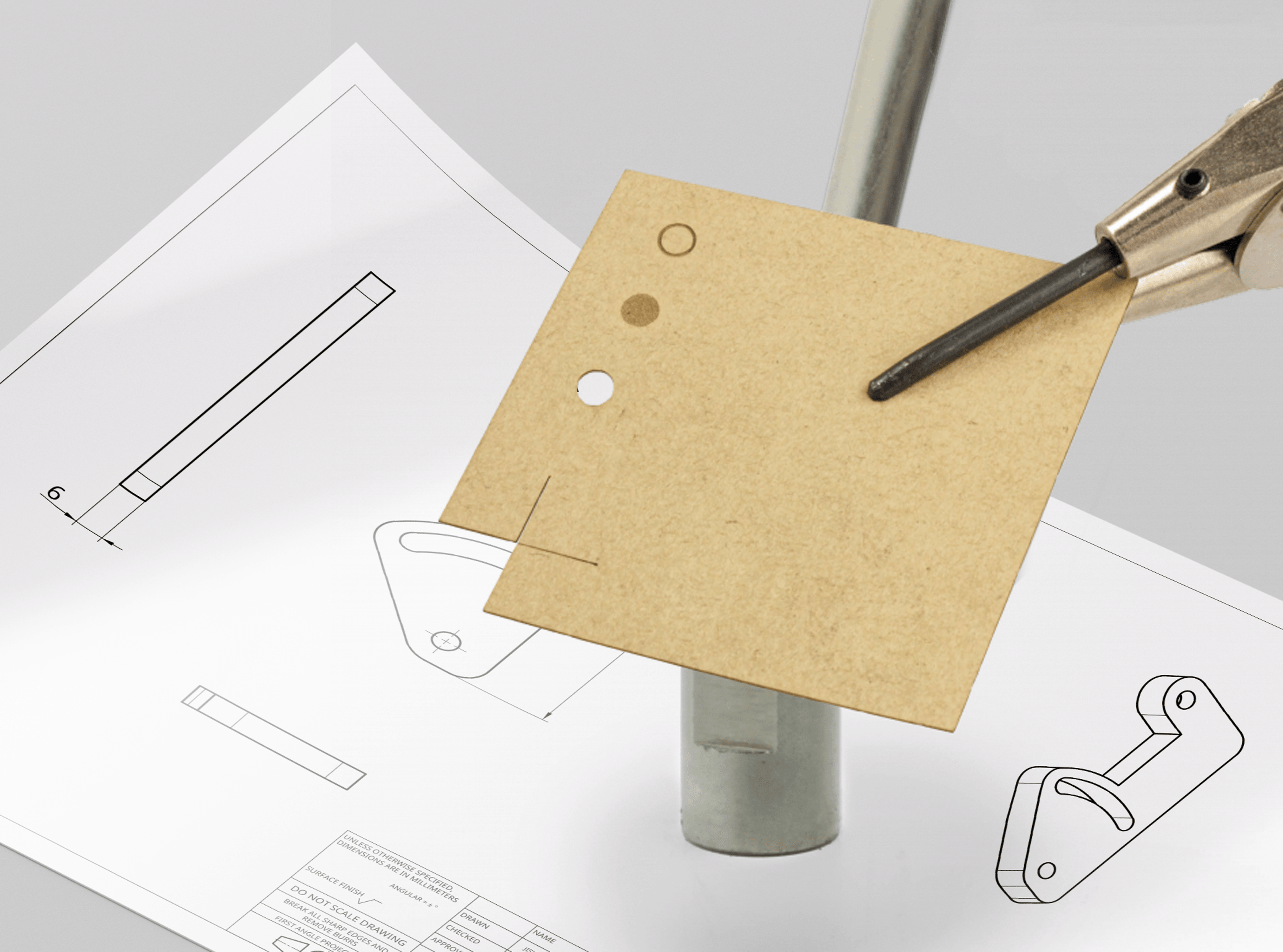

In architecture, cardboard is widely used to make models. Laser cutting is especially useful here because the design often already exists digitally. It is then very easy to have it laser cut. You can make very small details. The cut of the laser is 0.1-0.2 mm wide, making openings of half a millimeter or more possible. Ideal for the smallest details, windows, ornaments, etc.

Because cardboard and paper are easy to cut with a Stanley knife, it does not matter if you want to adjust things here and there. When ordering, choose 'supply residual material' so that you always have some extra material for cases like this.

Moreover, you can laser engraving. With this you create, for example, (brick) patterns on the facade, markings for alignment, texts and logos.

Similarly, you can laser cut paper and cardboard in model making.

Stencils can be made well from thin cardboard. Large stencils are also sometimes made out of corrugated cardboard because it is stronger.

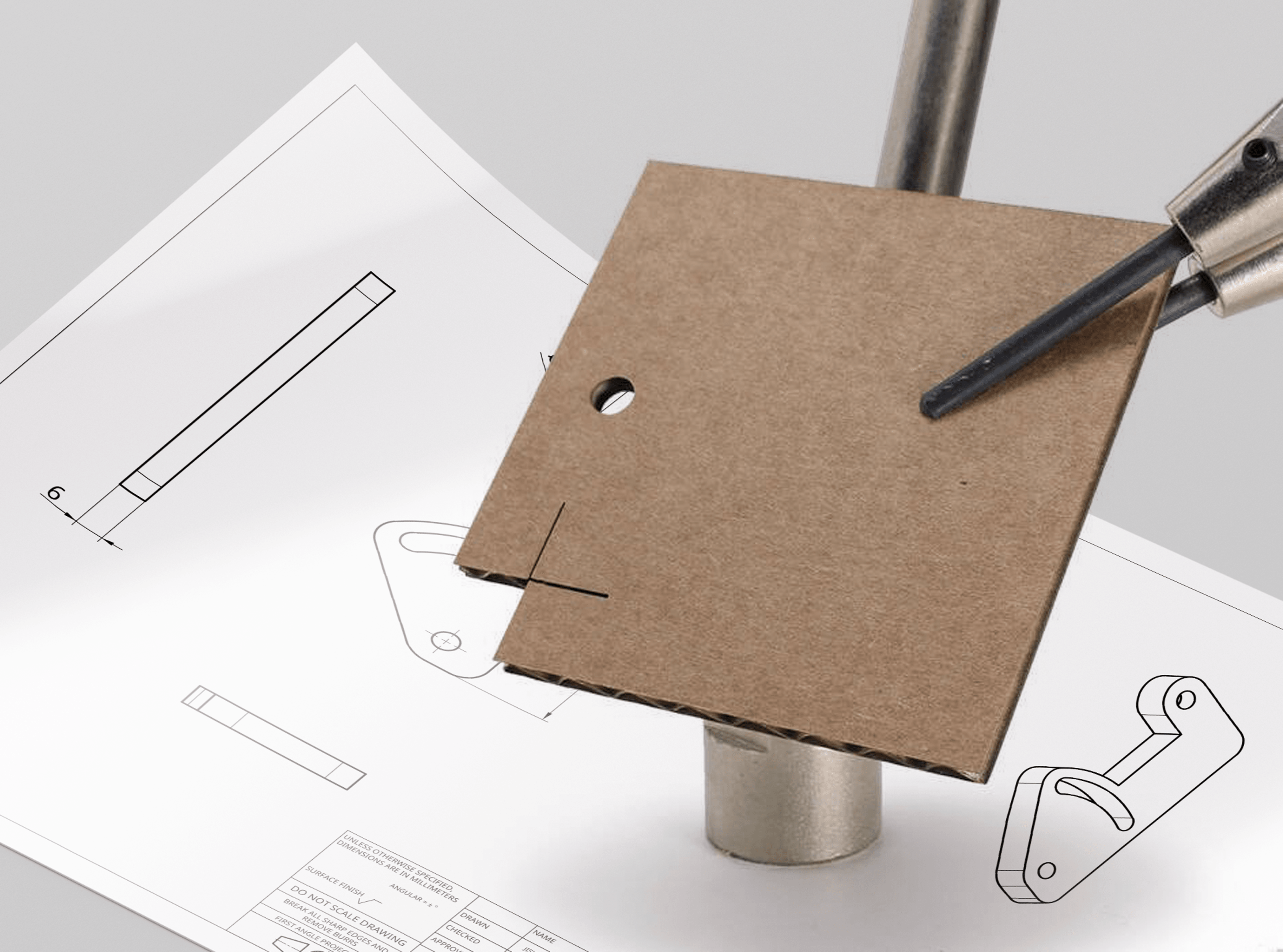

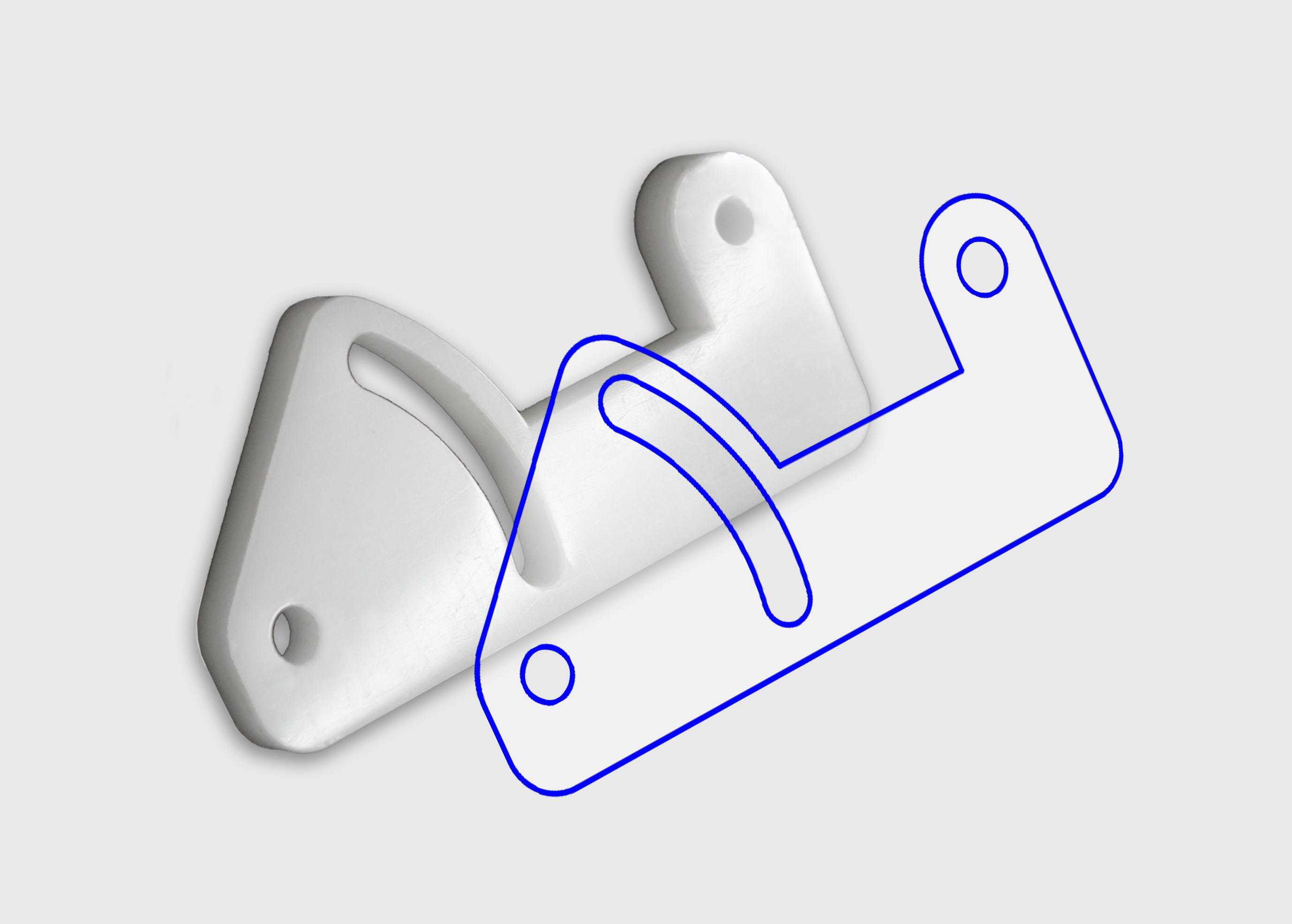

Shape studies, mockups and other models and prototypes are also easily made from cardboard. Corrugated cardboard is very inexpensive and has low environmental impact, making it an ideal candidate for prototypes.

And what about custom boxes and packaging, or even sophisticated products like the google cardboard? All easily and inexpensively lasered.

Different kinds

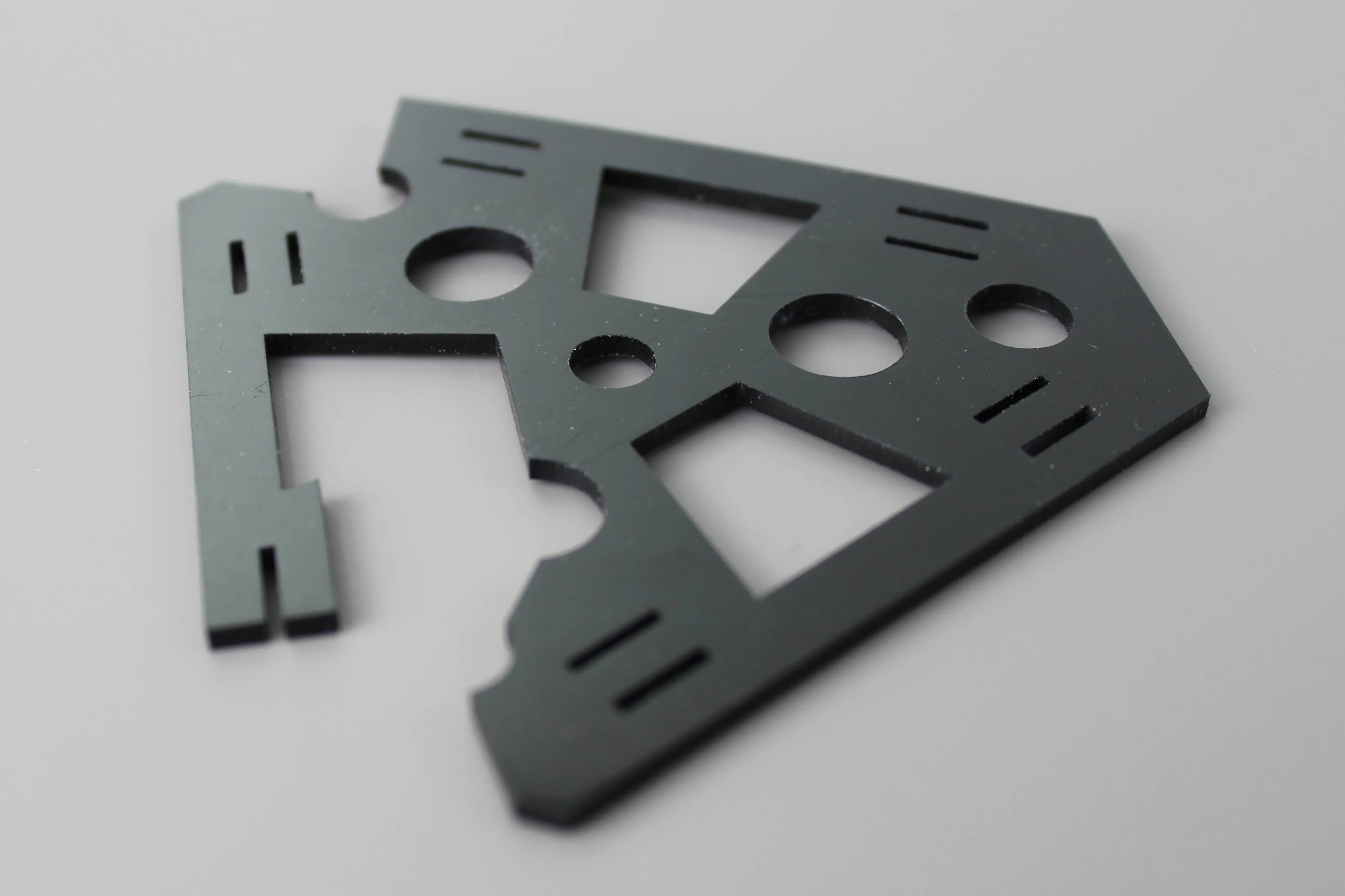

Corrugated cardboard. The well-known material from which boxes are made. Corrugated cardboard is particularly economical and strong. But did you know that you can also laser cut very small details into it? With a laser you can easily cut out contours. Engraving is also possible and produces a light surface with reasonable contrast.

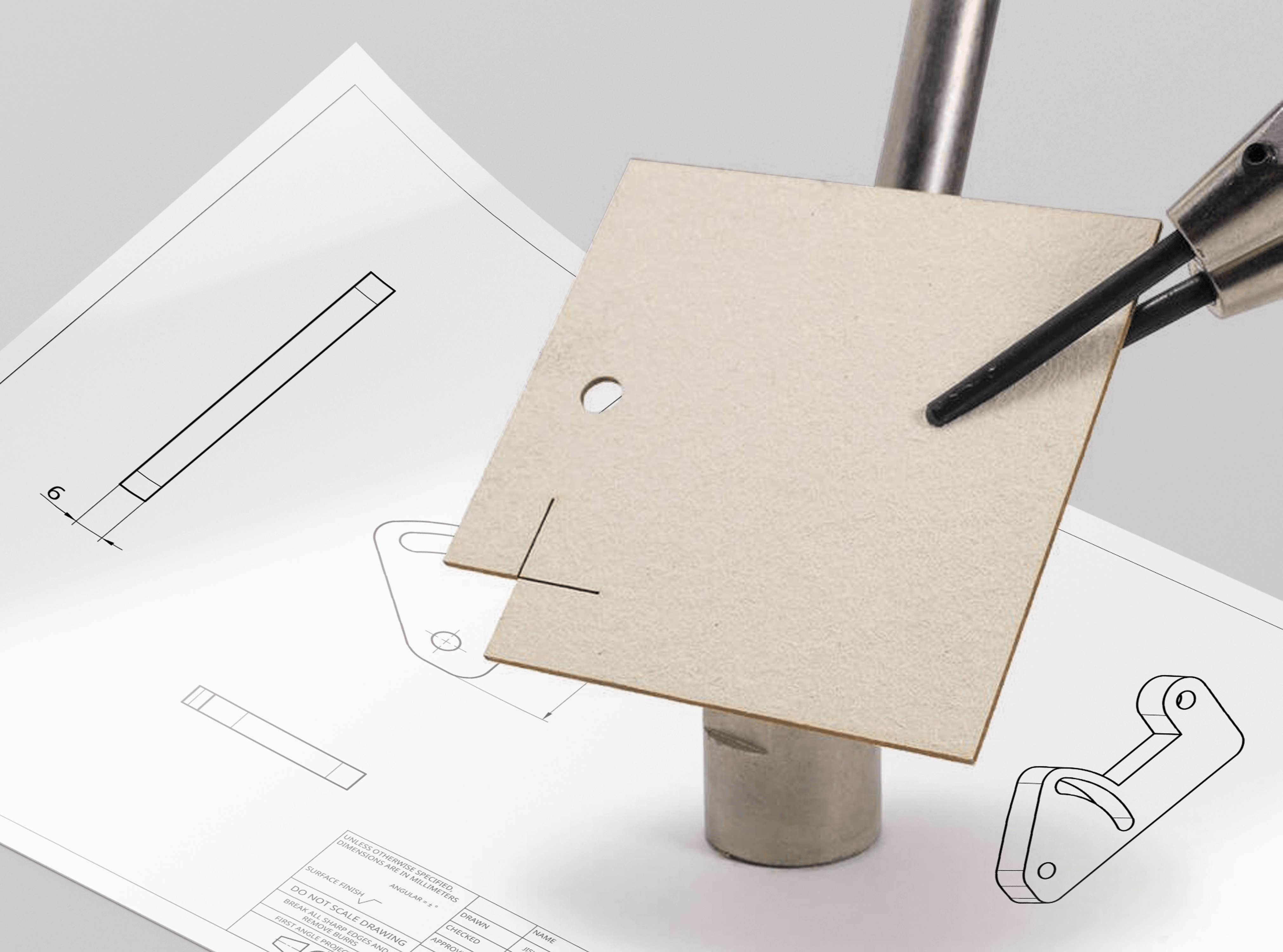

Felt cardboard is the material you know from beer mats. It is off-white and fibrous. It gives a particularly light edge after lasering, as well as soft brown engravings. All in all, lasered felt board has a quiet aesthetic which makes it very suitable for models. We recommend felt board as an alternative to grayboard.

Grayboard can be lasered but we intentionally do not offer it. Grayboard contains an adhesive that produces very sooty, black-shedding edges after cutting. This so contaminates the workpiece that we do not want to deliver it with satisfaction. Feltboard is a better alternative.

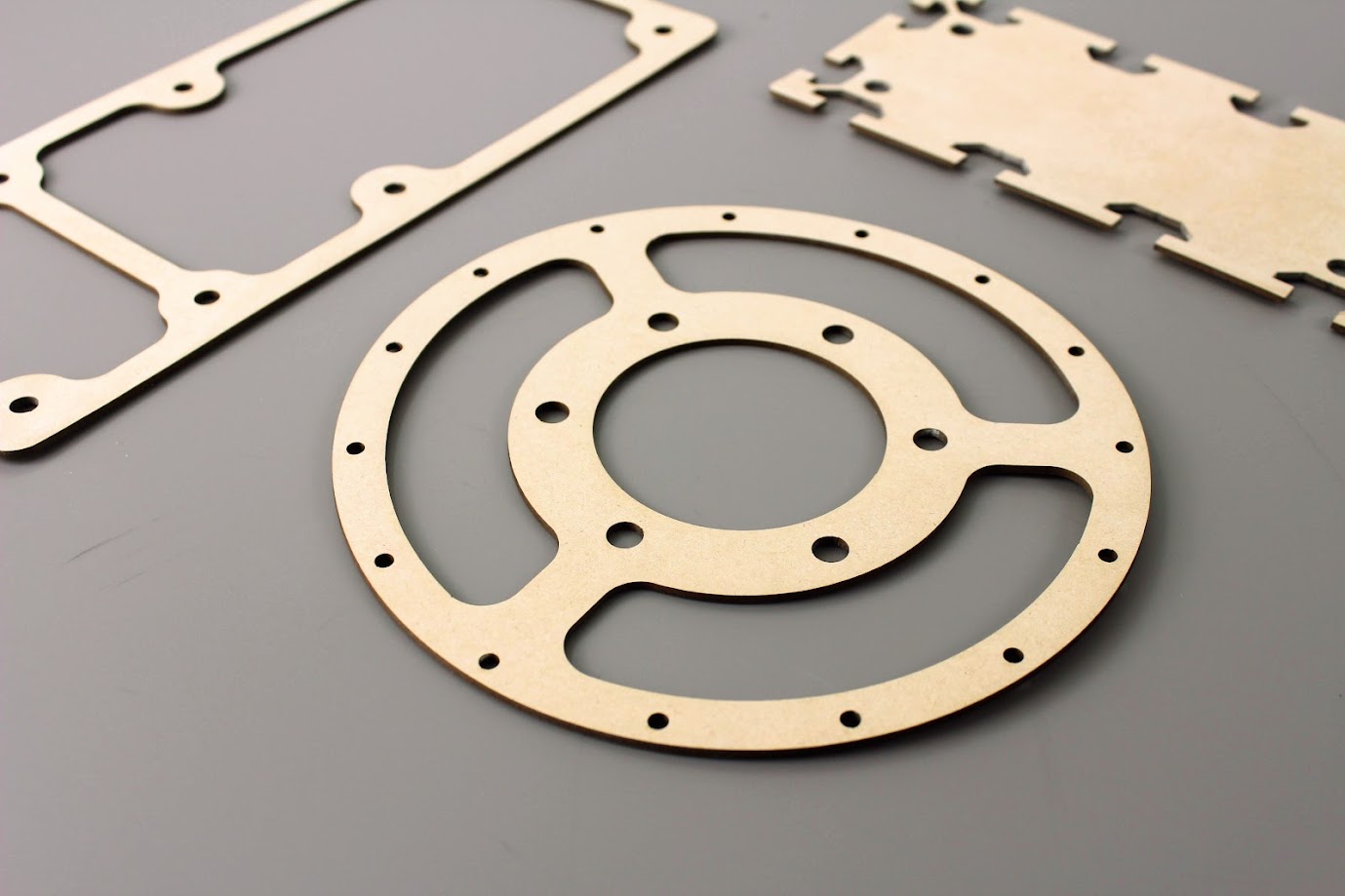

Laserboard is a special material. It is wood fibers soaked in resin in very thin sheets. The resin makes it extremely strong and impervious to deformation from heat. The laser cut is particularly thin in this material. Because of all this, you can make particularly small details in laser board which makes it suitable for the most challenging model making and model making applications.

Museum board is the go-to board when you need sleek and snow-white board. The edges turn light brown and you can engrave fairly neatly on museum board.

Easily ordered online, delivered quickly.

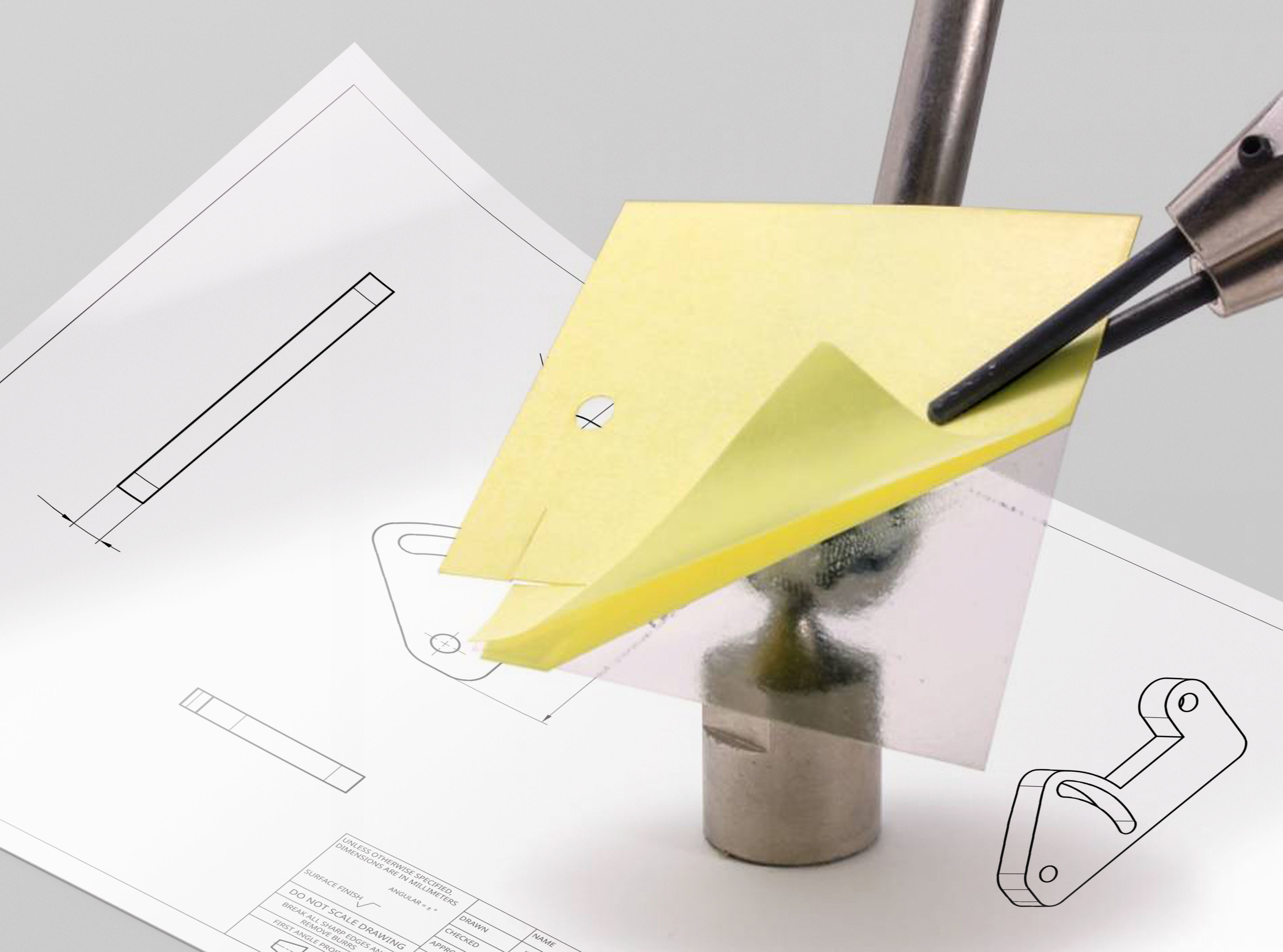

To laser cut and engrave cardboard or paper, you need a digital drawing of your design. You create that with Illustrator, AutoCad or Inkscape, for example. Save that drawing as DWG, DXF, AI or vectorPDF. create a free account at account.snijlab.nl and drag the drawing into the browser. Then choose a material and you will immediately see the price. Next you can make a delivery date choose a delivery date and checkout online. Then we will get to work and you will get your lasered design delivered to your home.

Have any questions? Our customer service is happy to help.