Laser cutting is ideal for making wooden parts. It is precise and fast. Whether you need complex shapes or small details, wood laser cutting offers countless possibilities.

With care, we have built up an assortment of high-quality wood species over the past 14 years. Each species has different properties. For example, birch plywood is strong for almost any project, while through-and-through red colored MDF then fits only for a certain type of designs.

But which of the thirteen types of wood is best for your project? Read on to discover the differences and make an informed choice.

In this blog, we'll help you with a flow chart, explanations and specifications for our wood species.

Why laser cut wood?

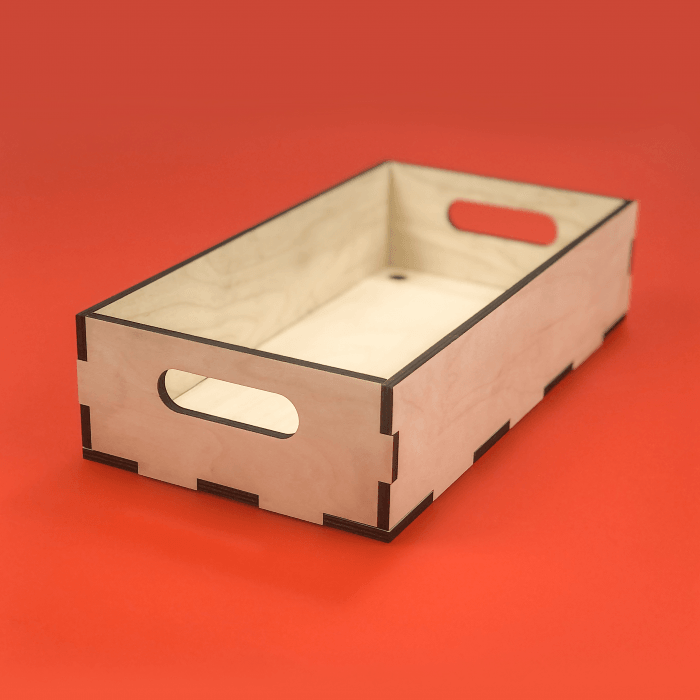

Wood is a strong, durable and versatile material, it is suitable for many different applications. The laser cuts sharp details and clean lines, which is not always possible with other techniques such as CNC milling. Our customers successfully create beautiful model parts, kits, lamps, letters, housings and machine parts from wood.

Want to know more about wood laser cutting? Go to wood laser cutting.

Do the decision aid: Which wood should I choose?

Each type of wood has unique properties. Use the handy decision aid below to quickly determine which type of wood is right for your project.

Want more explanation on materials? Below the decision aid is a detailed explanation of the differences and advantages of our wood species.

Our wood species explained

Wood board material can be divided into three categories: plywood, MDF and solid wood. Each species has different advantages, from strength to price. Are you looking for a suitable material? Then keep in mind the characteristics of each category before looking at the appearance of a material.

Category: plywood

Plywood consists of multiple layers of wood, making it strong and less prone to breakage than solid wood. The layers are cross-glued. It has a natural wood grain and is suitable for everything from small decorations to large furniture.

Birch plywood 0.5 mm - 9 mm

Our best-seller. Birch wood is strong, has a subtle wood grain and is manufactured in B/B quality. B/B quality means that there are no visible knots in the surface and inner layers. Thanks to the special glue, there is less soot along the laser cuts.

Poplar plywood 6 mm - 12 mm

Lighter in color and weight than birch, due to lower density. This makes it less strong, but we can cut poplar wood up to 12 mm thick.

Bamboo plywood 0.5 mm - 5 mm

A sustainable, 100% FSC-certified option. Bamboo plywood is strong, lightweight and less prone to breakage than solid bamboo.

Lime plywood 2 mm - 15 mm

Light in weight, but less scratchy than poplar. Available up to 15 mm, the thickest type of wood we laser cut.

Category: MDF

Medium density fiberboard, or MDF, are boards made of compressed wood fibers. It has no wood grain, usually a matte surface and you can see fibers up close. The big advantage of MDF is its price; it is very inexpensive. It is also strong, although it is sensitive to water and vulnerable at corners. MDF is easy to process.

Brown MDF 1 mm - 9 mm

Standard MDF has a neutral brown color. It is inexpensive, versatile and popular for many different applications.

Black MDF 3 mm - 6 mm

Through-and-through black colored MDF is slightly stronger than ordinary MDF, because the dye makes it slightly stiffer. The surface is smooth, you can see fibers in the board. The laser edges also color black and give off a little soot.

Colored MDF 5mm

This is similar to black MDF, it is also colored through-and-through and slightly stiffer than regular MDF. But then it comes in the colors red, orange, yellow, green, blue and gray. Unlike black MDF, the cut edges and engravings color light brown.

Coated MDF 3 mm

MDF with a water-resistant white coating on both sides. The coating has a slight texture and sheen. Please note that the sides are not water resistant.

Veneered MDF 4.2 mm - 4.4 mm

MDF with a veneer of real wood on the top and bottom. The wood gives a luxurious appearance. Easy to process, straighter and more break-resistant than solid wood. Available in:

- Oak light brown and luxurious appearance

- Ash wood light blond in color

- Walnut dark brown with characteristic grain

- Mahogany warm brown color

Category: massive wood

Bamboo side-pressed 5mm

Compressed strips of bamboo create a characteristic appearance. Suitable for decorative designs, but less so for fragile or large parts due to its susceptibility to breakage.

The best sellers

These materials have been the most chosen by our customers for years.

- Birch plywood - Strong and therefore versatile

- Brown MDF - Economical

- Lime plywood - The thickest wood we can cut

Specifications

In this table you can read the specifications for each type of wood. The stars give in estimate and show how materials relate to each other. Strength determines how fast a material breaks and hard surface says more about how fast a wood board dents. We determined how suitable wood is for making large objects based on how break-resistant and strong it is.

| thickness of | thickness to | inexpensive | strength | weight (kg/m³) | hard surface | decorative |

suitable for large objects

|

|

| Birch plywood | 0.5 | 9 | ★★ | ★★★★ | 750 | ★★★★ | ★★★★★ | ★★★★ |

| Poplar plywood | 6 | 12 | ★★ | ★★★ | 400 | ★ | ★★★ | ★★★★★ |

| Lime plywood | 2 | 15 | ★★★ | ★★★★ | 600 | ★★ | ★★★★ | ★★★ |

| Bamboo plywood | 0.5 | 5 | ★ | ★★★★ | 820 | ★★★★★ | ★★★★★ | ★★★ |

| Bamboo side-pressed | 5 | 5 | ★ | ★★★ | 770 | ★★★★★ | ★★★★★ | ★ |

| Brown MDF | 1 | 9 | ★★★★★ | ★★★★ | 880 | ★★★ | ★ | ★★★★ |

| Colored MDF | 5 | 5 | ★ | ★★★★ | 860 | ★★★★ | ★★★★ | ★★★ |

| Black MDF | 3 | 6 | ★★★★ | ★★★★ | 1060 | ★★★★ | ★★★ | ★★★★ |

| Coated MDF | 3 | 3 | ★★★★ | ★★★ | 860 | ★★ | ★★ | ★ |

| Oak (MDF core) | 4 | 4 | ★★★ | ★★★ | 780 | ★★ | ★★★★★ | ★★ |

| Ash (MDF core) | 4 | 4 | ★★★ | ★★★ | 780 | ★★ | ★★★★★ | ★★ |

| Walnut (MDF core) | 4 | 4 | ★★★ | ★★★ | 780 | ★★ | ★★★★★ | ★★ |

| Mahogany (MDF core) | 4 | 4 | ★★★★ | ★★★ | 780 | ★★ | ★★★★ | ★★ |

Available thicknesses

This table shows the thicknesses in which our woods are available.

| 0.5 | 1 | 1.5 | 2 | 3 | 4 | 5 | 6 | 9 | 10 | 12 | 15 | |

| Birch plywood | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||

| Poplar plywood | ✓ | ✓ | ✓ | |||||||||

| Lime plywood | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Bamboo plywood | ✓ | ✓ | ✓ | ✓ | ||||||||

| Bamboo side-pressed | ✓ | |||||||||||

| Brown MDF | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||

| Colored MDF | ✓ | |||||||||||

| Black MDF | ✓ | ✓ | ||||||||||

| Coated MDF | ✓ | |||||||||||

| Oak (MDF core) | ✓ | |||||||||||

| Ash (MDF core) | ✓ | |||||||||||

| Walnut (MDF core) | ✓ | |||||||||||

| Mahogany (MDF core) | ✓ |

The board thickness of a material can deviate slightly from the indicated thickness, the margin we calculate for this is called the thickness tolerance. You can find the thickness tolerance for each material in the specifications.

Want to know more?

Already know which wood you want to choose? Check out our material overview for more details. Have any questions? Please feel free to contact us, we are happy to help!