How Snijlab delivers custom-made, laser-cut parts for a medical care station

How AMiS-PRO came into being

Parts are not available on the market

AMiS-PRO contains a number of custom parts that are not available as standard. These parts must be custom-made and of consistent and high quality. At the same time, Alphatron also wants to be able to make adjustments to the design with progressive insight, without major consequences for the cost price.

SolutionCustom parts laser cut

Laser cutting is an ideal way to make custom parts. It is fast and flexible, because you can make continuous adjustments to the digital design. This leaves room for development and progressive insight. Laser cutting is also reliable: as a customer, you can always have parts made again, even in the long term. They are never 'unavailable'.

Thanks to their online quotation tool, you as a customer can see for yourself which design adjustments affect the price. This way you can easily make adjustments.

Sander Vieveen, Alphatron Medical

Challenge

Customer wants flexibility in design process

It is important for every customer to quickly see the influence of a design process

decisions, especially in terms of costs.

Solution

Alphatron can create and adjust quotations online itself

In the quotation tool on Snijlab.nl one can upload drawings without obligation and choose from the material, finishing and delivery options. The influence of design adjustments on the price can be checked directly.

The screen must be flexible

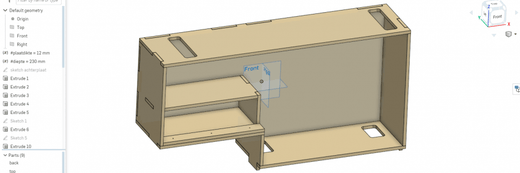

AMiS-PRO is a medication cart with medication drawers and at the same time a care station with built-in software and a screen. The cart is driven around the departments, whereby the screen must be able to be easily lowered. In addition, it is important that the nurses can work ergonomically. Adjusting the screen to individual eye level is therefore an important function of this device.

Adjusting the screen with sliding discs

The smooth movement of the screen is done by means of sliding discs. Snijlab has over 80 materials in stock and Alphatron chooses to make the discs from polyacetal. Polyacetal parts turn smoothly, without jerking or jamming. It is also impact and wear-resistant, so very durable. Due to the large stock, this material is always immediately available.

Challenge

Prevent failure with the right materials

AMiS-PRO contains a medication box with different types of drawers in which medication can be stored. The drawers are linked to the digital patient file, so that each patient receives the right medication in the right quantities. Alphatron initially had the partitions in the drawers made of cast acrylic (standard plexiglass), but due to the variation in thickness of that material, some partitions did not fit.

Solution

A material with lower thickness tolerance

On the advice of Snijlab, the use of extruded acrylic was changed. The properties are almost the same as cast acrylic, but the thickness varies much less. As a result, the partitions now always fit.

"Snijlab thinks along, switches quickly and delivers prototypes in a short time."

Sander Vieveen, Alphatron Medical

Challenge

Parts for AMiS-PRO require serial production

Large quantities of these custom-made parts are required. When produced with regular laser cutting techniques, this is expensive.

SolutionSnijlab also supplies laser-cut parts in larger quantities

Snijlab is the only company in the industry with machines that fully automatically load and unload material. This makes it possible to laser cut series of parts, in a short time and at low costs. Snijlab offers a solution for customers who want both flexibility and larger quantities. An additional advantage is that the parts of this production line do not have smoke deposits.

More about AMiS-PRO

An all-in-one mobile care station that enables safe, efficient and ergonomic working for nursing staff: AMiS Solutions