Info over akoestische panelen

Wat is er leuker dan een akoestisch paneel zelf ontwerpen en laten lasersnijden? Bestel vanaf één stuk, of maak een ontwerp met een serie tegels bijvoorbeeld. Maar welk materiaal is het beste voor jouw akoestiek panelen? En waar moet je op letten bij het ontwerpen? Lees verder, we leggen het je uit.

Materialen voor akoestische panelen

Filters

6 products

Materiaaltip

New material: acoustic PET felt

PET felt is made from recycled PET bottles. In addition to being color and wear resistant, it has excellent acoustic properties. Namely, it is sound-damping and sound-absorbing. In addition, it is ...

Welk materiaal moet ik kiezen voor mijn akoestische paneel?

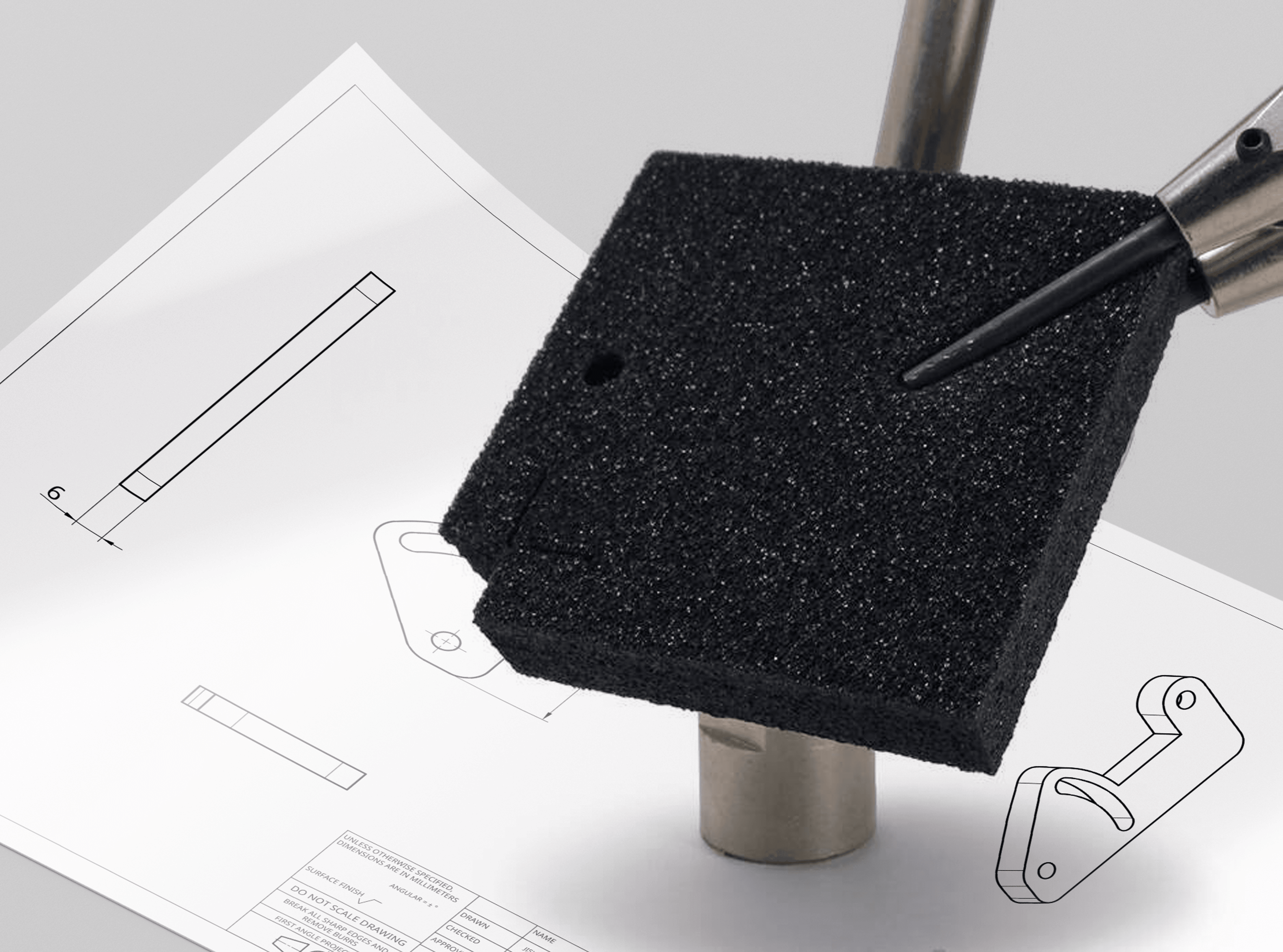

Wil je minder geluidsoverlast op kantoor? Of de echo verminderen in een grote ruimte? Een paneel of object voor akoestische isolatie kun je goed lasersnijden.

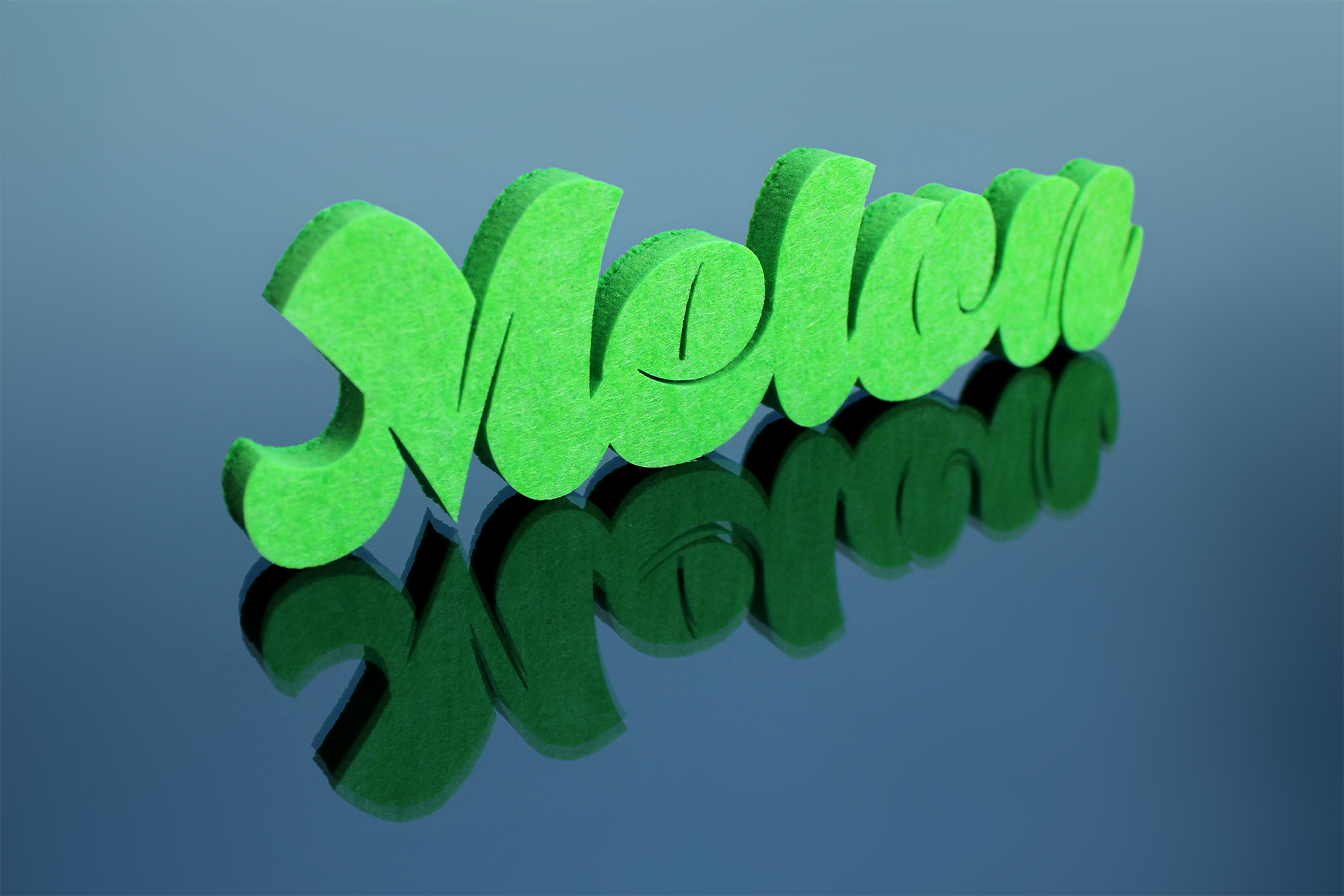

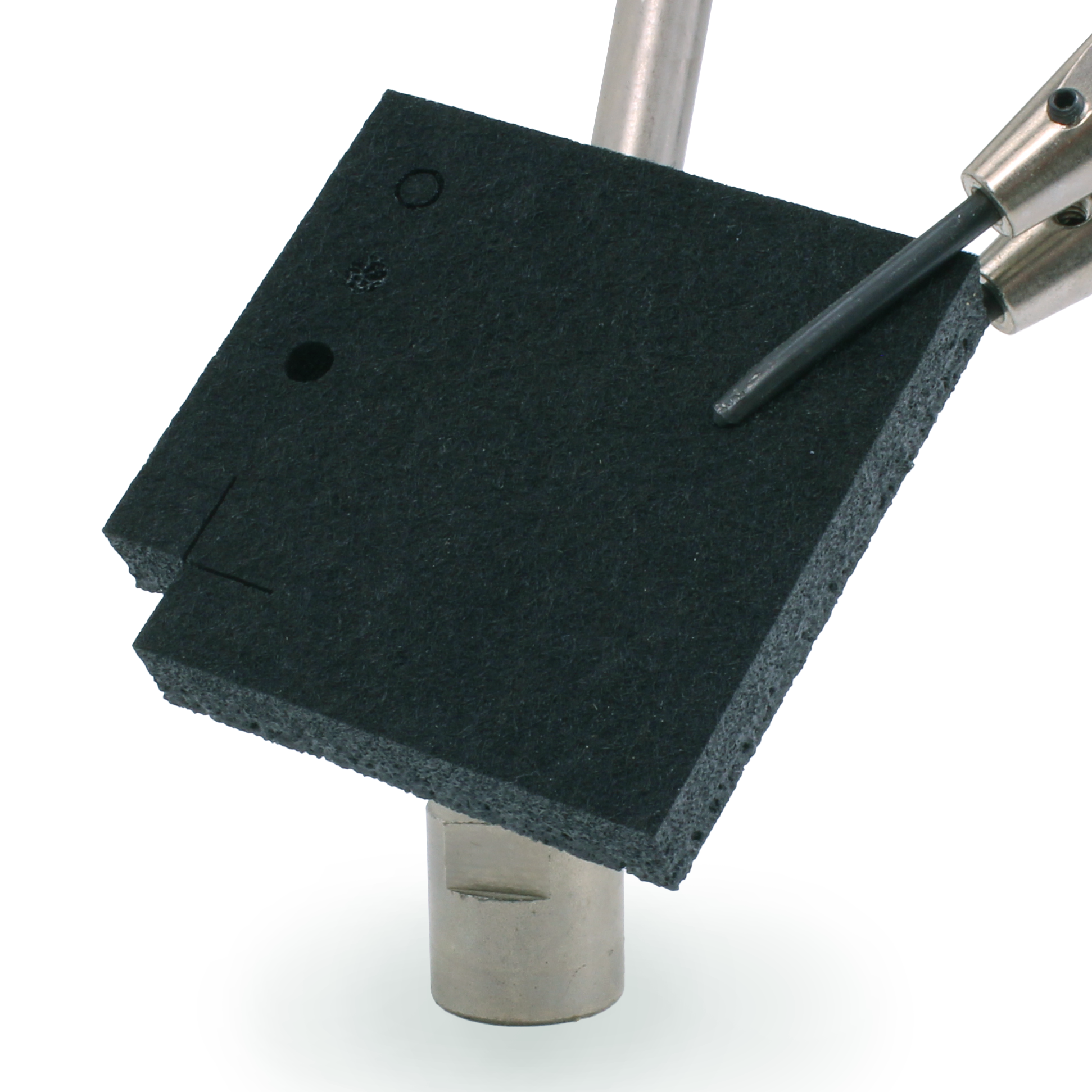

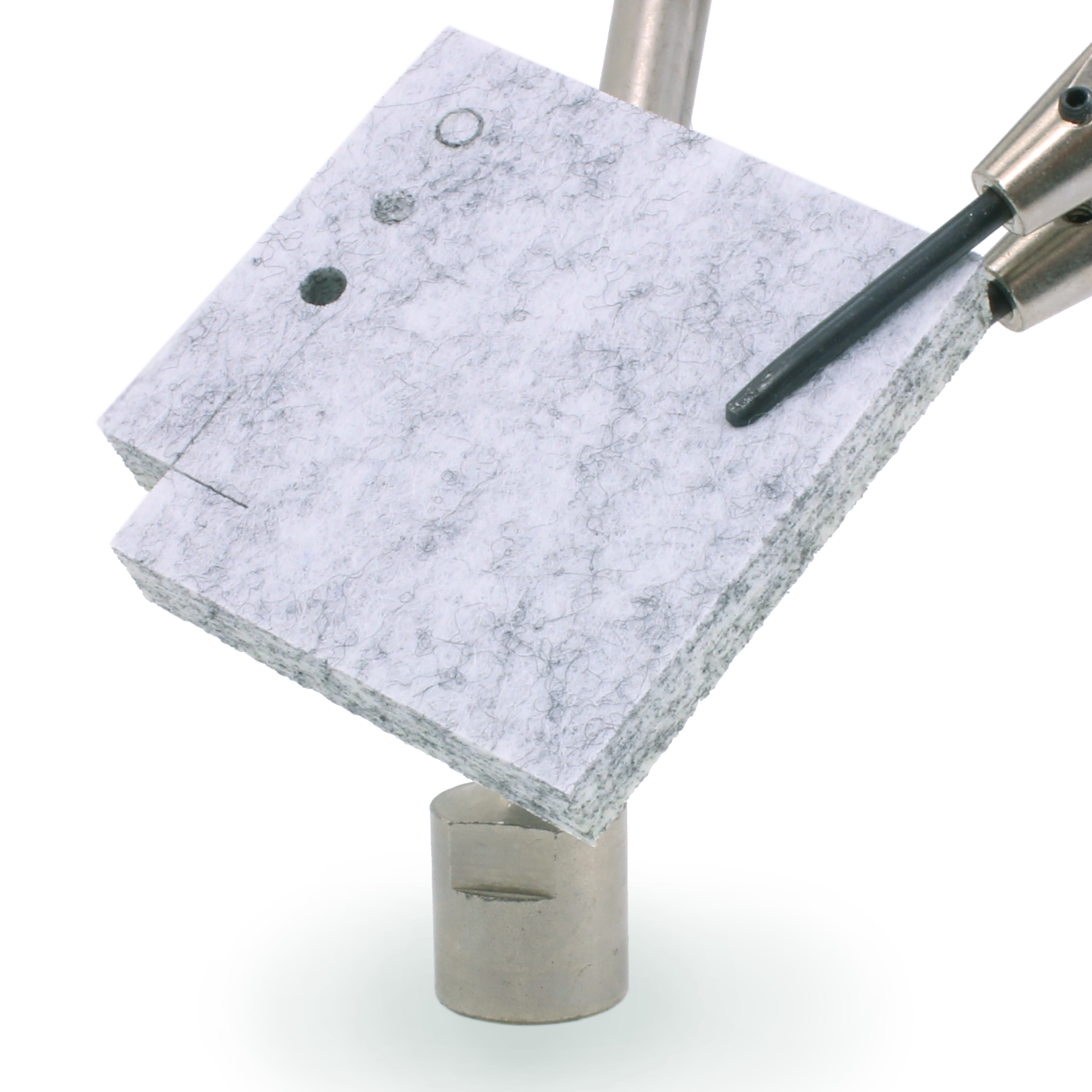

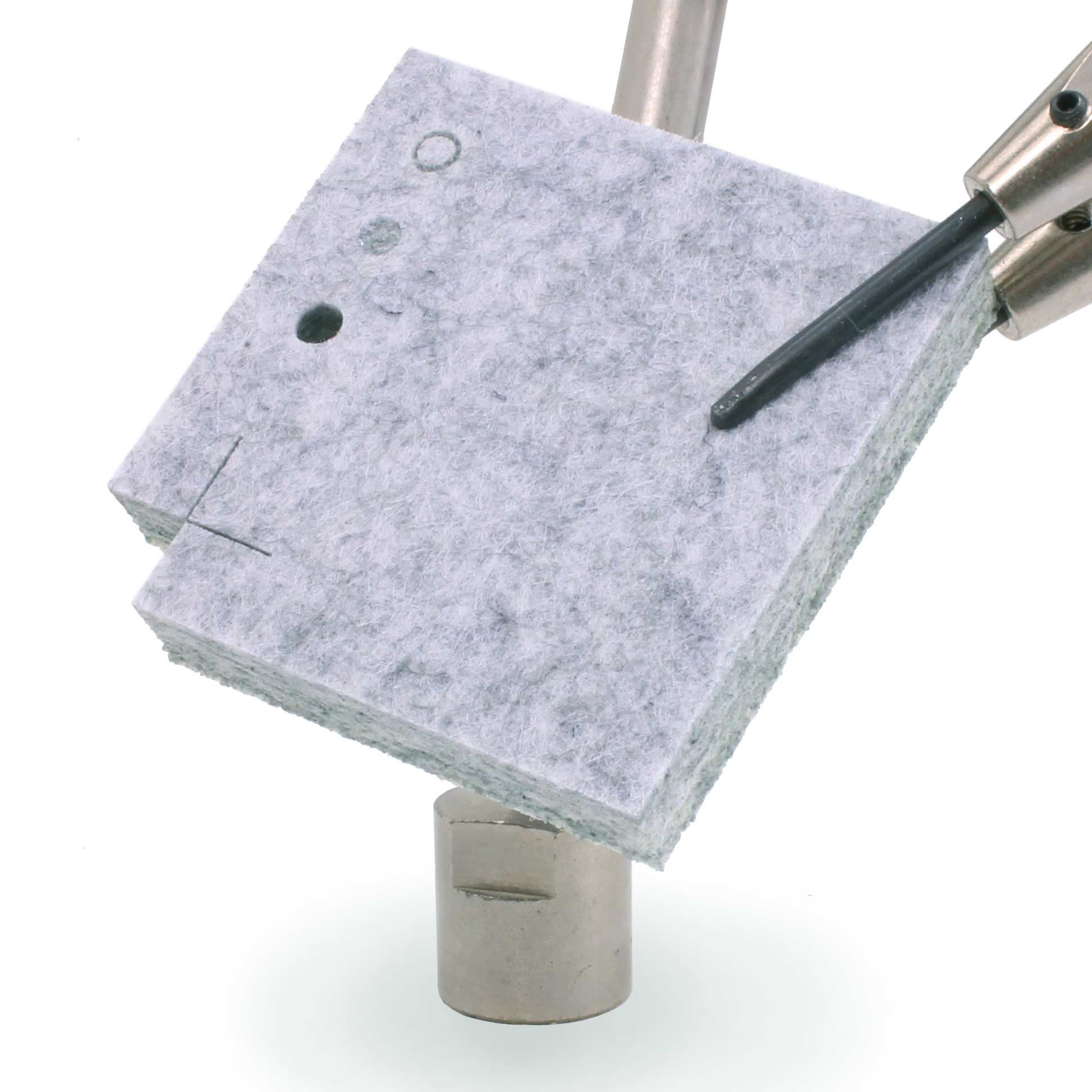

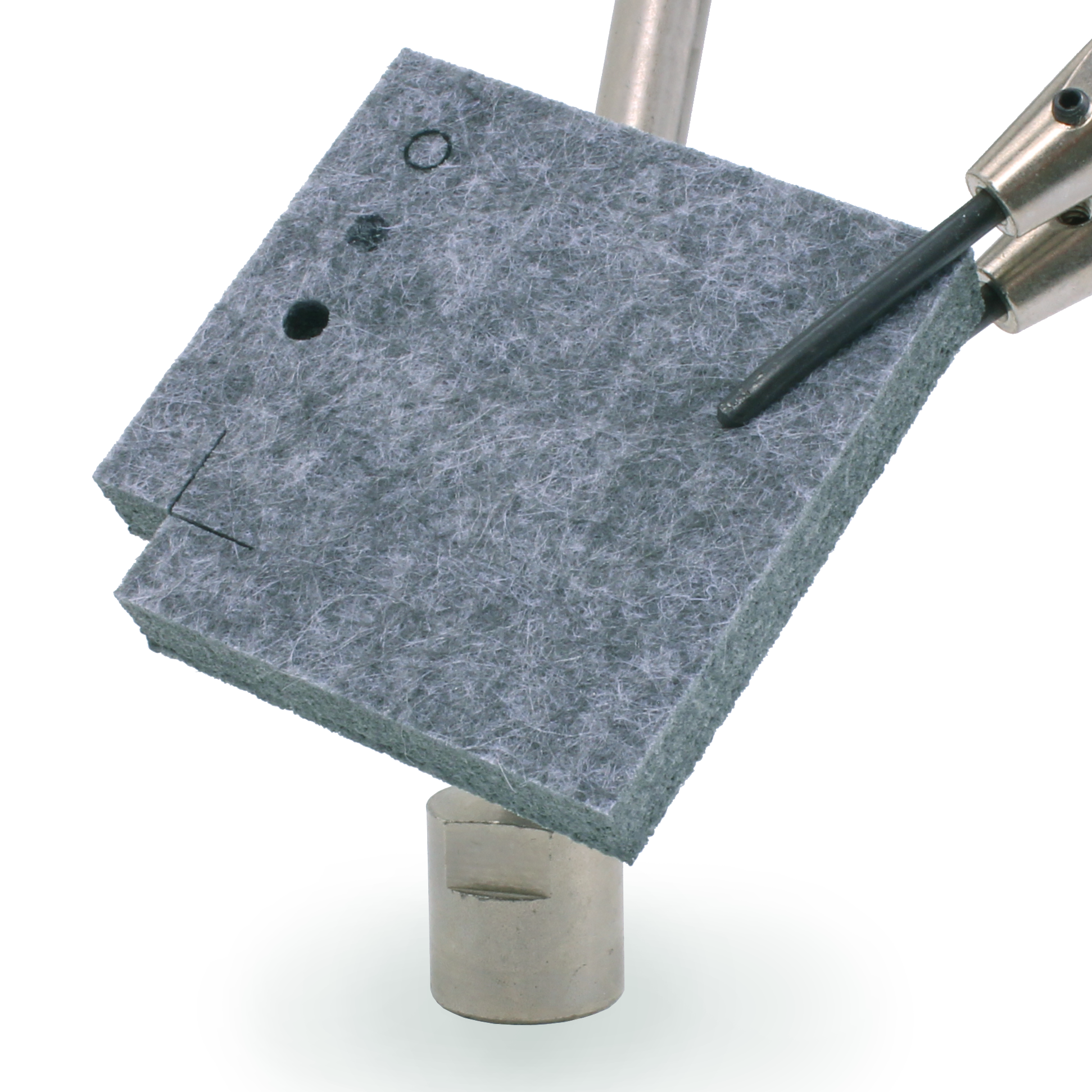

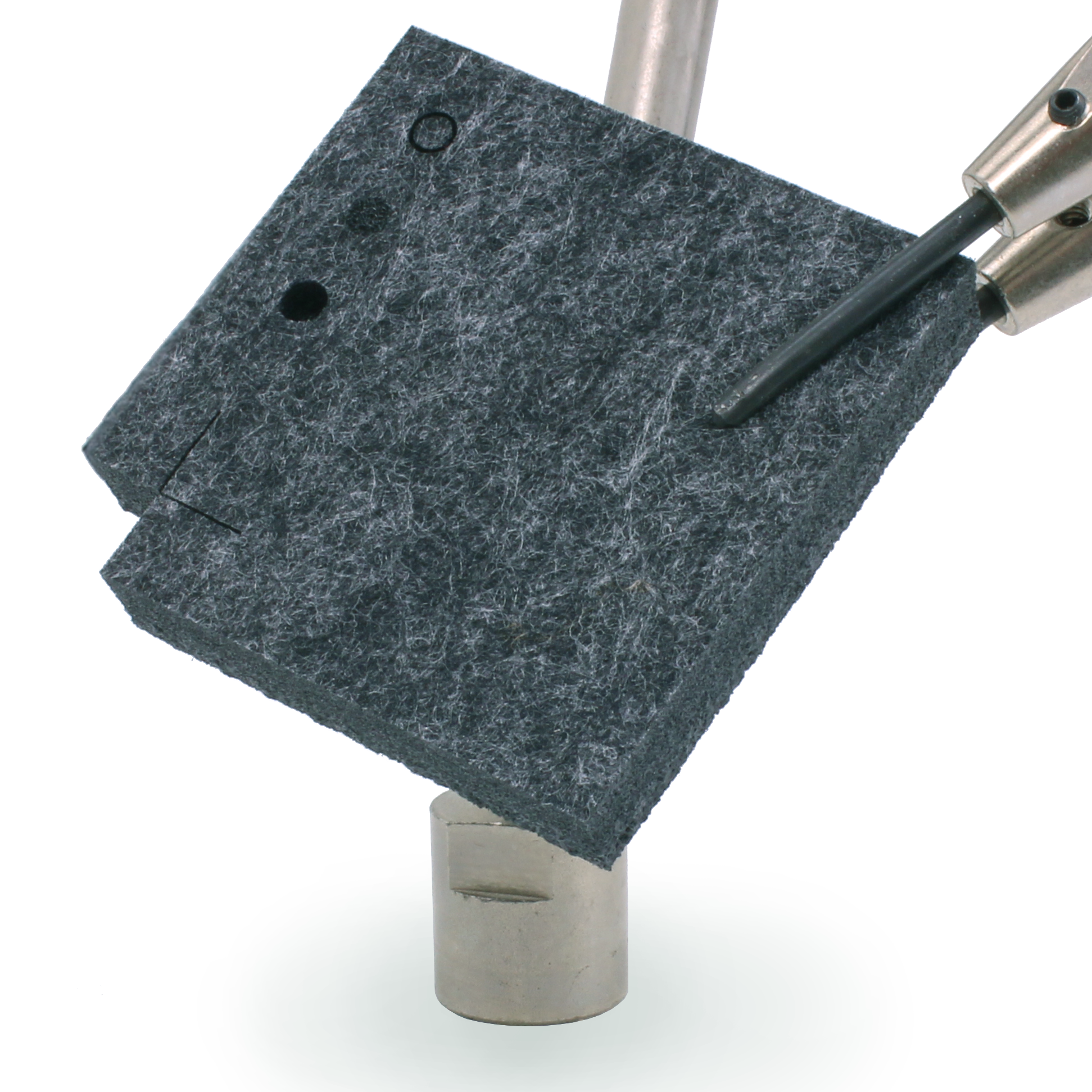

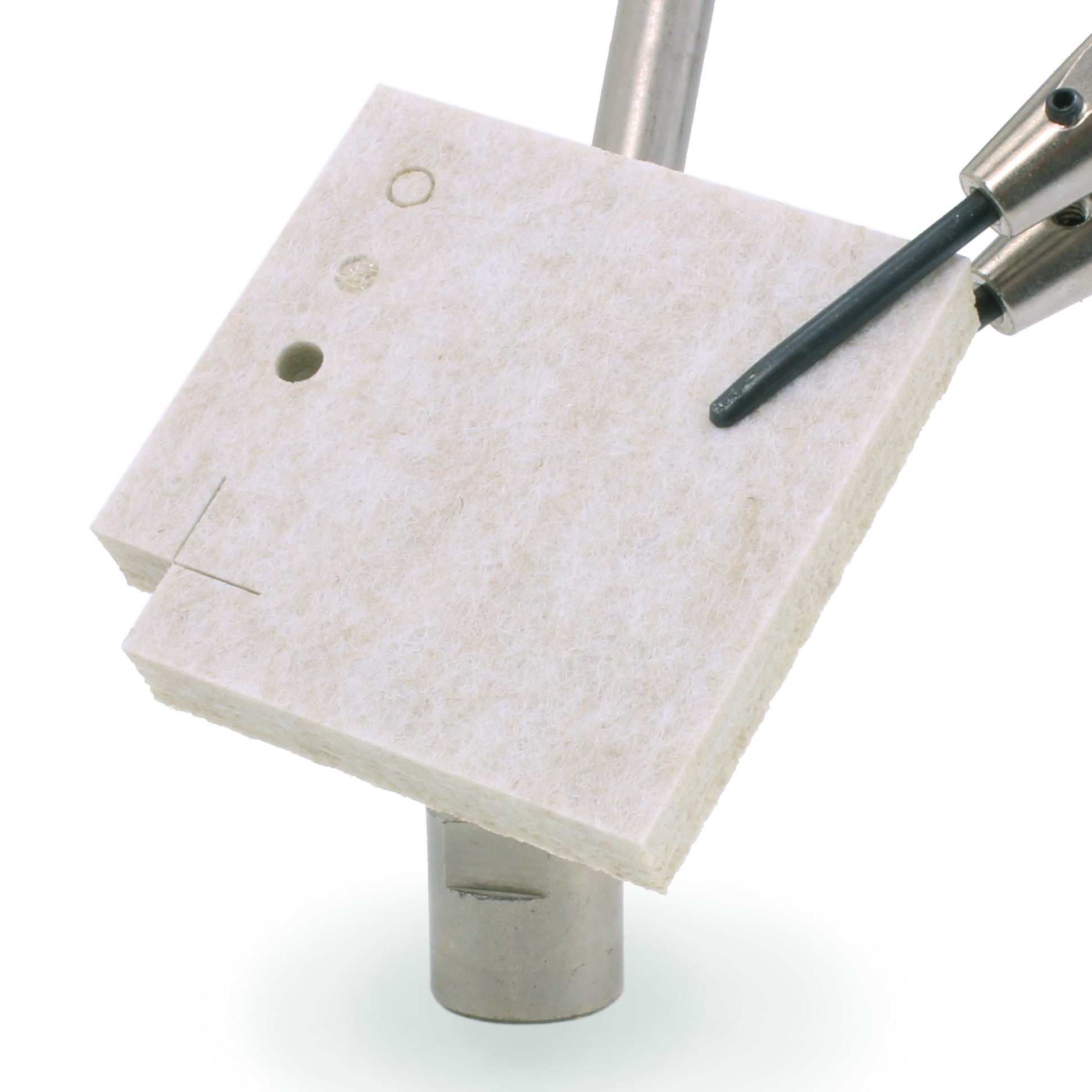

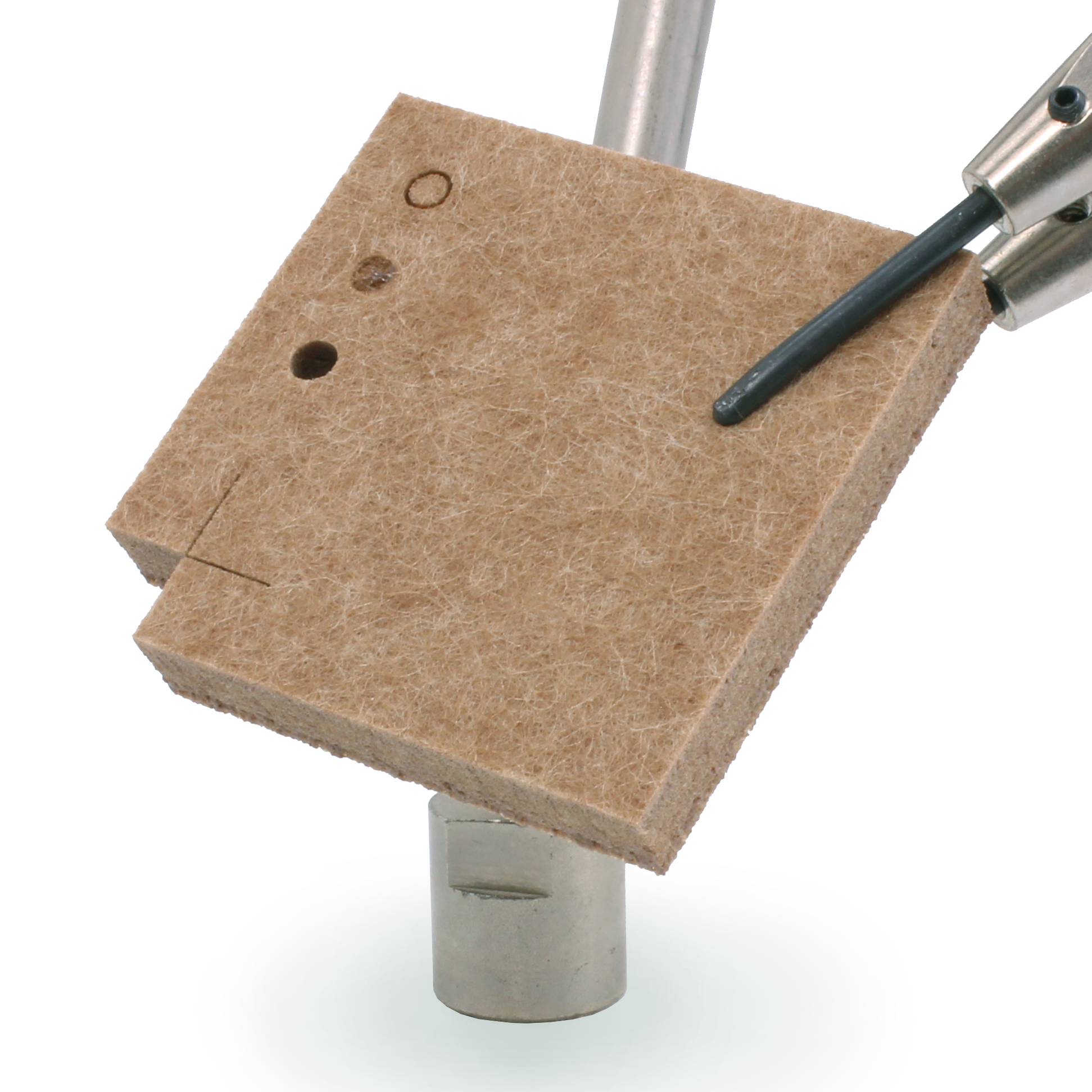

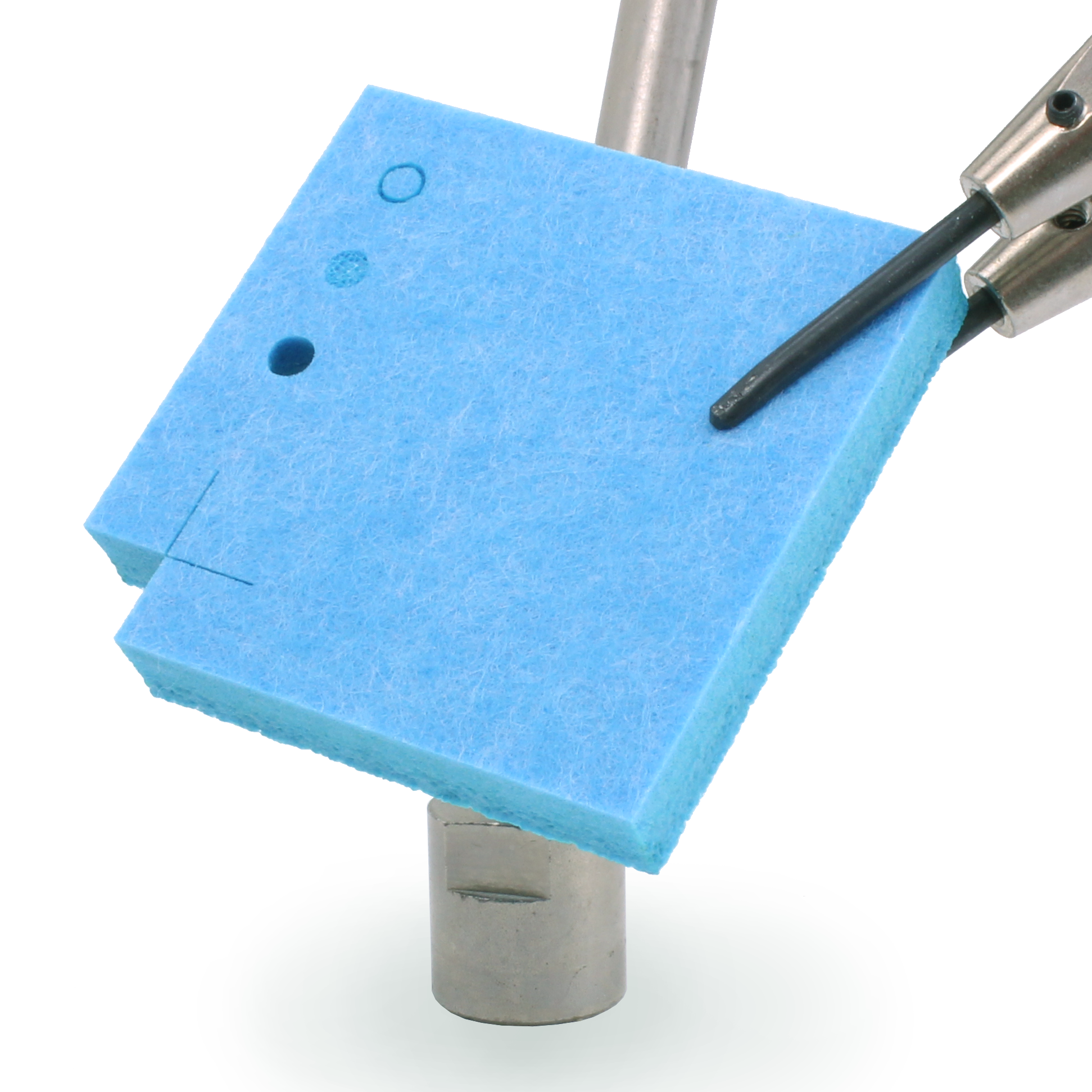

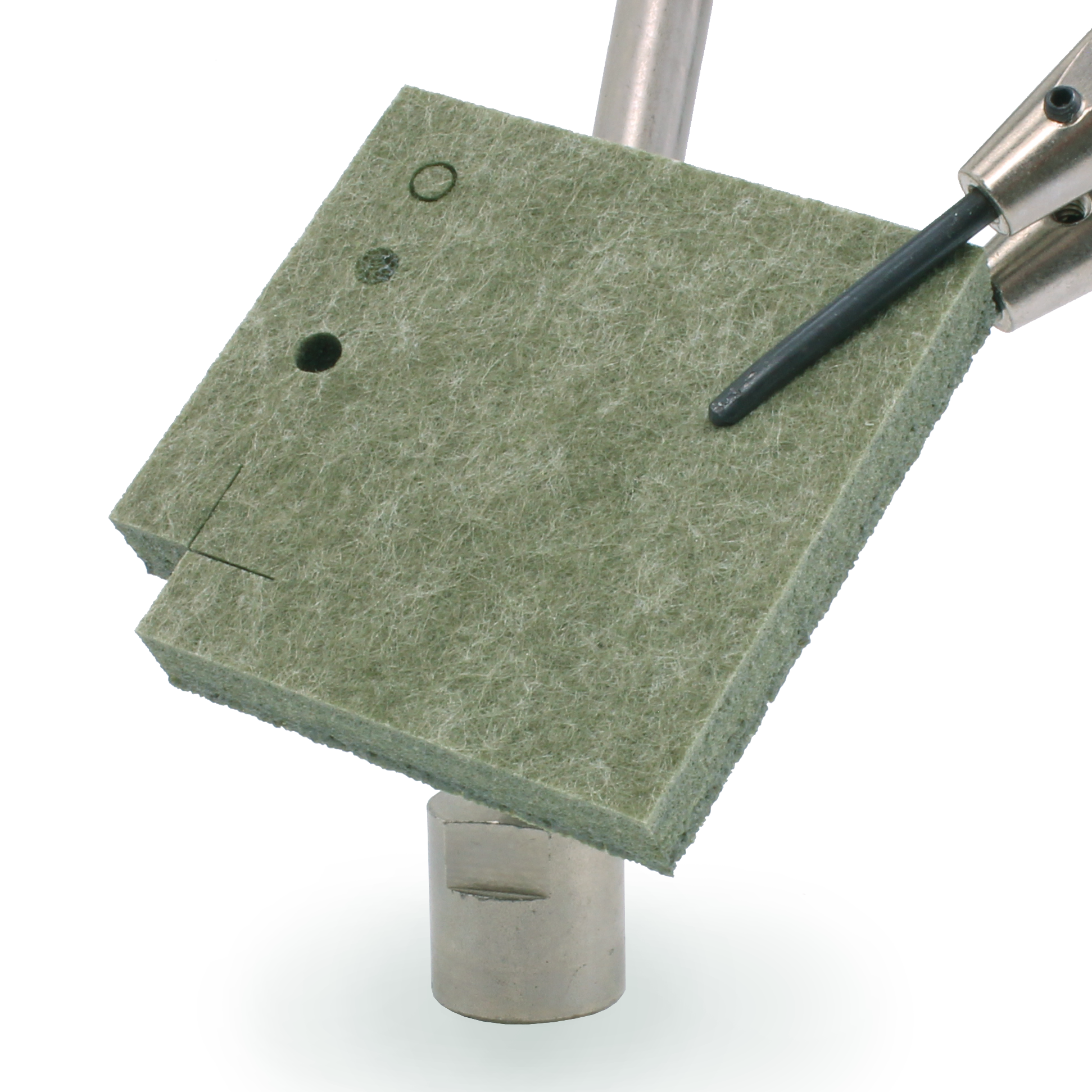

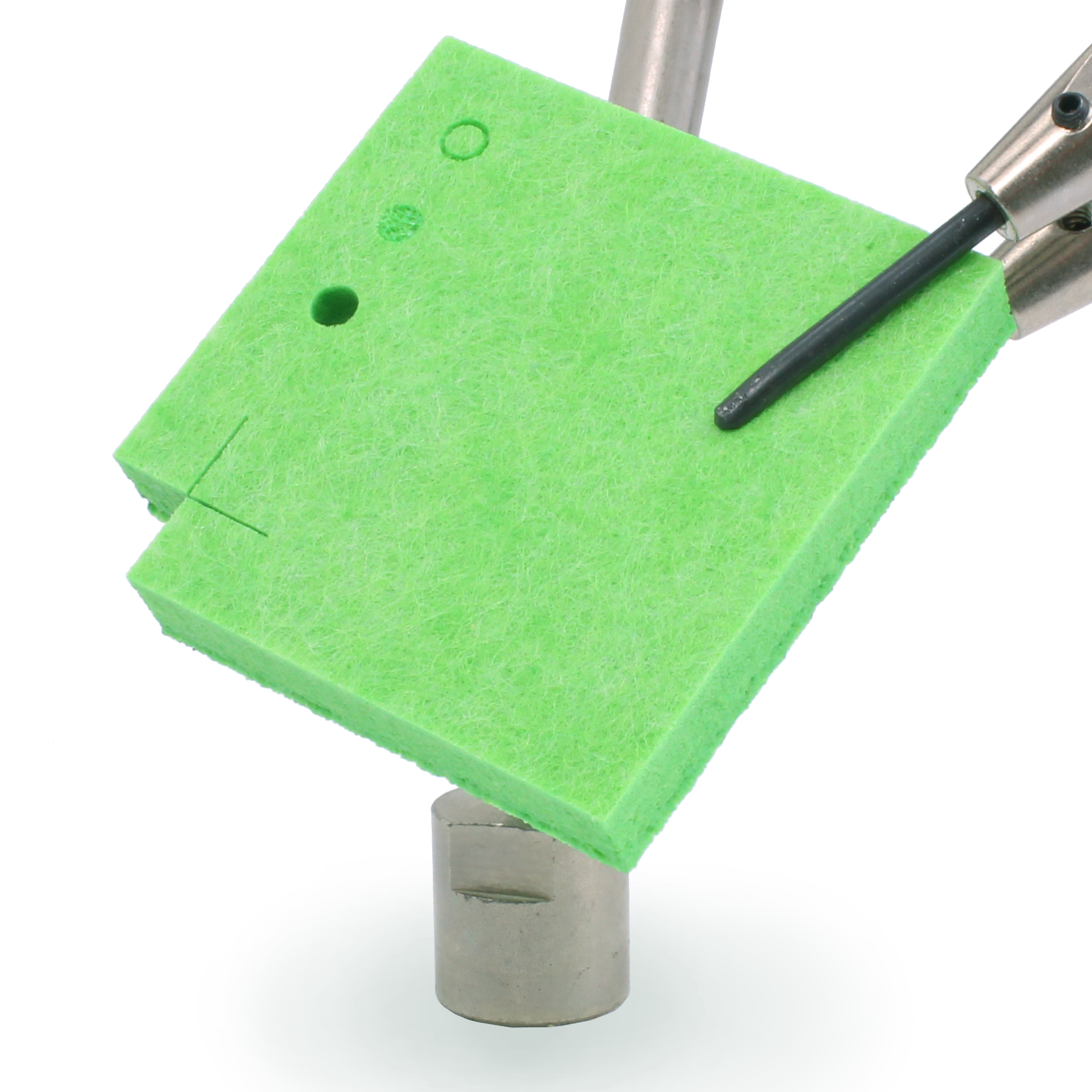

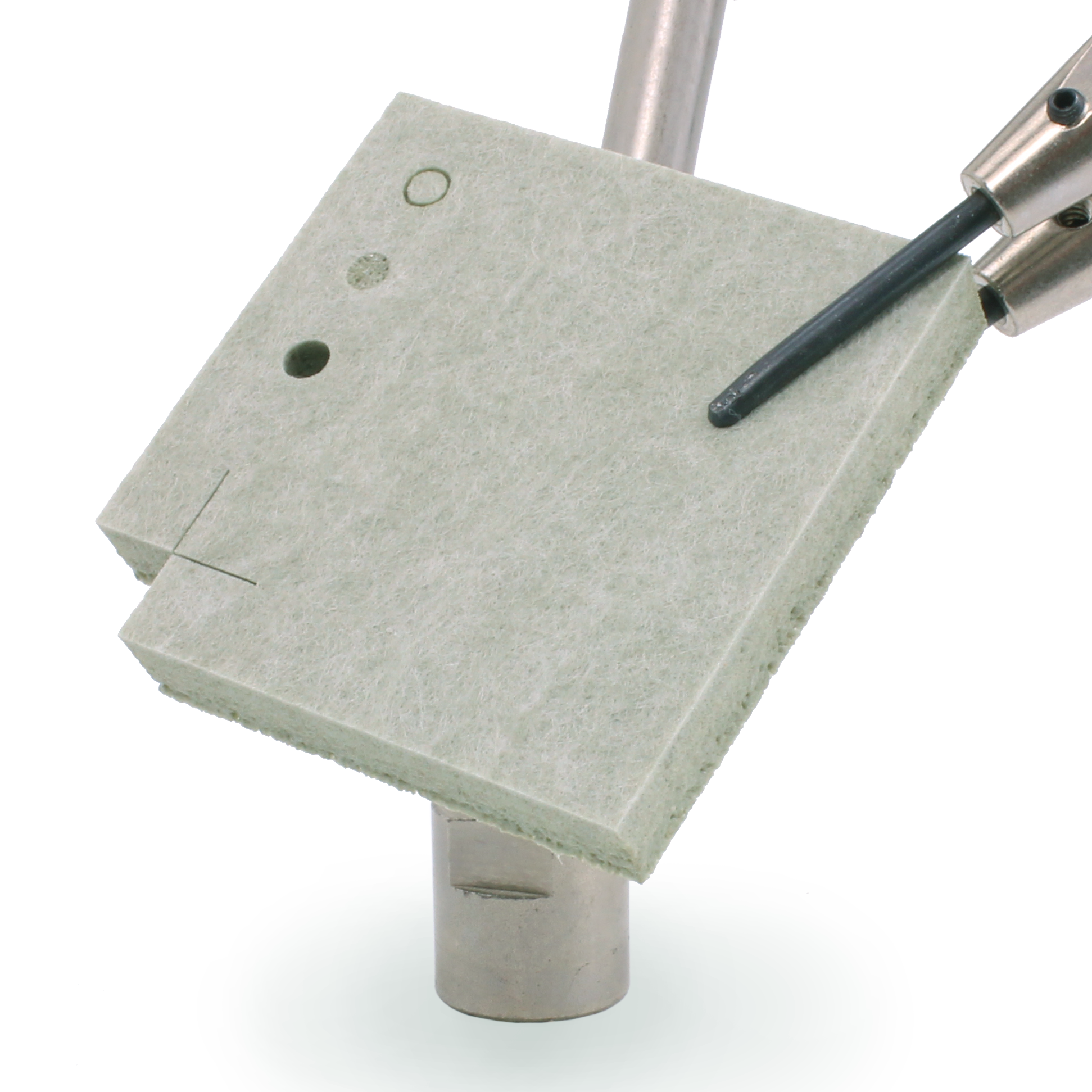

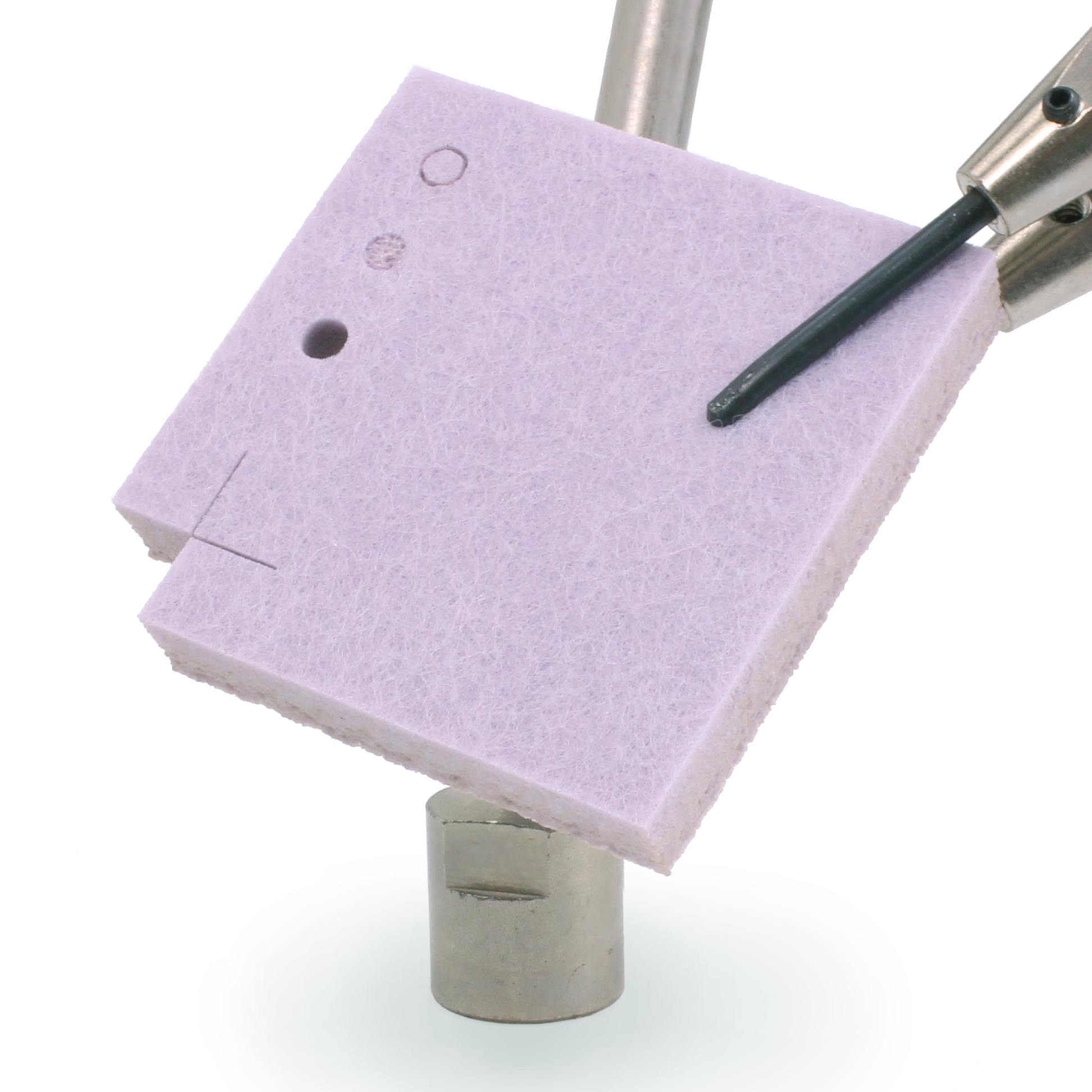

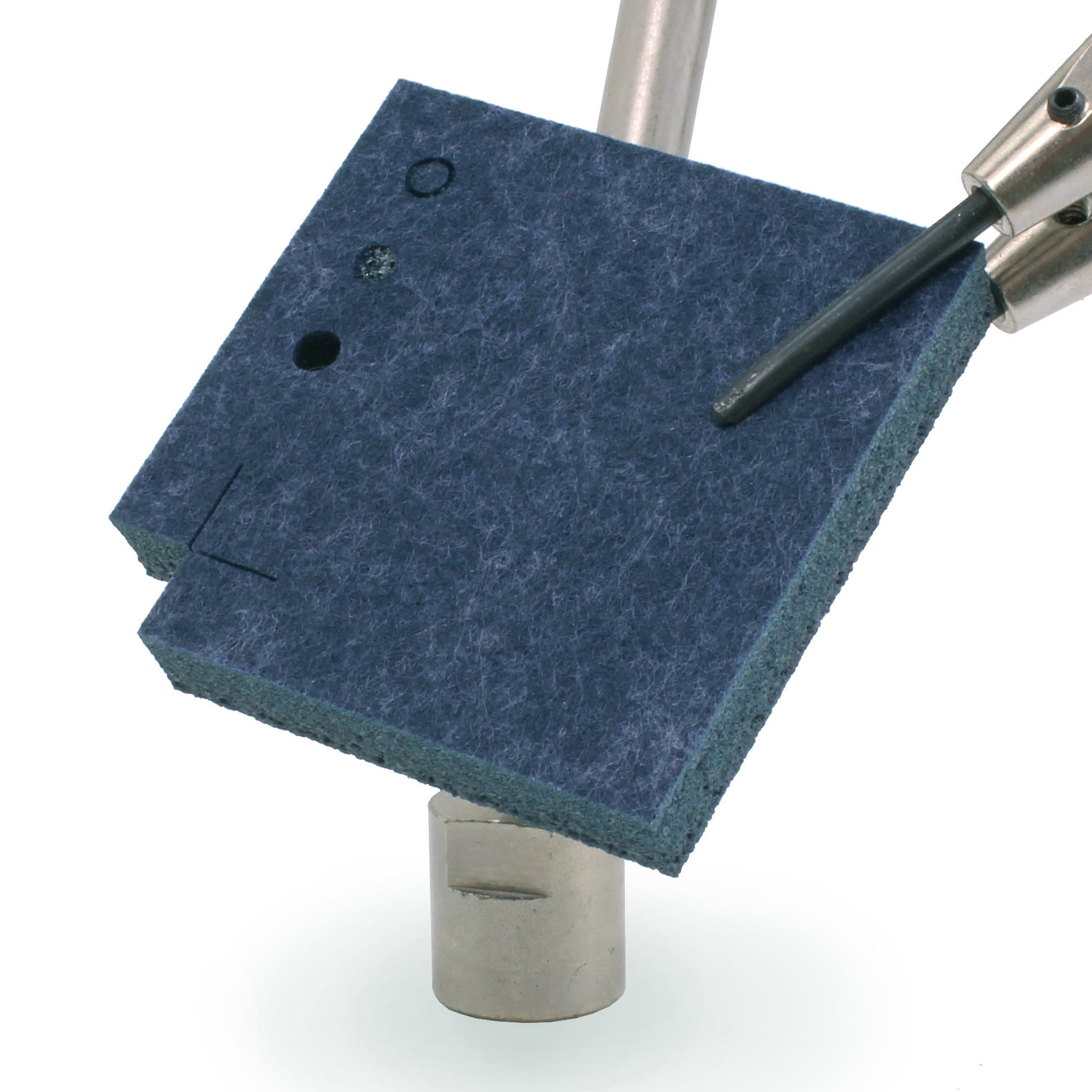

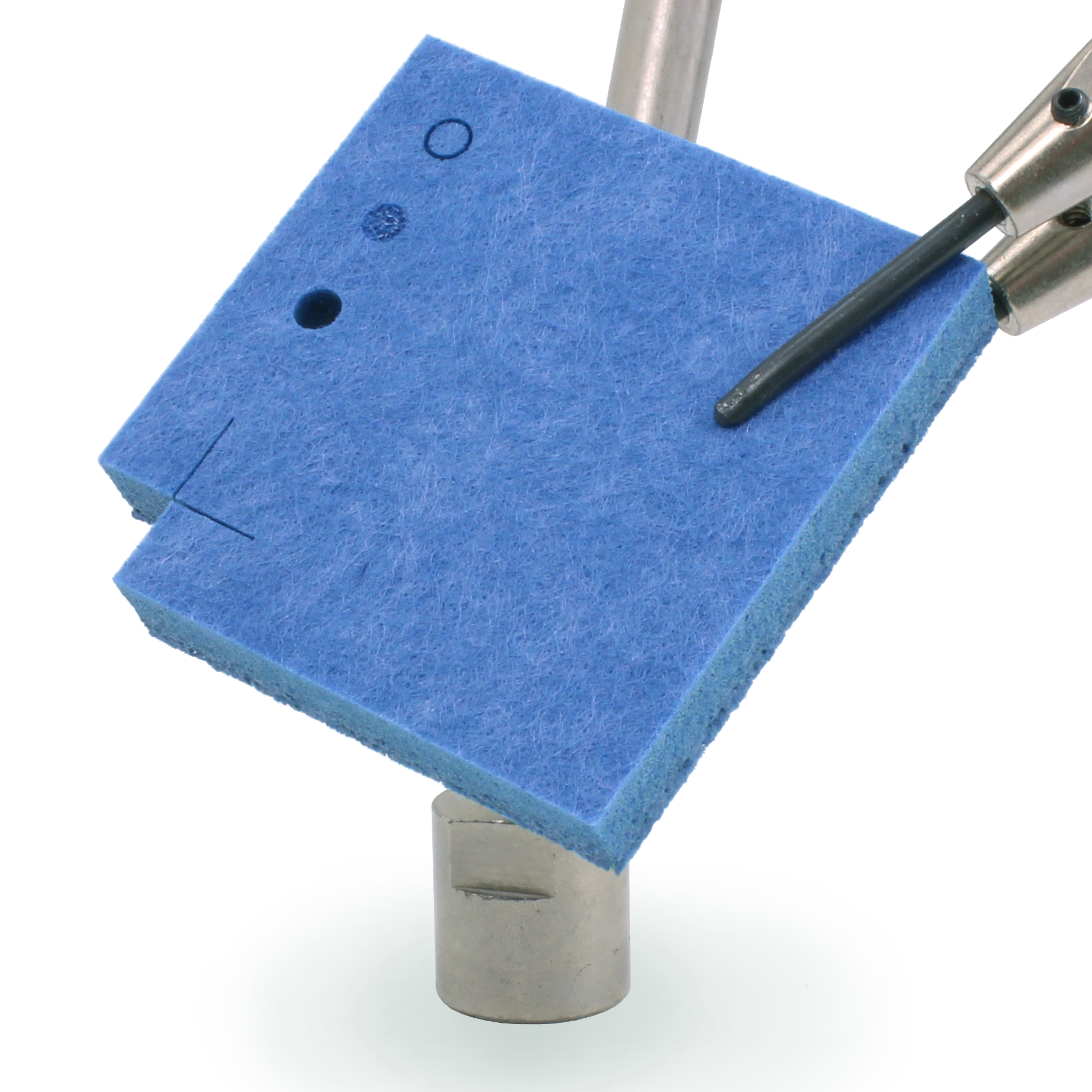

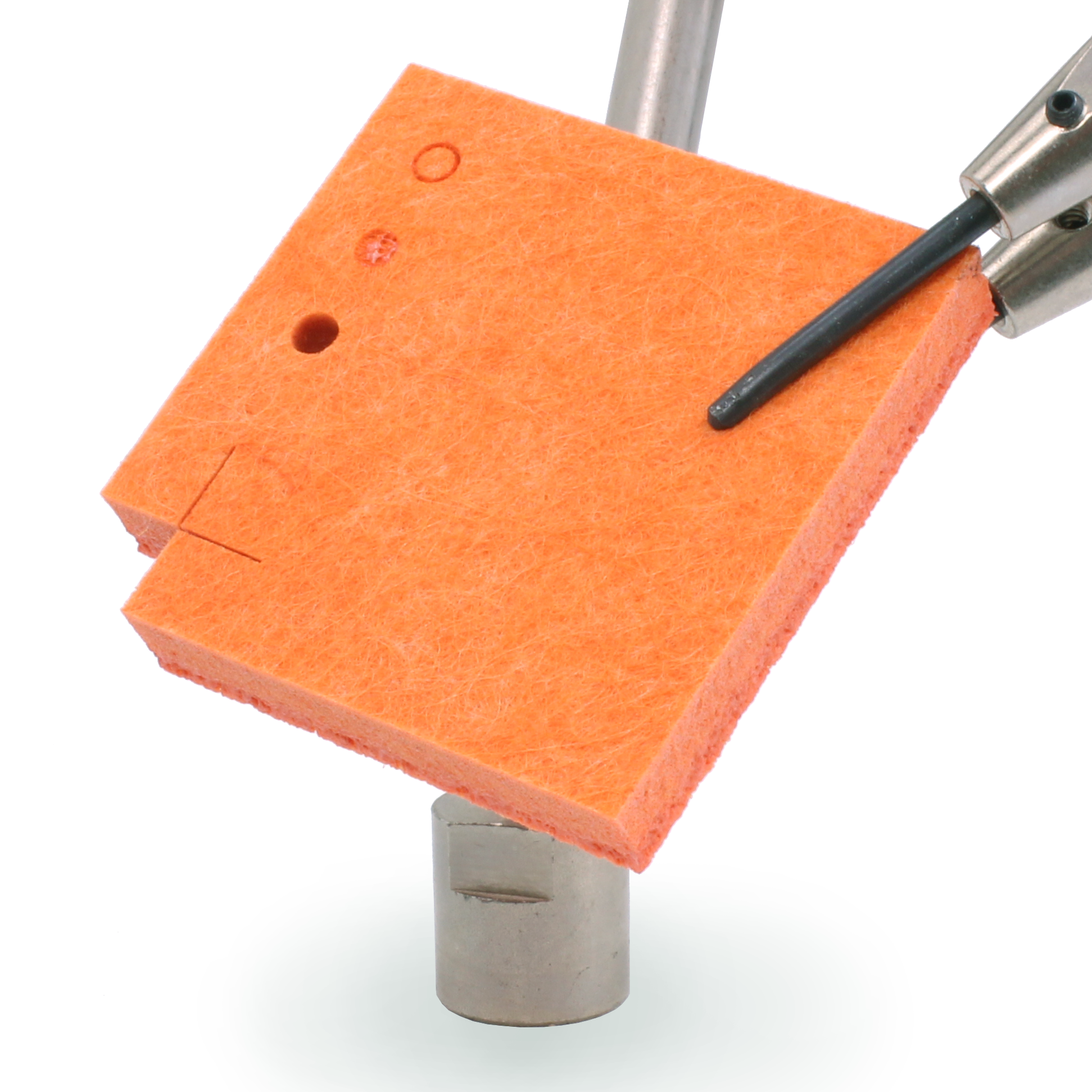

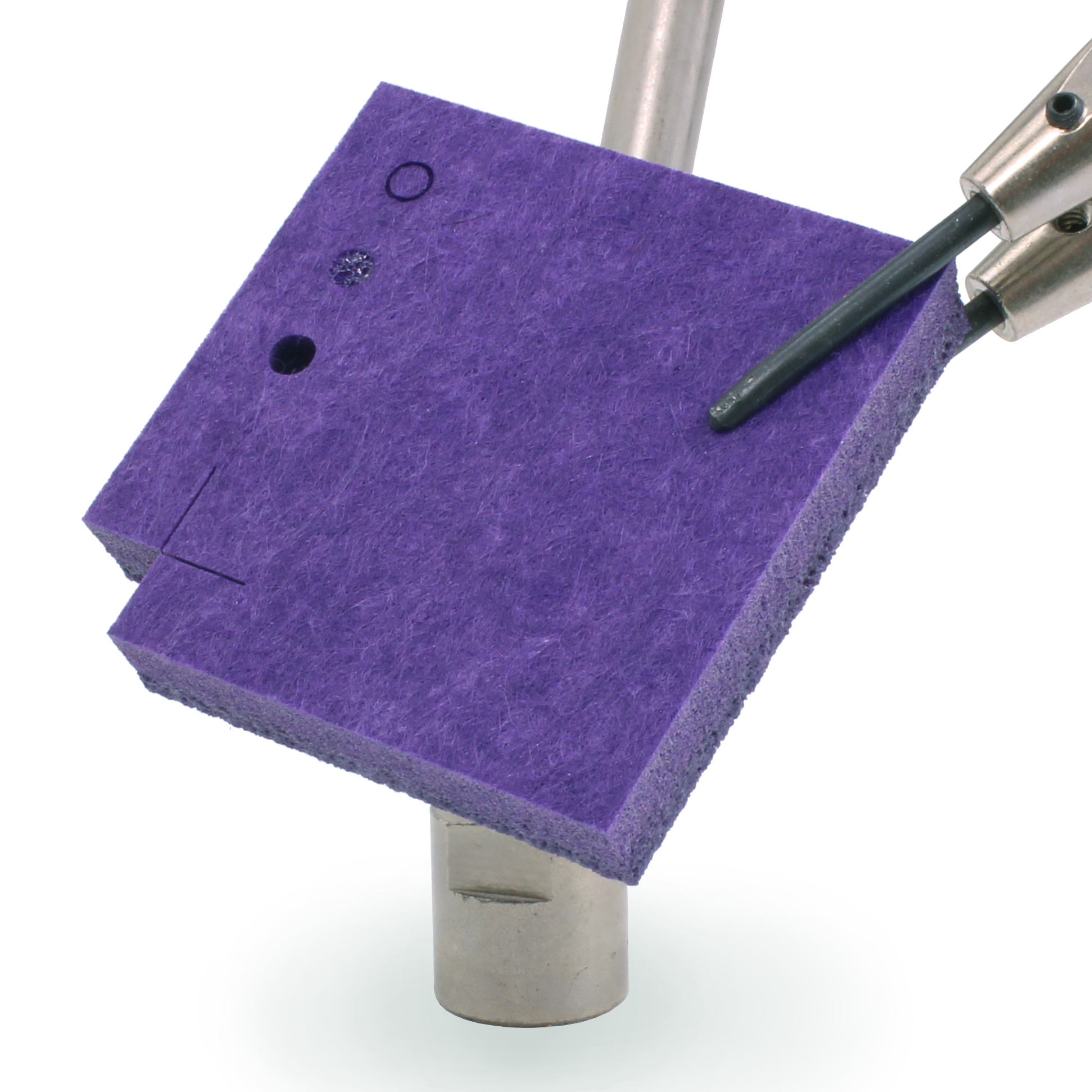

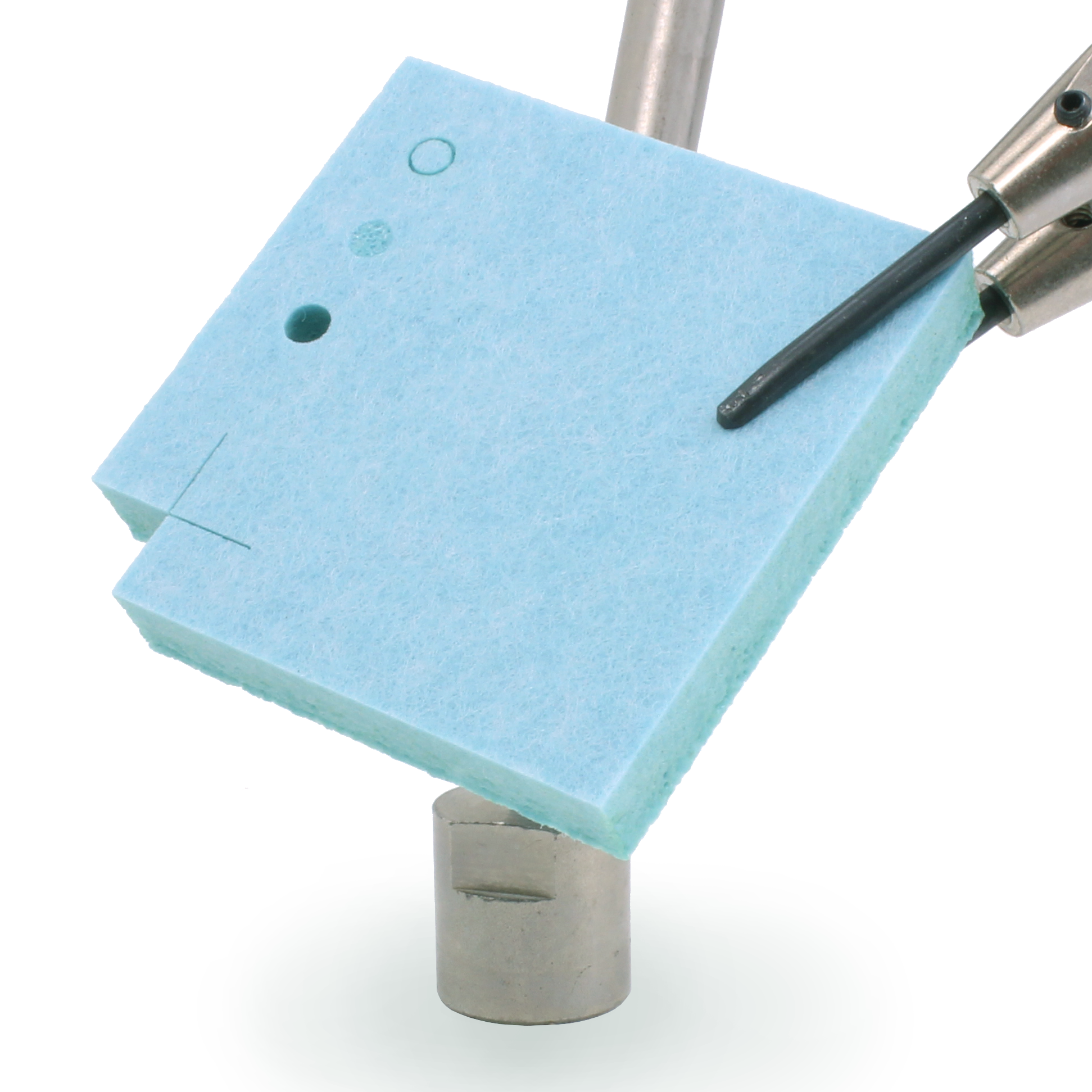

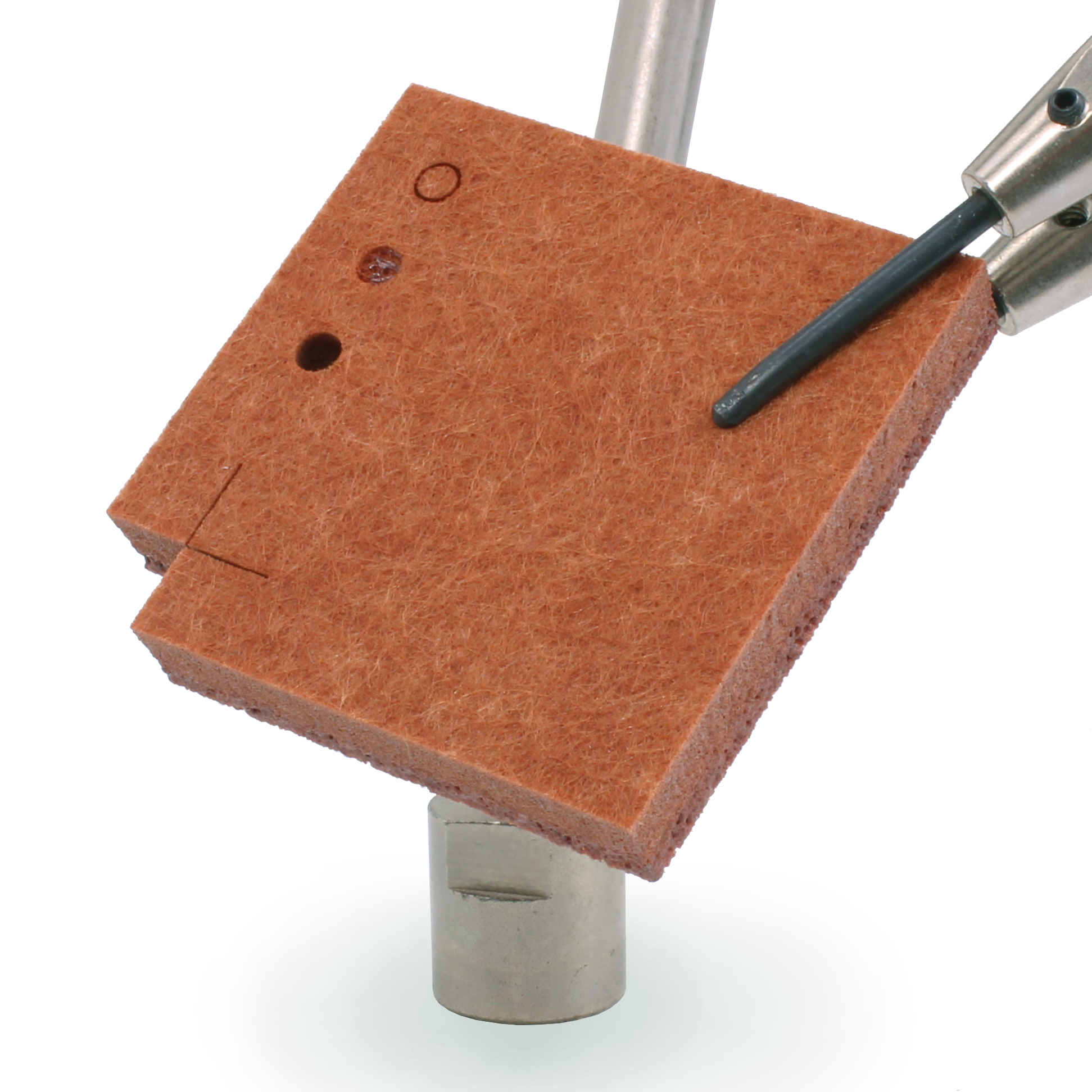

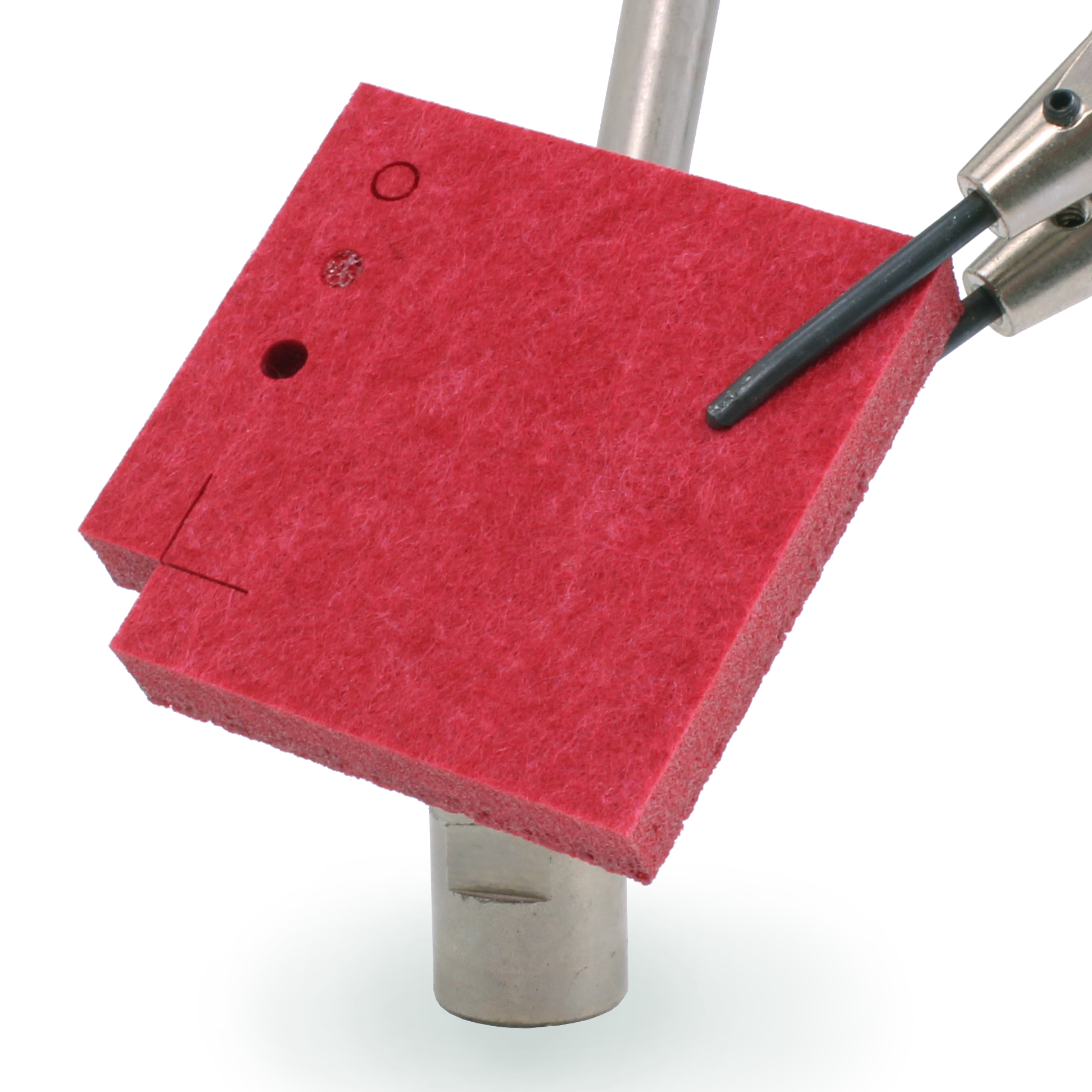

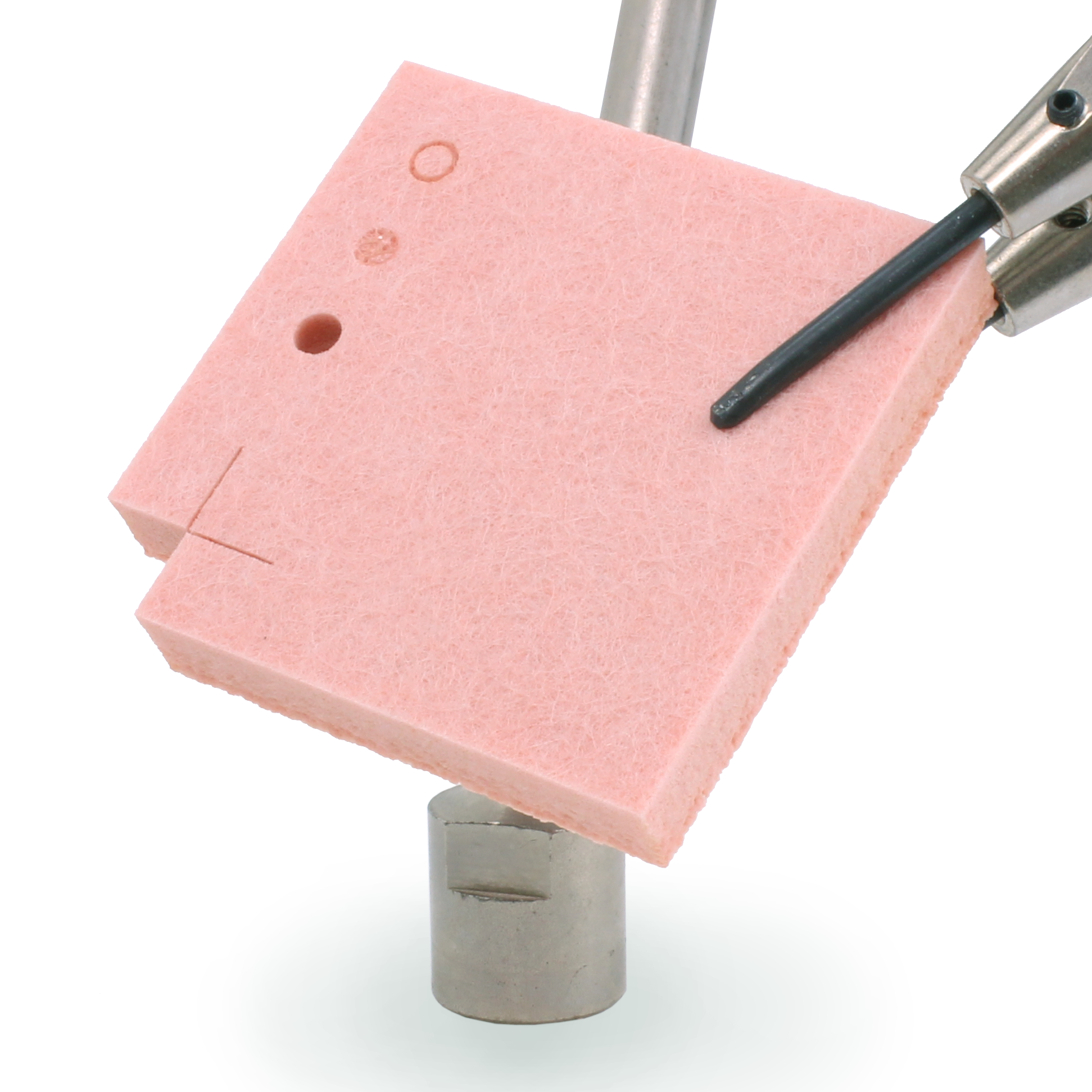

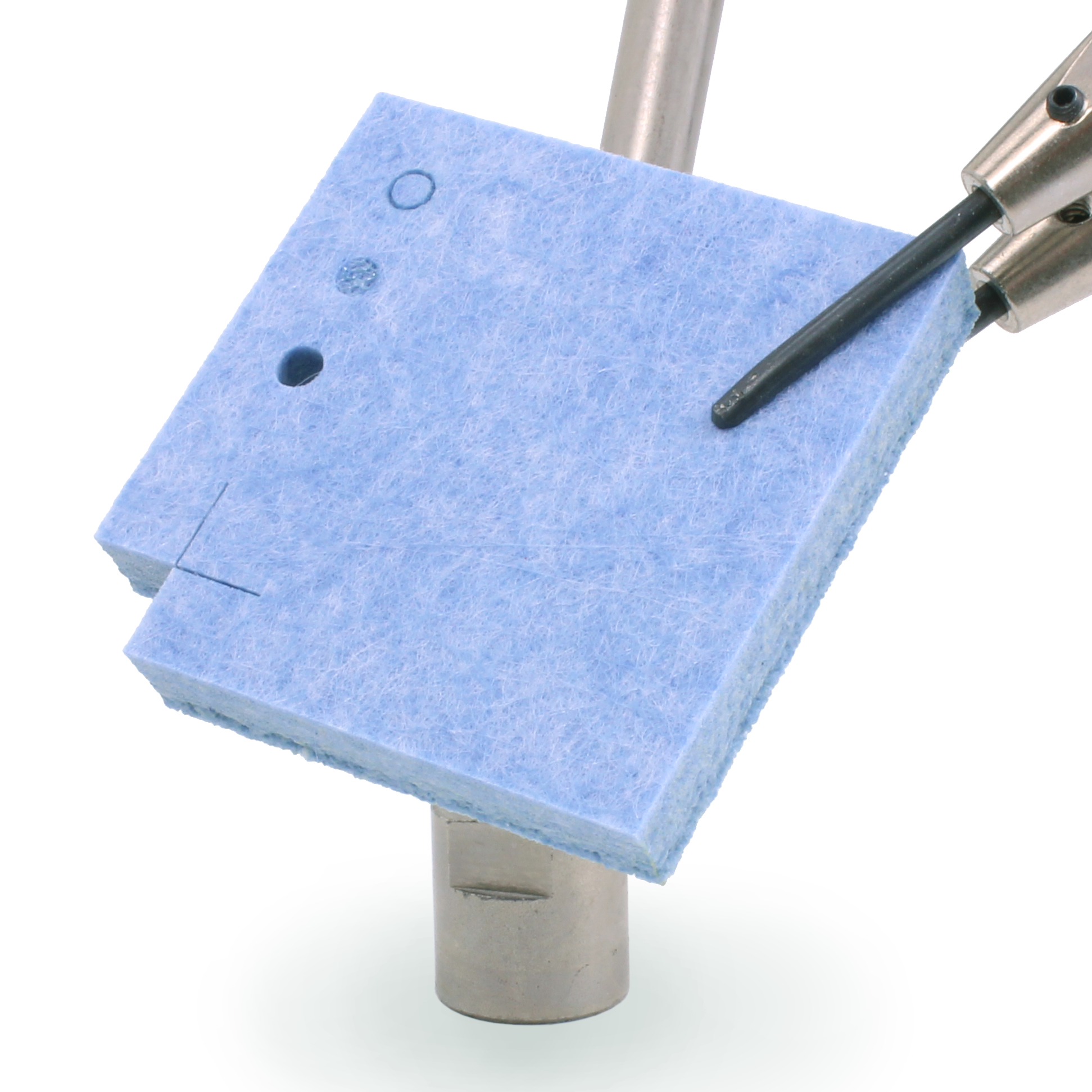

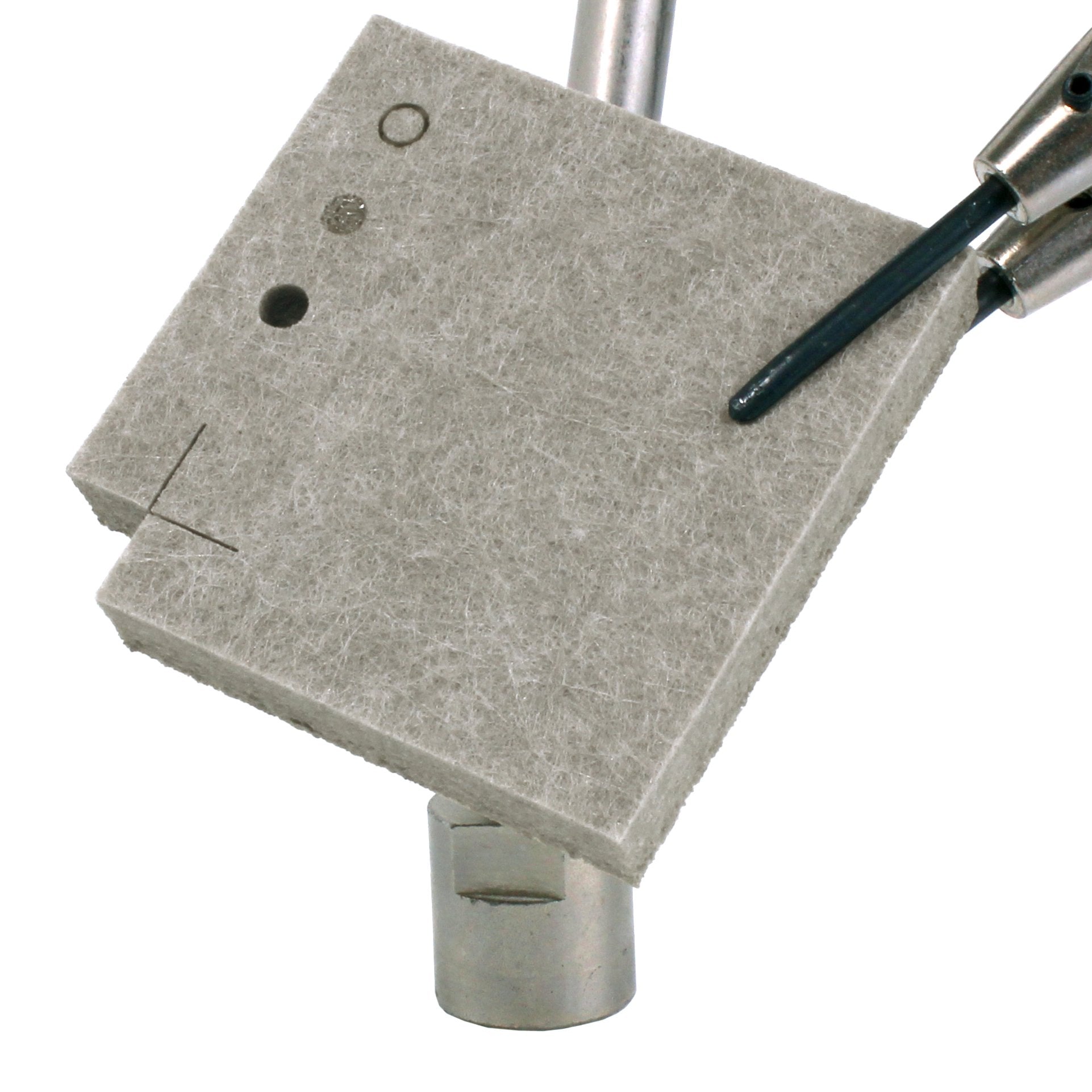

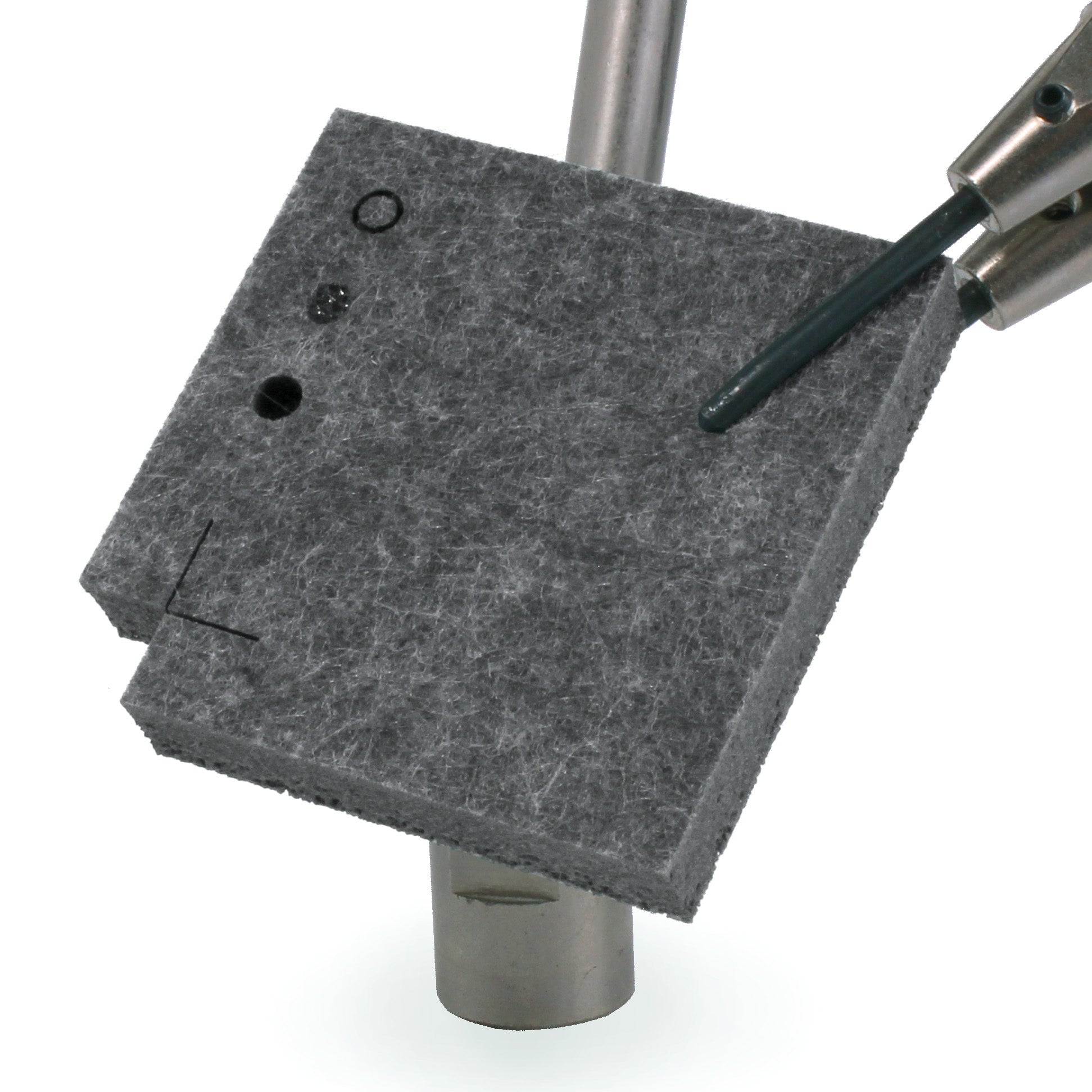

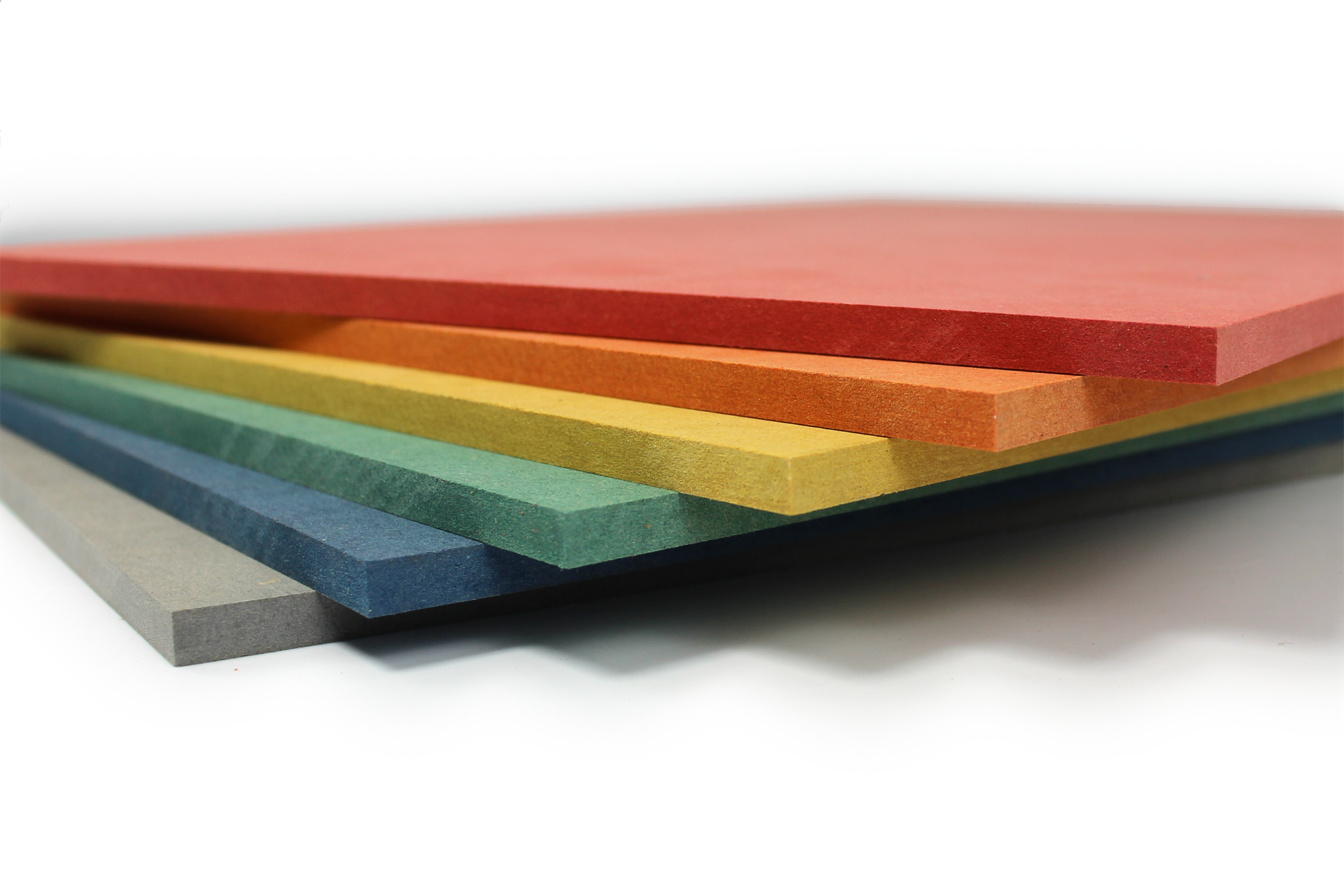

PET-vilt

De eerste keus voor akoestische panelen is PET-vilt. Deze platen van 70% gerecyclede PET dempen geluidsgolven, het poreuze oppervlak absorbeert en doorbreekt geluid. Waardoor je minder last hebt van hard geluid en weerkaatsing.

PET-vilt is verkrijgbaar is veel kleuren, van vrolijke kleuren tot neutrale tinten. Er zijn veel combinaties mogelijk en voor elk ontwerp is er een passende optie.

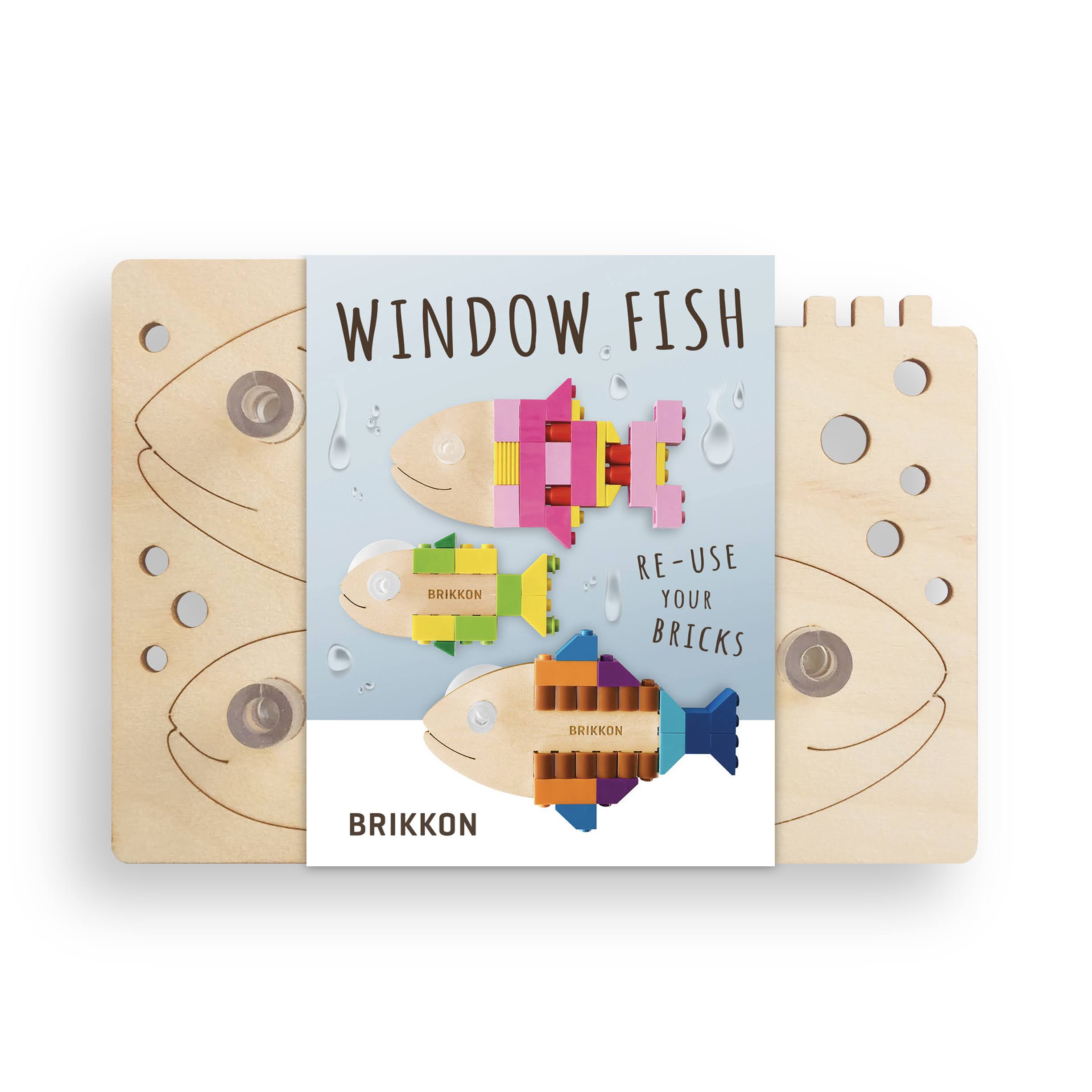

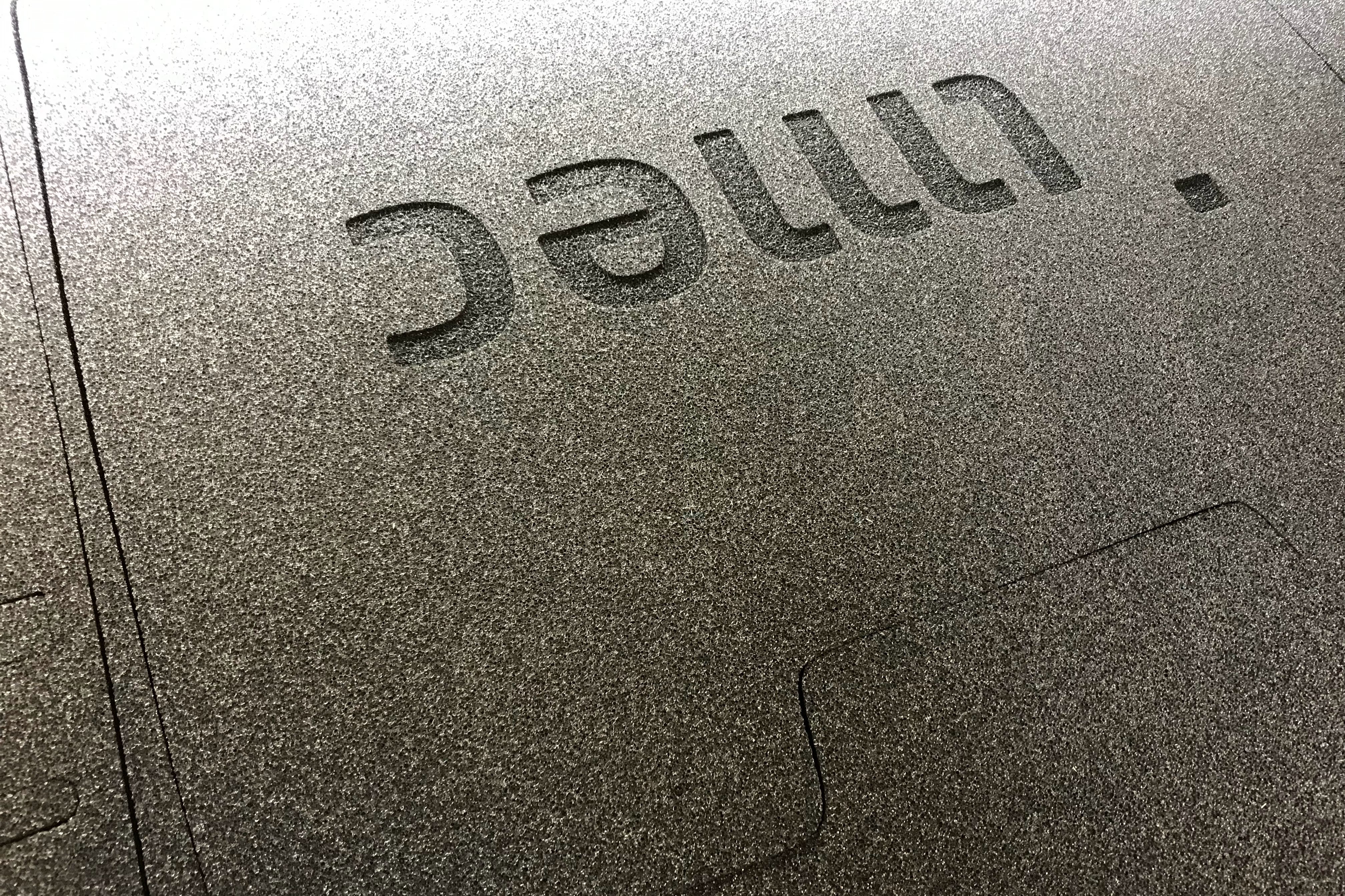

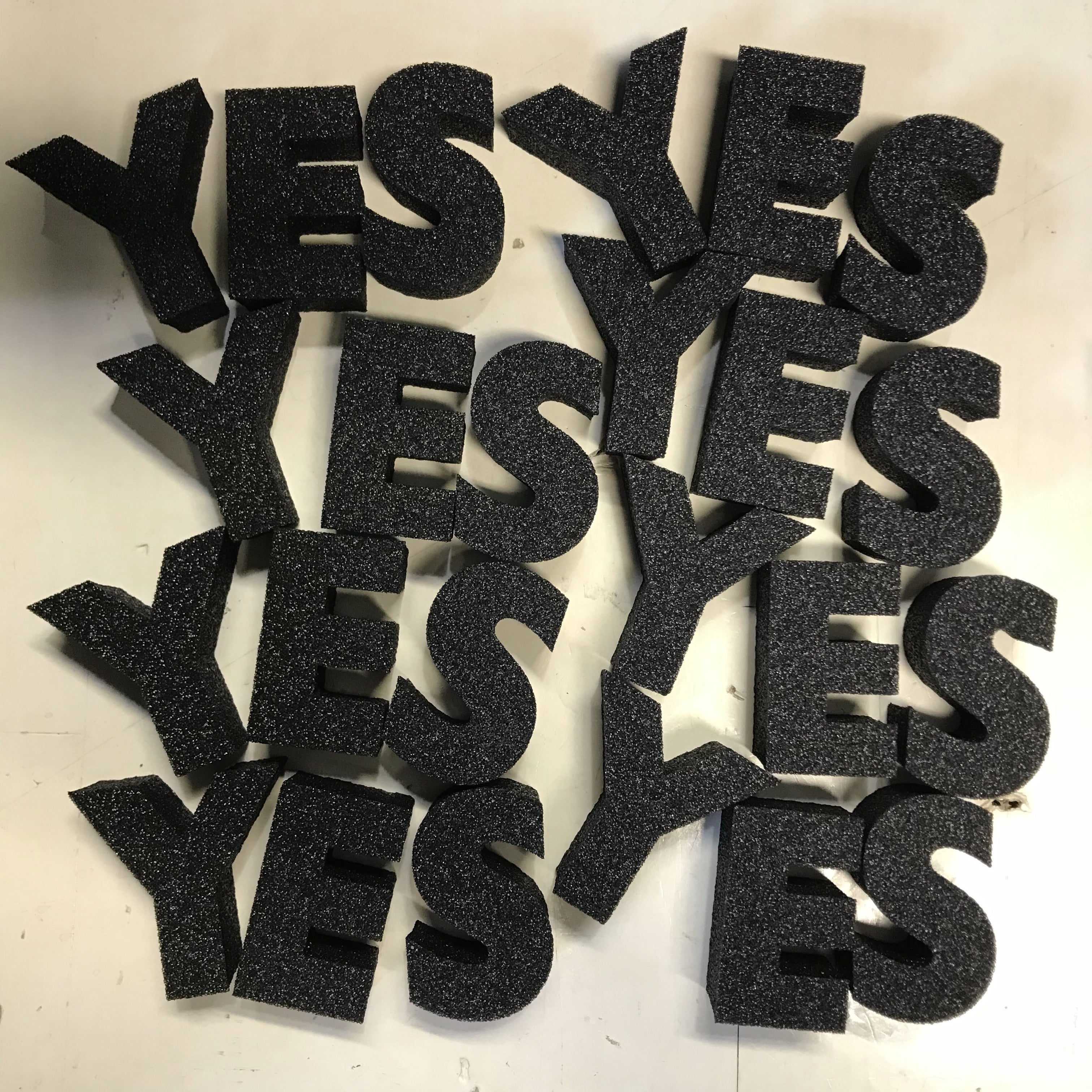

PET-vilt akoestiek panelen kun je bijvoorbeeld in de vorm van je logo maken. Je kunt ook een wandbekleding maken of losstaande objecten uitsnijden.

PET felt

Description

Strong and lightweight acoustic panels made of 70% recycled PET felt

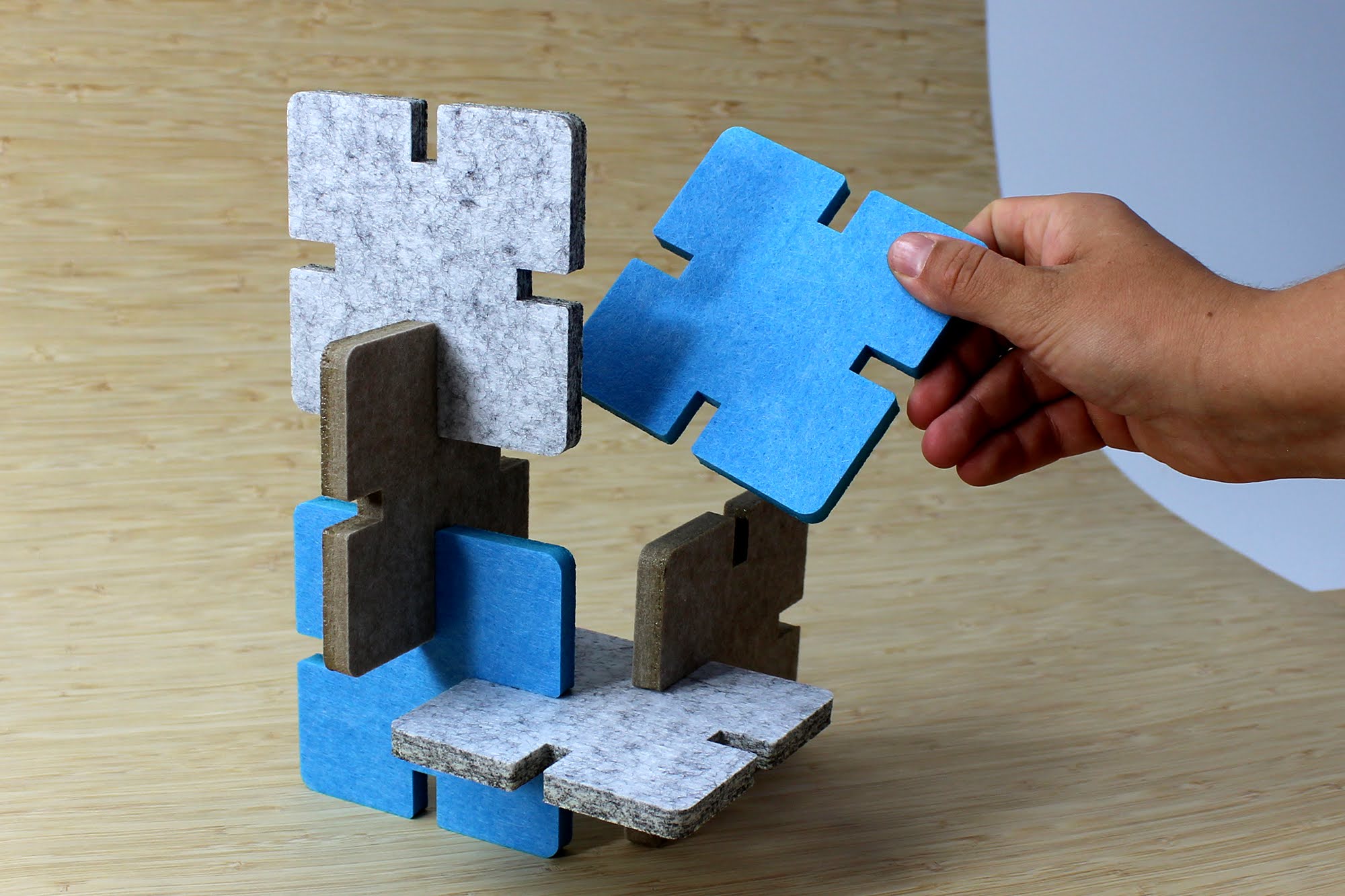

Just new and already one of our favorite materials. Designing in PET felt is a pleasure because of the vibrant colors that also combine great. The material feels soft but the panels are also strong and light. So you can easily make (3D) sculptures that you can slide together and easily hang.

What is PET felt

This is an acoustic panel made of polyester fabric. It is made of 70% recycled PET, such as recycled PET bottles. You can saw and cut it with a Stanley knife in addition to laser cutting. This felt panel (also called EASYfelt) is fine to glue with, for example, mounting glue.

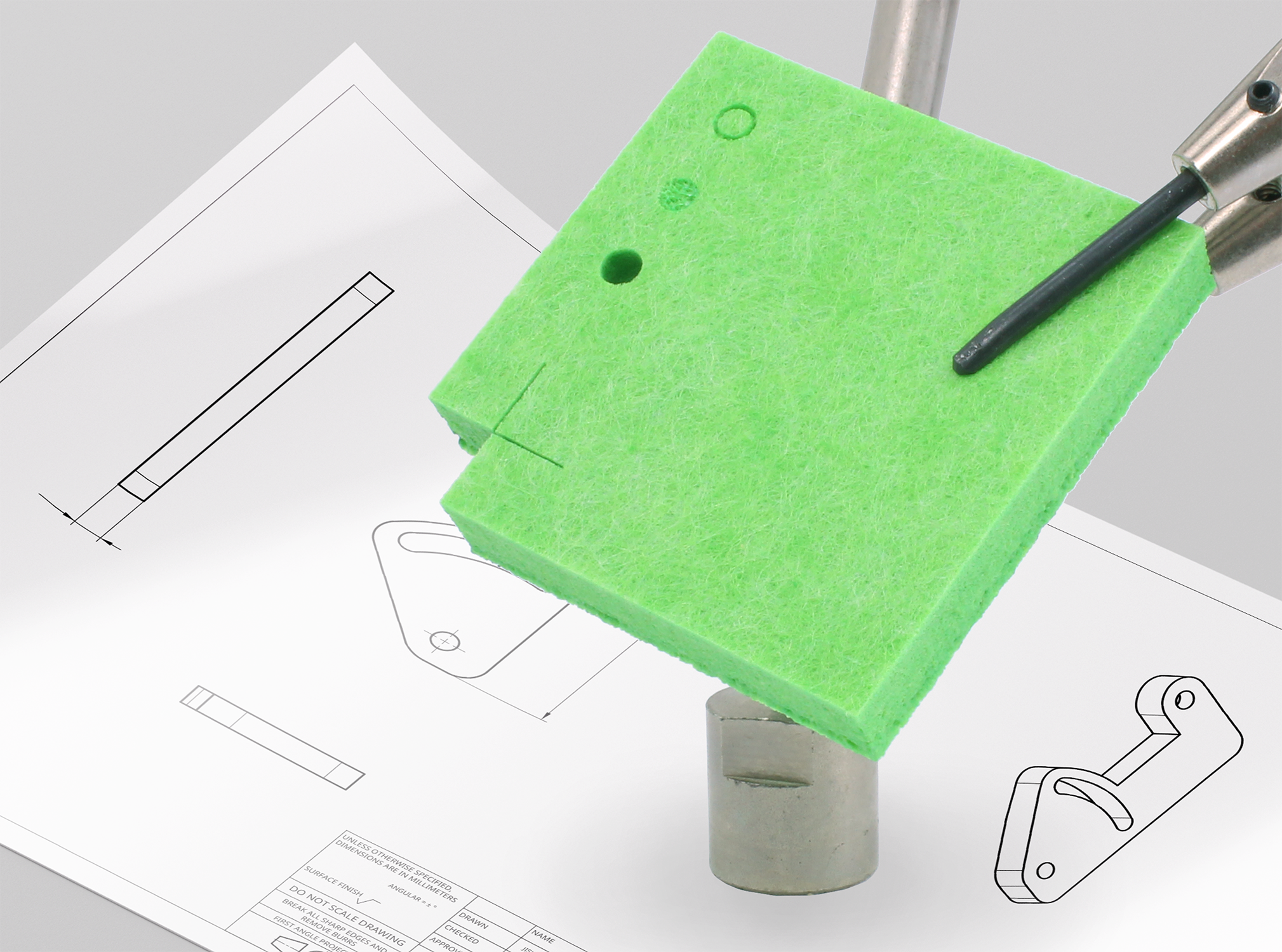

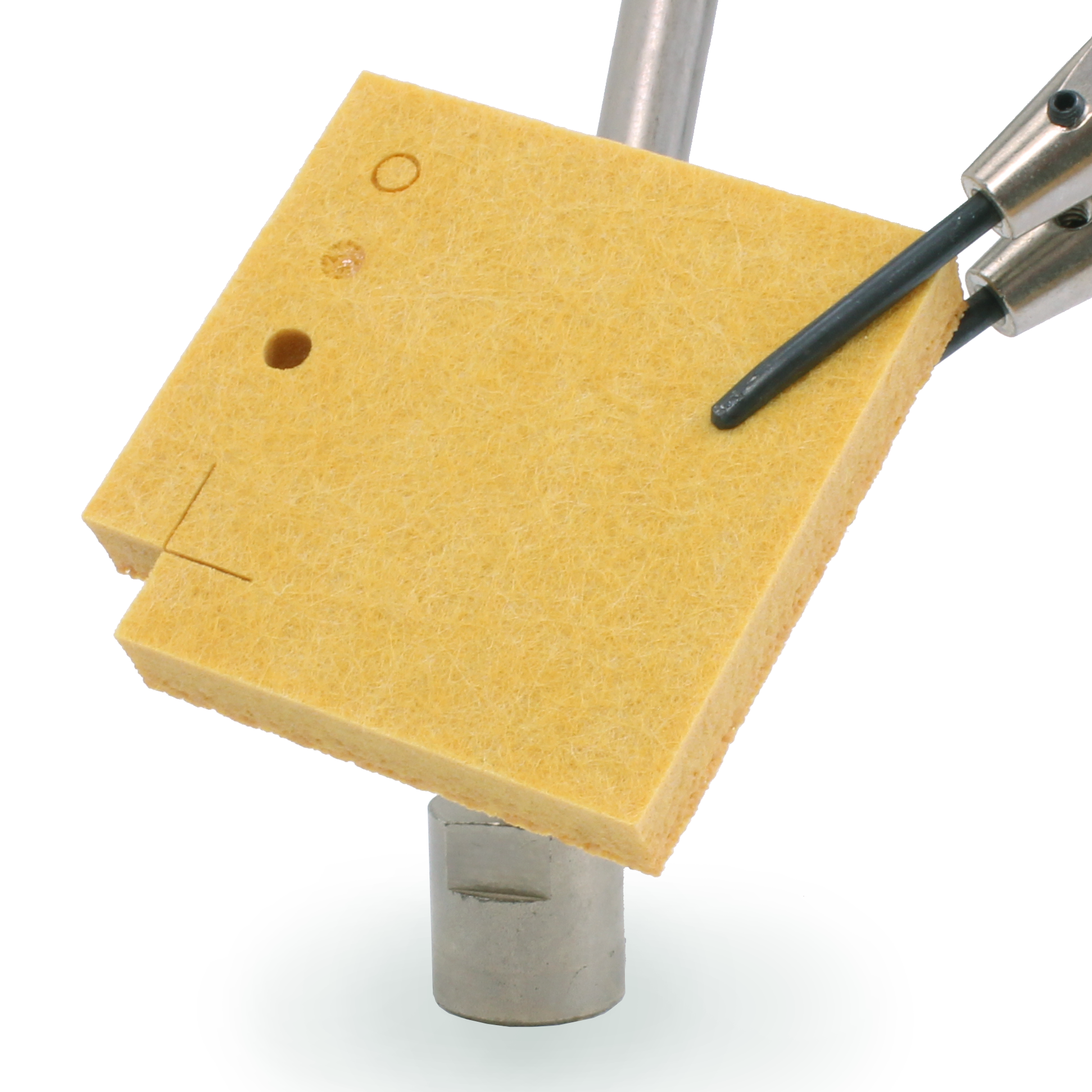

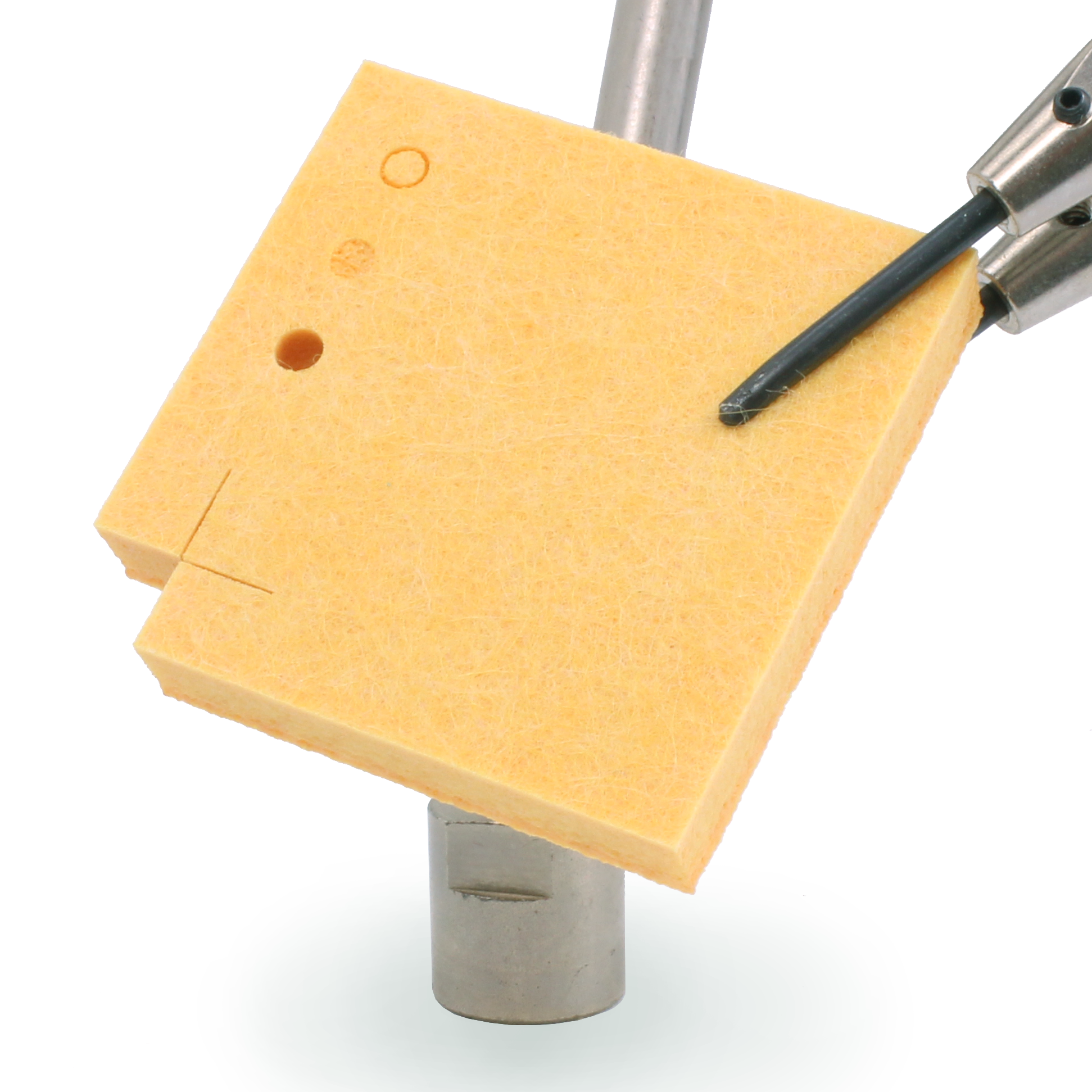

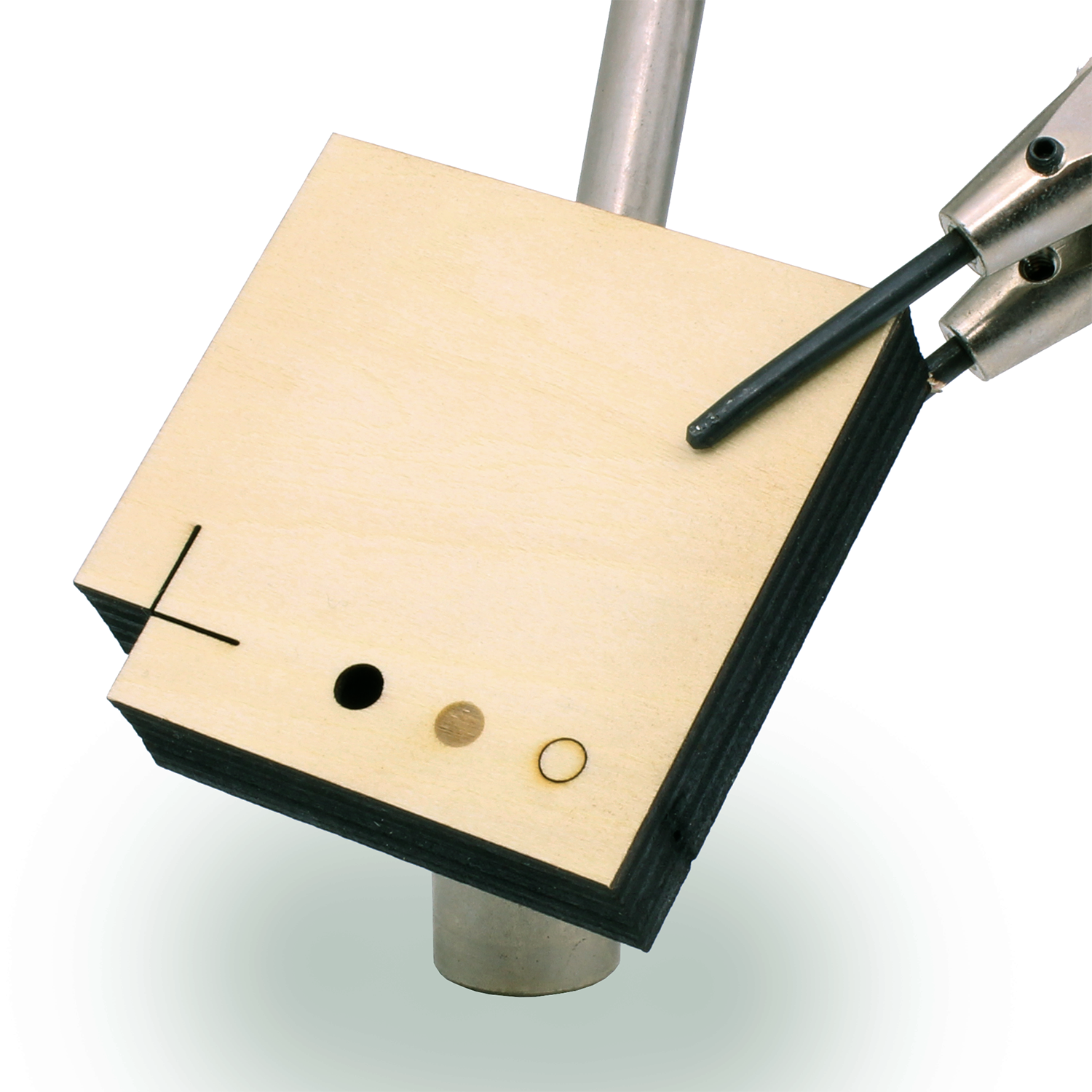

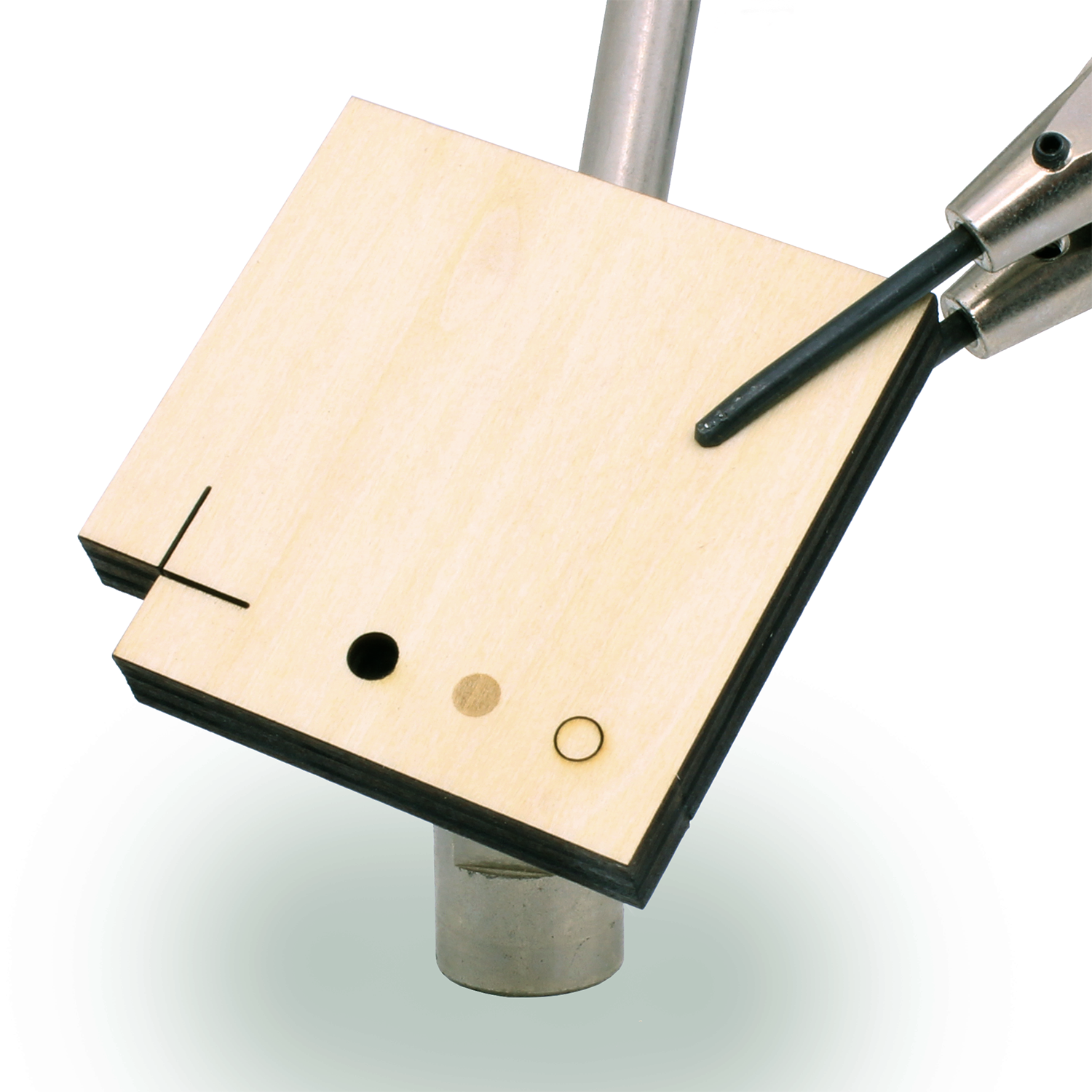

Laser-cut quality

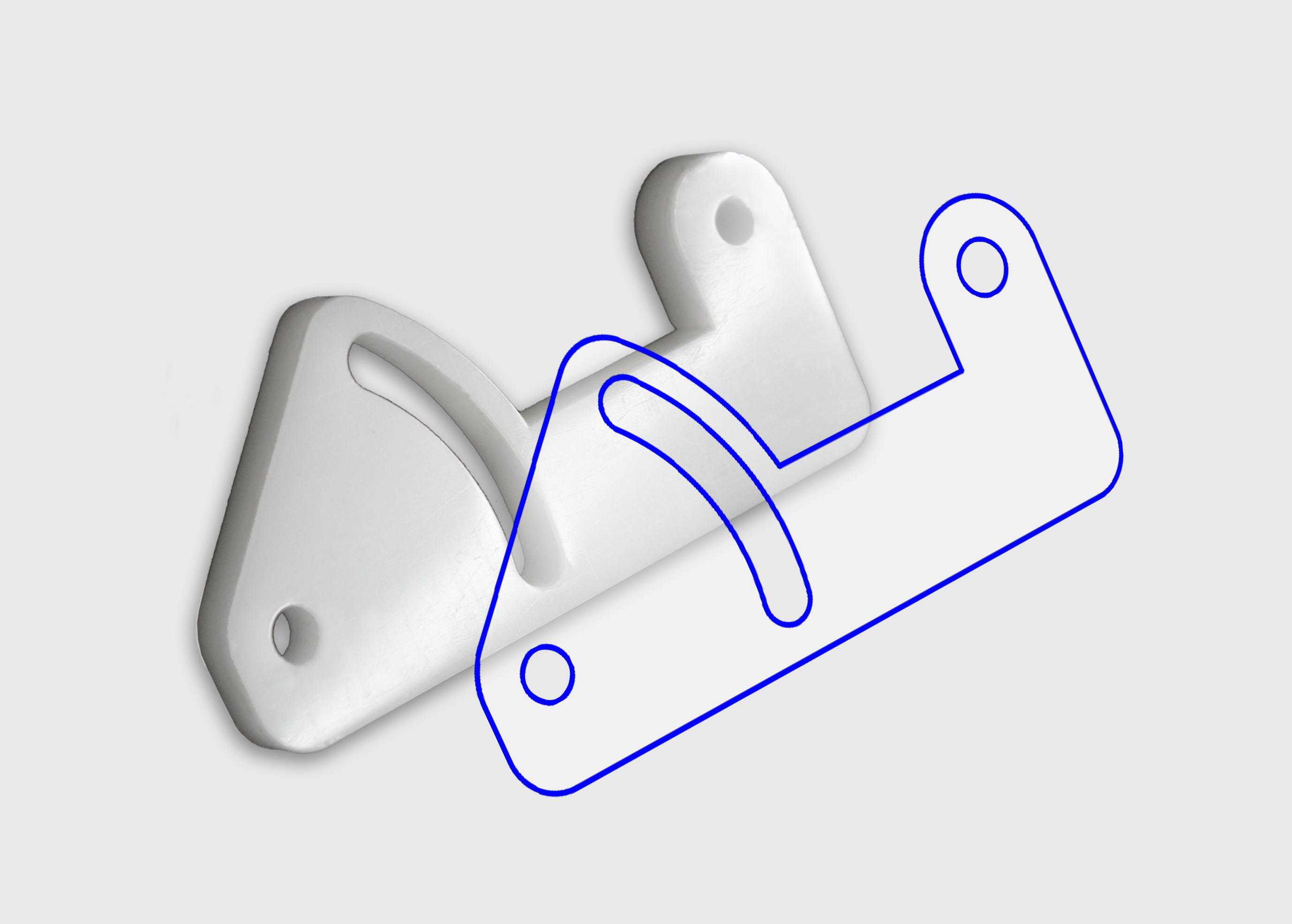

The laser cut is about 0.2mm wide and you can make sharp inside corners. Please note that the laser cut has some ridges (see pictures) and is a little hard. The laser cut has the same color as the surface.

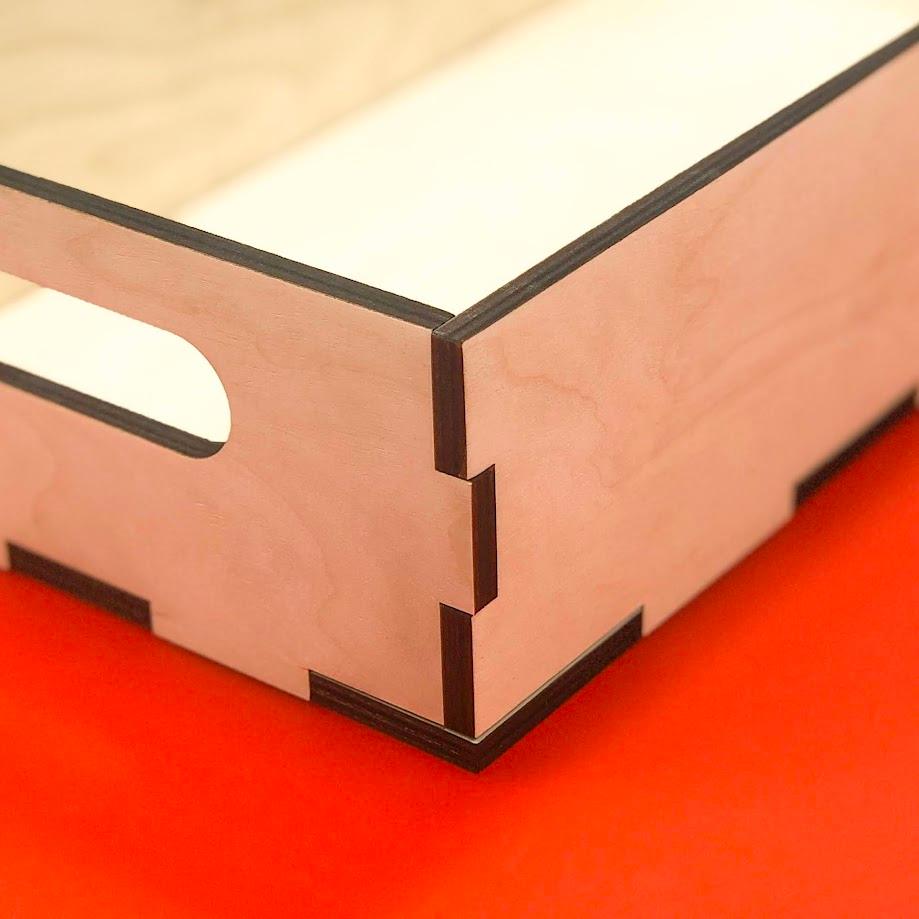

If you make joints such as mortise-and-tenon or slots that need to fit together, make them 8.5mm wide. That way you can still slide the pieces together just fine and it clamps without glue.

If you are making inlaid graphics or text, give the inside shapes (letters) an outside offset of about 0.2mm and the outside shapes (recess where the letter comes in) an inside offset of 0.2mm. That way it will fit together neatly and stick by itself.

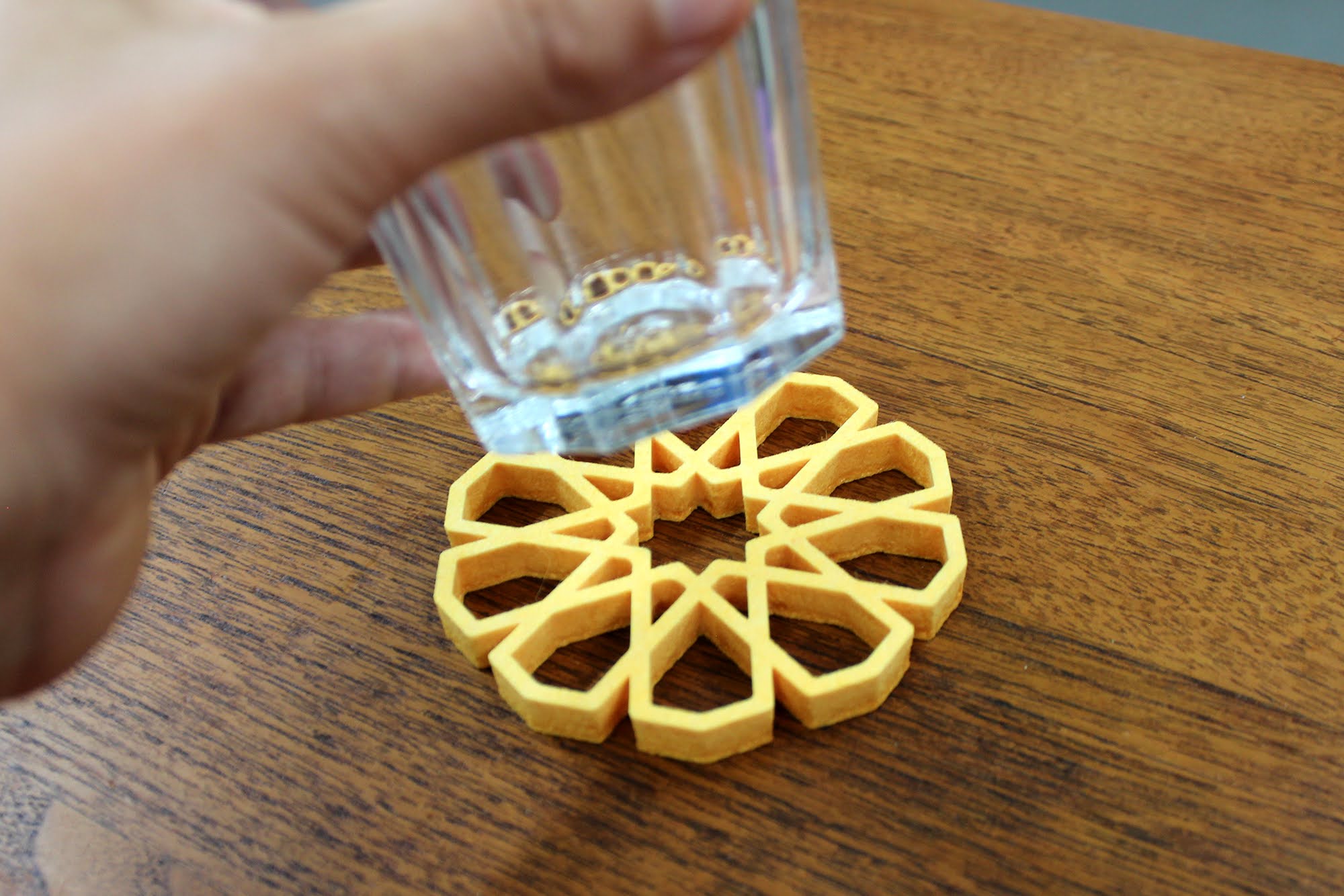

2D applications

This acoustic felt is suitable for absorbing sound in a busy office, for example. And because you can have it cut any contour you want, you can immediately make it into a logo or image or text. Ideal in restaurants, classrooms or just for at home. You can also use it as a coaster, play mat and even as plates in a suspended ceiling. For example, make a hole pattern in these plates to make the acoustic properties even stronger.

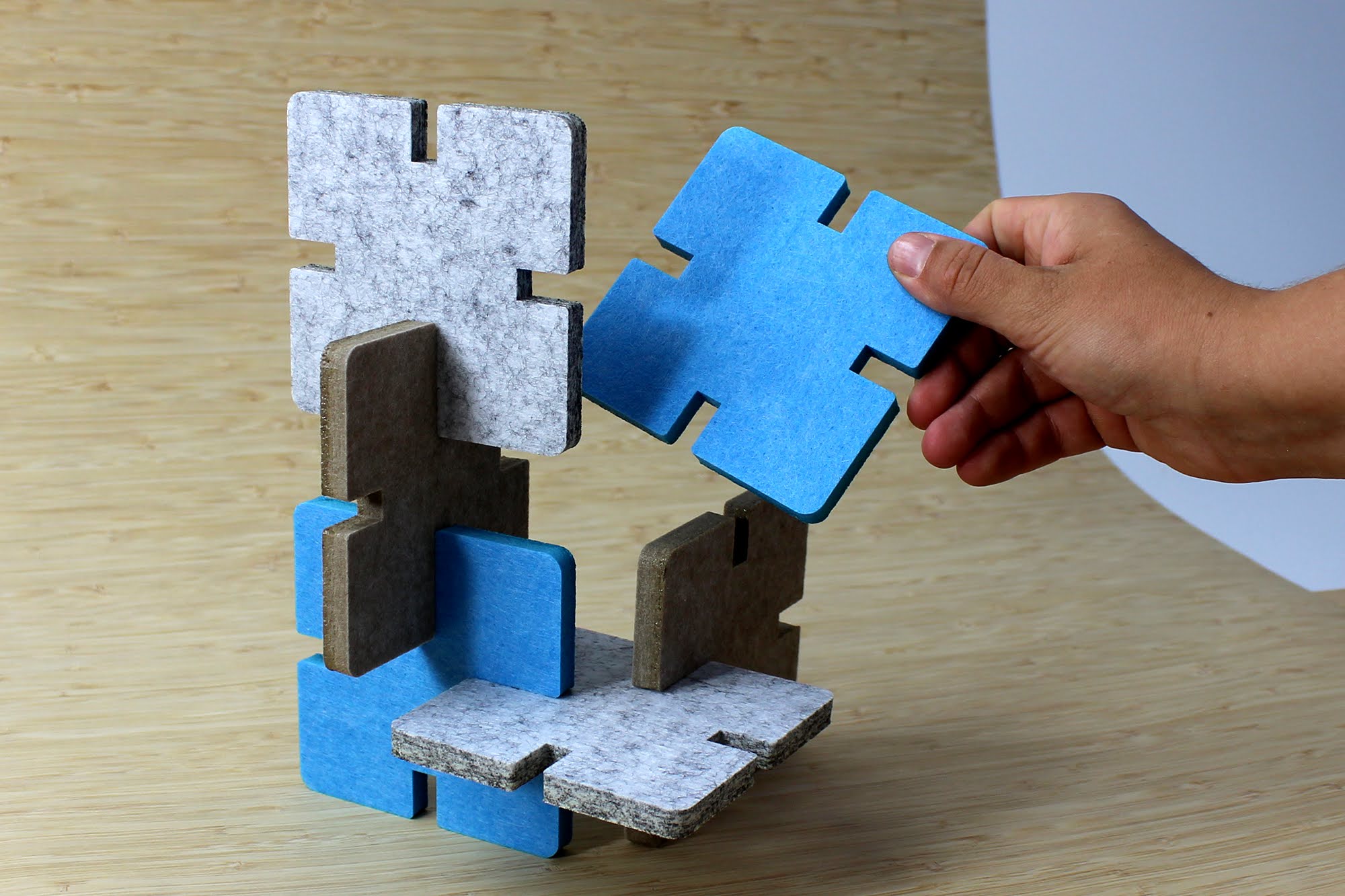

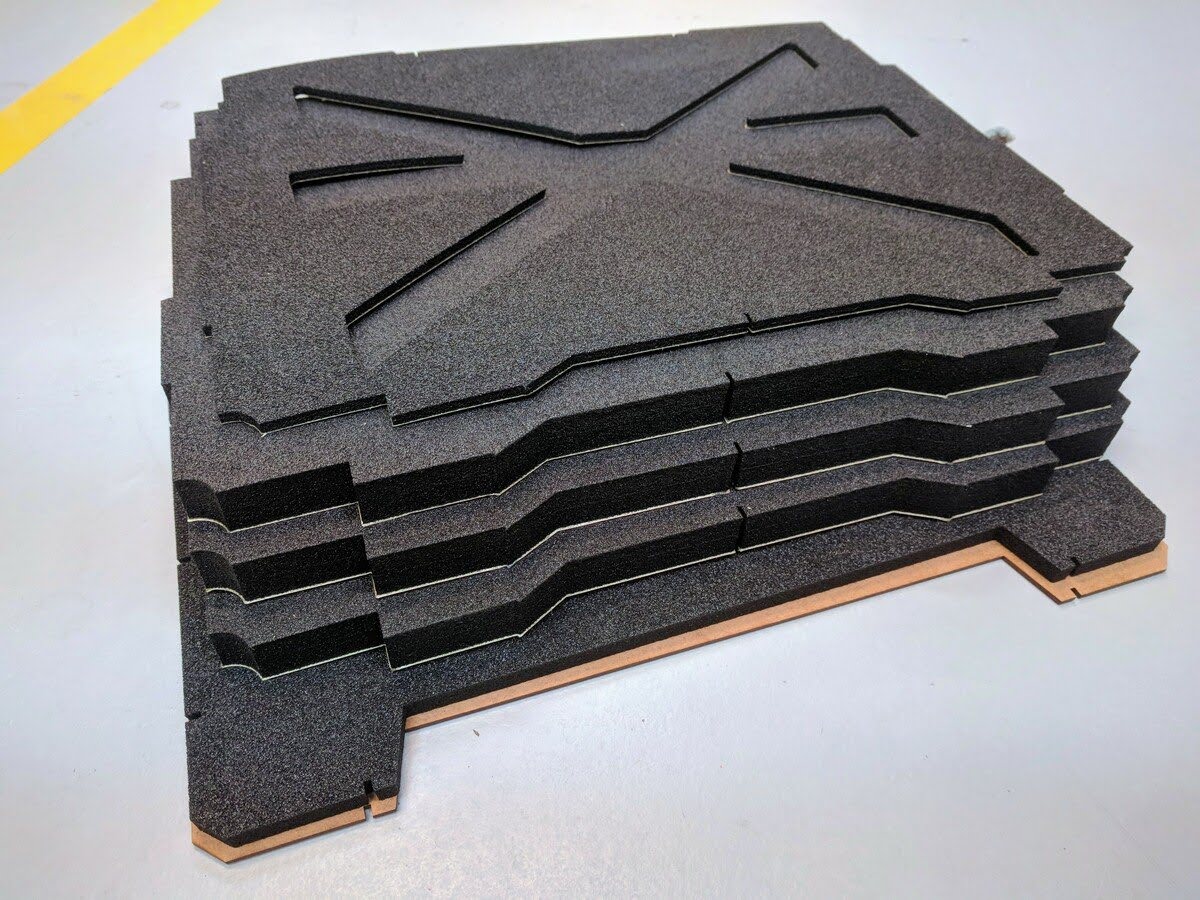

3D applications

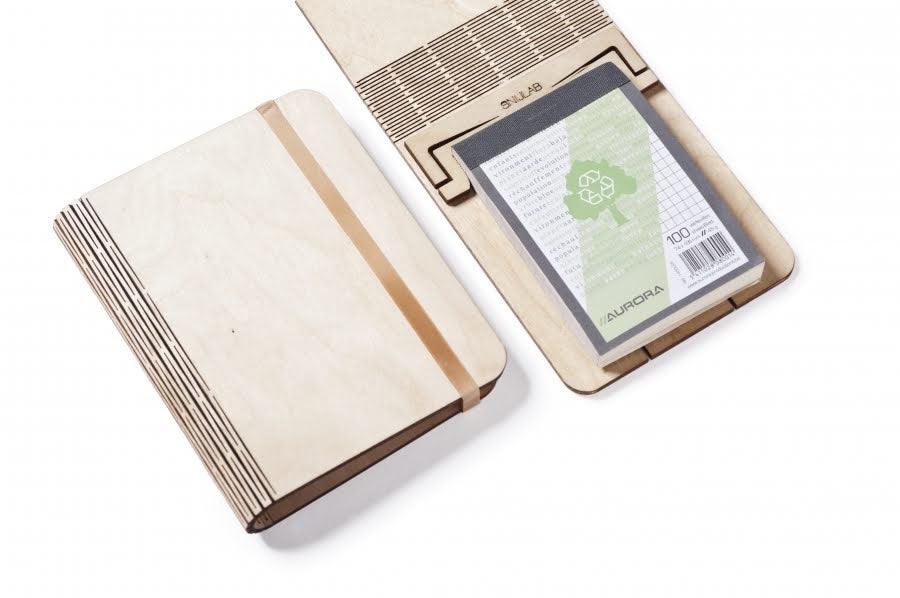

Through slots or mortise and tenon joints, you can easily connect pieces together to create 3D objects. Acoustic objects, of course, but also office items such as desk cabinets and pencil cases. And last but not least, lamps and fixtures.

Kleuren van PET-vilt vergelijken? Bestel samples

Bestel een sampleketting en vergelijk alle soorten PET-vilt in je eigen hand. Zo maak je een goed geïnformeerde beslissing over je ontwerp.

Samples geven een representatief beeld van de lasersnij-kwaliteit die Snijlab levert.

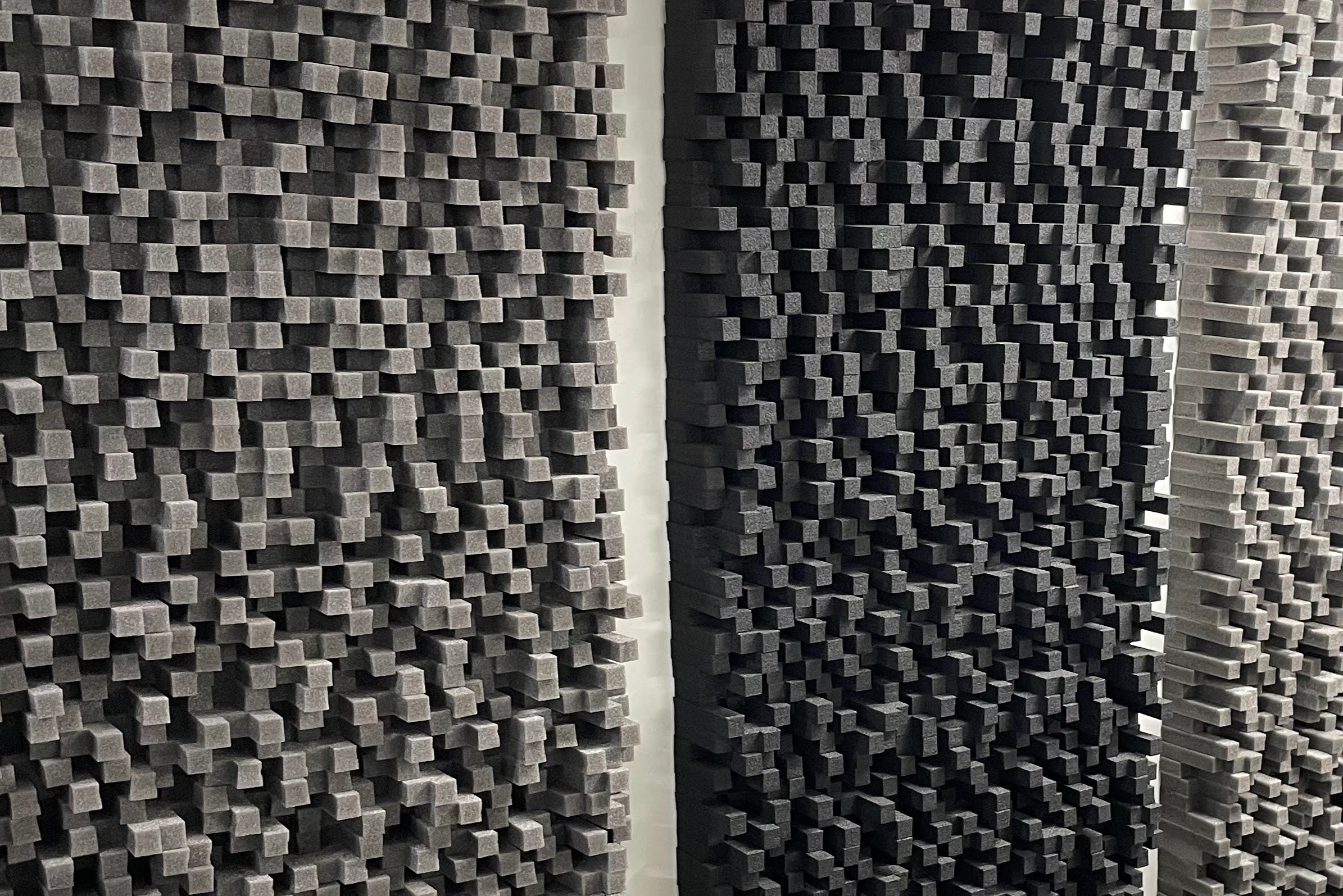

Naar de samplesAkoestisch paneel van hout en schuim

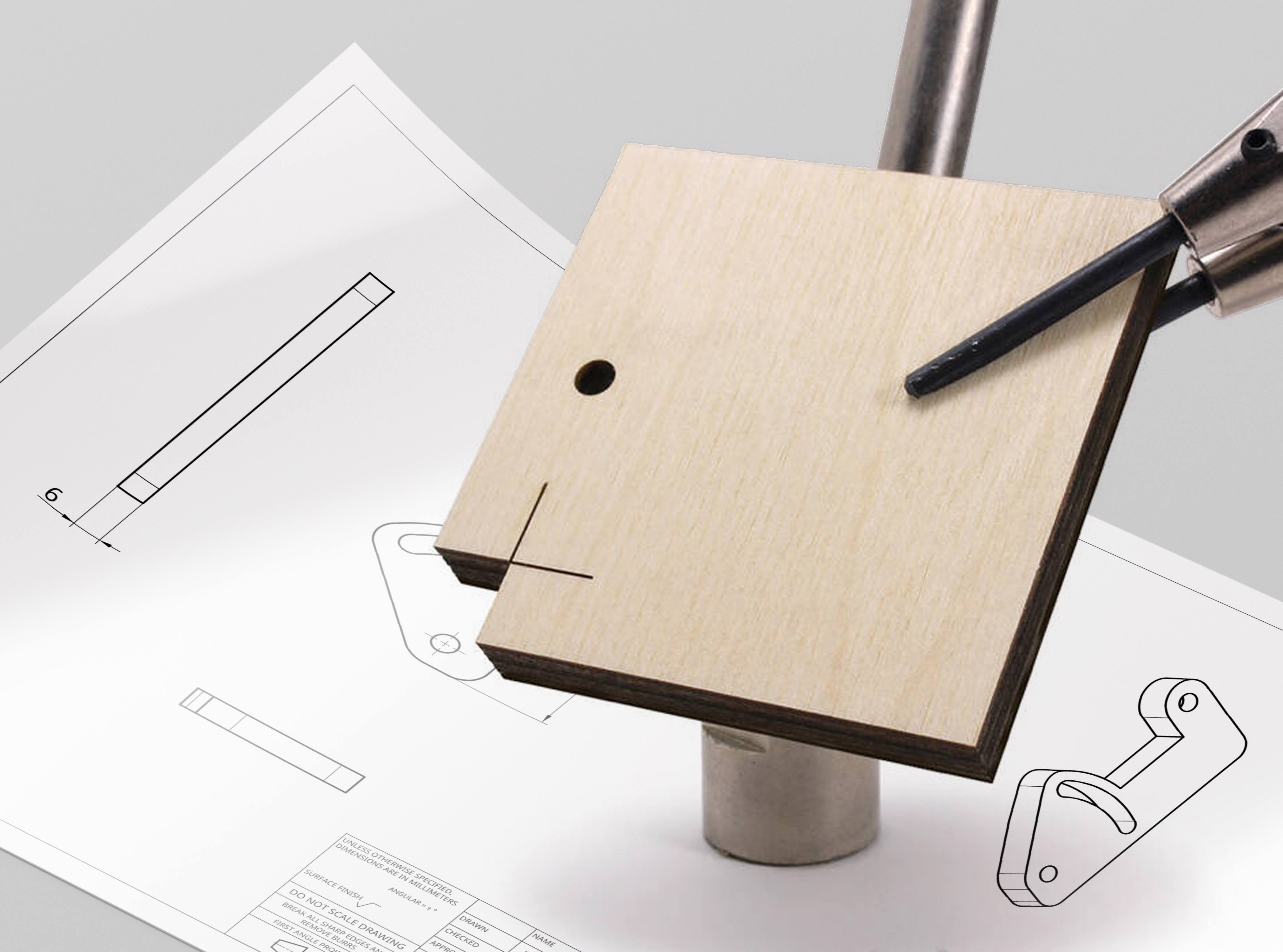

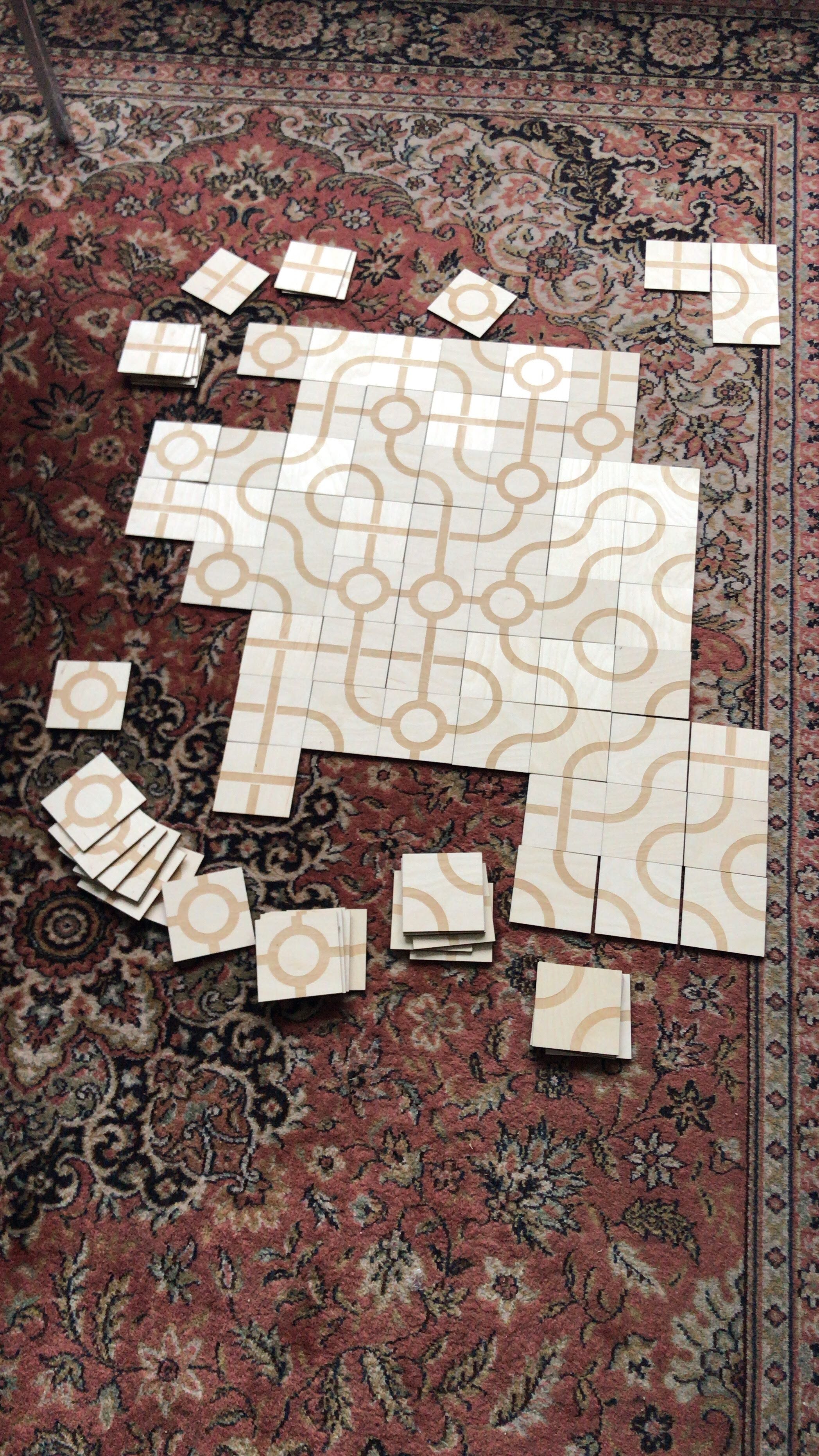

Ook uit hout en schuim kun je een stijlvol paneel voor betere akoestiek maken. Bijvoorbeeld met een houten voorplaat waar een gatenpatroon in zit, en een schuim achterkant. Dit breekt en absorbeert geluidsgolven.

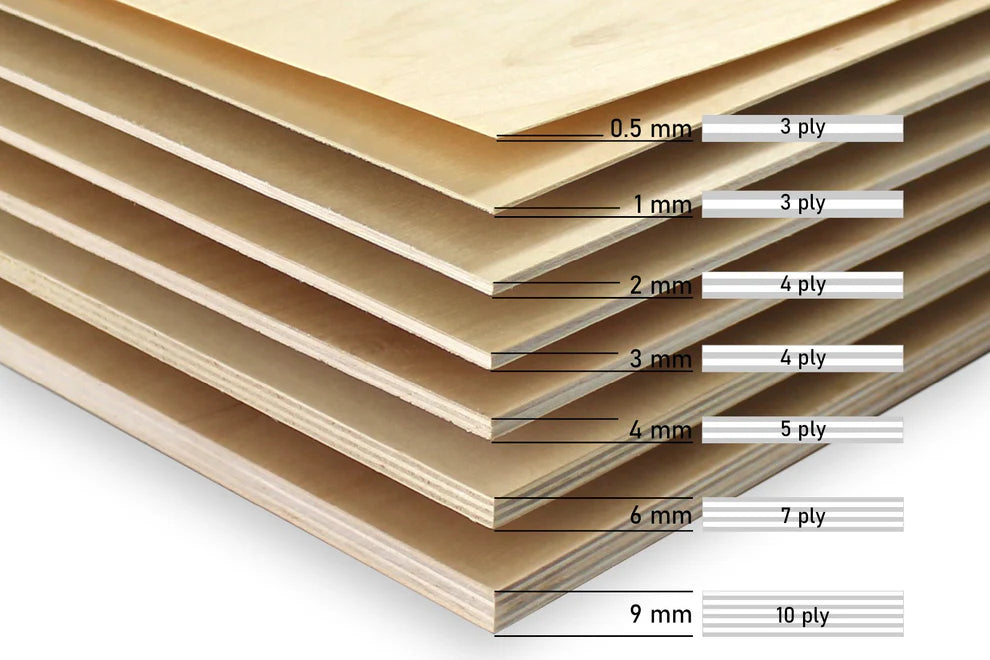

Hieronder zie je een voorbeeld van een foto die is omgezet naar een halftone-grid. Dit paneel is lasergesneden uit Berken multiplex 3 mm met een een laag PE-Hardschuim 20 mm daarachter.

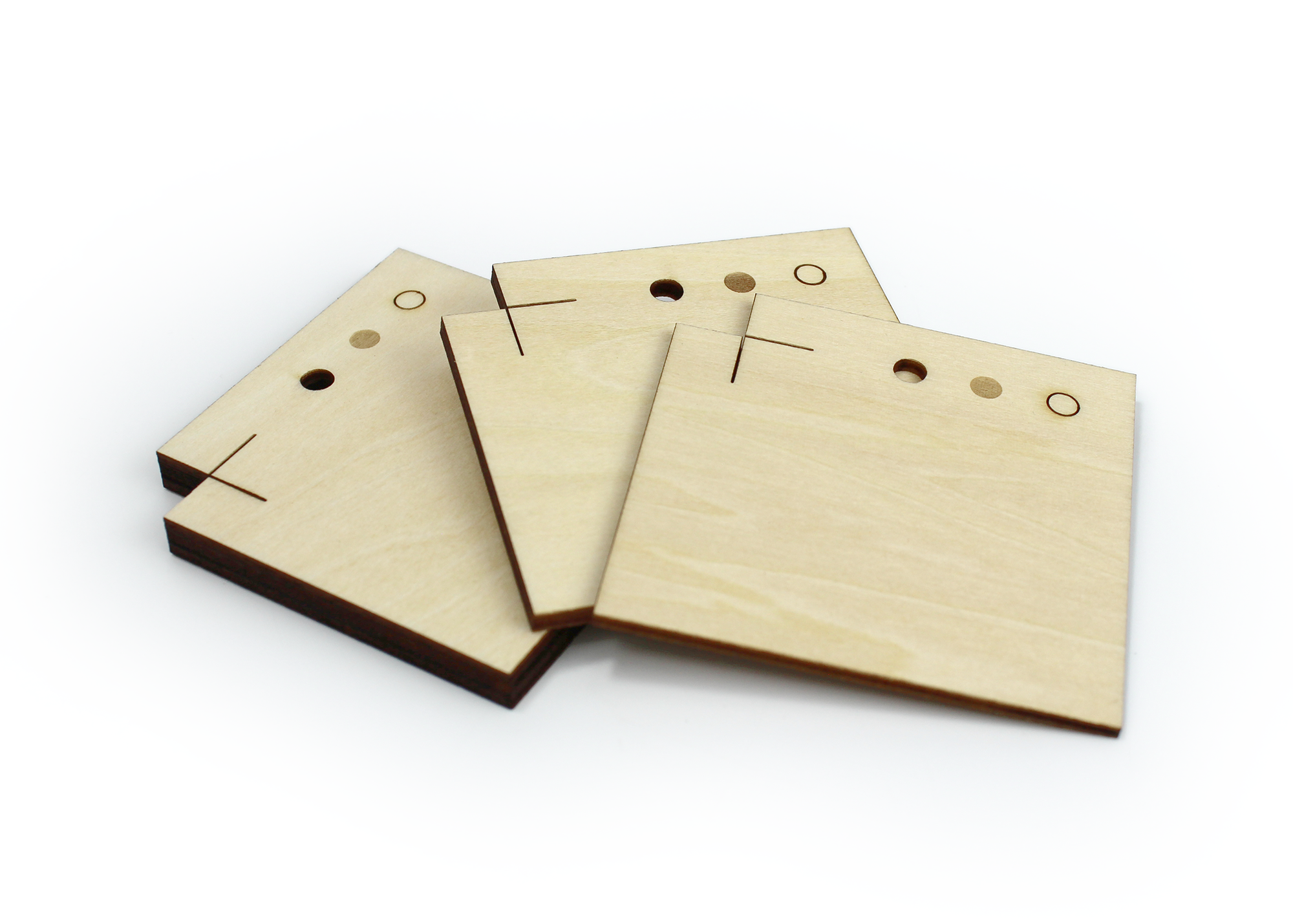

Kies eerst een houtsoort

Voor het maken van een akoestiek paneel uit hout en schuim, kies je eerst een houtsoort. Let er in je ontwerp op dat je genoeg onderbrekingen in het oppervlak maakt.

In principe zijn alle houtsoorten bij Snijlab hiervoor geschrikt. Wij raden je aan eerst eens te kijken naar de drie houtsoorten hieronder. Berken multiplex heeft een mooie glans en natuurlijke houtnerf. Linde multiplex is licht in gewicht. En gekleurd MDF leent is goed voor decoratieve toepassingen waarbij de mooie kleuren een pré zijn.

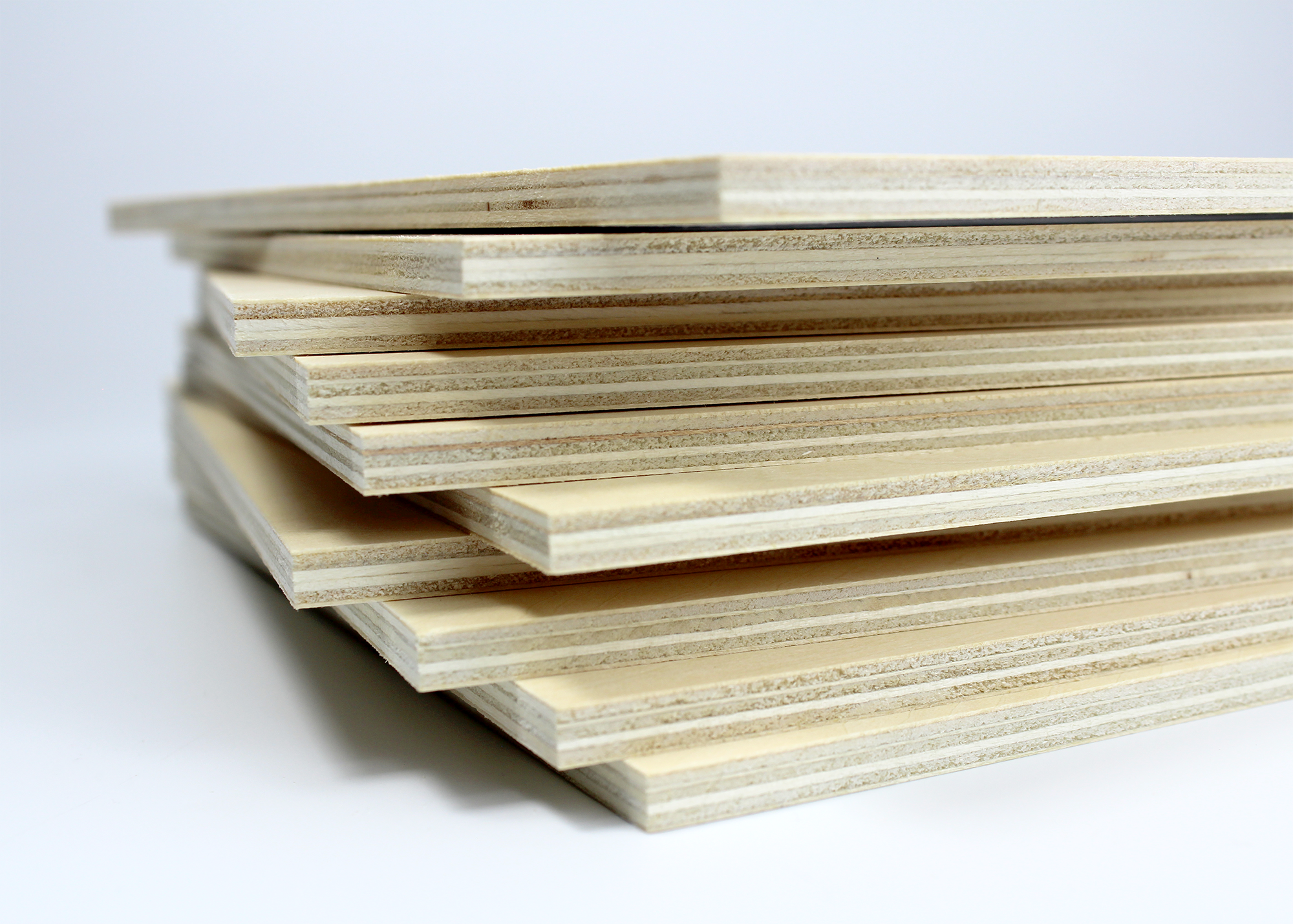

Birch plywood

Description

A widely used and universally applicable type of wood. It is hard, strong and has a distinct wood look.

Properties

Because plywood is constructed of cross-glued layers, it is strong in all directions and less prone to breakage than solid wood. However, all plywood has a main grain direction in which the boards are stiffer, by default this is along the long side of the board. This plywood is B/B grade and has a bonding suitable for laser cutting. The internal layers are virtually knot-free. Birch is light in color and has visible but not predominant grain markings. Because it is a natural material, the appearance may vary from sheet to sheet.

Applications

Birch plywood is used for a wide range of applications, from key chains to furniture to models to 3D printers.

Lime plywood

Description

A high-quality wood species, lightweight and versatile. Lime plywood has a solid color and is particularly flat. The layers contain few knots.

Properties

Lime plywood is composed of cross-glued layers, which provides strength and stability in all directions. This makes it less susceptible to breakage than solid wood. However, basswood plywood has a main grain direction in which thin boards up to 3 mm are stiffer. The internal layers contain few knots, which contributes to the boards' attractive appearance. Lime wood is naturally light in color, with a subtle and even grain structure.

Applications

Lime plywood (or basswood plywood) is used for many different applications, including decorative objects, furniture and art projects. Its light weight and flat boards make it ideal for precision work such as model making and musical instruments. Its attractive, almost knot-free layers also make it suitable for decorative panels and interior finishes. For outdoor use, however, the material must be finished to provide weather protection.

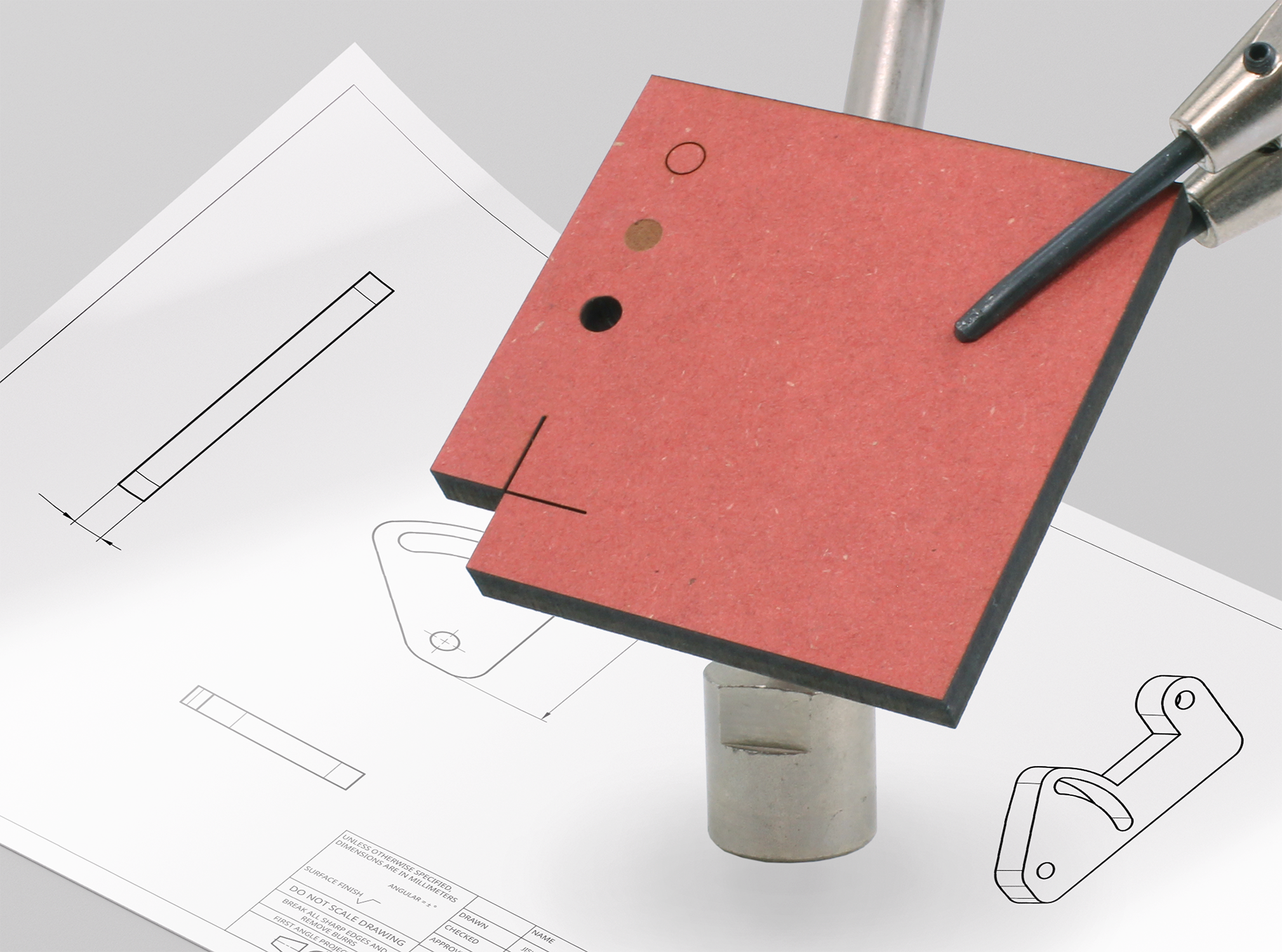

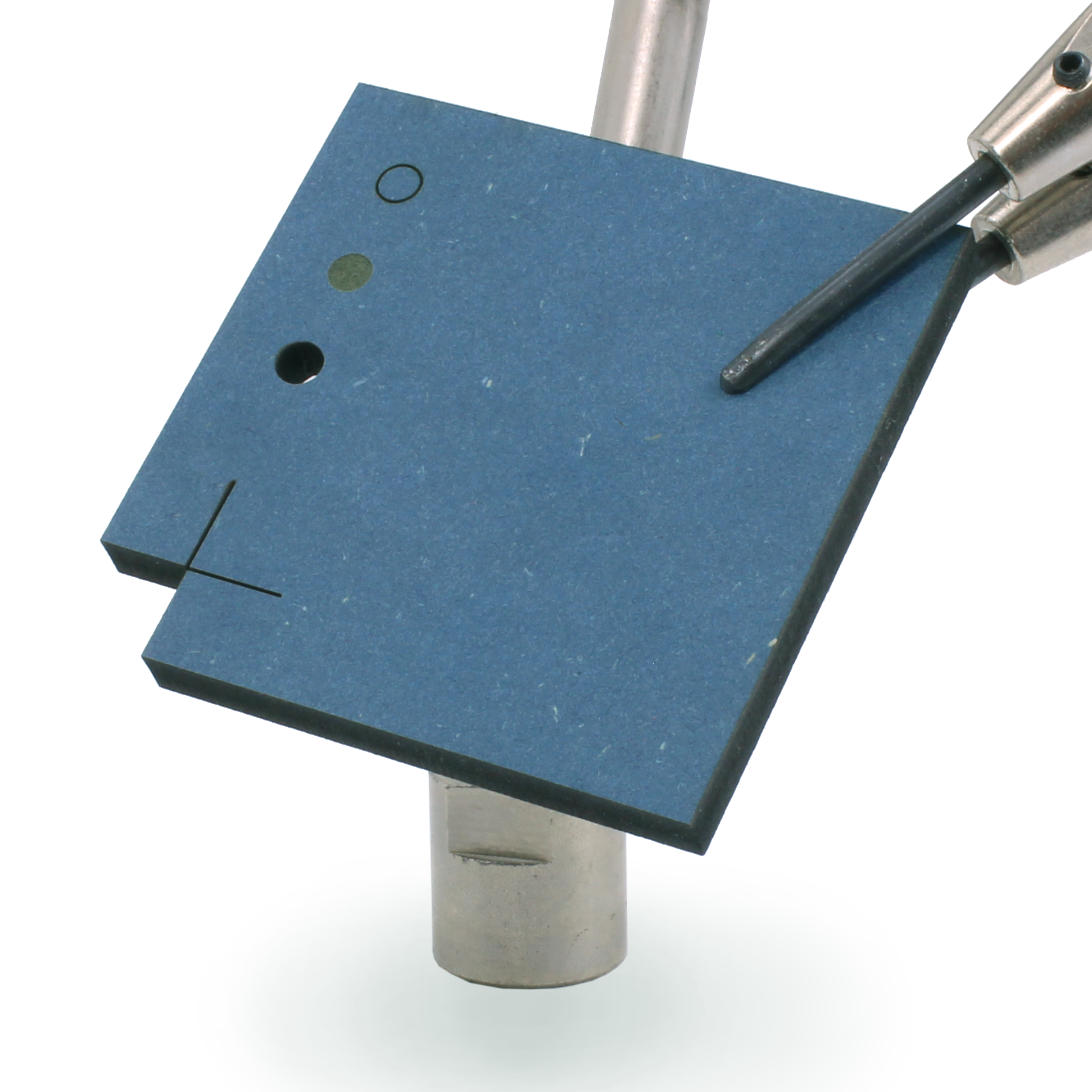

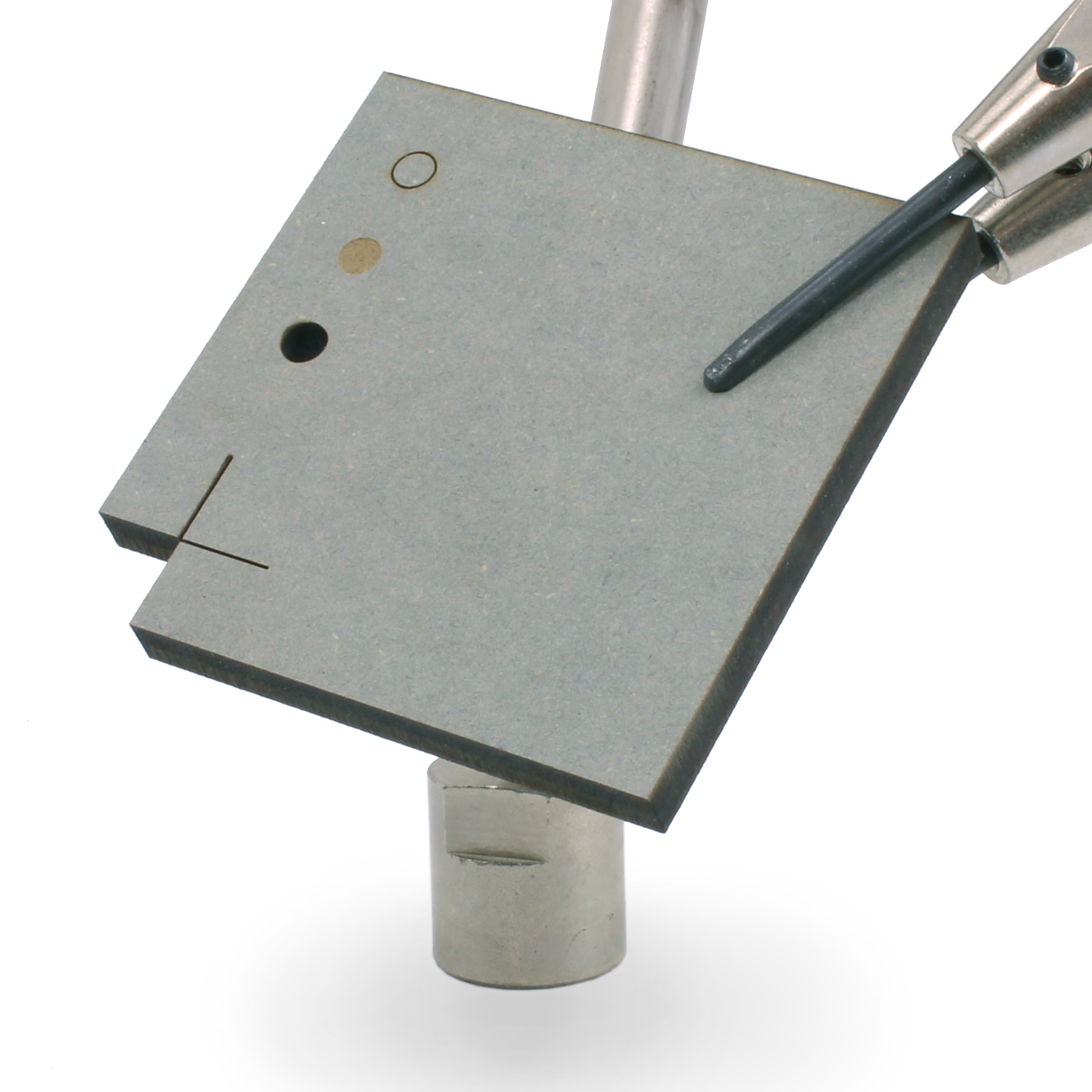

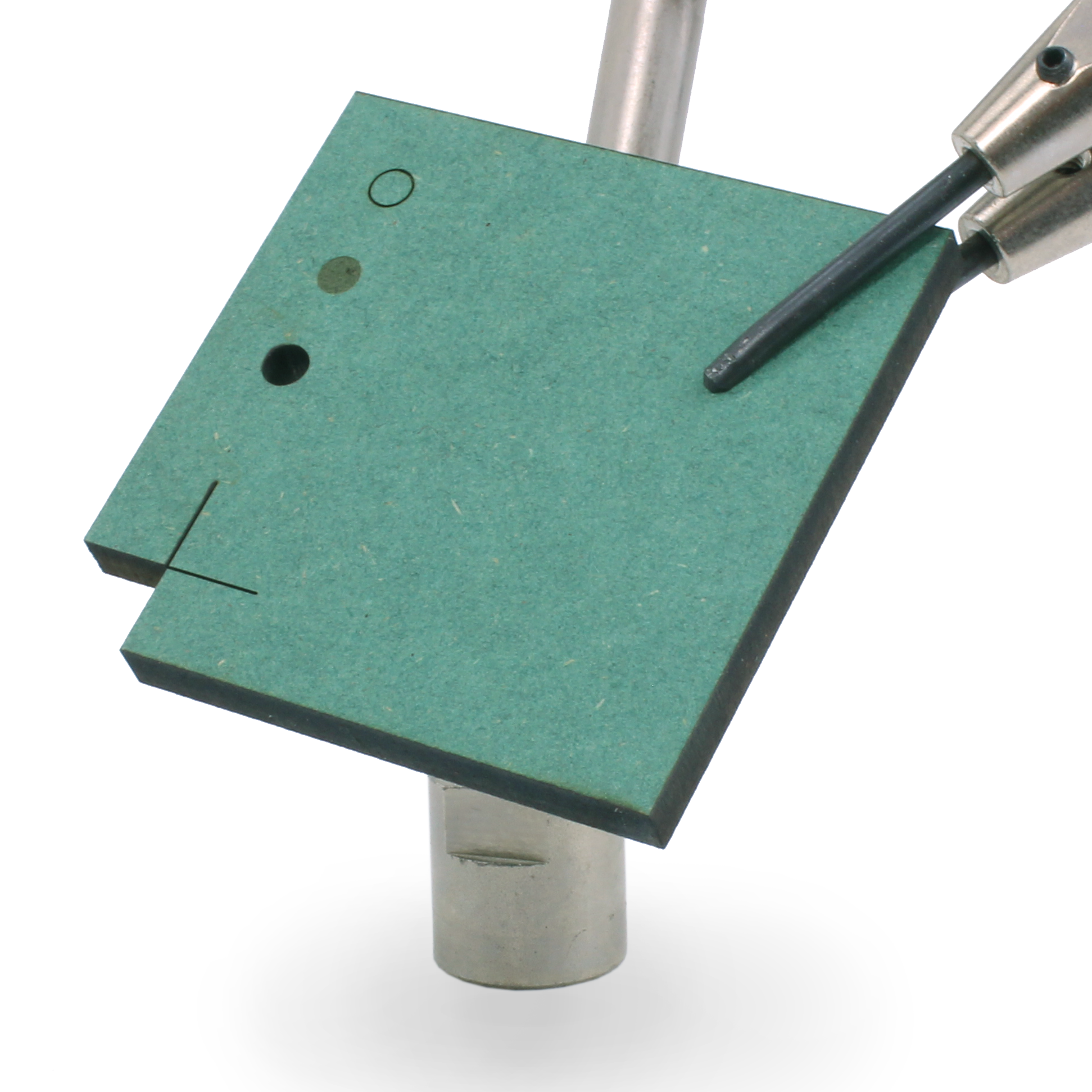

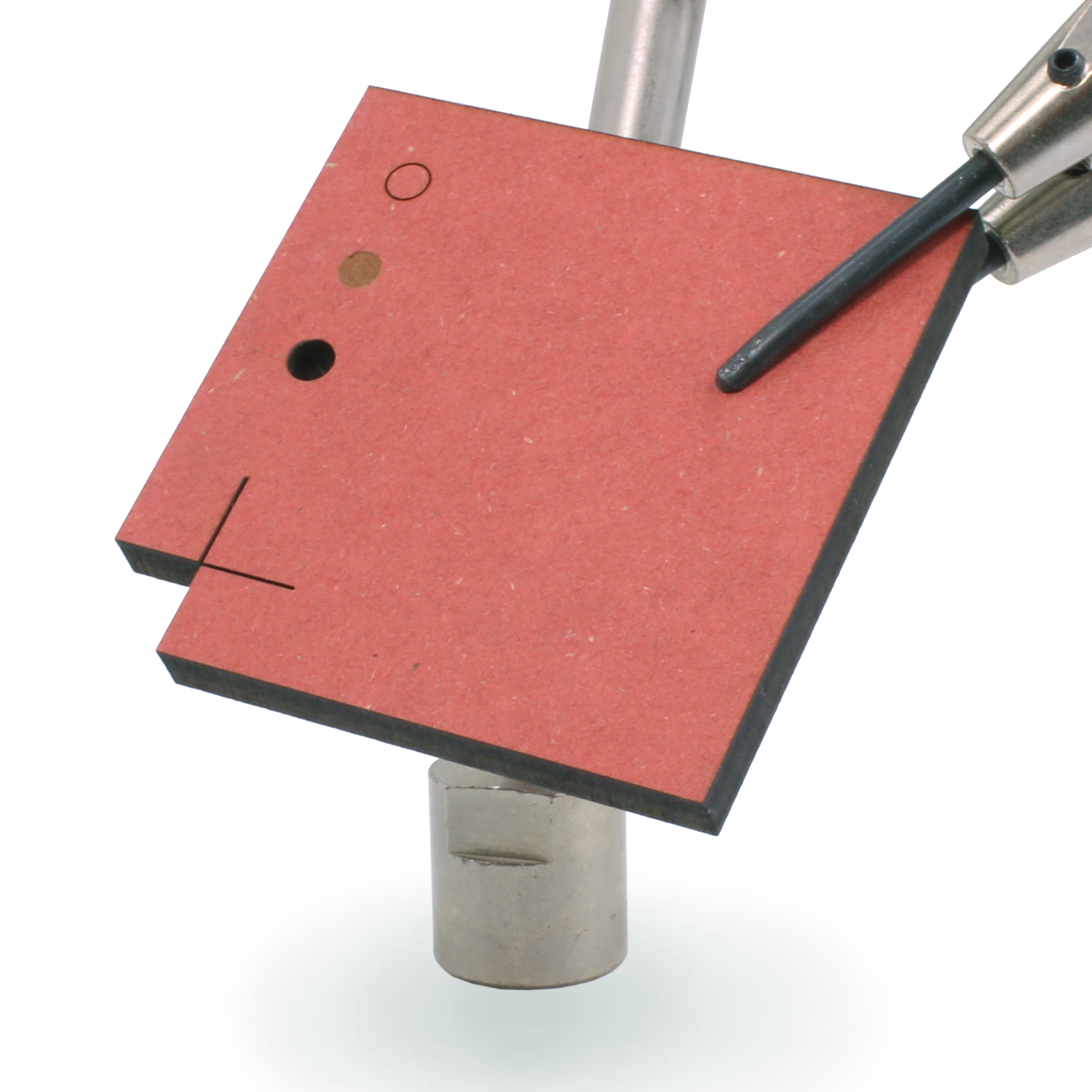

Colored MDF

Description

Make your own parts and save the time to paint them. This MDF is colored throughout and has a nice soft appearance.

Colored MDF is hard and strong, even slightly stiffer than normal MDF.

These colored boards are as easy to use as normal MDF: They are flat and strong because it consists of pressed wood fibers. The boards are equally strong in all directions because MDF is a homogeneous material. The great advantage of this through-and-through colored variant is, of course, that you immediately have beautiful colors.

For outdoor use, you can finish MDF with clear varnish. For indoor use, oil or wax is also a nice option.

Colored MDF can be laser cut into any shape or pattern you want. The laser cut turns black which gives a nice contrast against the colored surface. The laser cut is thin (approx. 0.15mm) and precise, allowing you to make small details and precisely fitting joints.

You can choose from six colors:

- mdf green 5mm

- mdf blue 5mm

- mdf red 5mm

- mdf orange 5mm

- mdf yellow 5mm

- mdf grey 5mm

Are you looking for black MDF? here.

Akoestisch paneel van hout en schuim

Kies dan een schuimsoort

Zowel voor PE-Hardschuim als Zachtschuim raden wij aan 20 mm te gebruiken. Hiermee absorbeer je het meeste geluid omdat deze platen dikker zijn.

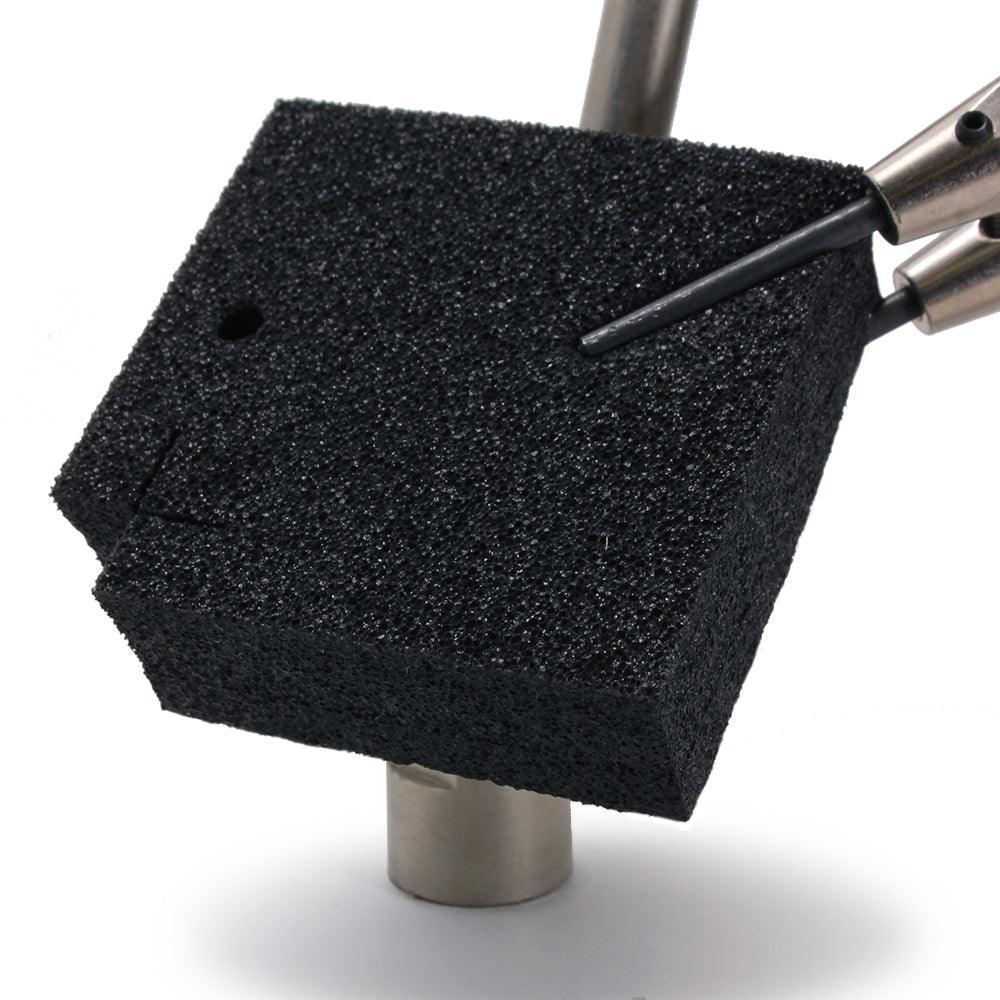

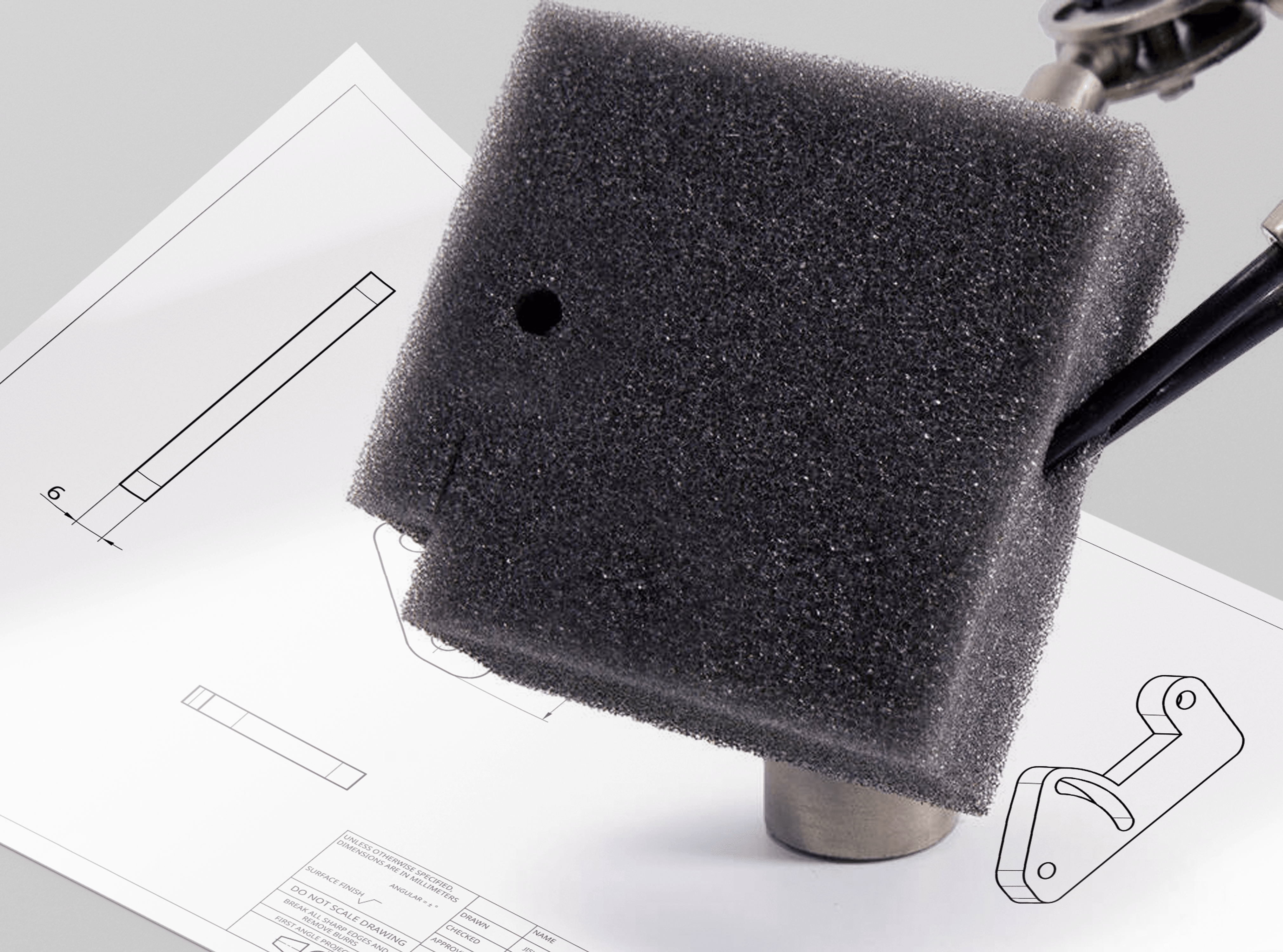

PE rigid foam

Description

Properties

This material is known from the flight case industry, where it is used to line the inside of transport cases. It has closed cells that make it impervious to liquids, floats and is highly resistant to chemicals. It is slightly harder than an average mattress.

Applications

PE foam is widely used to make inlays for cases or tool drawers. It is also an original material for company logos and signing, or for customized packaging. Due to its thickness, layered sculptures and sectional models can also be easily made.

Soft foam

Description

A budget alternative to PE foam

Properties

Polyether foam is known as mattress foam, but you can also laser cut shapes from it. It can in some cases be an economical alternative to PE foam in (temporary) inlays of cases and crates. However, there are some important differences from PE foam. It is less sturdy. It is lighter in weight. It is lighter in color (gray). It has open cells so it absorbs liquid. It is less suitable for detailed shapes

Voorbeeld van een akoestisch paneel met hout en schuim