When you are looking to have parts produced in large volumes, you may not immediately think of laser cutting. Laser cutting is often seen as a way to easily produce prototypes or small volumes. The fact that laser cutting in larger volumes is also perfectly possible is not known to everyone. In this article we will tell you the ins and outs of laser cutting in larger volumes and what the benefits are.

First, let's clarify the terminology. By "larger volumes" we mean several hundred to hundreds of thousands of copies, depending on the dimensions. Compared to what laser cutting is commonly used for, this is a form of mass production.

On the other hand, in the established world of mass production (for example, through injection molding), these numbers of hundreds to hundreds of thousands of pieces fall into the 'low volume' category.

So what do we call it? 'Low volume' or higher volume?

We will talk in this article about laser cutting in larger volumes, because it is special for laser cutting that we can produce in volumes from hundreds to hundreds of thousands.

Larger volumes

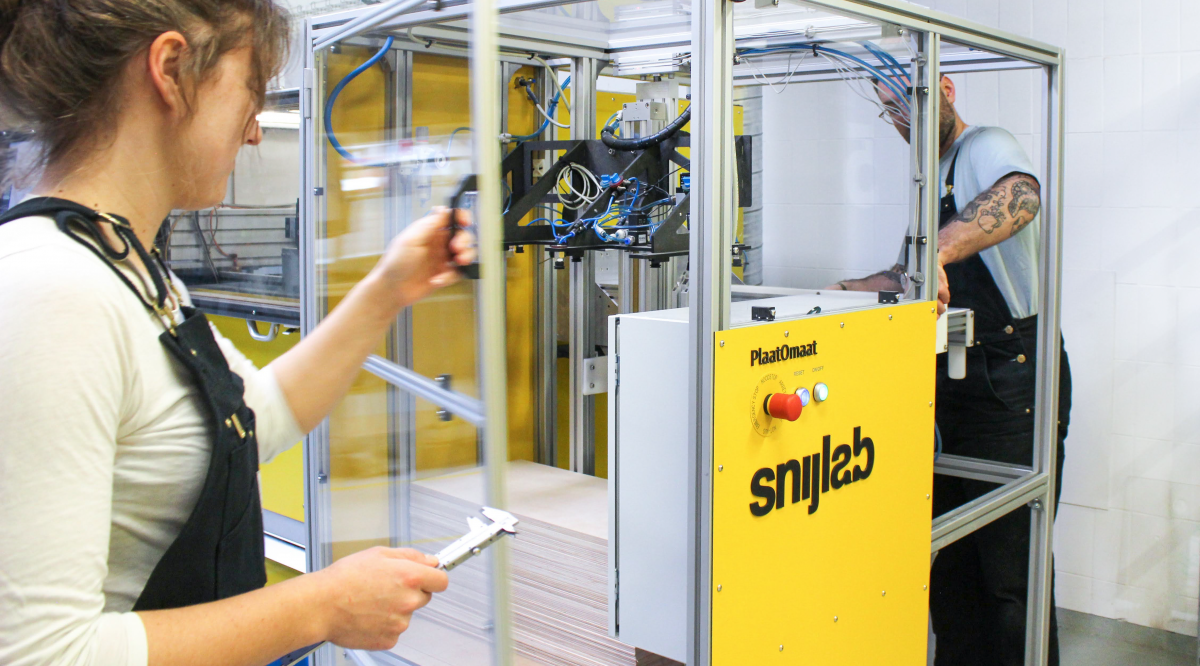

What is unique about laser cutting at Snijlab is that we produce larger volumes. For this we have developed our own special laser cutter, autoSPOT. With this laser cutter, the sheets of material no longer have to be placed in the machine manually, but this is done automatically. In this way, laser cutting is extremely suitable for producing larger volumes of parts where precision and accuracy are of great importance.

Why we are so enthusiastic about laser cutting in larger volumes

No longer a manual process

With a simple laser cutting machine, the material to be cut must be loaded manually (sheet by sheet). This limitation bothered us so much that we developed a new machine: autoSPOT.

'Clean cutting without repetitive manual work.' That was the goal we had in mind while developing this automated laser cutter.

AutoSPOT is well suited for higher volume production and delivers the highest quality and speed of our machines.

The features of autoSPOT at a glance:

-

175W laser power

-

3x Linear motors for high accuracy

-

Machining area: 620x420 mm

-

Materials: plastic and wood sheet material up to 22mm.

-

Operations: cutting + engraving

Capacity

Because autoSPOT does not require manual supply of material, the machine can operate unattended. This allows us to produce 24 hours a day and capacity is not easily an issue.

No more deposits

Unsightly brown or black deposits on laser-cut parts; a common problem and potentially a showstopper when you want to produce in larger volumes. You can still quickly clean a prototype of your part by hand, but this is obviously not possible with larger volumes.

AutoSPOT produces clean parts. Plastics can therefore be cut and delivered without protective film. That film does not have to be removed from the (thousands of) parts later. And wood no longer needs to be sanded clean. This smoke- and stain-free cutting saves an enormous amount of time and annoyance during finishing and makes the difference that makes laser cutting at Snijlab possible that other players in the market do not offer.

Laser cutting in larger volumes compared to other techniques

Freedom of shape

Although 3D printing naturally takes the crown in terms of freedom of shape, parts can often be designed perfectly well for laser cutting as well. Moreover, you then have access to many high-strength plastics, decorative materials and wood....

Suitable for prototypes - fast time to market

How many rounds can you prototype in one week? Because let's face it; how often is a design right the first time? Usually you need a few rounds of improvement. The speed at which you go through those determines your time to market. With 3D printing you can already go much faster than before, but if you outsource it, you still often wait a week or more for your delivery. With laser cutting you can have your prototype in house the next day, so you can move very quickly.

This is especially an advantage over injection molding. Injection molding is great for really large volumes, but because it requires expensive molds, making prototypes or small volumes is costly.

Suitable for larger volumes

Conventional laser cutting is good in the above three aspects, but not in producing larger volumes (due to the manual nature of conventional laser cutting). Laser cutting at Snijlab is.

|

|

time to market |

freedom of form |

suitable for prototypes |

suitable for larger volumes |

|---|---|---|---|---|

|

3D printing |

☆☆☆ |

☆☆☆☆☆ |

☆☆☆☆ |

☆ |

|

injection molding |

☆ |

☆☆☆☆ |

☆ |

☆☆☆☆☆ |

|

conventional laser cutting |

☆☆☆☆☆ |

☆☆☆ |

☆☆☆☆☆ |

☆ |

|

Cutting lab laser cutting |

★★★★★ |

★★★ |

★★★★★ |

★★★★ |

Our laser cutting process scores well across the board, making it an all-rounder.

It has become clear to you by now that laser cutting with autoSPOT is a very convenient way to produce larger volumes. It has many advantages and hardly any disadvantages.

In this case study you can read how Alphatron Medical had various parts made in larger volumes for their mobile care station "AMiS-PRO".

If you want to have hundreds to hundreds of thousands of copies of your design made, knock on our door. You can start immediately or get in touch.