Cutting out a part from Solidworks is very easy.

Open the part

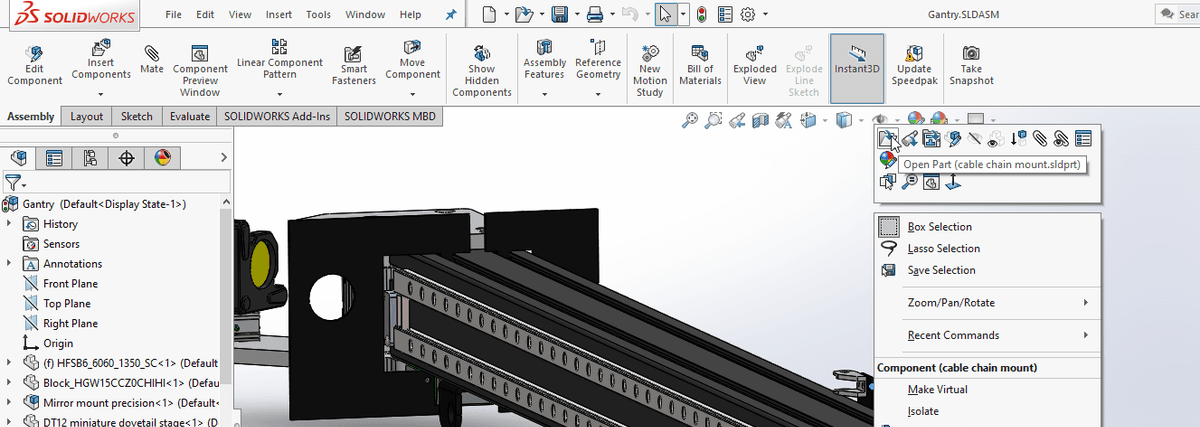

We start in an assembly. Right click on the desired part and choose ' Open Part '

You are now in the Part editor:

Export to DXF

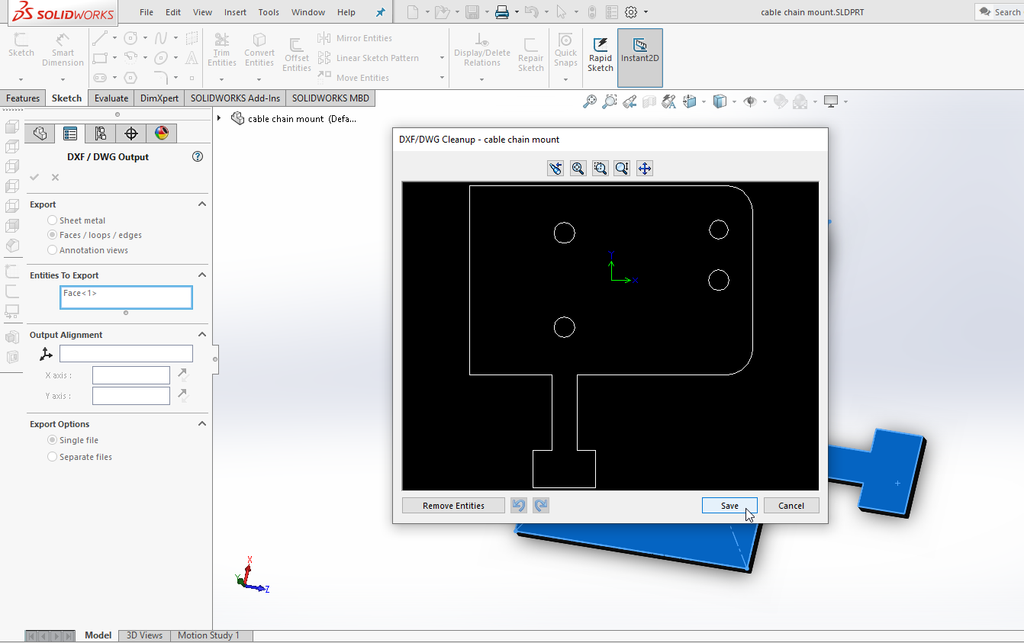

Right click on the part plane and choose ' Export to DXF/DWG '

Choose a folder and file name

Make sure the correct face is selected under 'Entities To Export' and click the green check mark

Check that all desired lines are in the preview and click ' Save '

You can immediately upload the DXF file you just exported to order.