Calculating laser cutting costs is a complex story. There are many things that affect how much laser cutting costs. That's why you often see that prices can't be found online with laser cutting companies. The price is always calculated specifically for you.

We wanted to have as fair a price as possible and not have to calculate it ourselves. That's why we created snijlab.nl where you can upload your drawing and a price will be calculated automatically.

In this article we will explain what things affect the cost of laser cutting. We will also look at what the cost of laser cutting is compared to other production methods.

What determines the cost of laser cutting?

Simplicity/complexity of design

In general, the simpler your design, the faster it can be made. This is because you pay for the "cut length," that is, how long the line is that is cut (or engraved). Based on this, we calculate how much power the making of your order consumes, which helps determine the production cost.

Material

Material choice plays a role in production time. After all, thick heavy materials take more time to cut than thinner ones. With very small designs, this is often less relevant because startup time plays a bigger role there.

Production time

Because each part is custom, production time varies for each part.

Start-up costs

Start-up costs also play a role. It is important that your drawing is well checked so you can be sure that production goes well and no material is wasted. After production, your work should be well checked. For example, for flaws in the material, whether the engravings have good contrast, etc. This makes the production of a single piece of a unique part relatively expensive.

Examples

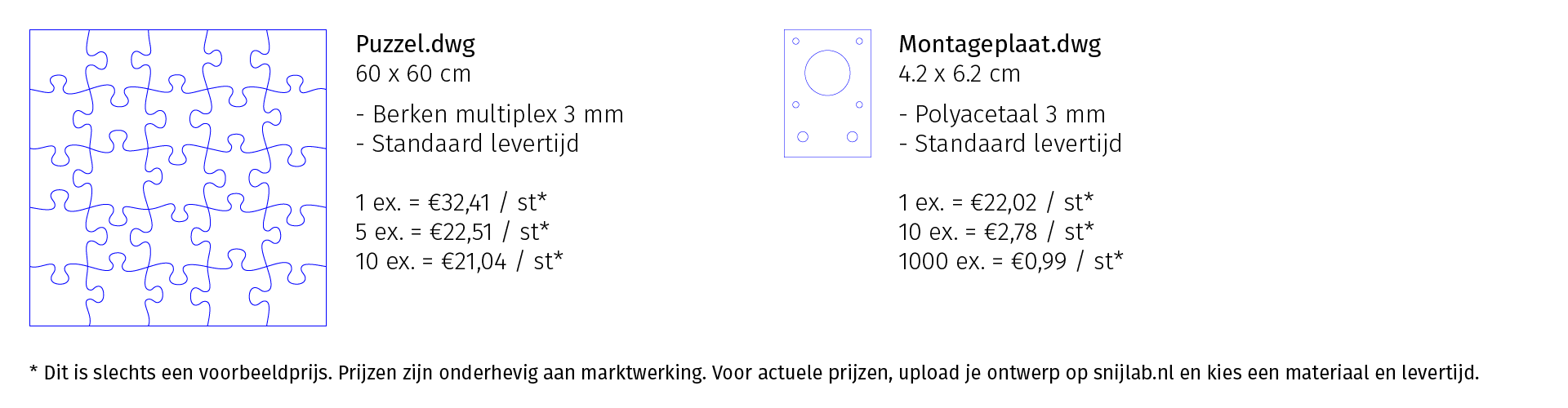

A single piece of a unique part can be had for as little as €25, a large collection plate of an expensive material can exceed €100 and a small part in a series can be laser-cut for as little as €0.10, for example.

Compared to other techniques

In our article Laser cutting in larger volumes we already compared different production techniques in terms of time to market, freedom of form, suitability for prototyping and suitability for producing larger volumes.

In terms of cost, of course, there are also differences between the various production methods.

We will assume in this comparison that you want something made to your own design from wood or plastic. Are you using wood? Then milling and laser cutting are the only options, 3D printing and injection molding of wood are not possible.

3D printing

3D printing is sometimes cheaper for single pieces of small (<10cm) objects because the start-up costs are low. If you want more than one piece, the price of 3D printing per piece usually doesn't get much cheaper. This is because a large part of the cost is in the production time and it does not get less.

3D printing quickly becomes expensive for larger designs, due to the long production time. Laser cutting and milling are more suitable then.

CNC Milling

Milling has somewhat higher start-up costs than laser cutting. The process also takes longer. But it does have advantages with large formats. It produces nice edges and makes it possible to create pockets.

Injection molding

In injection molding, the die (the hollow mold) is the largest investment item in most cases. The design and complexity of the part determine the cost of the mold, which easily runs into the thousands of dollars.

Cutting lab laser cutting

With laser cutting, production itself is much faster but there are some more start-up costs than with 3D printing. That means the price goes down quickly with larger volumes.

A single piece of a unique part can be had for as little as €25, a large collectible plate of a precious material can exceed €100, and a small part in a series can be laser cut for as little as €0.10, for example.

In short, there are a few areas where laser cutting always beats other techniques in price

-

Medium-sized (up to 1m) designs in wood and plastic

-

Small (<20cm) objects in wood and plastic in series

How to keep the cost of laser cutting low

Choice of material

Are you making a prototype? Then choose an inexpensive material such as corrugated cardboard or MDF. Products can also often be made from these materials.

Do you need wood? Then for thin materials <6 mm choose birch plywood. This is mechanically strong and relatively quick to process. For a thicker product, Poplar plywood may be more economical. This depends on your design, so check online.

Not too many different materials

For each subsequent drawing of the same material, you get a discount. After all, many of the start-up costs have already been incurred. Again, that saves. So whenever possible, choose the same material for all your parts.

Smart design

Don't draw unnecessary cutting lines. See where you can have parts adjacent to each other so they are separated by one line instead of two.

Choose an economical delivery time

Choose a longer delivery time if you can wait a little longer. This allows more time to process your order, making production more economical.

More pieces = lower costs

The first copy is always the most expensive. Choose a larger print run, then you spread the start-up costs over more products.

Many different parts?

Combine them together in one drawing. That saves in start-up costs.

Extra services at no extra cost

-

An engineer checks your drawing before it goes into production

-

Minimal smoke stains and shadow edges on your parts

-

Quality control so that 99+% arrive correctly (we measure this continuously)

-

Your part numbers clearly stated on delivery for quick commissioning

-

Free design consultation via video call

-

Free advice on choice of material

Want to know what producing your design by laser cutting at Snijlab costs? Then request an online quote or order directly.