The answer, of course, is: Tolerances.

We supply our laser cut parts, unless otherwise specified, in accordance with ISO9013-1. This international standard specifies the limit tolerances to which nominal dimensions of products with thermal cutting operations (such as laser cutting) must comply.

Linear dimensions (ISO 9013-1).

| Nom. size Sheet thickness |

to 3 | > 3 to 10 | > 10 to 35 | > 35 to 125 | > 125 to 315 | > 315 to 1000 | > 1000 to 2000 | > 2000 |

| 0 to 1 | ± 0,1 | ± 0,1 | ± 0,1 | ± 0,2 | ± 0,2 | ± 0,3 | ± 0,3 | ± 0,3 |

| > 1 to 3 | ± 0,1 | ± 0,2 | ± 0,2 | ± 0,3 | ± 0,3 | ± 0,4 | ± 0,4 | ± 0,4 |

| > 3 to 6 | ± 0,3 | ± 0,3 | ± 0,4 | ± 0,4 | ± 0,5 | ± 0,5 | ± 0,5 | ± 0,6 |

| > 6 to 10 | ± 0,5 | ± 0,6 | ± 0,6 | ± 0,7 | ± 0,7 | ± 0,7 | ± 0,8 | |

| > 10 to 50 | ± 0,6 | ± 0,6 | ± 0,7 | ± 0,8 | ± 1 | ± 1,6 | ± 2,5 |

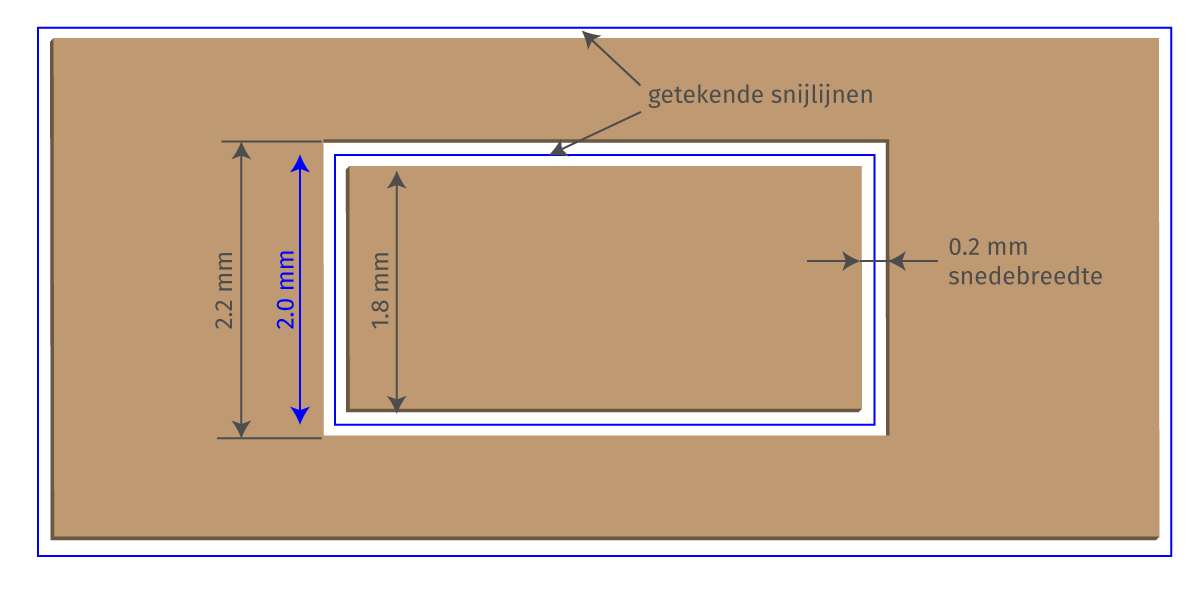

Note: no compensation for cutting loss by default

Unlike laser cutting of steel, for example, we do not adjust drawings to compensate for cutting loss (cut width). This means that outside contours become slightly smaller and holes slightly larger. How much larger? The cutting loss is indicated on the respective material pages and we cut in the middle of the drawn line.

If you want size-accurate (small) parts, you need to compensate for the cutting loss in your drawing. Of course, we can help you with this. In that case, please contact us.

Tolerances on the thickness of the base material

The sheet materials as supplied by our suppliers can vary quite a bit in thickness. Especially with acrylics you soon have a thickness tolerance of +- 0.6 mm. This is generally the most important tolerance to take into account!

At the material overview on our website, these thickness tolerances are specified for each material.

Precision and flexibility

With this knowledge in hand, laser cutting plastics and wood is an ideal way to create precision parts that are guaranteed to fit.