Why we stock POM and not PA6.

TLDR; POM is neater to laser cut and otherwise the differences of laser cut POM and polyamide for most applications are not that great

What about all those names?

We are talking about Polyacetal, or POM, known by brand name Delrin (but it is also made by other manufacturers). Other names for POM are acetal, polycetal or POM-C. For convenience, we will refer to it as POM in the remainder of this article.

And in addition about Polyamide, or PA6, known by brand name Nylon. This material is also called PA, PA6+ oil-filled, Ertalon, Nylon 6, PA 12, PA66, Akulon, Ultramid, Zytel, and Nylatron. Below, we will stick to Nylon for a moment

What are POM and Nylon?

POM and Nylon are thermoplastics, that is, plastics that soften (and eventually melt) when heated. Nylon is very common in everyday life. In textiles, in yarn and rope and as film. POM is often used in appliances and technical installations. In the context of laser cutting, in this article we are talking about sheets of POM and sheets of Nylon.

Both materials are categorized as "engineering plastics. That is, they are chosen for their good technical properties such as strength, abrasion resistance, thermal range, etc. Aesthetics are thus less important in these applications.

POM is particularly strong. It is highly resistant to chemicals and has high dimensional stability. Which means so much that its shape and dimension is stable under different conditions and over time. POM sheets, incidentally, can be slightly warped due to internal stresses. So it is a good plastic for applications that require stiffness, low friction and high dimensional stability.

Nylon is also tough, strong, and resistant to shock. It is also wear-resistant with a low coefficient of friction. In addition, nylon is also sound-absorbing. Nylon has high moisture absorption depending on temperature and humidity.

Both materials feel hard, smooth and a little waxy. Nylon has just a slightly different light transmission.

Laser cutting of POM and Nylon

Both POM and Nylon can be laser cut at Snijlab . POM is one of our commonly used materials and we always have plenty in stock for next business day delivery. Nylon we do not have in stock but you can provide it for laser cutting.

Laser cutting makes it possible to produce small details, sharp corners and complex designs at low cost. Laser cutting is used for prototyping as well as in small and medium runs with POM and Nylon. If your production volumes get really large, you can also injection mold both plastics.

In many ways, POM and Nylon are similar. Why did we choose to stock POM and not Nylon?

Nylon and POM compared

So sheets of Nylon and POM are very similar. The technical properties are also very similar but there are a few differences.

Mechanical properties

Let's compare mechanical properties in detail.

|

POM |

Nylon |

||

|

Density (DIN EN ISO 1183-1). |

g/cm³ |

1.41 |

1.14 |

|

Tensile strength (DIN EN ISO 527) |

N/mm |

67 |

80 |

|

Elongation to rupture (DIN EN ISO 527) |

% |

40 |

50 |

|

Modulus of elasticity (DIN EN ISO 527). |

N/mm² |

2800 |

3200 |

|

Impact strength (DIN EN ISO 179). |

kJ / m² |

6 |

3 |

|

Shore hardness |

Shore °D |

81 |

82 |

|

Coefficient of friction |

0.36 |

0.5 |

|

So the density (weight of a given volume) of POM is 24% higher than Nylon. Both are higher than the density of water so they sink.

The tensile strength is the maximum stress the material reaches just before it fails (permanently deformed). In practice, a material well below this limit is used. Nylon is 19% stronger than POM.

The modulus of elasticity indicates how much the material deforms under a given stress. Also called; the stiffness of the material. This is an important property in practice because it determines how large you need to size a part to handle a given load. So it is often directly related to weight and cost. Nylon is 14% stiffer than POM.

Impact strength indicates how well the material can absorb shocks and blows. In the test, the material is held at two ends and struck in the middle with a special impact hammer. POM twice as impact resistant as Nylon.

Surface hardness is measured on a Shore D scale. For comparison, at shore D, a car tire is 15, a skateboard wheel is 50 and a construction helmet is 80. POM and Nylon barely differ with 83 and 82 Shore D, respectively.

The coefficient of friction indicates how much resistance a material provides to friction. Simply put; the lower this number the better the material glides. POM glides 39% better than Nylon.

In summary: Nylon is stronger and lighter, POM is more shock resistant and glides better.

Thermal properties

In many applications, temperature range is important. Anyone who has ever left a plastic product in a car in the sun knows how easily plastics can melt. Basically, all plastics we laser cut are thermoplastics and will melt at a certain temperature. But the differences between them are great. Let's see how Nylon and POM compare.

|

POM |

Nylon |

||

|

Melting point |

°C |

165 |

220 |

|

Heat conductivity (DIN 52612-1). |

W/m°K |

0.31 |

0.23 |

|

Heat capacity (DIN 52612) |

kJ / (kg * K) |

1.50 |

1.70 |

|

Coefficient of expansion (DIN 53752). |

10e-6/K |

110 |

90 |

|

Operating temperature long-term |

°C |

-50 ... 100 |

-40 ... 85

|

|

Maximum temperature momentary |

°C |

140 |

160 |

|

Heat mold resistance (DIN EN ISO 75, Paint. A, HDT) |

°C |

110 |

95 |

At 220C, the melting point of Nylon is a lot higher than that of POM. But that is not saying everything.

The thermal conductivity of POM is slightly greater than for Nylon. Depending on the application, this is an advantage or disadvantage. But realistically, neither material is very good at conducting heat (metals are much better) nor a fantastic insulator.

POM expands more when heated: 0.110 mm per meter of material per degree of heating versus 0.09 mm. So here Nylon wins because it deforms less.

The maximum and minimum temperatures are similar. POM has a slightly wider temperature range.

Briefly, you can also use Nylon at a slightly higher temperature.

Heat Deflection Temperature (HRT) is one of the most important parameters in high-temperature use. It indicates the temperature up to which a material remains rigid under load. To test HDT, a sample of the material is imposed in an oil bath on two sides and loaded in the middle. Then the temperature of the oil is slowly raised until the sample reaches a certain deflection. POM has an HTD of 110C and Nylon of 75C.

In summary: POM and Nylon are similar in thermal properties, but in practice you can use POM in a wider temperature range.

Moisture absorption

|

POM |

Nylon |

||

|

Moisture absorption (DIN EN ISO 62) |

% |

0.2 |

3 |

If a material absorbs moisture then its volume also increases. So that means that depending on the climate your part varies in size. Especially in an assembly together with other materials, this can cause major stresses or mismatched joints. With tight-fitting parts, it is important to leave room in your design for this kind of variation.

When a material absorbs moisture, its mechanical properties also change. The material becomes tougher and more resistant to shock, but also less flexible.

Nylon absorbs up to 3% moisture, much more than POM and much more than most other plastics.

Electrical properties

|

POM |

Nylon |

||

|

Dielectric constant (IEC 60250) |

3.8 |

3.9 |

|

|

Dielectric loss factor (IEC 60250 50Hz) |

0.002 |

0.02 |

|

|

Specific resistance (DIN EN 62631-3-2). |

Ohm * cm |

10^13 |

10^15 |

|

Surface resistance (DIN EN 62631-3-2). |

Ohm |

10^13 |

10^13 |

|

Creepage resistance (IEC 60112) |

600 |

600 |

|

|

Breakthrough voltage (IEC 60243) |

kV/mm |

40 |

20 |

The dielectric constant or permittivity is the ability of a material to store electrical energy in an electric field. This can be important in high-frequency electronics, where a component can affect an electric field. The difference between POM and Nylon is small.

Specific resistance is the electrical resistance per length of material. Nylon has a higher specific resistance than POM.

Among other things, surface resistance affects static charge dissipation and is also important in high-frequency applications. The surface resistance is the same for both materials.

The breakdown voltage is important when the material is used as an insulator and indicates the voltage at which the material stops insulating and starts conducting. POM has a breakdown voltage twice as high as Nylon, namely 40 kV/mm.

In short; both materials are good electrical insulators, with a few specific differences.

Fire behavior

|

POM |

Nylon |

||

|

Flammability (UL94) |

HB / HB |

HB / HB |

Het brandgedrag van POM en Nylon is vergelijkbaar. Beide worden als HB geclassificeerd volgens de UL94 standaard. Dat betekent: Langzaam branden op een horizontaal voorwerp, de snelheid van branden is <76 mm/min voor diktes van <3 mm, of het branden stopt vóór 100 mm.

Disclaimer

The above numbers vary slightly between manufacturers. There are also different measurement methods that yield slightly different values. Some values also depend on temperature, humidity and shape of the product. Always allow sufficient margin in your designs to accommodate these kinds of differences. The above figures are taken from the data sheets of the materials we usually supply.

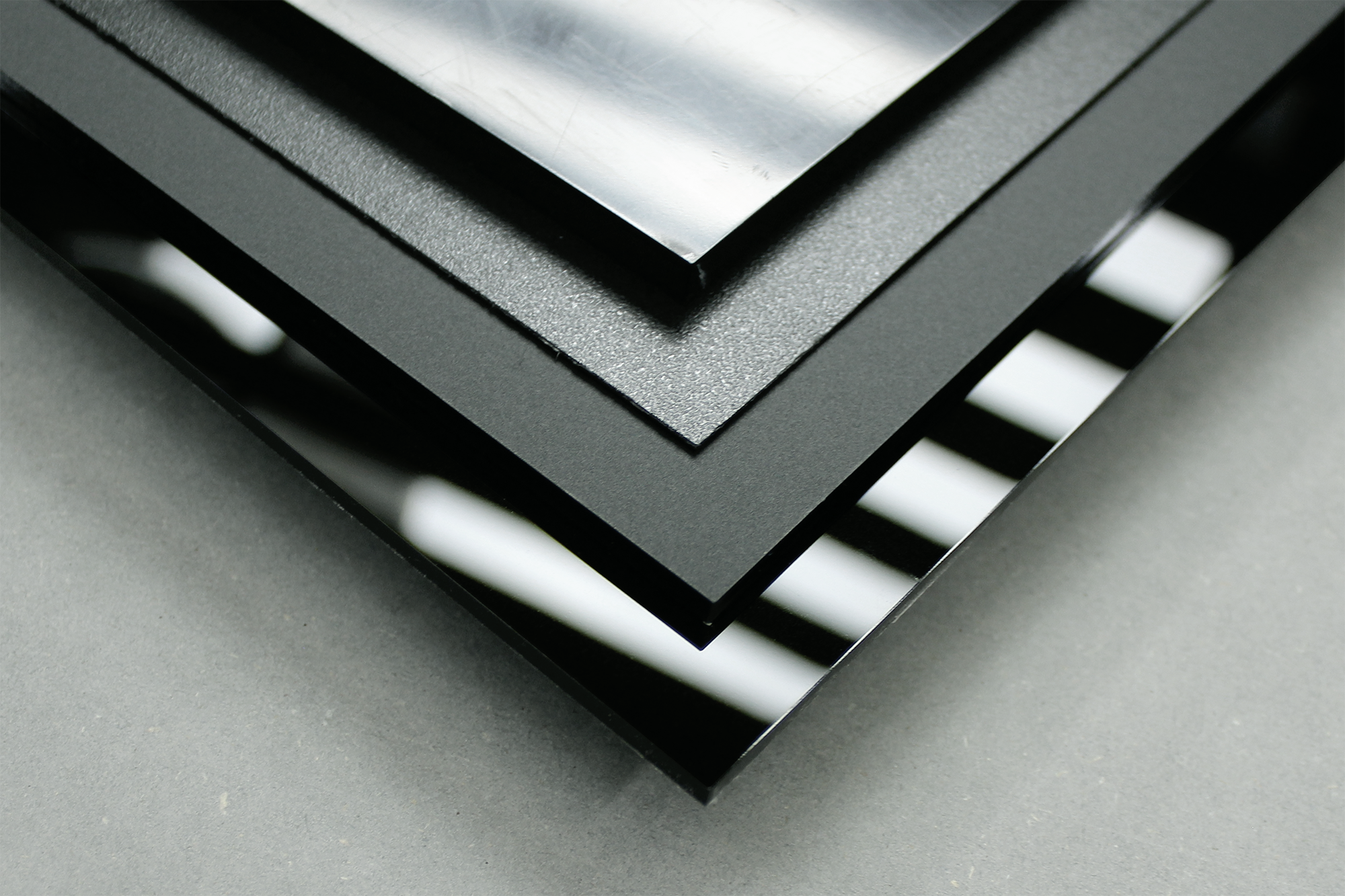

Edge quality of the laser cut

At Snijlab you can have both POM and Nylon laser cut. The laser cut of POM looks clean and does not discolor. With the thicker plates 6 mm and thicker, a thin melting edge forms at the bottom of the sheet. You can remove this with a deburrer, a Stanley knife or with a file or sandpaper. Another option is to select protective underside film during the ordering process. You will then receive the laser cut parts with foil and after removal the melted edge will also be gone. This remains on the foil. The top side of the laser cut is tight and neat. In short, POM is very good for laser cutting.

Nylon can also be laser cut but suffers more from melting. Thinner sheets therefore also need post-processing and/or foil unless the melt edge is not a problem. The laser-cut edge may turn slightly brown from lasering. The machining speed of Nylon is slightly slower than POM, resulting in slightly higher cutting costs. In short; Nylon can be laser cut reasonably well.

Melt edge and black deposit prevention

If you want clean parts right away, choose the "protective foil underside" option when ordering. The melt edge will then be on the foil and can be easily removed with the foil. Another option is to use a deburring knife to cut the edges clean or sand them briefly (150-400 grit).

Colors

Nylon is available in a number of colors such as natural, black, blue, green, gray and purple. Generally, the colors are available only from 15 mm thickness. POM is available in natural, black, blue and red. The colors are available only from 10 mm thickness.

manufacturing and thickness tolerance

Nylon is extruded to about 10mm. Thicker sheets are cast. POM sheets are extruded. The advantage of extrusion is that the thickness tolerance is a lot better than with cast plates.

Prices of POM and Nylon laser cutting

On the price difference you don't have to make the choice. The prices of POM and Nylon differ (at the time of writing) less than 5%

Delivery time POM and Nylon laser cutting

POM is one of our most widely used materials for technical parts. We therefore have a whole range of plate thicknesses from 0.5 to 9 mm in black and natural in our assortment. We keep these plates well in stock in our own warehouse so that we can always get to work immediately. So with POM you can take advantage of our express delivery where, if you order before 12:00, you will receive the parts the next day. If you come to pick them up yourself, you can pick them up on the day of order from 16:00 in Rotterdam.

If you want to laser cut Nylon, you can upload your design online and choose "self-supplied plastic up to {thickness} mm" as the material. You will then see the price in advance (excluding material!) and can checkout online. Once your order is placed, you can order Nylon sheets yourself and order them (or have them delivered) to us. Make sure you clearly mention your name and order number at the delivery so we can match it to your order. The selected delivery time starts when the order and materials are received by us.

We can also order Nylon for you. This involves a minimum order of one industry plate plus order costs. Please contact us to request a quote.

Summary

POM and Nylon sheets are very similar. Nylon is slightly stronger but again less impact resistant. POM gives neater parts after laser cutting and is more economical to machine. A decisive reason for us to keep a full range of POM in stock.

Therefore, for most applications, POM is the best choice. For very specific applications, Nylon may be better, and in that case, of course, we are happy to help you.