Our different plastics have different surfaces. Learn about the differences so that your laser-cut plastic stays looking good even with use.

All our plastics can be cleaned with water, all-purpose cleaner or glass cleaner. Alcohol-based cleaners (such as isopropyl) are also safe to use.

Note: Never use acetone to clean plastic, as it dissolves with it!

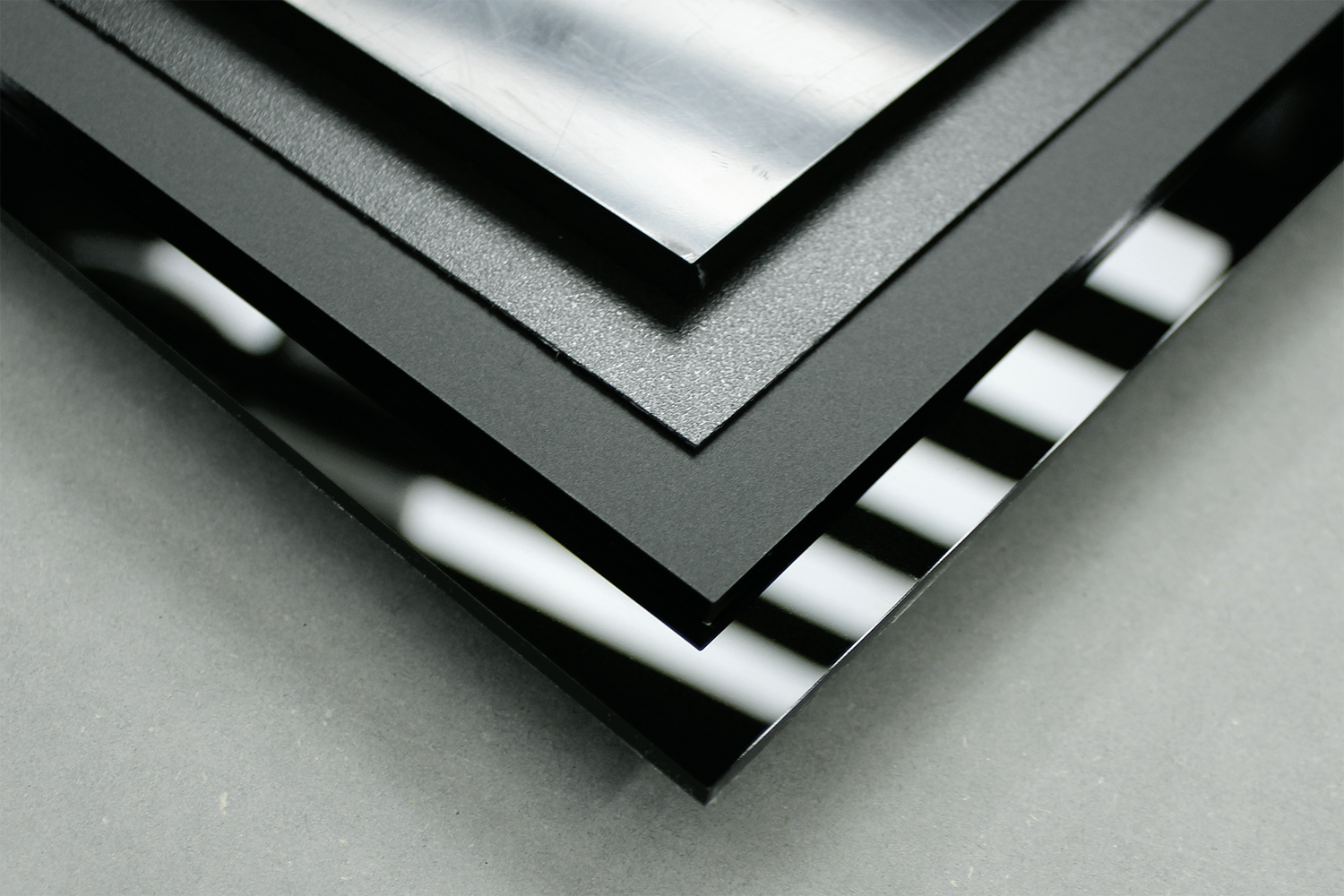

Glossy

Glossy steals the show so is particularly intended for aesthetic applications. But beware; glossy plastics are prone to scratching. Care should be taken when cleaning: use a soft microfiber cloth. You can usually repair any scratches with polish. Glossy plastics always come with a protective film so they arrive at your door perfectly.

Glossy plastics at Snijlab:

- Acrylic clear

- Acrylic glossy

- Acrylic clear colored

- Acrylic opal

- Acrylic fluorine

- Extruded acrylic

- Precision acrylic

- Mirror Acrylate

- PETG (polyester/varnish)

- Acetate film

Matt

A matte surface has microscopic imperfections that cause light to refract in all directions. Matte gives a calm image because you can't see reflections in it. It is also more robust than gloss because grease stains and small scratches are much less noticeable. Therefore, a matte surface often stays looking nice longer. Deep scratches can be made on it, so caution is advised. You can clean matte plastics using a damp cloth with detergent or glass cleaner. Our matte acrylics come with protective film so they arrive at your door perfectly.

Matte plastics at Snijlab:

Structure

A textured surface intentionally has small bumps, small but just visible. It often feels a little smoother because you make less contact with the surface. A textured looks neat and is even less prone to scratches and stains than a matte surface. Just think about a car dashboard, which is also often textured so that it stays looking good even if you don't clean for a change. So textured is ideal for surfaces that are often touched and used.

Textured plastics at Snijlab:

Technical

Sometimes appearance is of lesser importance. For example, for mechanical and structural application. This surface has some gloss, but is already supplied by the factory without a protective film. As a result, it may contain small scratches.

Technical plastics at Snijlab:

Whatever plastic you are having laser cut, now you know which surface to choose for your next project.