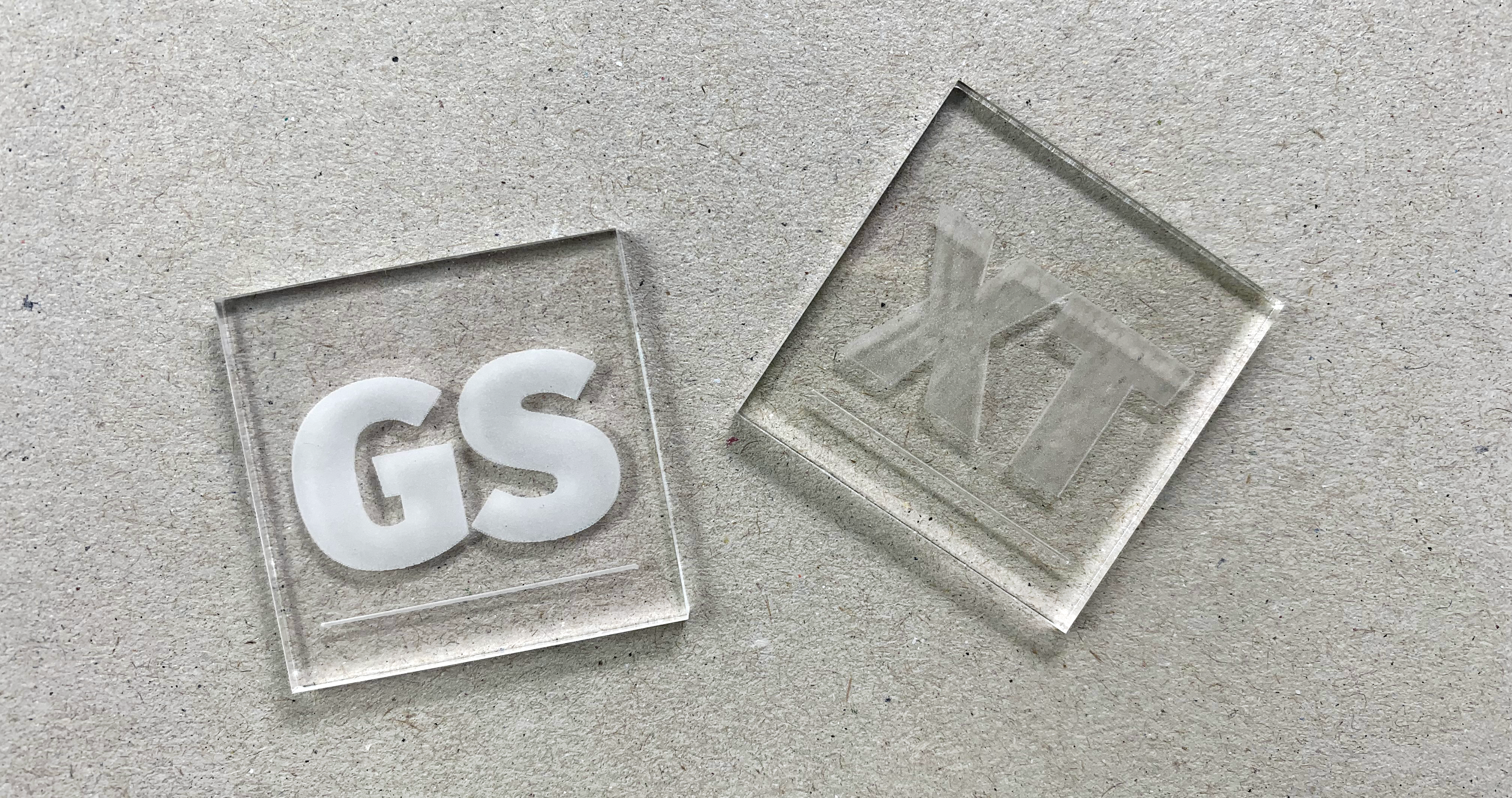

A new type of acrylic has been added to our range: extruded or also known as XT acrylic. At first glance this looks the same as our other clear acrylic, but because it is made in a different way it exhibits different properties.

The big advantage is that this material has a very even thickness, so for parts that need to fit together precisely, this is ideal.

What is extruded acrylic?

Extruded acrylic is made by melting granules and pressing them through an extrusion profile under high pressure. This makes the thickness of a sheet very consistent, so the thickness tolerance is very low. XT acrylic is very precise and suitable for parts that have little margin on fit.

But extrusion also has the consequence that this material engraves poorly. Engravings do not become clean or clear, and we therefore do not recommend engraving in XT acrylic.

Also, the internal stress of extruded acrylic is high, making it less amenable to machining or finishing.

So what about the other acrylic?

The other acrylic in our range is cast, abbreviated as GS acrylic. Cast acrylic has a higher thickness tolerance. A higher thickness tolerance means that the thickness of a sheet may vary more.

In contrast, GS acrylic allows for good engraving. The result of engraving depends on the color of the material, but is generally matte and has sharp details.

Cast acrylic is also low-stress, making it excellent for machining or finishing.

Wondering what you can do with XT acrylic?

Alphatron Medical uses XT acrylic to divide the drawers of mobile care stations. Medications are stored in these drawers, stock and dispensing are managed by the computer associated with the care station.

The fit of these parts is very precise. Because they are made from extruded acrylic, there is significantly less product waste.

Alphatron Medical uses laser-cut parts to create a product that reduces the workload of medical personnel, read how they do it here....