This is our roof. Snijlab is powered by solar electricity.

Solar power

Our roof is full of PV panels that provide us and the businesses around us with solar power.

Recycling

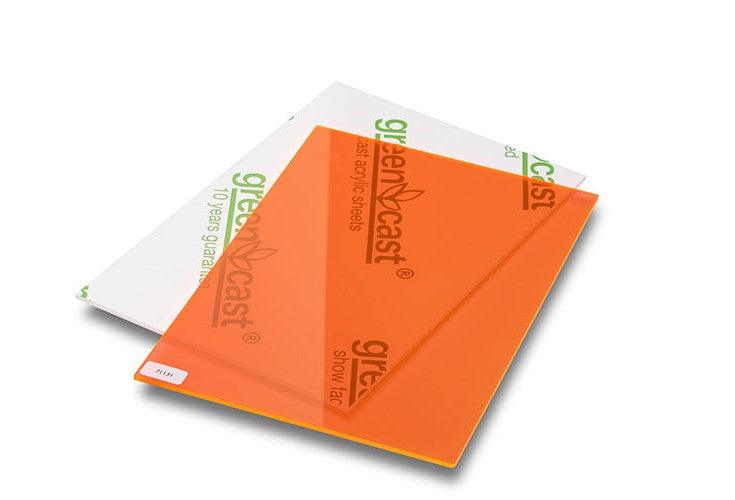

Laser cutting is and remains a subtractive technology. Fortunately, the plastics we process can be properly recycled. We separate our waste into as many as 6 different streams that are processed by specialized recyclers.

Reuse

As much as possible, we process residues from the cutting process into smaller orders. Small residual pieces are less usable for our production but still good for use in schools and fablabs, for example. Through the Lasersheets MixCrates we ensure that they get a second life and do not have to be thrown away.

FSC

Snijlab is FSC® certified. This means that we are allowed to supply materials and products that carry the FSC® label. For example, we currently produce FSC-certified Brikkon products. We can also supply FSC® for other (serial) work productions.

Note: Only products marked as such are FSC certified.