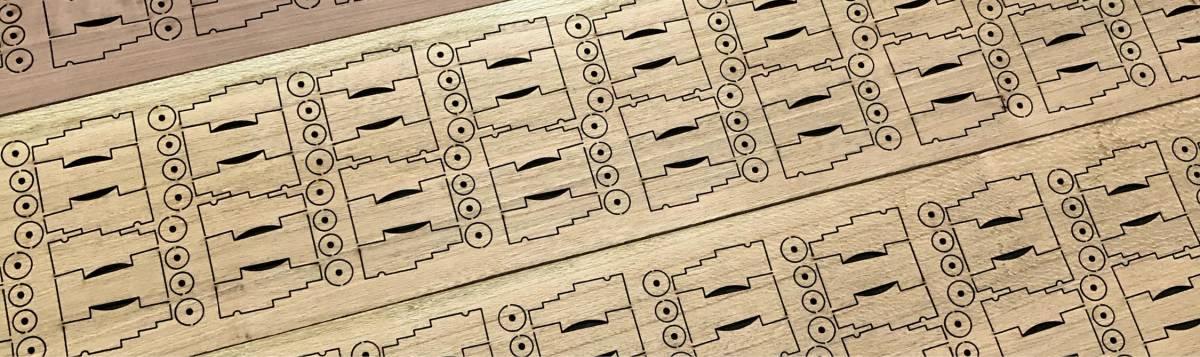

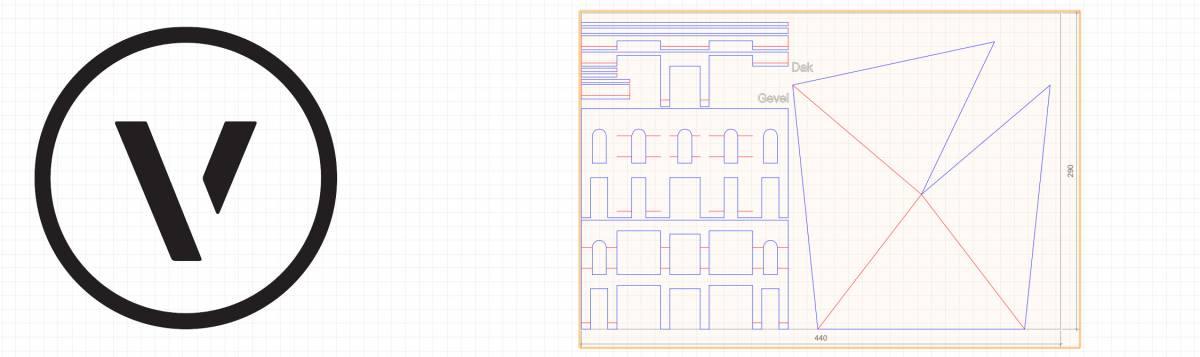

With a thread tap, you can easily create threads in laser-cut plastic parts. The most suitable material for threading is POM (polyacetal) because it is tough and strong. In your laser cut drawing, place circles where the tapping holes should be. You can then directly* tap the laser-cut holes.

How big do you actually draw the holes for regular tap sizes? We figured it out for you:

|

Tap |

Diameter of the hole in your drawing |

|---|---|

|

M3 |

2.33 mm |

|

M4 |

3.13 mm |

|

M5 |

4.03 mm |

|

M6 |

4.83 mm |

|

M8 |

6.58 mm |

* People familiar with metalworking may know that laser-cut holes in steel cannot be tapped directly. They are hardened by the laser and must be pre-drilled first. With plastics, this is not the case. You can tap the laser-cut hole without pre-drilling.