Miniature wooden guns, by Hans van Nieuwkoop

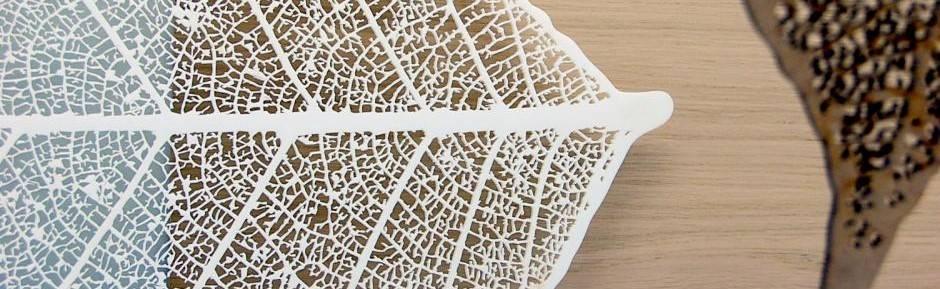

For all materials, parts smaller than 5x5 millimeters may be lost during the laser process. We cannot guarantee to supply residual shapes of small holes.

If you want to make small parts, you need to make sure that they stay attached to the rest shape. You do this by adding tabs in your drawing, which are like little bridges between your drawing and your rest shape, or simply breaks in the cutting line.

With thin materials such as resin board and paper, the use of tabs is recommended for shapes up to 50x50 mm. For larger underparts, tabs can also be applicable to keep parts in the right place in the sheet .

- Gebruik minimaal één bruggetje voor zeer kleine onderdelen (< 10x10 mm)

- Use at least two to three bridges for larger parts (up to 50x50 mm)

- Use even more and possibly wider bridges for parts larger than 50x50 mm

When drawing small parts, keep in mind the cutting width.

| Material | Tab size in millimeters |

|---|---|

| MDF 1.0 mm | 0.6 mm |

| MDF 2.0 mm | 0.6 mm |

| MDF 3.0 mm | 0.5 mm |

| Plywood birch 1.0 mm | 0.6 mm |

| Plywood birch 3.0 mm | 0.5 mm |

| Plywood birch 6.0 mm | 0.5 mm |

| Resin board 0.5 mm brown | 0.6 mm |

| All cardboard types | 0.6 mm - 1.0 mm |

| All paper types | 0.6 mm |

: