During the COVID-19 pandemic, European companies were forced to face the facts: our supply chains are more vulnerable than we thought. A simple but crucial component that was missing could cripple entire production lines. At Snijlab , we were able to catch the manufacturing of many of these essential parts, mainly for the Dutch, Belgian and German markets.

As a business owner, you want to reduce the impact of external risks and ensure the continuity of your products or services. This is why more and more companies are considering bringing back their manufacturing of critical components/products, a strategy known as near- or reshoring. By producing locally, we can guarantee shorter delivery times, better manage quality and communicate more efficiently with our partners and customers.

In addition to operational advantages, local manufacturing also offers economic and environmental benefits. It reduces inventory storage costs due to fast delivery times, thus promoting more efficient operations. It also helps to stimulate the local economy and reduce the carbon footprint through shorter transport routes and reduced CO2 emissions.

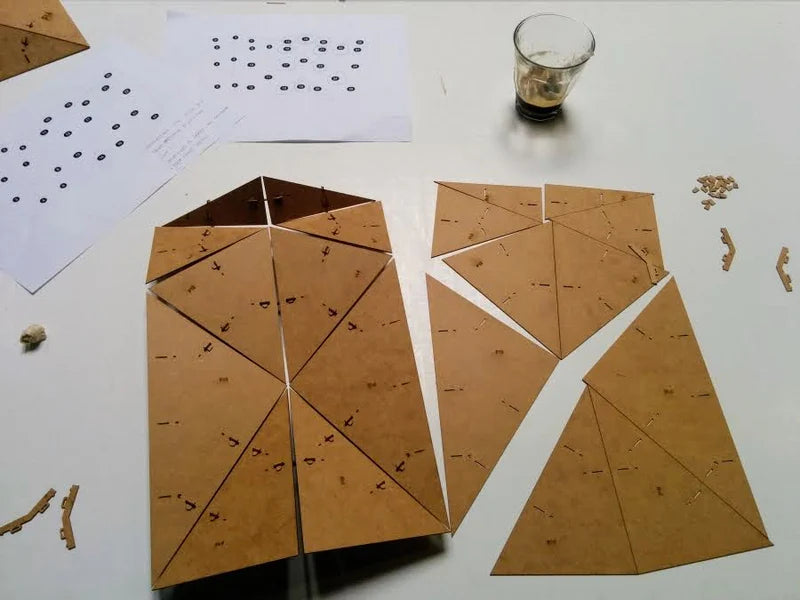

At Snijlab we believe in the power of local manufacturing. Our advanced laser cutting process allows us to produce quickly and efficiently, even in larger volumes. In doing so, we put quality, durability and flexibility to our customers.

Benefits of local laser cutting at Snijlab:

- Fast delivery, as little as 1 business day.

- Low start-up costs.

- Flexibility: Professional team thinks along for customized solutions.

- Rapid prototyping: Rapid development and optimization of your product.

- Scaling up from prototype to larger manufacturing is quick.

- Durable manufacturing.

- Diversity of materials.

- User-friendly ordering portal.

Wondering what we can do for you? Get in touch via [email protected] or 010 307 0949