Systainers are robust, convenient and readily available. They lend themselves perfectly to making professional cases for instruments, tools, cameras or other sensitive equipment.

Download here the template for the Systainer T-lock (396×296mm)

So that you can easily draw in and order your own inlay.

What are systainers?

Systainers are modular, stackable plastic containers. Originally they were developed by Festo for transporting power tools. Nowadays they are produced by Tanos and sold by several brands such as Festool, Makita, Hitachi, BTI, Metabo, and so on. The template fits systainers of all brands, as long as it is the "T-lock" type. The template does not fit the older systainers that work with clips on the side.

Layout

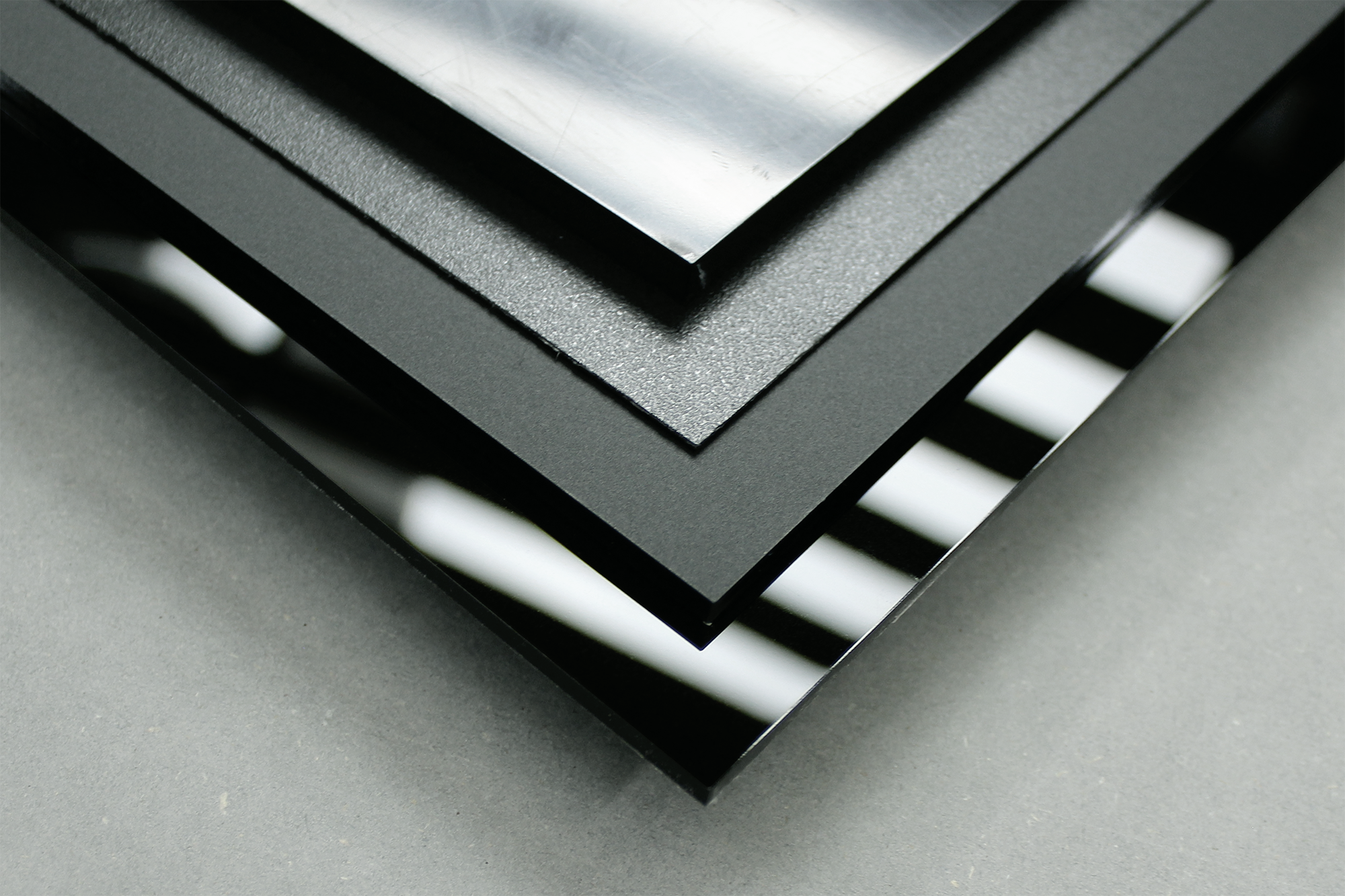

The bottom of the inlay consists of a 5mm thick layer. This layer has a recess for the relief which is in the bottom of the systainer. Above this is room for three foam layers of 20mm thick. This is where your products will lie. Depending on the thickness of your product, you can draw recesses in one, two or three of these layers.

The lid inlay consists of a sheet of 2 mm thick MDF and a 10 mm thick foam layer. Alternatively, a ready-made lid liner made of bubble foam is also available in several web shops.

Tip 1 To ensure that the products clamp nicely, draw the recesses on all sides approx. 1mm smaller than the size of your product.

Tip 2 Do not forget to draw recesses for your fingers so that you can easily remove the products.

Tip 3 You can also flat engrave in PE foam. So if necessary, you can have a logo or text engraved. Don't make your engraving too small (at least 10mm letter height).

Assembly

Once you have the drawing ready you can order the layers. Choose as material PE foam of the desired thickness.

Want extra convenience? Then also choose self-adhesive film on the underside. This allows you to glue the layers together easily and permanently. Alternatively, you can use spray adhesive to glue the layers together.

Other systainers

Other systainers

The above layer assembly applies to a Systainer T-lock type 1 (the smallest) 105 mm high.

- For Systainer T-lock type II (157.5mm height) you need to add three foam layers to the middle section; 2 x 20mm and 1x 15mm. The lid and bottom plate remain the same.

- For Systainer T-lock type III (210mm height) you need to add five 20mm foam layers to the middle section. The lid and bottom plate remain the same.