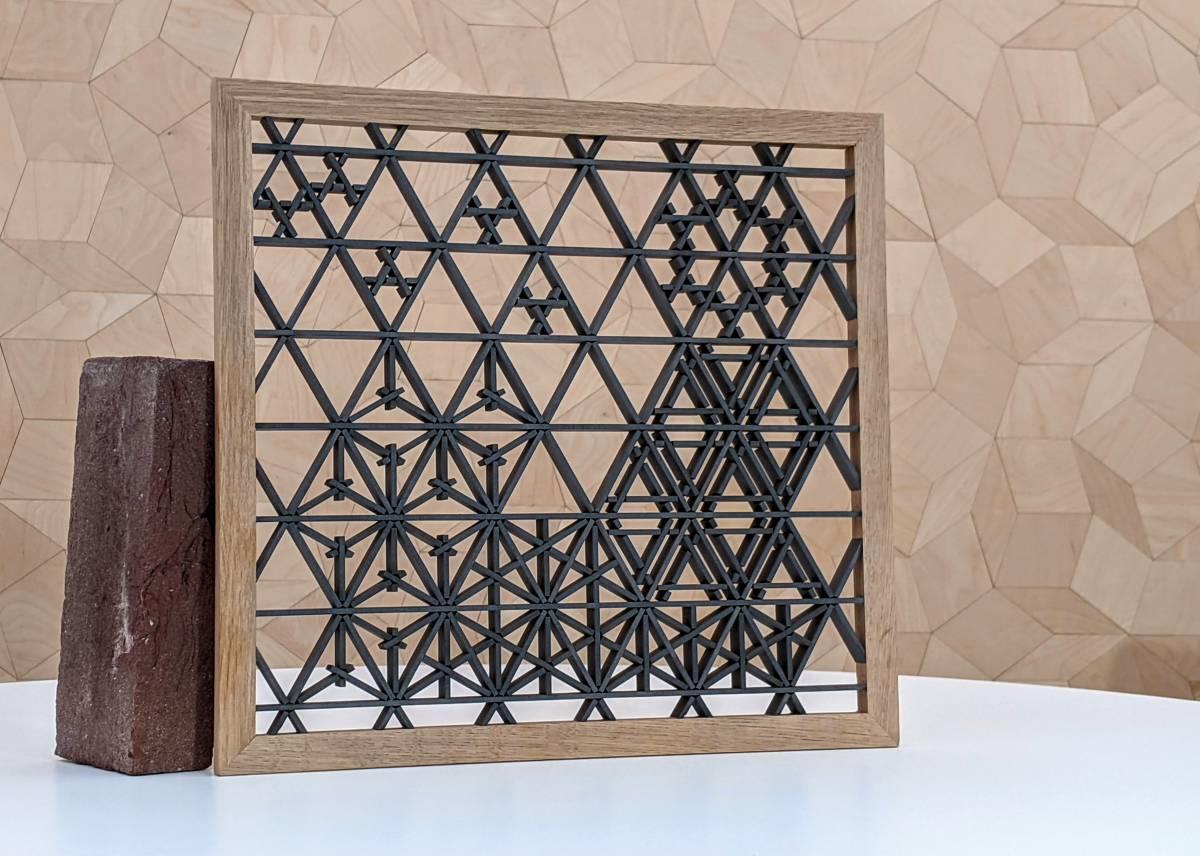

We recently conducted an experiment to make kumiko-like panels efficiently with laser-cut parts.

Process:

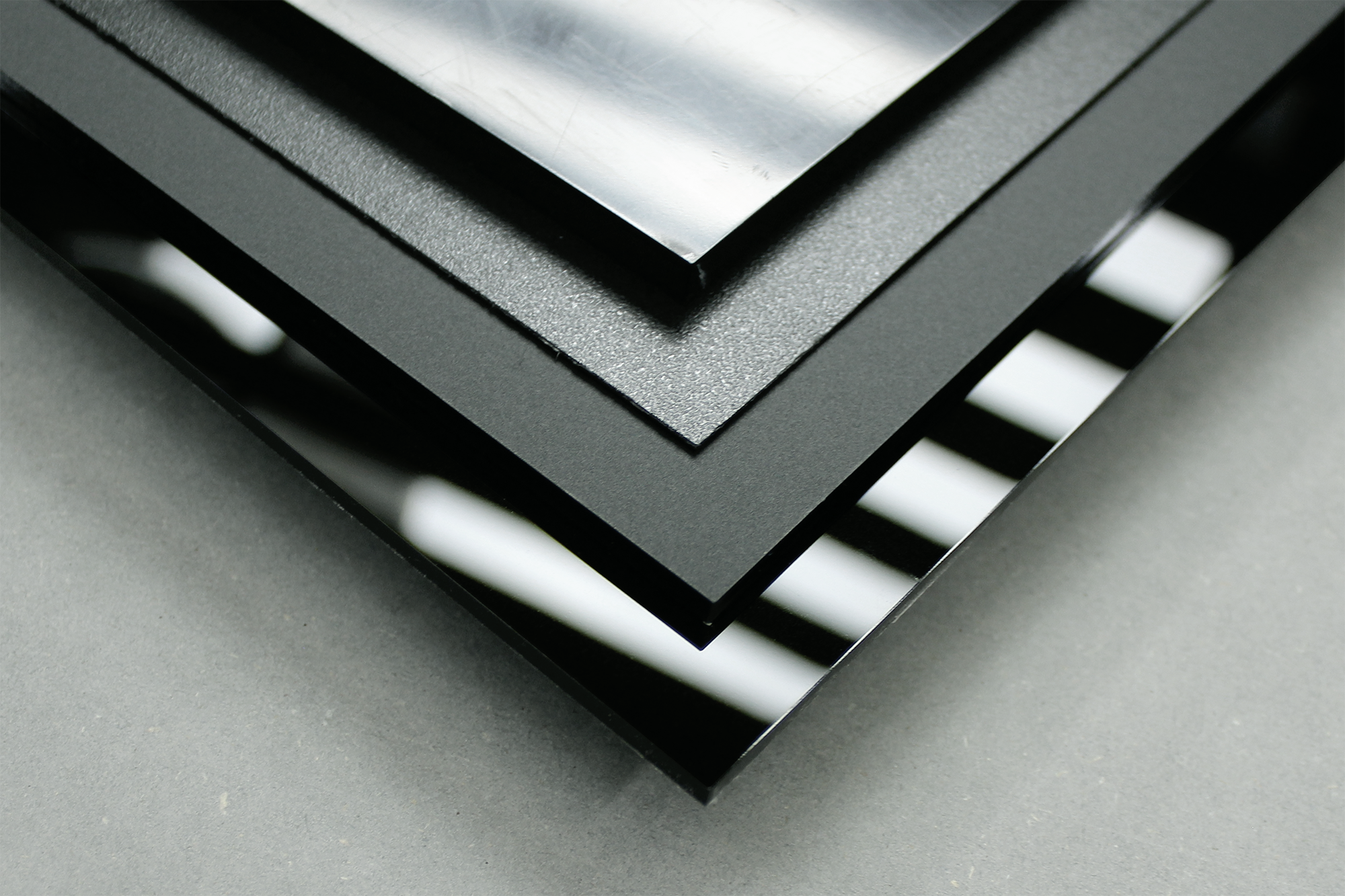

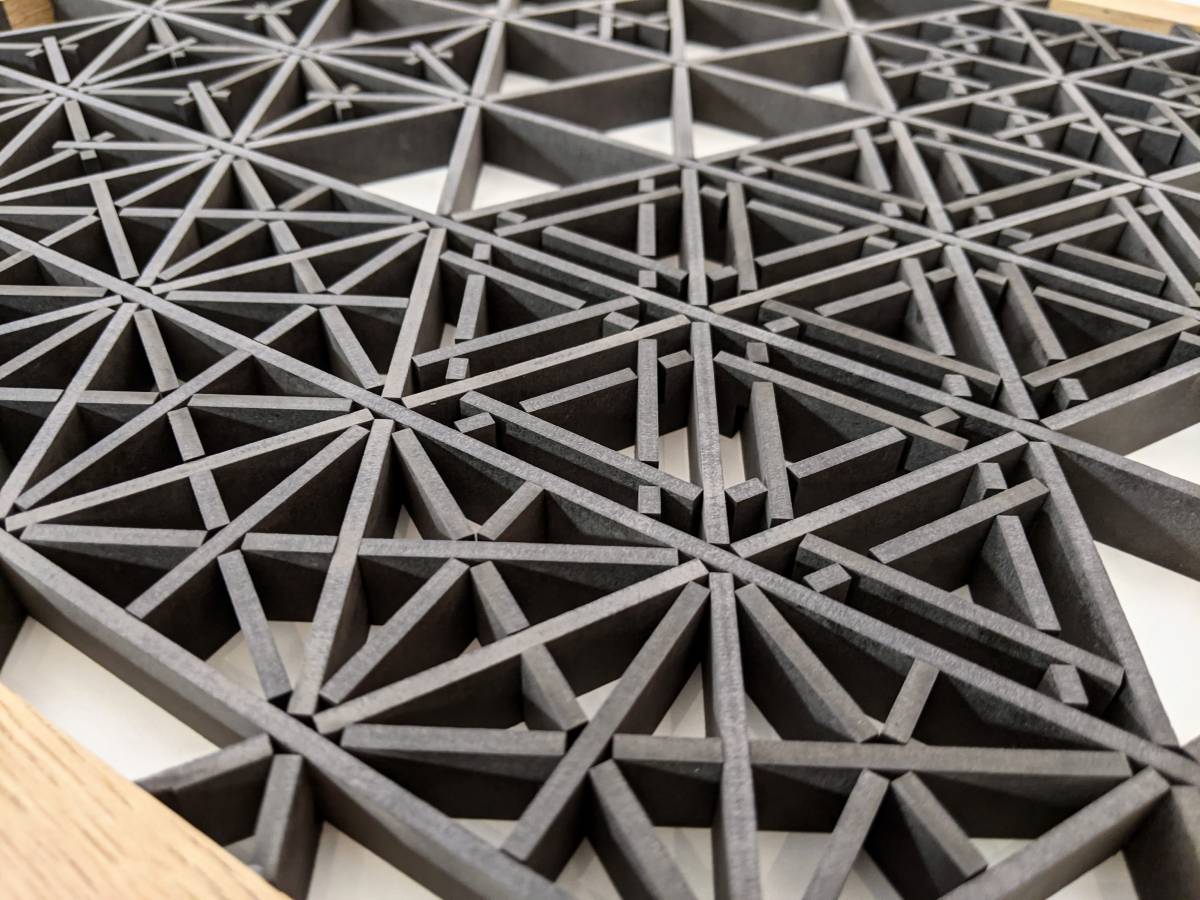

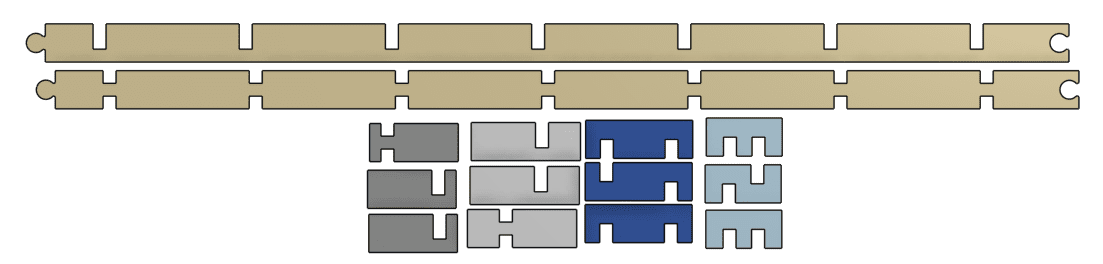

First, I set up a parametric model of a grid with triangles. The grid consists of two models of strips with incisions falling into each other. The strips have connections at the beginning and end so that it is infinitely extendable to all sides. The depth is set at 15mm, the wood thickness at 3mm and the side of a cell is 50mm. In addition, I drew four different "inserts. Finally, I nested and cut the parts out of 3mm MDF.

Should you want to experiment yourself; you can get a copy of this onshape workspace and modify and use the model.

Assembling is easy, although you have to be careful not to break the strips. The inserts clamp well and everything stays together without glue.

After assembly, I sawed the edges of the grid "shoon" on a table saw and fitted them with an oak frame.

And voila; a kumiko panel (almost) entirely from laser-cut parts!