POM laser cutting

POM (polyacetal) is for us the No.1 plastic for technical parts. To offer even more design freedom, we have expanded the range!

From now on you can have parts made in:

-

0.5 mm

-

1 mm

-

1.5 mm

-

2 mm

-

3 mm

-

4 mm

-

5 mm

-

6 mm

-

8 mm

Properties of POM

An engineering plastic used in mechanical and structural applications.

POM (polyacetal) is strong, tough and dimensionally stable. It has a low coefficient of friction and is wear-resistant. The static and dynamic coefficients of friction are the same, resulting in virtually no "stick slip" in sliding applications. Polyacetal is also resilient and can be used to absorb impacts and vibrations. It is chemically resistant to many fuels, oils and greases.

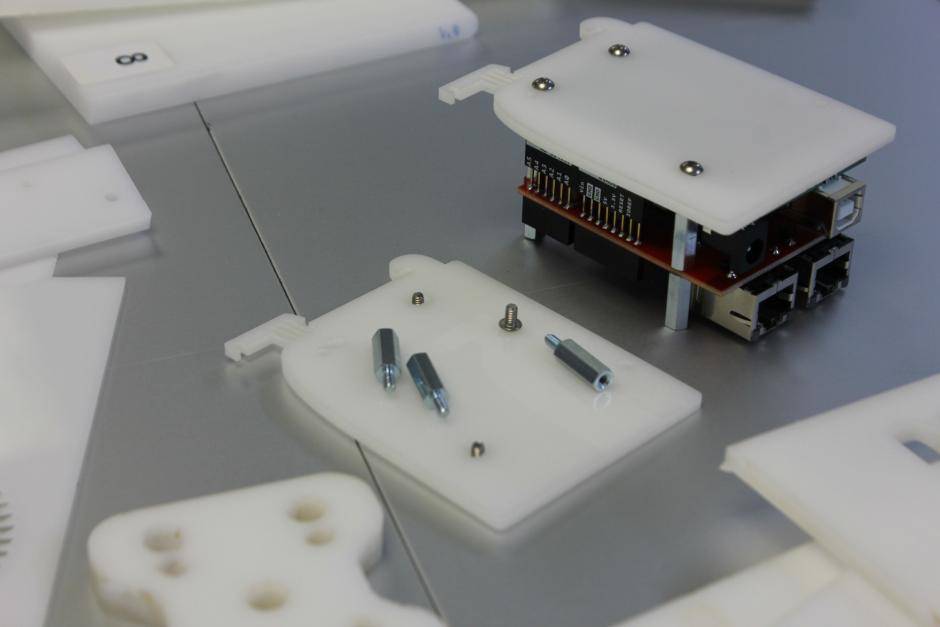

POM is used for machine parts such as (low-load) brackets, adapter plates and sliding joints.

POM can hardly be glued. For connections, bolts and the like are usually used. However, it is possible to connect parts with double-sided adhesive film.

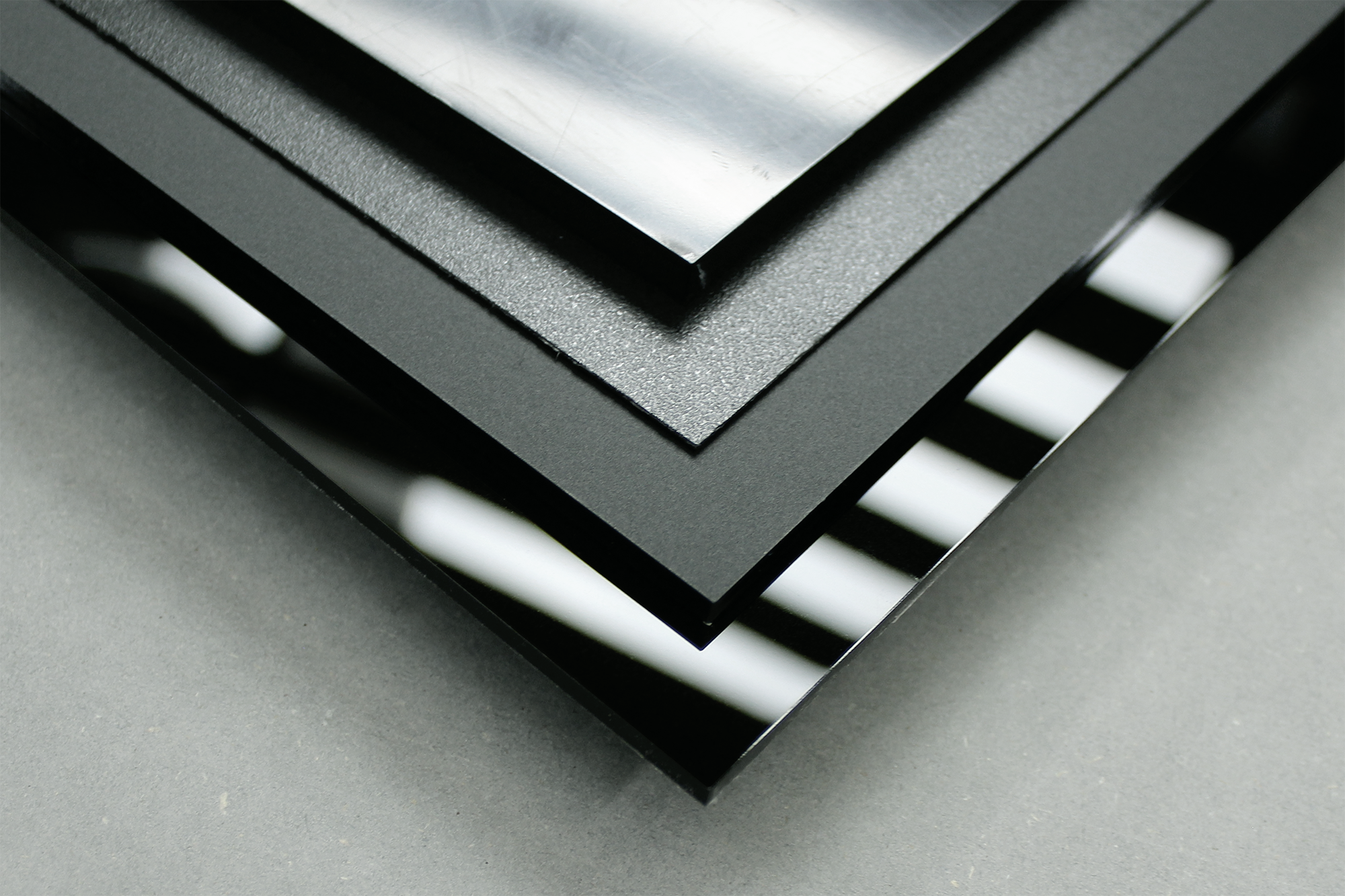

The surface is smooth but sometimes contains scratches. The sheets may warp slightly. The laser cut is neat and contains no melting edges and the cutting edge does not discolor. Without further measures, light smoke deposits are visible on the top near the starting points and a small (0.5mm) melt edge along the cut on the bottom. When using protective film, both effects disappear.

Surface engraving is poorly possible and produces little contrast. Line engraving is possible, however, the material does not discolor and therefore provides little contrast.

For indicative applications such as part numbers, line engravings are well suited.