The time has come. You've designed a great product and you're about to take it to manufacturing . You want to have one or more parts of your product laser-cut. First, just one sample to assess whether what you have in mind will work out in practice. And then, if it does and you decide to produce multiple copies, you want to be able to have the part easily cut into larger quantity .

In short, you are faced with choosing your laser cutting partner.

But what should you actually look for when choosing your partner in laser cutting?

It depends on what is important to you: are quick results a priority, or are low costs important? Is top quality a requirement, or does durability weigh heavily? Is it important to you that your laser cutting partner thinks and advises with you, or is the ordering process fast and efficient?

Below are a few things you'll want to consider when choosing your laser cutting partner.

Your design

The success of a laser-cut product depends largely on the design and choice of materials within the design. An experienced laser cutting partner works only with reliable materials and will be able to recognize (major) errors or problems in a design before manufacturing .

Within Snijlab , not only do we have extensive experience with laser cutting, we also have the design and engineering knowledge and experience necessary to recognize these errors or problems. When this is the case, we block the manufacturing of the part and contact the customer to identify the problem, and fix it by mutual agreement.

In prototyping and one-offs

When you need a prototype of your design, or you need just one at all, you want to be able to act quickly and cost-effectively yet accurately.

-

With your laser cutting partner to choose, is it possible to have a new version in house tomorrow, if you have to pass or have a presentation?

If you place a rush order with us before noon, you can pick up your order the same day after 4 p.m., or it will be delivered to you before noon the next day.

-

How high are the costs for one copy? Are these high and are there start-up costs?

A single piece of a unique part can be had for as little as €25, a large collection plate of a precious material can exceed €100. For us, each product has a start-up cost. If you order multiple copies, the start-up costs are spread out and the unit price drops. If you order several products of the same material, you pay lower start-up costs for each subsequent product.

-

With complex drawings; do you get a "proof", or preview in advance that you can check how your file is read in?

A preview is a standard part of our ordering process. The preview shows what operations we are going to do and counts as a contract piece. So very important to check this preview carefully.

For large numbers

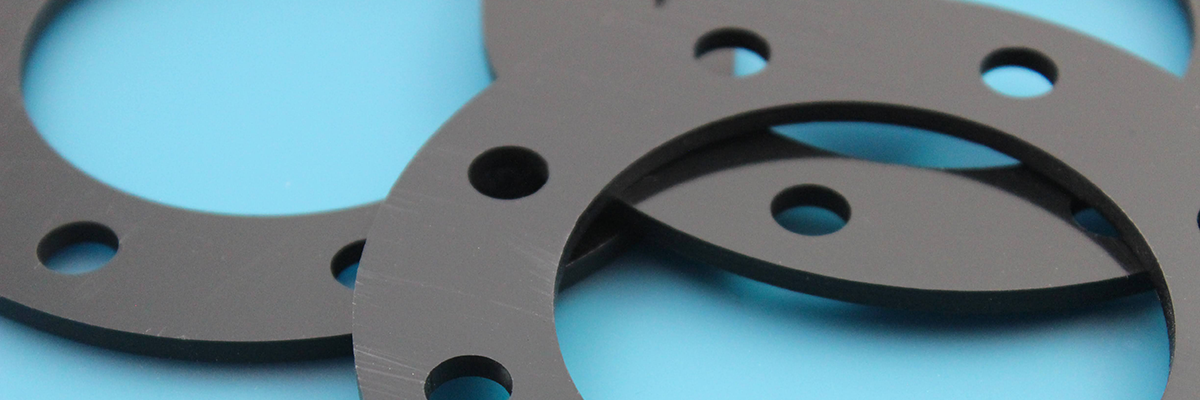

If you want your design cut in large numbers, then things like finishing, post-processing, packaging and simplicity of the ordering process become important in choosing your laser cutting partner.

-

How clear and easy is the ordering process? Is there a risk that the end result will be just wrong based on your design (drawing)?

With us, the ordering process is entirely online in one clear environment. No email exchanges with scattered information. No waiting time.

You have full control when ordering. Not only about your drawing and material but also what film is/isn't on it, is residual material included, how is it packaged, etc.

You can find a previously ordered product (drawing + settings) at 'my products' in the online environment and order it again. Then you can be sure that the end result will be exactly the same.

-

If you order many/often parts: is it possible to have your own part number or description put on the packaging? To be able to keep things apart, and make commissioning of parts smooth.

When ordering from us, you can specify your own name or article number per order, as well as per product. You will find these article numbers on the packaging upon delivery. Don't worry, there are no hard-to-remove stickers on your part ;-).

-

How are the parts packaged and how much work do you have to do to get them ready for use? Are they in the residual plate and do you have to take them out of sheet and process the residual material? This provides good protection during transport but with large quantities, taking them out is a lot of work.

Depending on what you are making and in which quantity it may be more convenient to receive individual parts or just parts in the sheet . With us, you have the choice and know what to expect based on this information.

-

Can your laser cutting partner make your parts without any film on them?

Laser cutting without foil is the standard for many wood and paper grades. Some plastics (a.o. polyacetal and HDPE) are also supplied without foil as standard. With acrylics, for example, this option is also available even though they are supplied with foil as standard; we then remove the foil before cutting.

The advantage of no film is that you do not have to remove the film. This is especially important with large numbers of parts. It also saves a bit in material use to use no foil.

The disadvantage is that process deposits can form on your parts. With wood you can remove this by sanding, with plastics by wiping away the deposits with a damp cloth. How distracting process deposits are depends on the level of detail (with large shapes it is often barely noticeable, with fine work it is more so), the type of material (on light colors of material it is more visible) and the application (in a visual application it is relevant, in technical applications often not).

-

But, without protective film, there is smoke and reflection deposits on the material. You have to finish that. How do you do that and how much time does it take? Or do you take lesser finish for granted?

"Clean" cutting without repetitive manual work. That was the goal when we developed autoSPOT, our machine suitable for volume production, ourselves. Laser cutting with autoSPOT requires no film and no/amper deposits.

For business orderers

If you are a "regular customer" with your laser cutting partner, then the way you do business is important. Ideally, you want the process of ordering, producing, delivering, invoicing and paying to run like a well-oiled machine.

-

Prepayment is common practice at many web shops. But this often does not fit into your purchasing process. Is it possible to register to order on account?

With us, you can register your company once for paying on account. Then you will get an additional payment option in the order environment that allows you to place orders on account.

-

When you have a lot and a lot of parts laser cut, it's helpful to have a clear order history from which to reorder things. Is this possible?

Previously created products can be found in 'my products' at snijlab.nl. Here you can search by product name, number, material type, order number, and so on. This makes placing a repeat order a piece of cake.

-

The finance department often requires a certain purchase reference/PO number to be on the invoice and the invoice to be sent to a specific email address. Is that somewhat easy to arrange?

As a business customer at Snijlab, your purchase reference is easy to enter and remains trackable in all correspondence. Do you need a quote in advance for approval within your organization? You can download it within a few clicks, including the correct references. Invoices can be sent by default to another e-mail address. For example, to your financial department so that you no longer have to deal with any administration yourself.

-

Are there benefits for regular customers, who order regularly?

We take/keep special materials, thicknesses or colors in stock for repeat customers. We also advise/contribute to design optimization at volume production . This can lead to lower costs, better quality or less work for the recipient. With recurring productions we can often make efficiency gains. If so, we can lower/discount prices for those manufacturing .

Sustainability

Finally, if sustainability is an important issue for you, then of course you want to know if the same is true for your future laser cutting partner and what they do in it.

-

How sustainable are the materials used?

Our wood comes from sustainably managed forests. We are FSC certified ourselves to maintain, where possible, the Chain of Custody.We already offer acrylates that are fully recycled. When purchasing, we strive for the shortest possible transportation routes.

-

How is residual material handled? Is this material recycled?

We separate the waste streams of our materials. Our desire is to be able to have each material recycled separately and we are actively working to develop these capabilities.

All in all, quite a few things to look out for when choosing your partner in laser cutting. Once you have made a choice based on the above points, a very promising partnership lies ahead of you. A cooperation that will enable you to design and produce ever better products, to keep innovating and thus strengthen your position in the market. Nice right!

After reading this article, do you think we might be your partner in laser cutting? You can start immediately or contact us.